18. Project Development

Individual Assignment:

Propose a final project masterpiece that integrates the range of units covered, answering:

- what tasks have been completed, and what tasks remain?

- what's working? what's not?

- what questions need to be resolved?

- what will happen when?

- what have you learned?

1. What tasks have been completed, and what tasks remain?

Completed tasks:

1. Laser cutting

- The sword blade part

2. 3D design, laser cutting and 3D print:

- The sword blade part

- The sword guard

- The sword handle

3. PCB mill and PCB design

- Designed and milled my PCB used for final project

4. Arduino Programming

- Use Xiao nRF82540 sense to control the LED strip.

Remained Tasks :

1. Asssemble all the components

2. Gesture Recoginition Training and Programming

2. What's working? what's not?

Working:

1. Laser cutting

- The sword blade part

2. 3D design, laser cutting and 3D print:

- The sword blade part

- The sword guard

- The sword handle

Not working :

The LED strip has too many LEDs (100)on it, so the power consuption is too much and the microcontroller chip is burned, so another PCB a new LED strip including less LEDs are needed.

3. What questions need to be resolved?

- Buy a new LED strip with less LEDs and better protection.

- Change the thickness of the Acrylic of the second and fourth layer, as the thickness of the LED strips increases.

- Need to mill another new PCB.

- Keep learning gesture recognition.

4. What will happen when?

- The new LED will arrive in 2 days.

- The new PCB can be milled today.

- The new acrylic layer can be cut today.

- Will learn gesture recognition next week.

5. What have you learned?

Laser Cutting

- Understanding Material Properties: I learned about the different characteristics of various materials and how they respond to the laser cutting process. This includes their melting points, flammability, and the quality of the cut edges they produce.

- Precision and Accuracy: Laser cutting demands a high level of precision. I mastered the skills of accurately setting parameters such as power, speed, and focus to achieve clean and precise cuts.

- Design Optimization: I discovered how to design parts for laser cutting to minimize waste and ensure efficient production. This involves considering the nesting of parts and the most effective use of the material sheet.

- Safety Precautions: Working with laser cutting equipment taught me the importance of following strict safety protocols to protect myself and others from the potential hazards of high-powered lasers.

3D Design:

- When using Fusion 360 for 3D design, I have gained several valuable insights and skills.

- One significant learning was in the area of parametric modeling. For example, when designing a complex mechanical component like a gearbox housing, I learned how to define parameters such as dimensions, tolerances, and material properties. By establishing these parameters, I could easily make modifications and variations to the design based on different requirements. This not only saved time but also ensured consistency and accuracy throughout the design process.

- Another important aspect was the ability to simulate and analyze the designs. I could perform stress analysis on a part to ensure it could withstand the expected loads. For instance, when designing a bracket to support a heavy load, I ran simulations to determine if the material and structure were adequate. This helped me optimize the design to reduce weight and material costs without sacrificing strength.

- Furthermore, I learned about efficient assembly design. When assembling multiple components into a complete product, I understood how to manage component constraints, mating conditions, and interference checks. This was crucial when creating a machine assembly where the proper alignment and functionality of all parts were essential.

- Overall, using Fusion 360 has enhanced my problem-solving skills, attention to detail, and the ability to create robust and functional 3D designs.

PCB Mill

- PCB Layout Design Skills: I gained proficiency in planning the component placement and routing on the PCB to ensure optimal signal integrity and functionality.

- Manufacturing Constraints Awareness: I learned about the limitations and requirements of the PCB milling process, such as minimum trace widths and drill hole sizes.

- Component Selection and Footprint Management: Understanding how to choose appropriate components and ensure their footprints are accurately defined for milling.

- Debugging and Troubleshooting: I developed the ability to identify and fix issues during the PCB milling process, such as incorrect traces or short circuits.

PCB Design:

- When working with KiCad for PCB design, I have gained substantial knowledge and skills.

- For example, when designing a PCB for a power supply circuit, I needed to source and manage various components such as capacitors, resistors, and integrated circuits. KiCad allowed me to create and customize my component libraries, ensuring that I had accurate footprints and symbols for each component. This was crucial as it prevented errors in component placement and routing.

- I also learned how to effectively use the schematic capture feature. In this project, I had to carefully plan the circuit connections and ensure that the schematic was clear and understandable. KiCad's tools for drawing wires, adding labels, and creating hierarchical schematics made the process organized and efficient.

