Week 7: COMPUTER COTNROLLED MACHINING

Group Assignment

- Complete your lab’s safety training

- Test runout, alignment, fixturing, speeds, feeds, materials and toolpaths for your machine

- Document your work to the group work page and reflect on your individual page what you learned

Individual Assignment

- Make (design+mill+assemble) something big

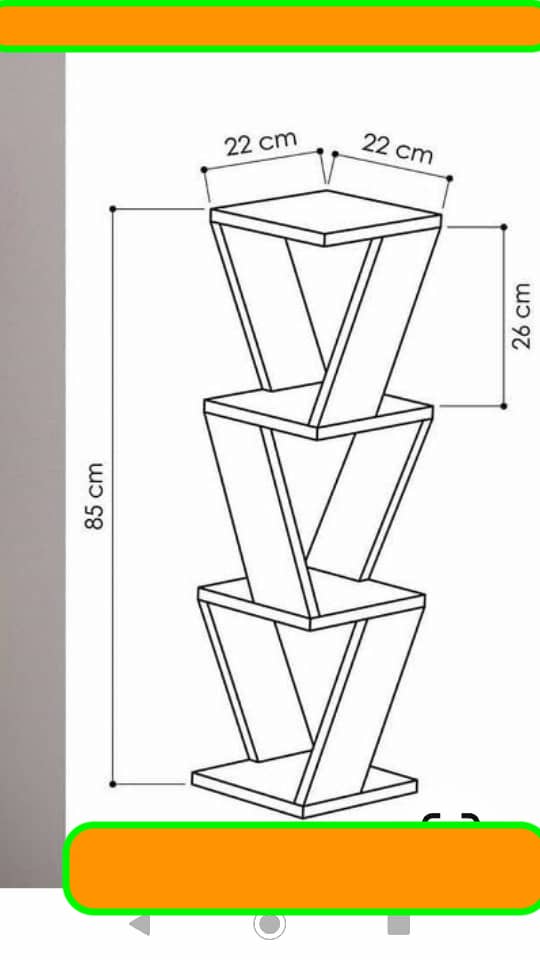

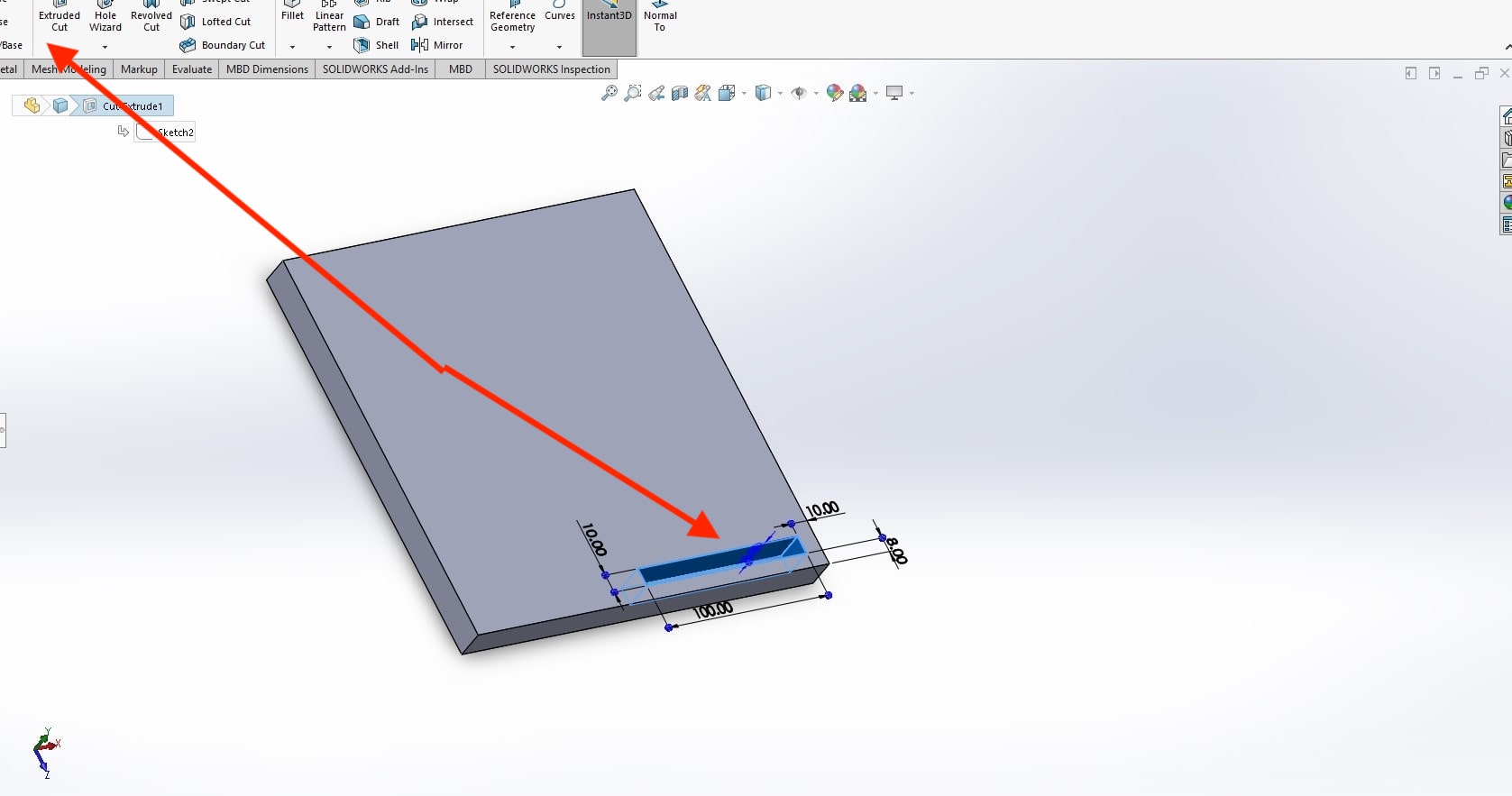

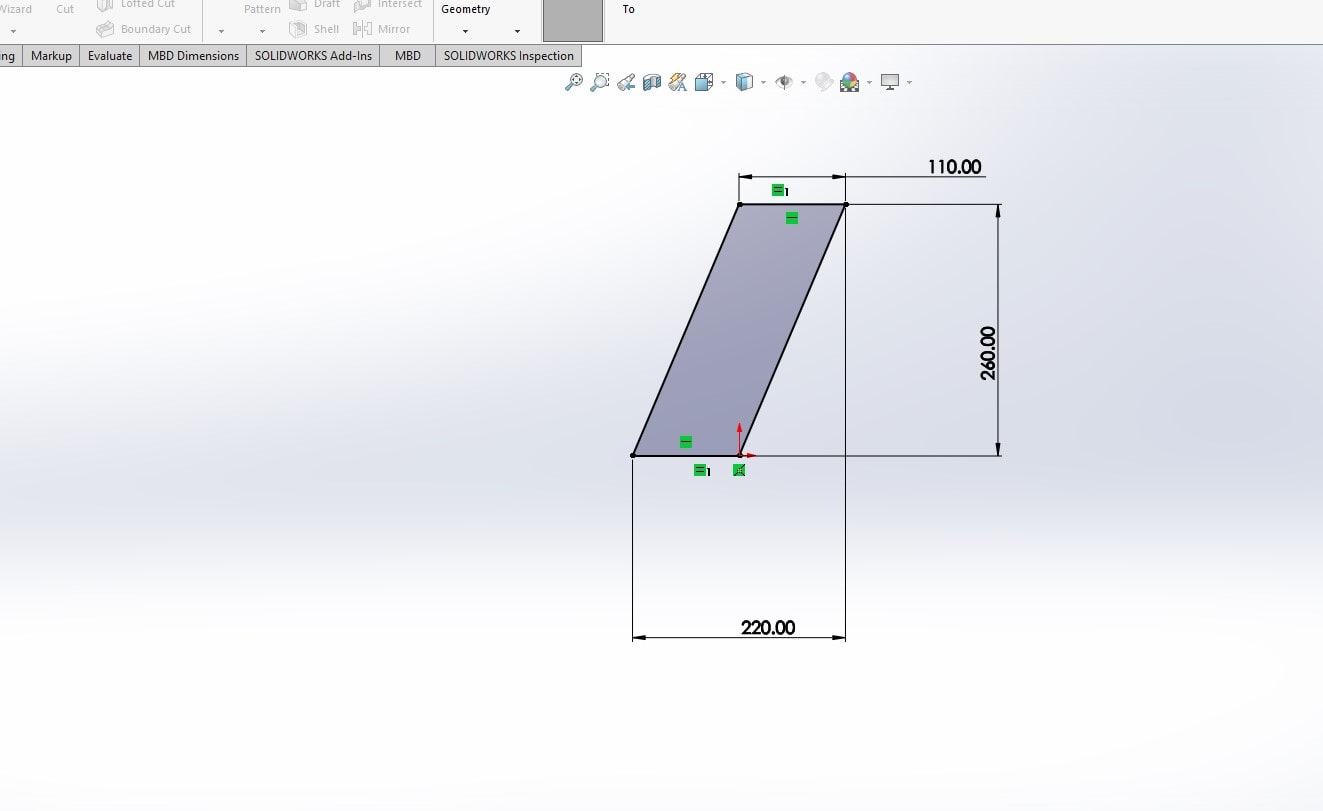

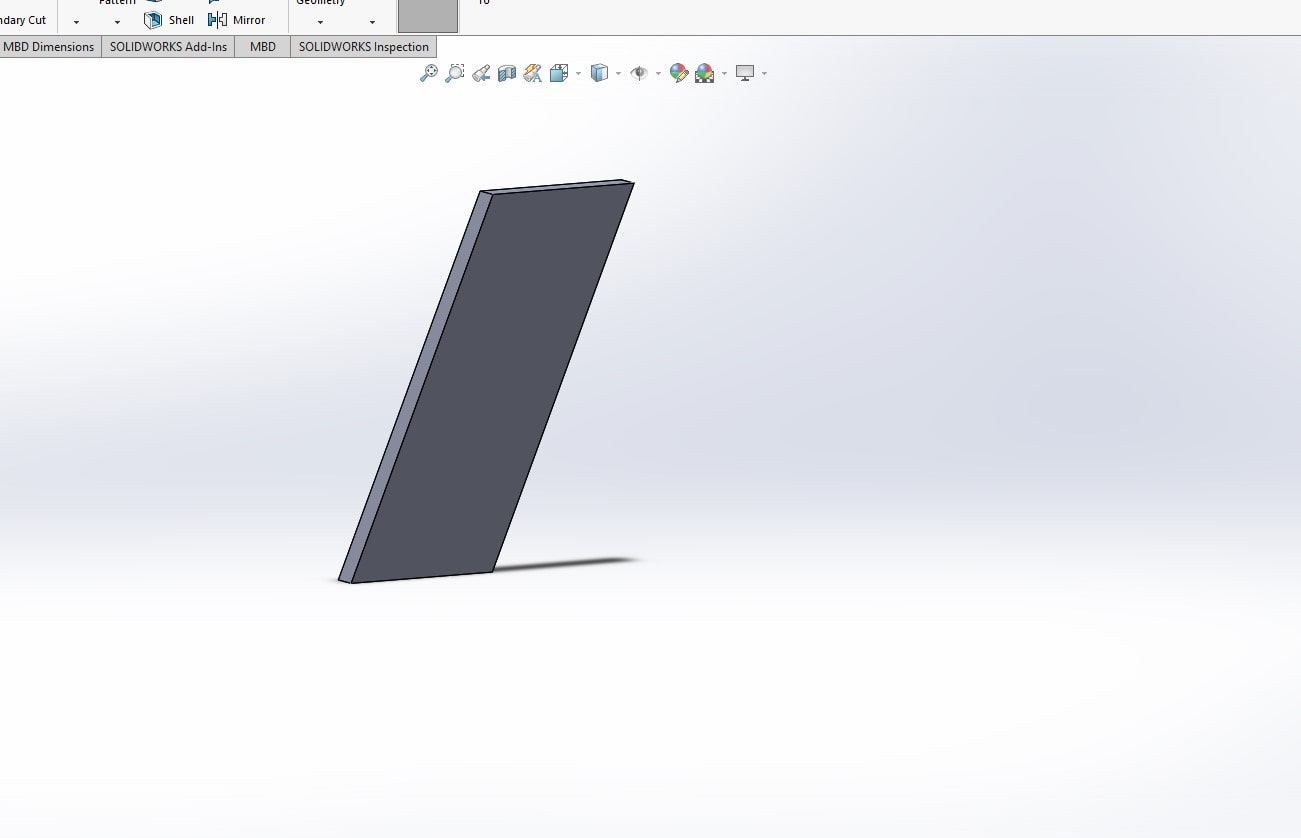

