Wildcard Week

Group assignment

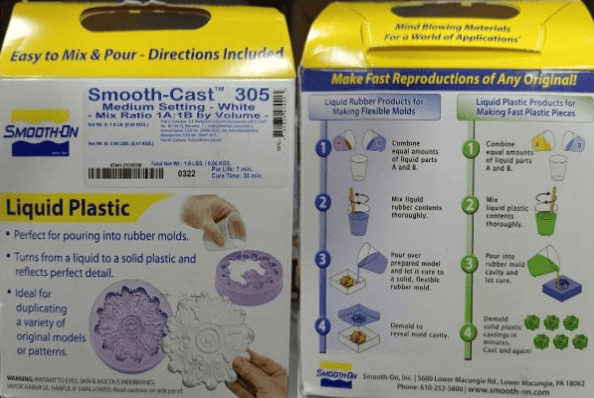

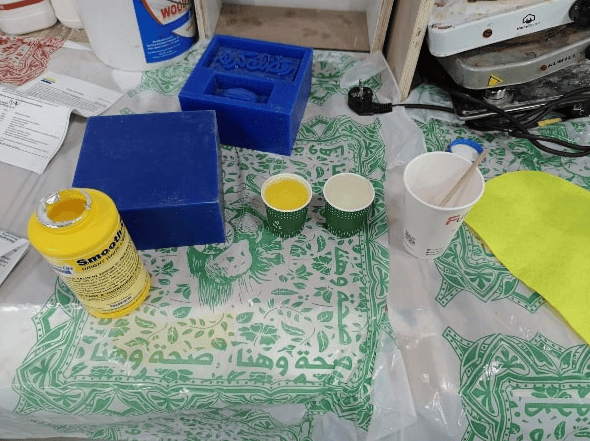

For our group assignment, we will be using Smooth-Cast™ 305 liquid plastic to conduct tests with fabric. we will use two different types of fabric to compare and see the differences between them. Additionally, we will perform tests on each fabric to observe the effects of varying the number of layers.

For the safety we followed:

1- Work in a Well-Ventilated Area: Resin can release volatile organic compounds during the curing process, which can be harmful if inhaled in high concentrations. It’s crucial to work in a well-ventilated area, preferably with exhaust fans or open windows to ensure proper airflow.

2- Wear Protective Gear: When working with resin, wear appropriate personal protective equipment such as safety gloves.

3- Avoid Skin Contact: Uncured resin can cause skin irritation or sensitization. Avoid direct contact with your skin by wearing gloves. In case of accidental skin contact, wash the affected area with soap and water immediately.

4- Store Resin Safely: Keep resin containers tightly closed and stored in a cool, dry place, away from direct sunlight and sources of ignition.

5- Keep Away from Children and Pets: Resin should be stored out of the reach of children and pets, as they may accidentally come into contact with it and risk injury.

6- Be Cautious with Heat Sources: Resin is generally flammable, so avoid exposing it to open flames, sparks, or high heat sources.

We will prepare the mix by measuring the ingredients based on volume.

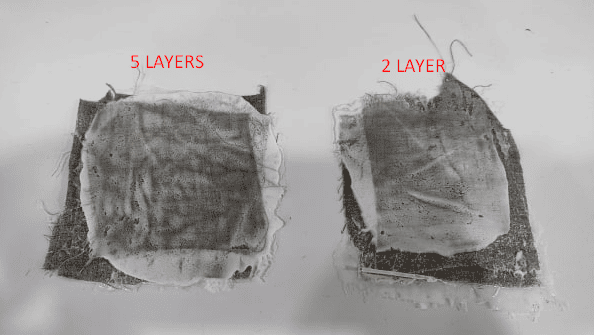

The first fabric we will use is linen. we will create two samples, one with 3 layers of linen fabric and the other with 5 layers as well.

