Applications & Implications

This week, I have to suggest a final project that combines everything I have learned so far in the course. The project should involve using all the knowledge and skills I gained. It should include the following components:

-

2D and 3D design.

-

Additive and subtractive fabrication processes.

-

Electronics design and production

-

Embedded microcontroller interfacing and programming.

-

System integration and packaging.

Through this week I will answer the following questions:

-

What will it do?

-

Who has done what beforehand?

-

What will you design?

-

What materials and components will be used?

-

Where will they come from?

-

How much will they cost?

-

What parts and systems will be made?

-

What processes will be used?

-

What questions need to be answered?

-

How will it be evaluated?

Individual assignment

What will it do?

I'm working on designing a rotating table specifically for scanning objects. At TechWorks, our digital fabrication lab in Amman, Jordan, we currently rely on a rotating chair for scanning operations. However, I encountered a challenge when trying to rotate the chair manually while simultaneously handling the scanner. To overcome this hurdle, I'm developing a table that can automatically rotate at a precise speed. Moreover, I aim to incorporate a feature that allows for pausing or resuming the rotation as required during the scanning process.

Who has done what beforehand?

In this project Romanko made his own bearing, thats in some way similar to what I wanted to make, but I am planing to use bearing balls and much smaller.

Solomon worked to design and build an Automated Turntable for capturing 360 Product Photos.Throughout the design process, Solomon faced some challenges. Manufacturing the main part using FDM (Fused Deposition Modeling) 3D printers and dealing with support material affected the smoothness of movement and introduced friction on the bearings, thereby adding extra load on the stepper motor. That is why I am planing to not use 3D printed parts in the rotation mechanism.

In this project Diar Amin made turntable, The design incorporated a large gear as the support surface and a small gear as the pinion, connected to the motor shaft. I will not use gears or belts, coupling the motor and the disk directly to make the rotation more efficient.

What will you design?

I will design:

1-The body of the turntable.

2-The disk where the part will set.

3-The chair where the disk will rest.

4- Flange to connect the desk and the motor rod.

5- Bracket for the motor.

6- The pcb board.

7- The control panel for the electronics.

8- The foots of the body.

What materials and components will be used?

For the mechanical part:

1- For the body, I will use a composite of fiber and resin.

2- For the chair and the desk I will use black teflon.

3- PLA for the control interface. and motor bracket.

4- TPU for the flange.

5- Stainless rod 8mm*10cm.

6- Flexible coupling.

7- Screws and nuts.

8- Bearing balls.

9- 3 spacers to fix the pcb board.

For the electronics:

1- For the MCU I will use the ESP32-C3.

2- For the Motor I will use NEMA17 stepper motor.

3- Slide switch to reverse the direction.

4- Potentiometer to control the speed.

5- LED as power indication.

6- Push button to pause/start rotation.

7- Switch to on/off the turntable.

8- Motor driver.

9- Copper board for the pcb.

10- Power supply 12v.

11- Power jack and voltage regulator.

12- Pin headers.

13- SMD LED.

Where will they come from?

All materials are either from the lab such as PLA,TPU and the other parts are from local suppliers.

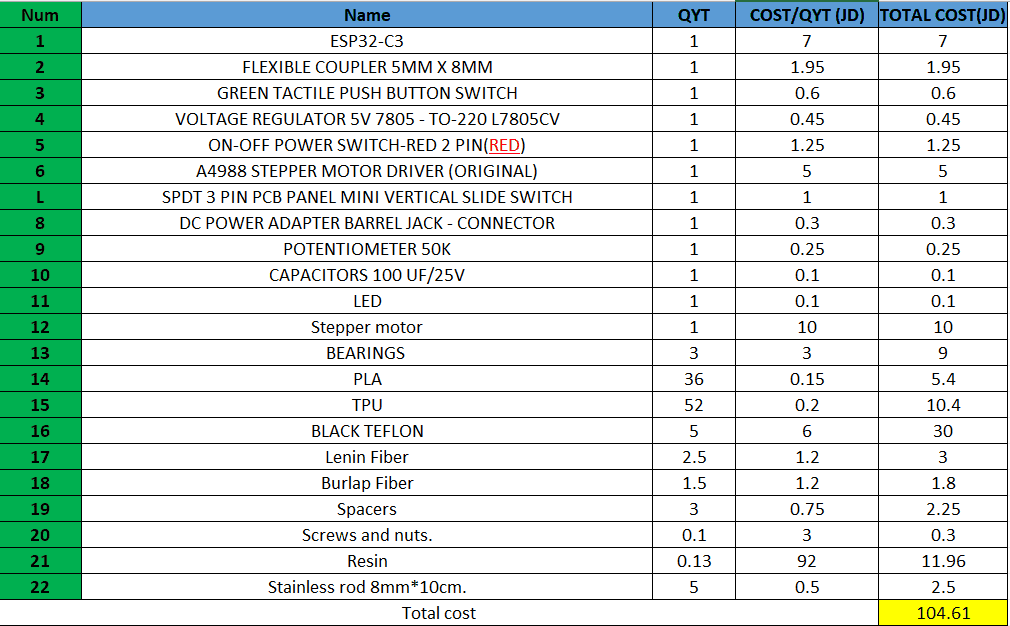

How much will they cost?

So the total cost for this prototype was almost 105 JD and it is around 140$.

What parts and systems will be made?

I will made the Disk, chair, motor bracket, flange, the main body, the pcb, and the interface part and integrate them together.

What processes will be used?

1- Design the 3D model on Fusion360.

2- 3D printing: FLange, Bracket, and interface.

3- Laser cutting: to make the mold for the composite.

4- CNC machining: to mill the disk and chair.

5- Composite: to make the body with fiber and resin.

6- Electronic design: design the circuit on eagle.

7- Electronic production: milling the board on Roland srm20.

8- Embedded Programming: Program the ESP32-C3.

What questions need to be answered?

1- How the desk will rotate?

2- How to make the motor stop and start?

3- How to control the motor speed?

4- How to reverse the direction of the rotation?

5- How to integrate all systems together?.

6- Is the interface is easy to use?

How will it be evaluated?

1- To be sure the chair can fits on the body and the bearing balls are moving freely with negligible friction.

2- To be sure the disk can be rotates freely on the balls.

3- To have control on the motor speed, direction, and pausing.

4- To have the system well integrated and ease to use.