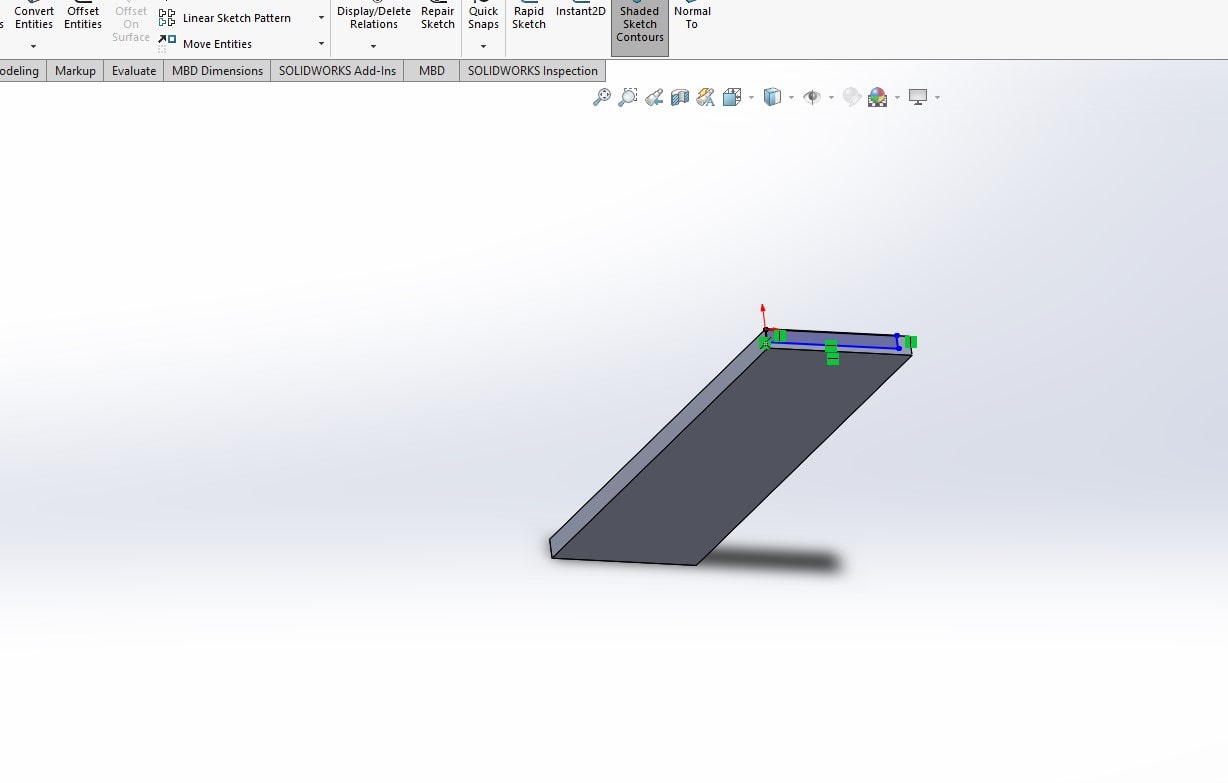

Furniture Material Design

my design idea: Floating and hanging shelves

Floating and hanging shelves can be a great addition to your home decor, providing both style and functionality. Here are some use cases for floating and hanging shelves:

| # | Use Case |

|---|---|

| 1 | Displaying Decorative Items |

| 2 | Storing Books |

| 3 | Creating a Focal Point |

| 4 | Maximizing Space |

| 5 | Adding Functionality |

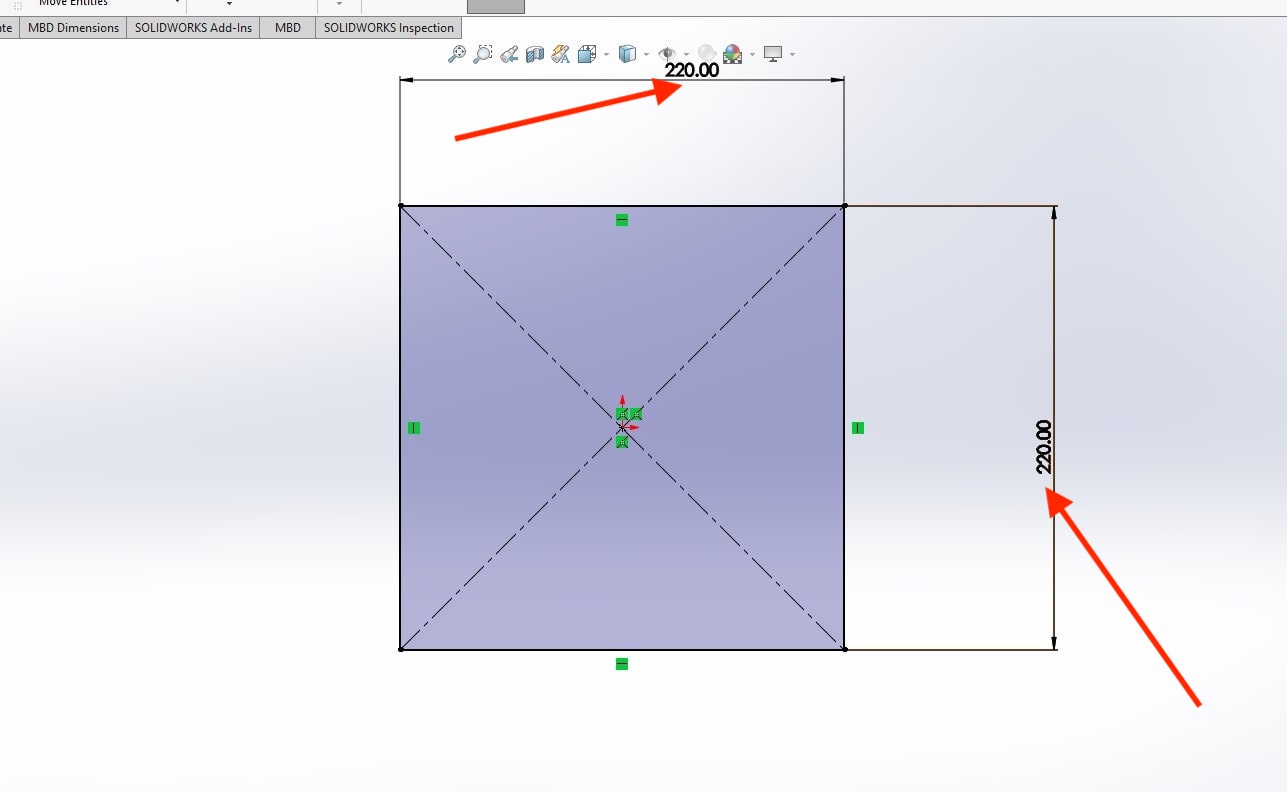