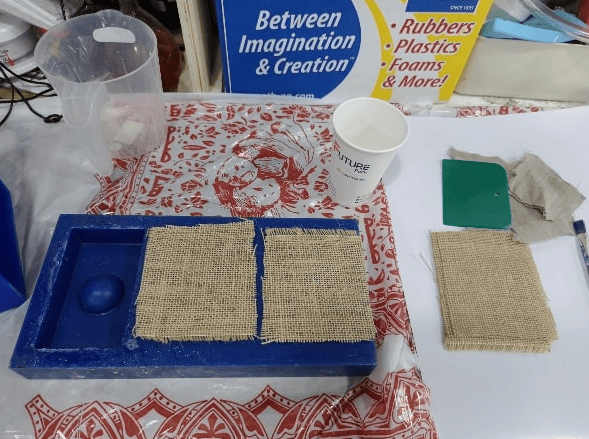

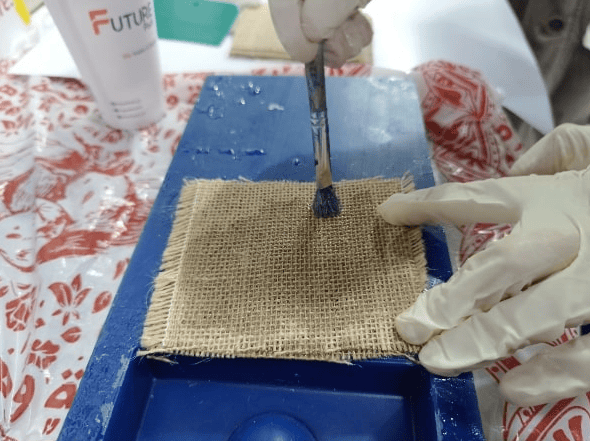

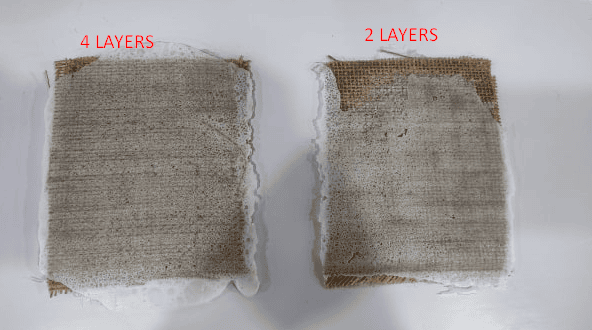

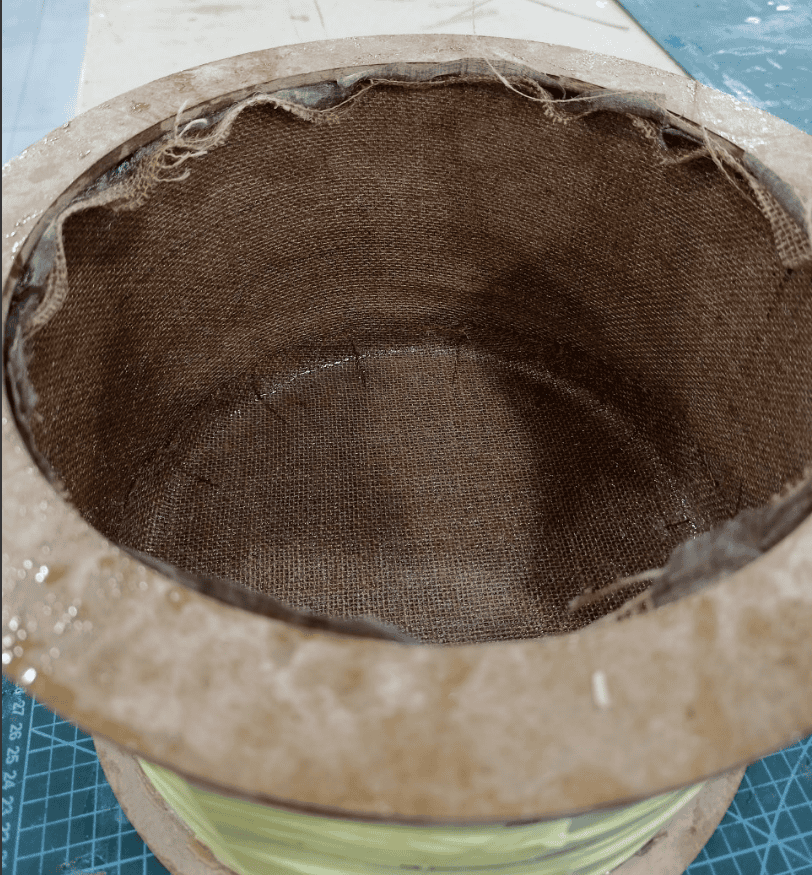

The second fabric I will use is burlap. I will create two samples using burlap: one with 2 layers and the other with 4 layers. This will allow us to compare the effects of layer thickness on the performance and characteristics of the burlap fabric in combination with the resin.

