16. Applications and Implications¶

For my project proposal you can go to my final project page. In this week I focust designing all the individual parts.

Pulleys¶

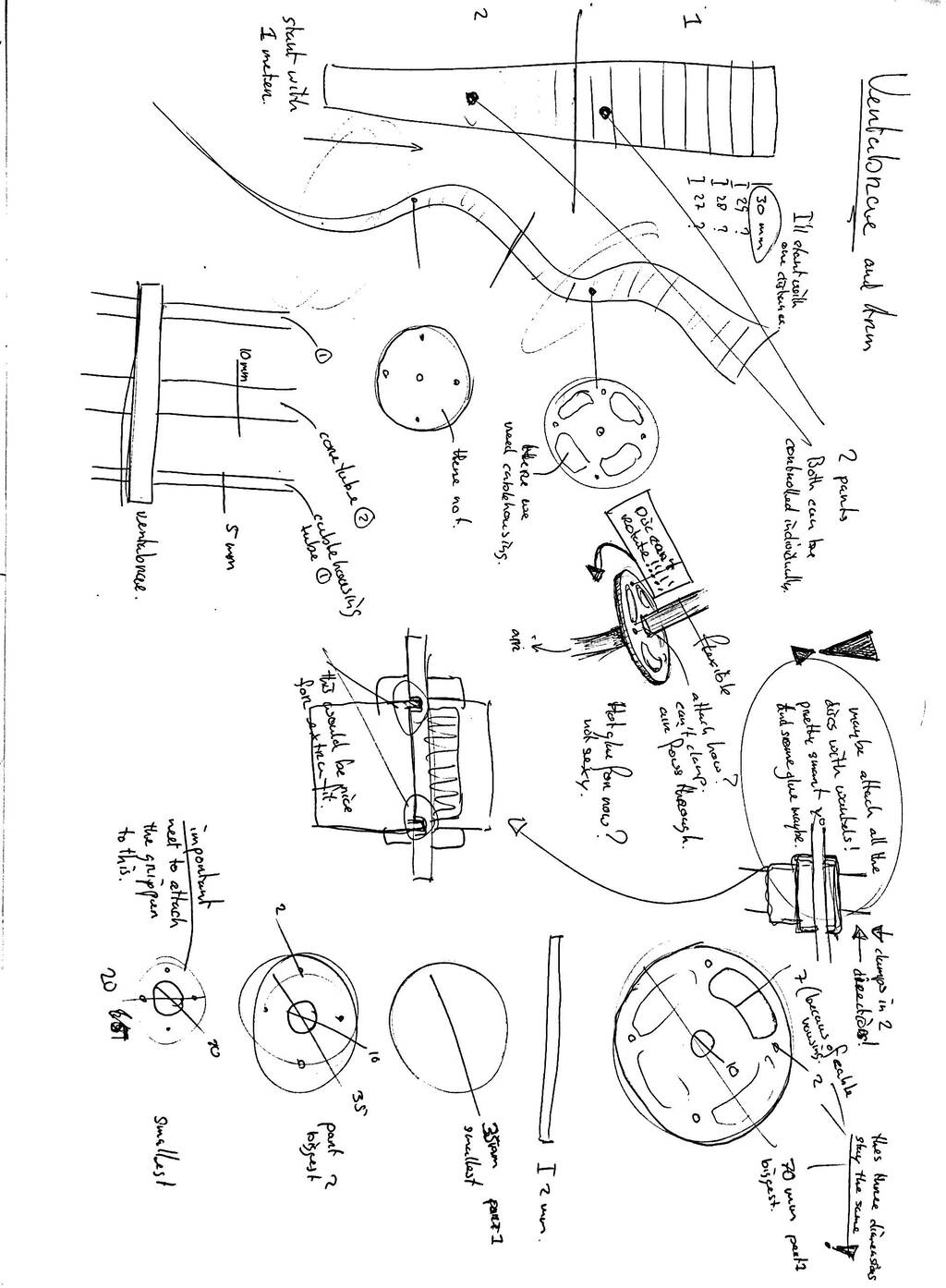

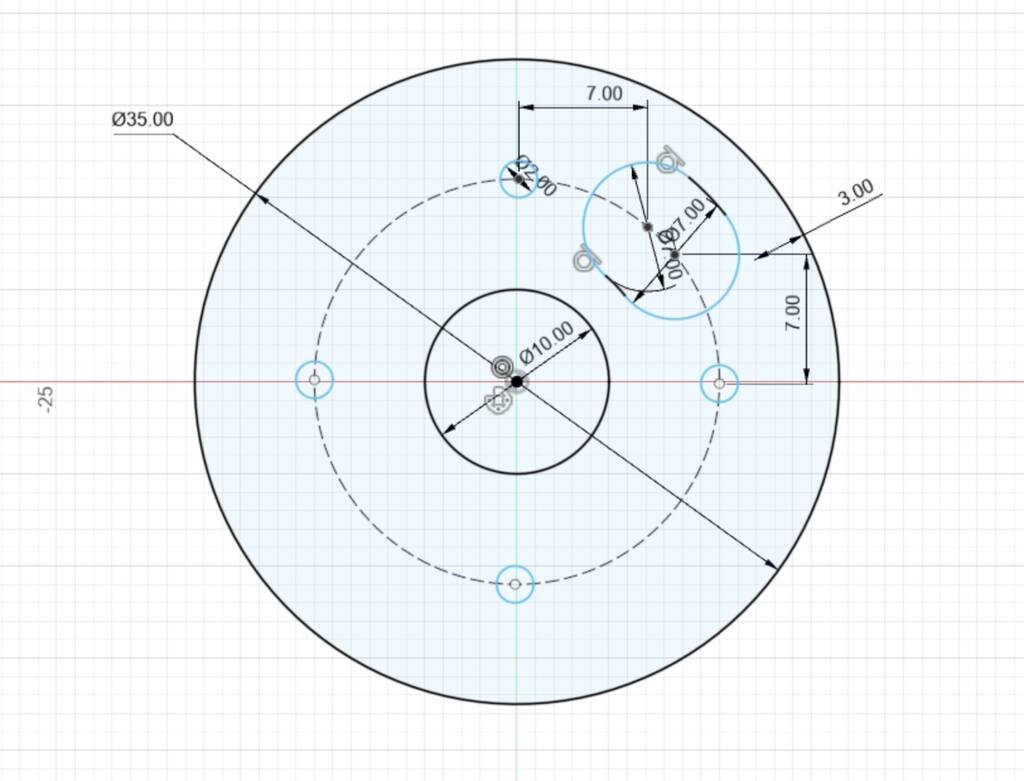

Started with a sketch for my pulley design.