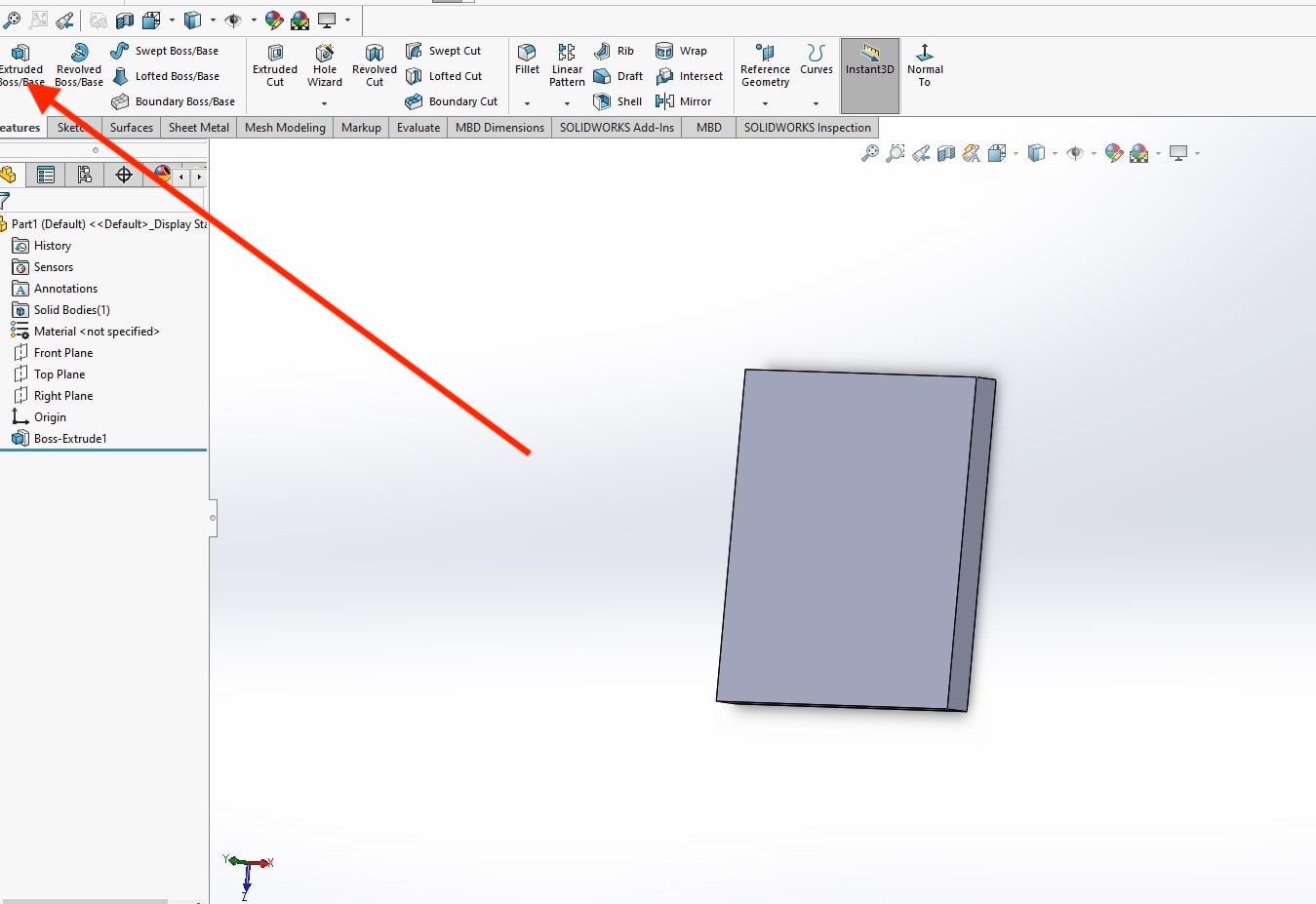

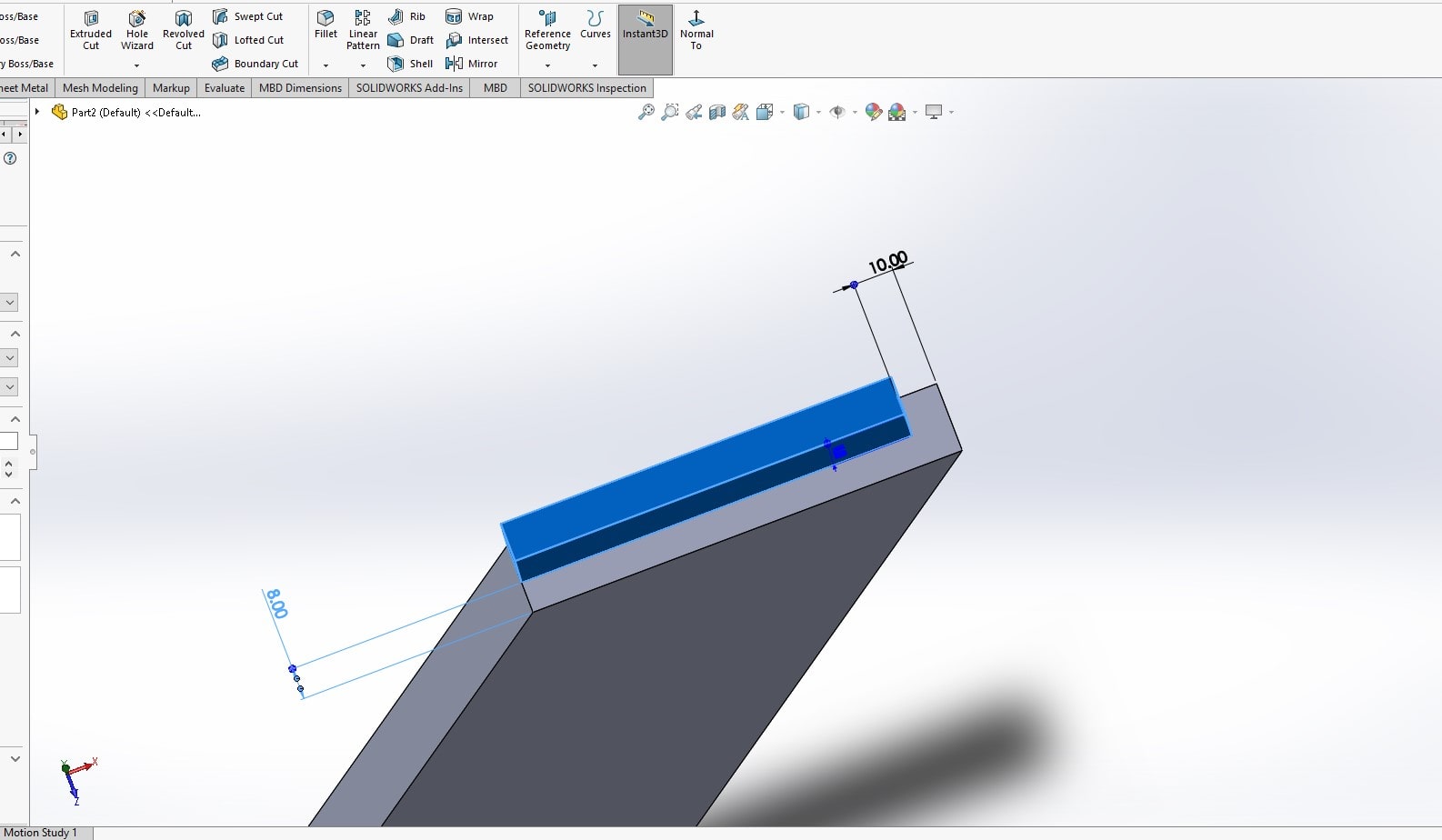

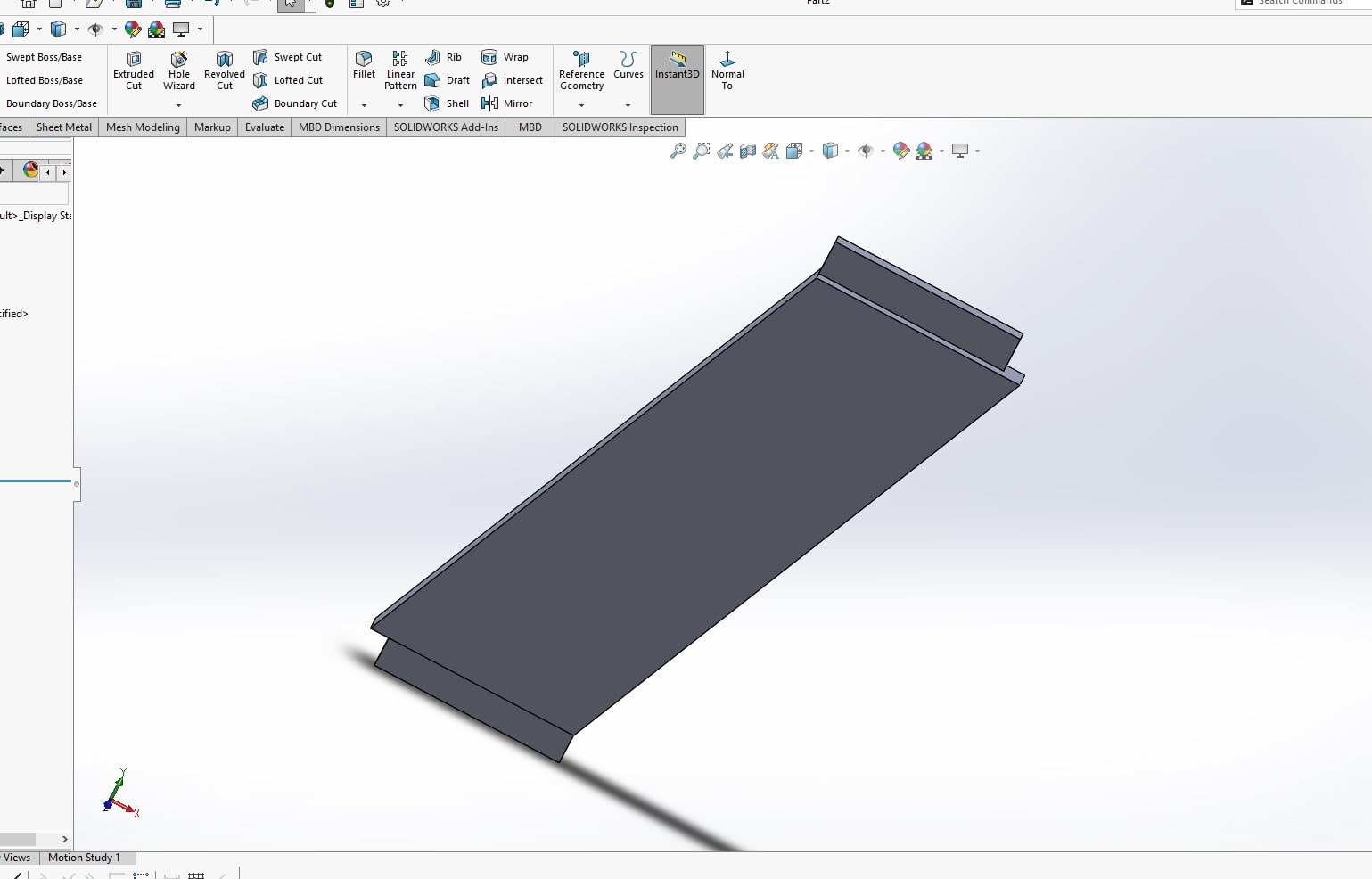