After preparing the mixture, we will apply it onto the fabric and use a brush to push and spread it evenly.

In conclusion, if we want to strengthen the model, we can add more layers of fabric. Additionally, the type of fabric used makes a difference. Between linen and burlap, linen fabric tends to be stronger than burlap. Linen is known for its superior strength, durability, and resistance to stretching compared to burlap, last thing we wanted to mention that the liquid plastic original color is white, and I think we added more liquid plastic so the white color appeared.

individual assignment:

For this week, I am planning to make the main body of my final project. I was thinking how could I make it, I found some choices, first is to mill circles of wood on cnc router and glue them together or make a mold then using fibers and resin composite layers on the mold walls, I preferred to use the composite since it gives tough and light weight compared with solid wood.

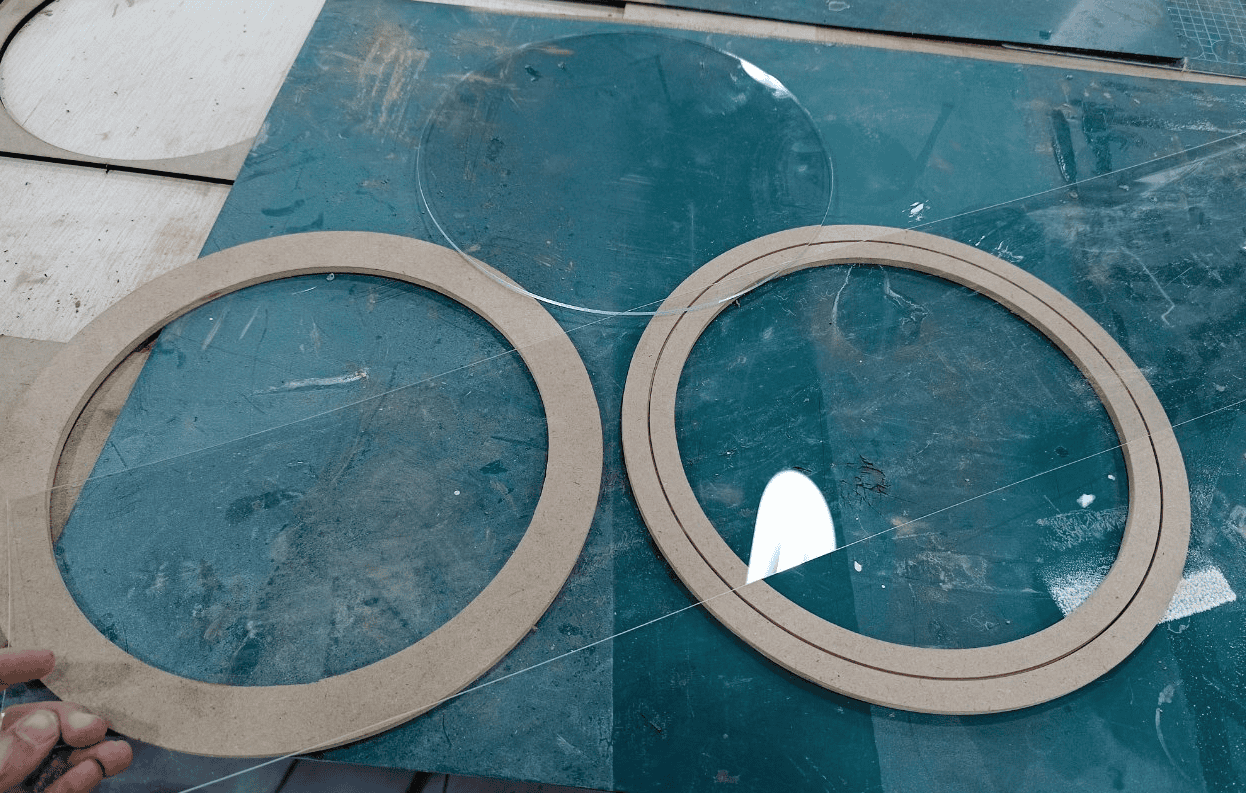

Making the mold was a challenge, since it big(30 cm diameter with 20cm height), so I thought to wrap a sheet of acrylic(1.2mm) thickness, and make two rings to fix the wrapping in place, so I made a sketch on fusion to visualize the body.