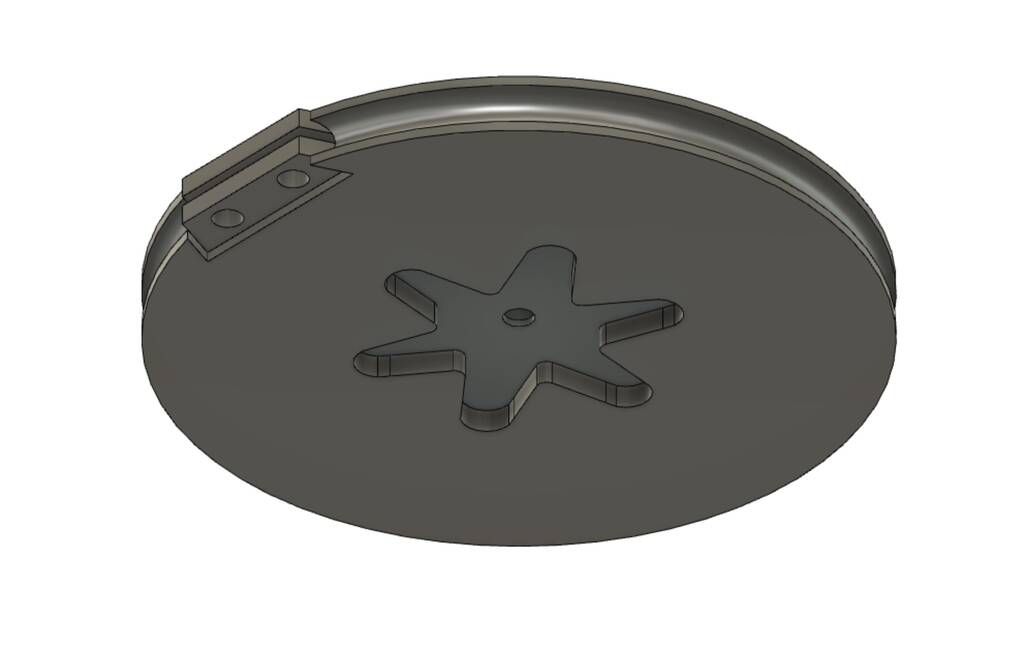

Found this [this] 6arm servo arm for the MG966R and converted it from mesh to a fusion 360 body.

Convert to mesh tutorial

- prepare (in mesh menu)

- genarete face group (accurate)

- modify

- convert to mesh (parametric , prismatic)

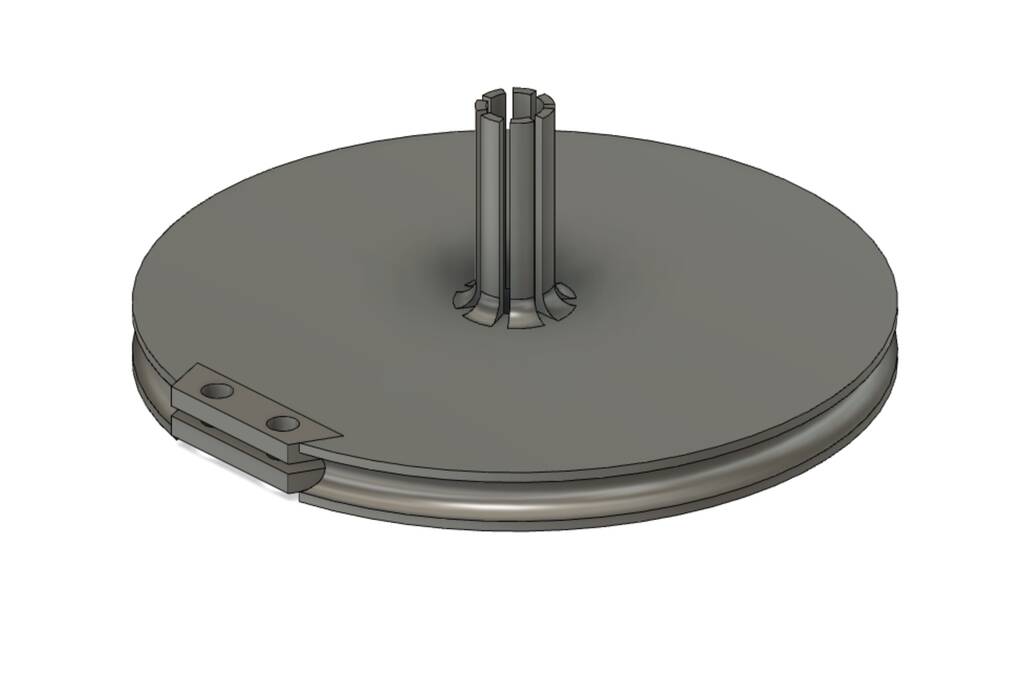

Made these pulleys with with a flexible finger in the middle so they fit in bearings. I hope this will prevent the shaft from bending so it won’t consume any power.