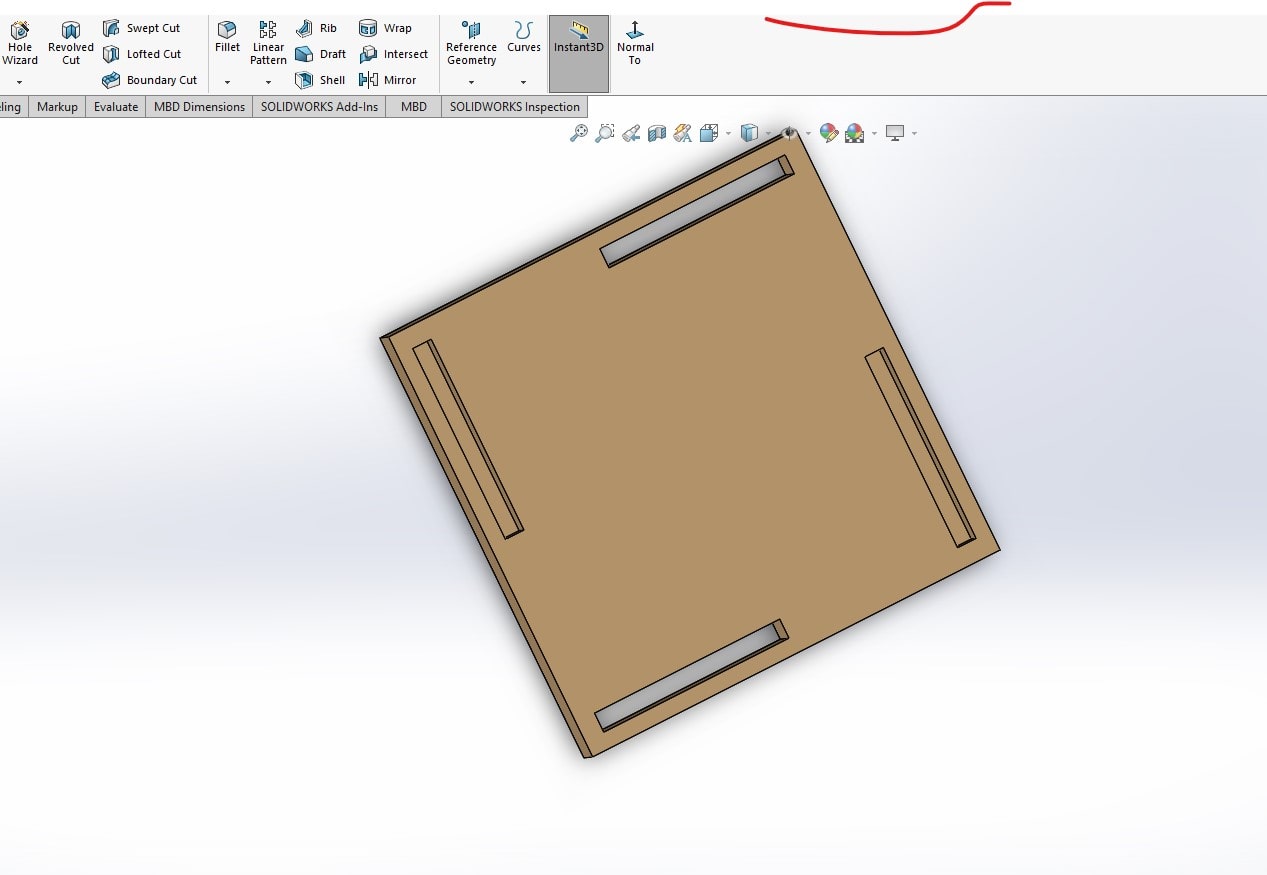

For this , i have to use solidworks for designing.