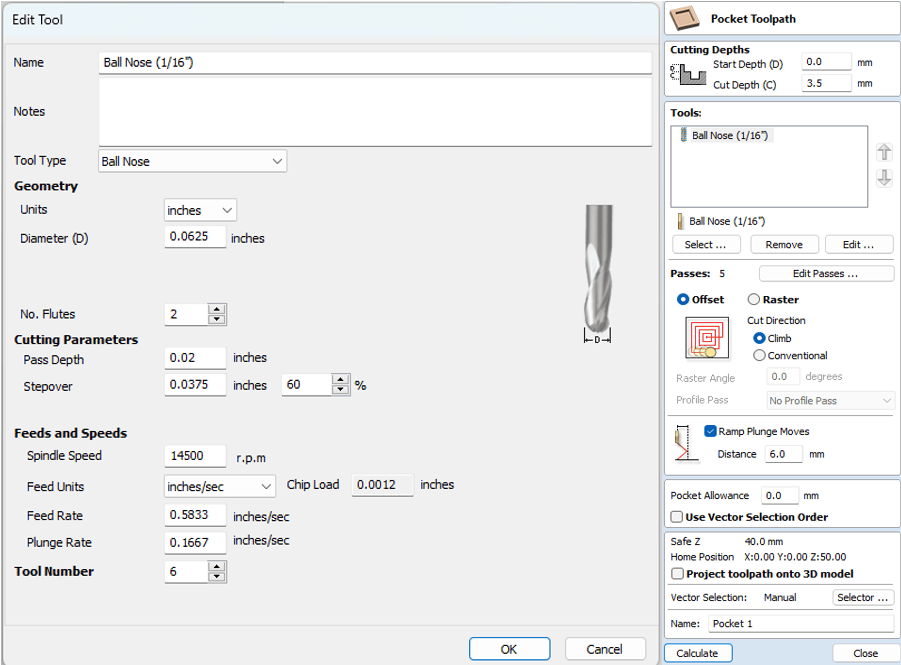

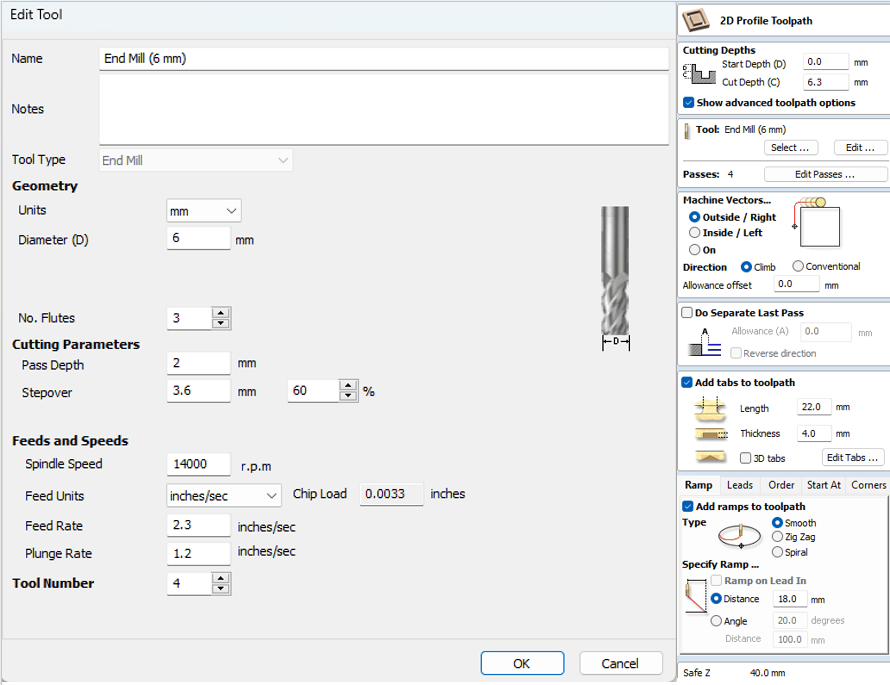

As on CNC week, I have exported the rings as dxf then I opened vcarve to prepare the toolpath, I used two toolpaths, first was the pocket with 1/16 inch endmill and profile with 1/4 inch endmill.