They old ones broke easily. The new ones also. Need to design something else.

Vertabrea¶

Made a sketch fo my vertabrea. The discs have space for cable housing and cables. For the second part of the tentacle it’s not neccessary to have space for the cablehousing.

The smallest vertabrea diameter for the first part is 35mm. For the second part I don’t need holes for the cable housing.

Made a couple of designs to see what diameter and lenght would work. My design is now super adjustable so I can easy expermiment with the offset, diameter, corediameter, etc.

(PHOTOS OF ARM ARE COMMING)

Disc and arm¶

I wanted a non permanent joint of the disc to the core of the arm. So I’m able to adjust the space between the discs and to change the discs whenever is necessary. My previous tentacle was with hot glue. Works but you can’t adjust the design. I also had an idea with set screws or bolds. But this takes ages and doesn’t work as good as the cable glands.

I thought of working with cable glands. It’s axactly what I need. It’s thight, the core stays hollow and it’s easy adjustable.

Work really nice! But the core is to flexible for rotating. I think for my final final final final design I want to use somthing that won’t rotate but only moves in x/y direction. Maybe like a bowden tube.

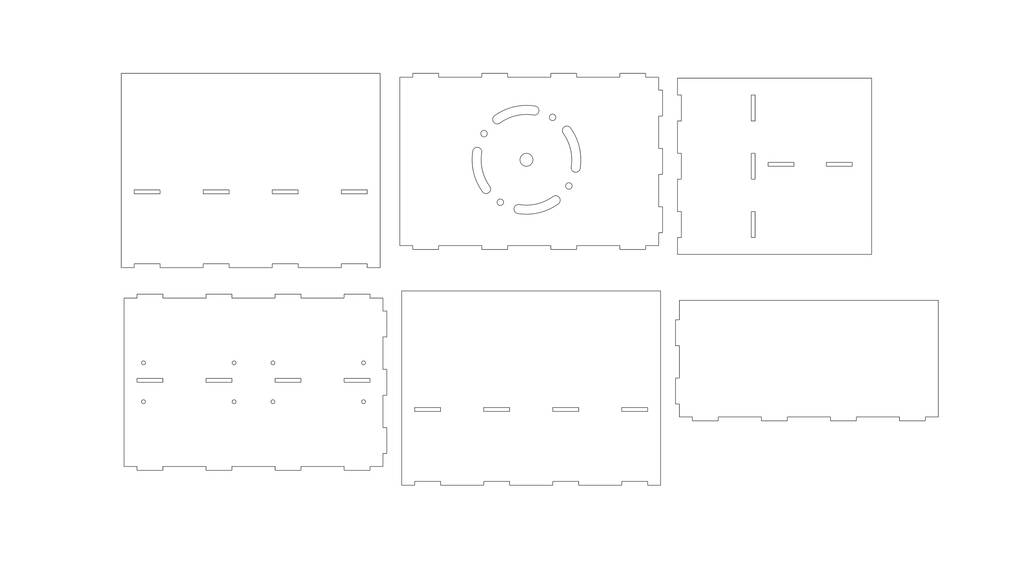

Housing¶

Gripper¶

X motion axle¶

Components¶

Component pictures¶

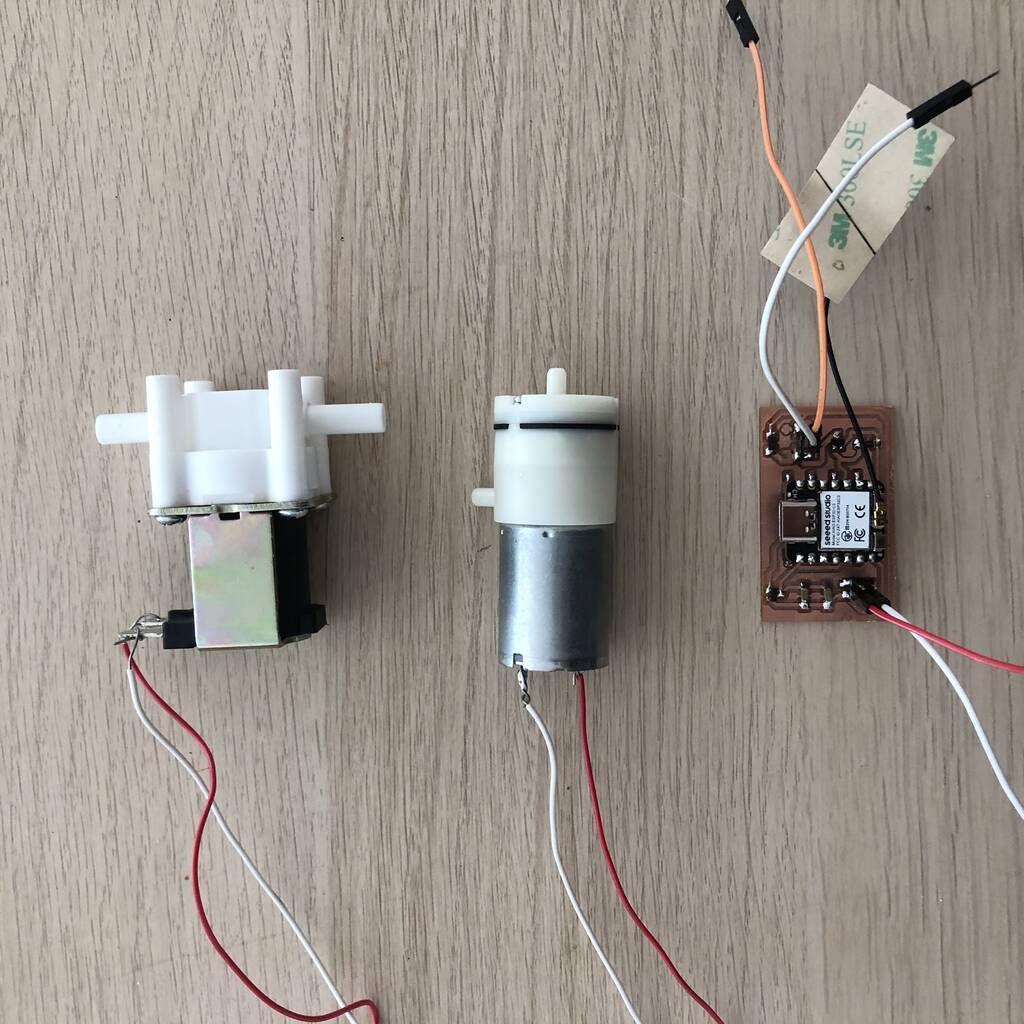

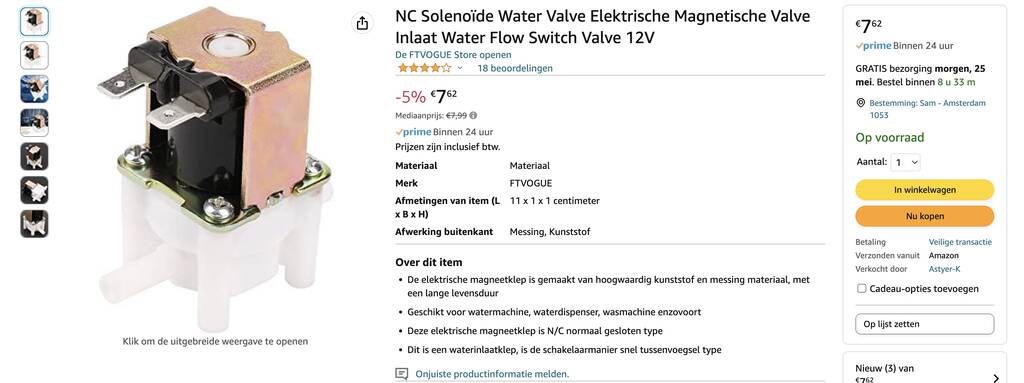

Solenoid valve

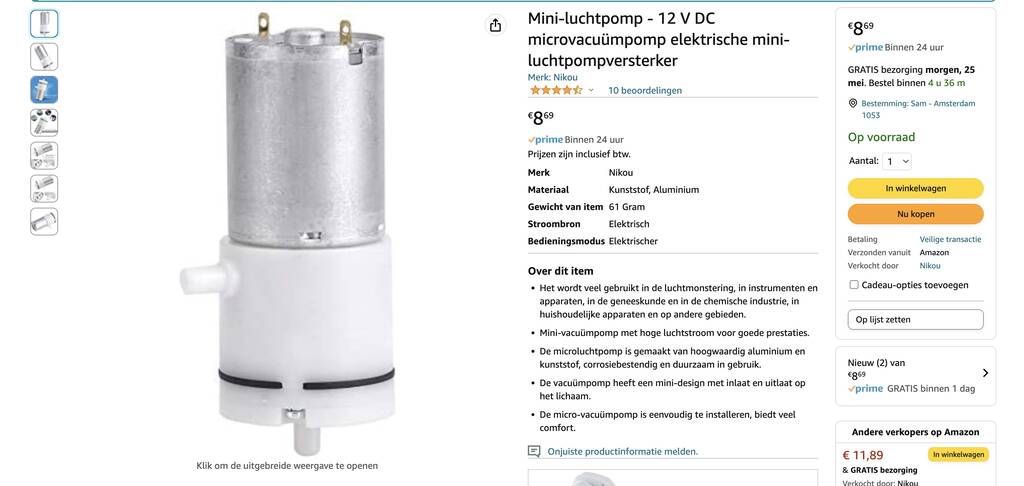

Dc motor air pump

Tube connectors

Cable glands 2x

Assignment¶

Propose a final project masterpiece that integrates the range of units covered

What will it do?

- I’ll make a controllable 2 axes robot tentacle.

Who’s done what beforehand?

What will you design?

- Vertabrae/discs

- Pulleys

- PCB 1: Esp32-c3, airpump, solenoid,

- PCB 2: esp32-c3, 4 servos,

- Pcb 3: Esp32-c3, 2 joysticks, 4 buttons,

- Box for components

- mould for

What materials and components will be used?

- 3d printer PLA

- cable clamps

- flexible core

- servos

- 2x esp32

- discs

- beehive axes

- airpump

Where will come from?

- Online -> amazone unfortunately

How much will they cost?

- circa €150 everything together

what|amount|cost|

—|—|—|—

cable glands | 40x | €25 |

esp 32 | 2x | | |

air pump | 1x | €7 |

Air let through | 1x | €10 |

Tubes | 3 meter | 10€ |

small tube | 25 meter | €10 |

What parts and systems will be made?

- See question what will you design

What processes will be used?

- 3d printing, lasercutting,

What questions need to be answered?

- Should I work with wifi or bluetooth?

- Are servos the best motors for this project? Wouldn’t it be better to use hight torque dc motors? Or steppers?

How will it be evaluated?

- Can the arm be controlled

- Does the arm exist out of two individual controlled parts?

- Can the gripper grip something by inflating

Your project should incorporate 2D and 3D design

additive and subtractive fabrication processes

- Laser cutting vertabrea

- 3d printed moulds

electronics design and production, - I’ll make 3 pcbs

embedded microcontroller interfacing and programming, - check

system integration and packaging - Cable management, behuizing, need to look finished

Where possible, you should make rather than buy the parts of your project - I made a lot

Projects can be separate or joint, but need to show individual - ok

Mastery of the skills, and be independently operable - this should be ok