- Furthermore, the PCB layout phase taught me about trace routing strategies. I needed to balance the need for short signal paths with the requirement of maintaining adequate separation between different signal types to avoid interference. KiCad's routing tools and design rules checker helped me adhere to these best practices and create a reliable PCB layout.

Arduino Embedded Programming

- Sensor Integration: I learned how to interface and collect data from various sensors using Arduino. This includes understanding sensor protocols and converting analog signals to digital values for processing.

- Control Logic: I developed the ability to write control algorithms and logic to make decisions based on sensor inputs and drive actuators or outputs accordingly.

- Code Optimization: I understood the significance of optimizing code for memory usage and execution speed in resource-constrained embedded systems.

- Debugging Techniques: I became proficient in using debugging tools and techniques such as serial printing and breakpoints to identify and fix errors in my code.

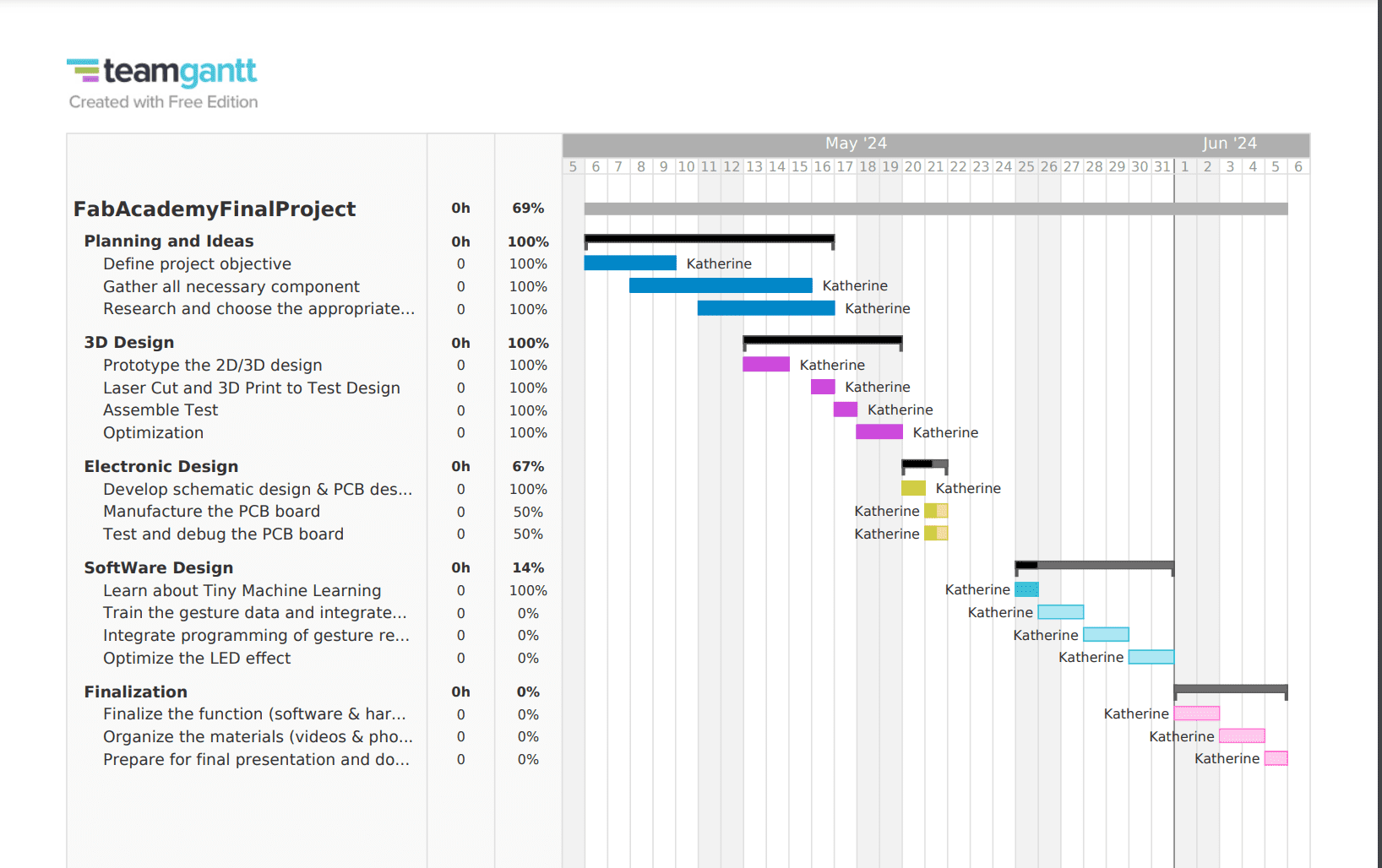

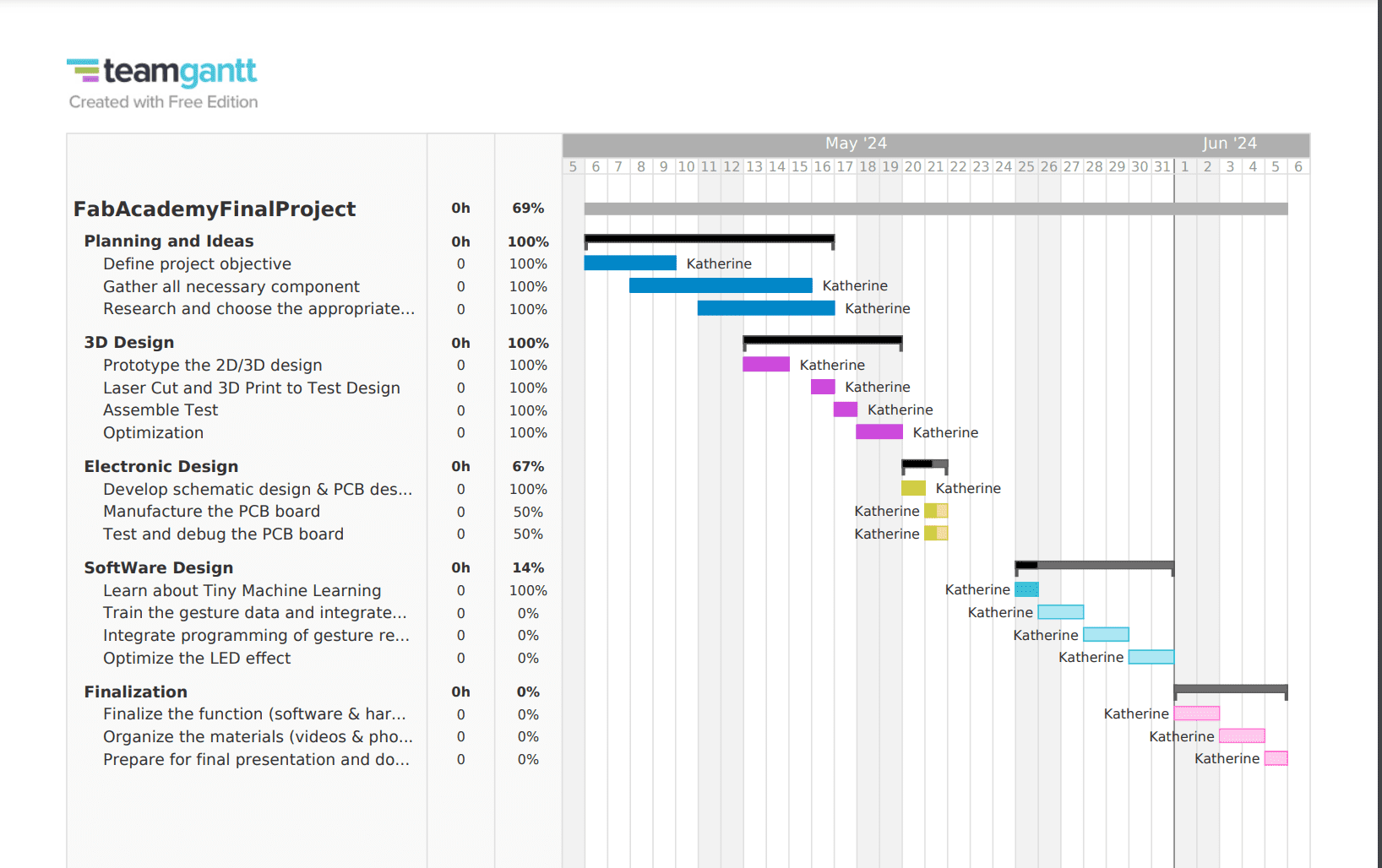

Gantt Track

I created a Gantt chart to monitor all my progresses and strive to complete everything on time. And I will finish all the tasks 100% before the presentation day!