Pocket settings:

Profile settings:

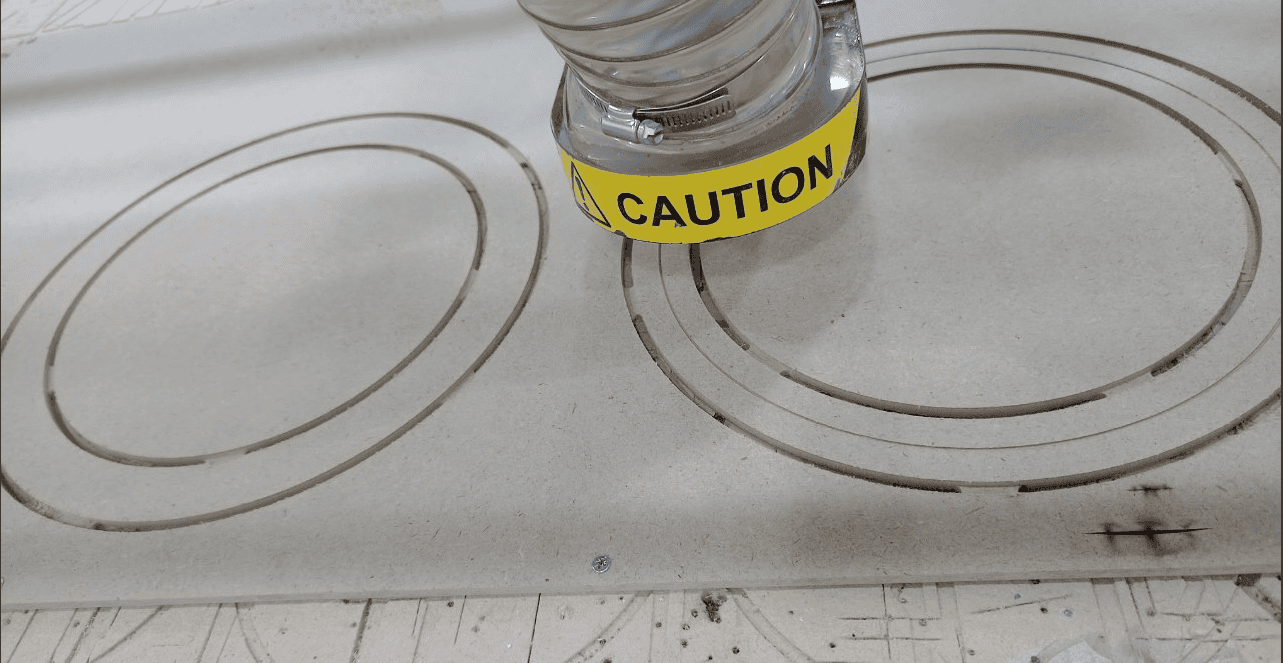

After I prepared the cam, I fixed a 6mm MDF board, and I zeros the axes, and I milled the two rings:

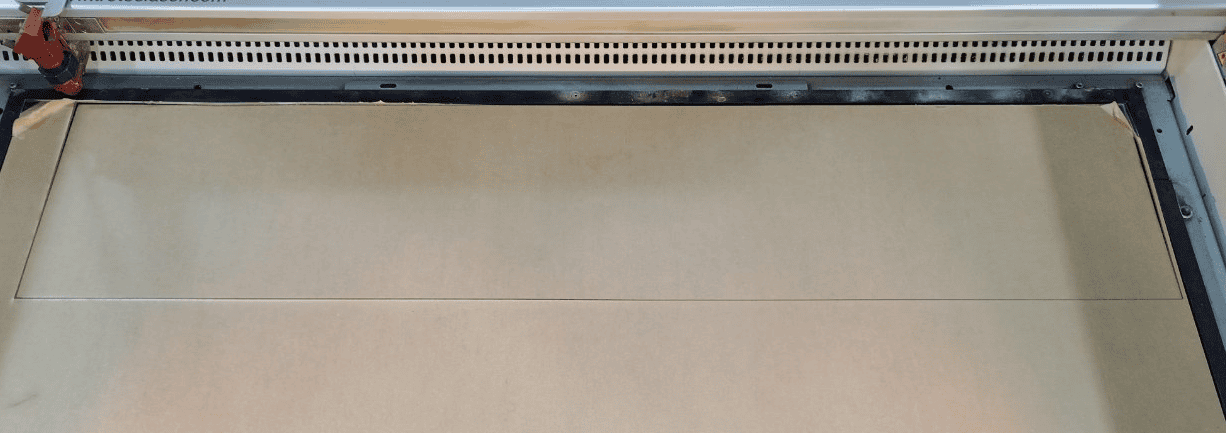

To cut the acrylic sheet I have calculated the length of it using the circumstance equation which is Length = pi*D and it was 950 mm so I drew a rectangle with 950mm width and 20mm height and cut it using laser cutting:

Also I cut an acrylic base with 30cm diameter:

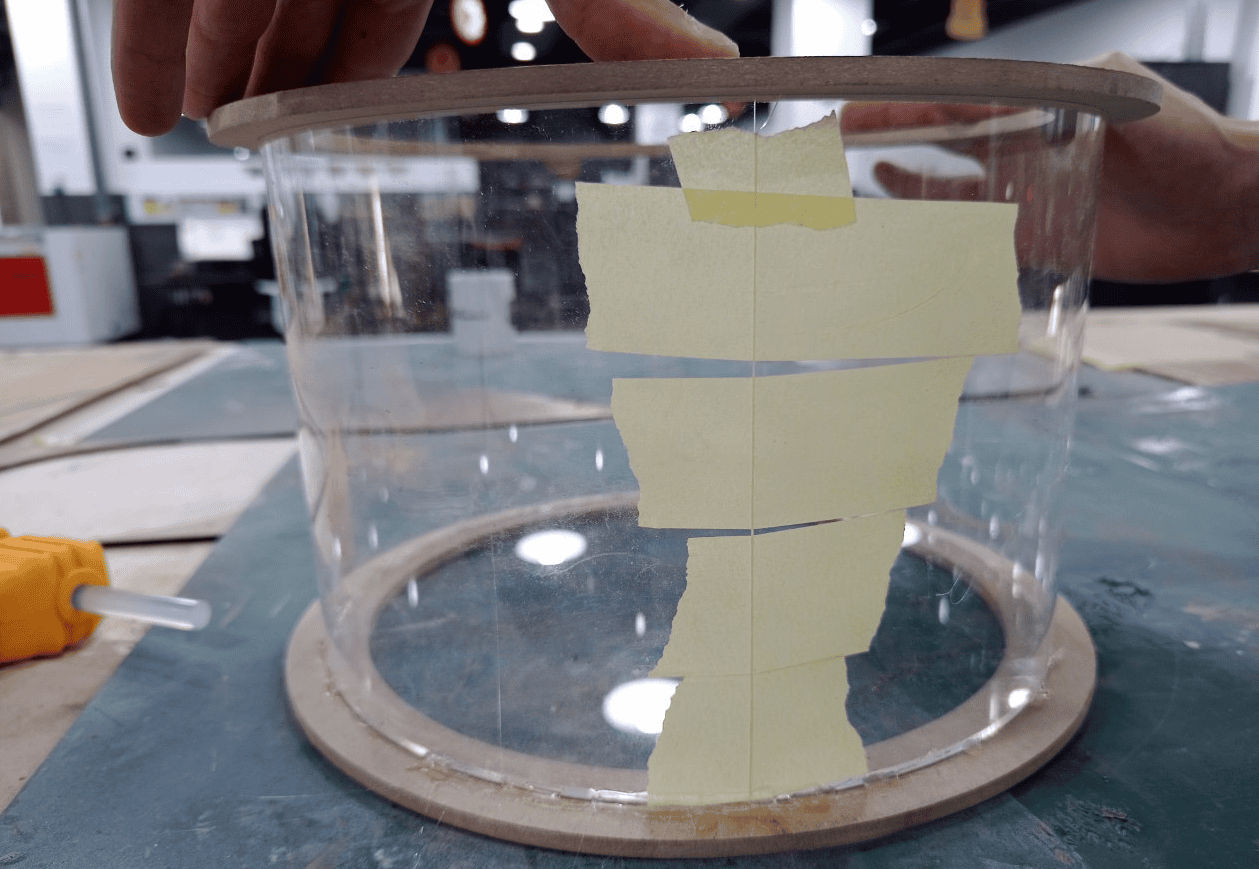

I wrapped the acrylic sheet with one ring thing I used the masking tape to close and fix the rounded shape also I used the glue gun with small drops on the outside(with mdf and the acrylic); then I fixed it using the other ring:

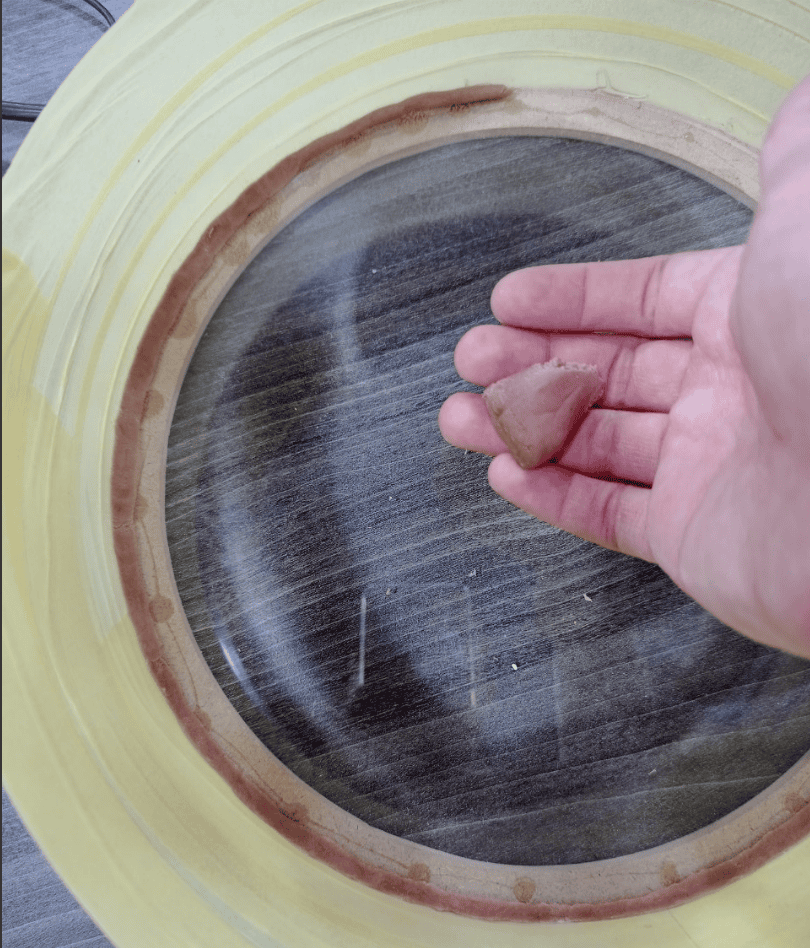

Next step was to seal the mold and prevent resin leakage, so I used paste which preferred on silicon for the ease of removal, and I sealed both bottom and the side of the mold:

The mold is sealed, but still it need to be waxed before using resin, I used candle wax by rubbing it with the walls and the base so I covered all the mold, this will help to prevent resin sticking and so the ease og removal:

I used the laser cut to cut the fabric pieces, I used burlap and linen fabric, I cut into tow shapes, a rectangle to cove the sides and a circles to cover the base, I made a cut at the tip of the circles so it will be easier to bent over the side

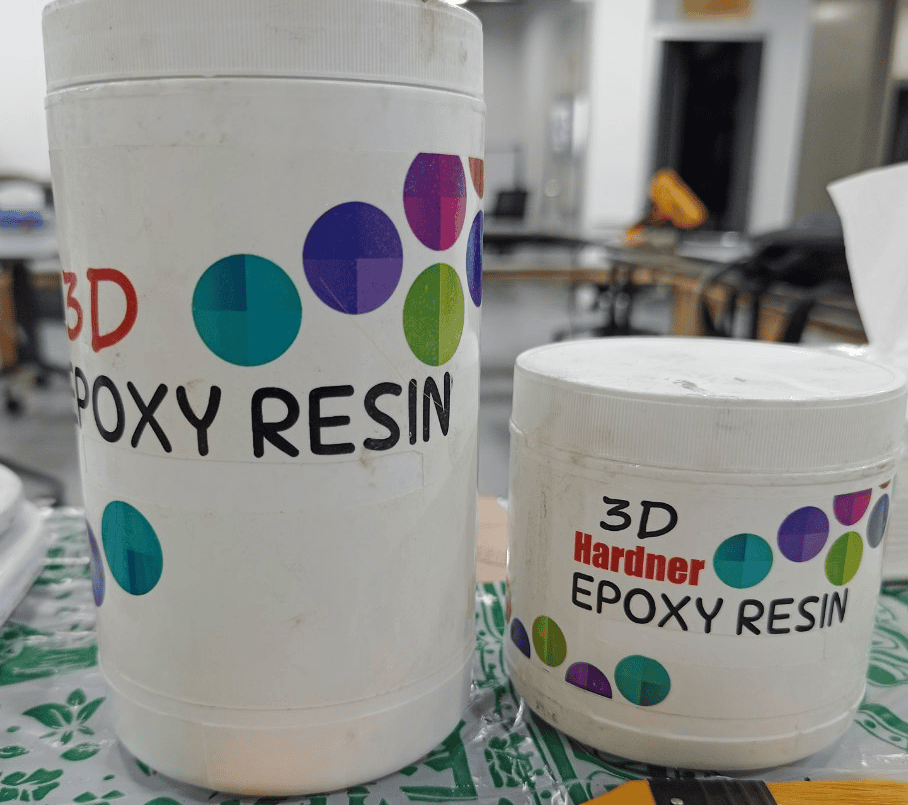

I will use the following resin, I did not find the safety data sheet, so I will handle it the same as the resin I used on Molding and Casting Week, sam as the technical data sheet, curing time is 24 hour and it comes with 2:1 mixing ratio this means with each 100 gram of resin , I will add 50 gram of hardener.

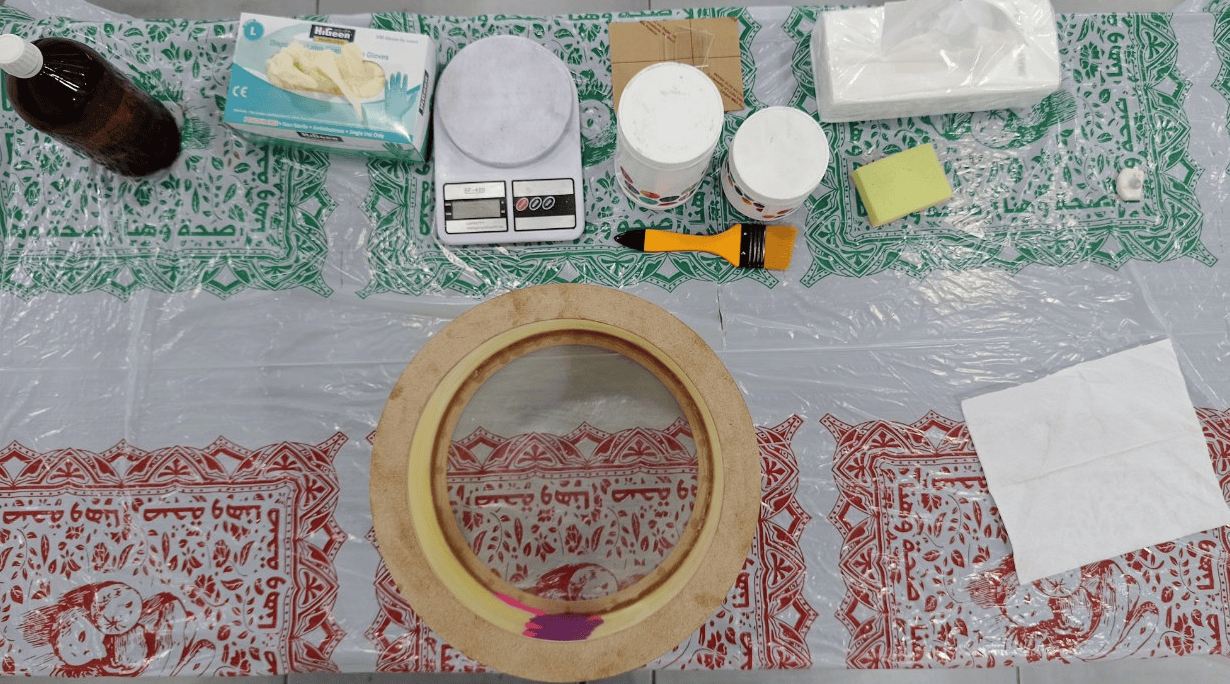

I prepared what I will need:

The best way to start is by preparing the resin, then apply a thin layer on the surface then put the fabric, starting with linen, best technique is by applying small pressure with the brush on the center of the fabric toward the outside, trying to not pull the fabric:

After I have finished all layers I will let it to dry for a couple of hours:

I checked the mold after 15 hour, it was cured!:

I started to take off the rings out then I removed the acrylic sheet, luckily it was not hard to remove, thanks to the wax, The body is ready, but for sure it needs some polishing to make the surface better in the soon future.