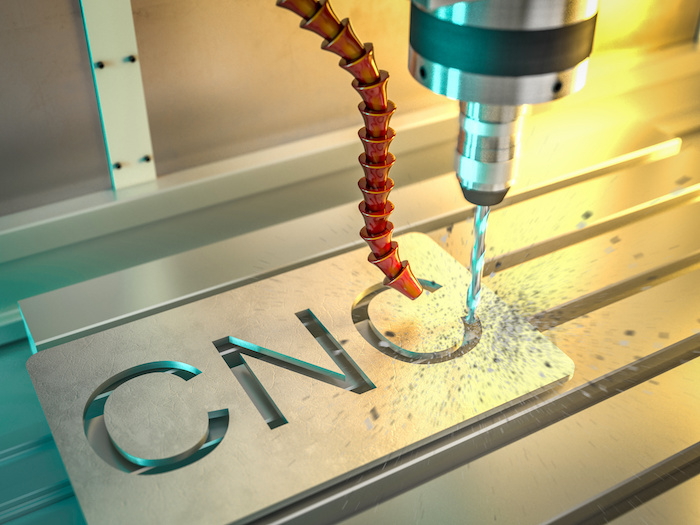

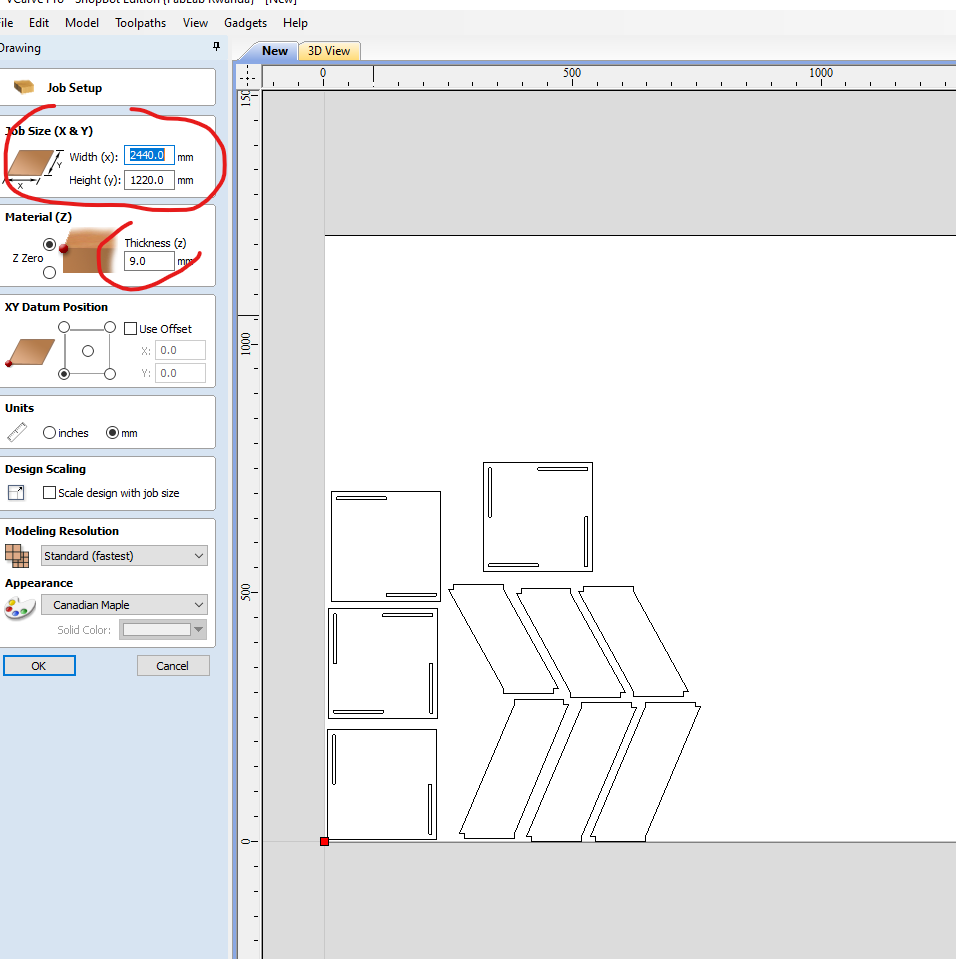

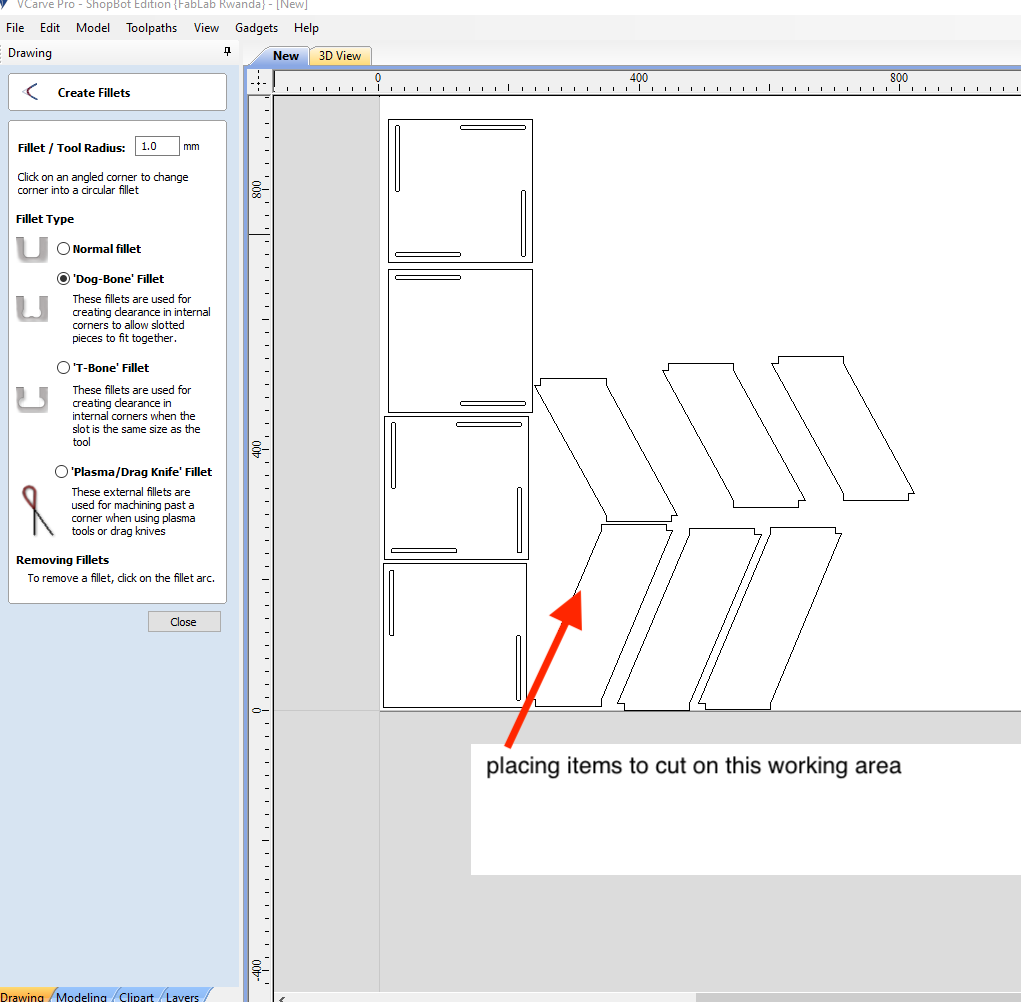

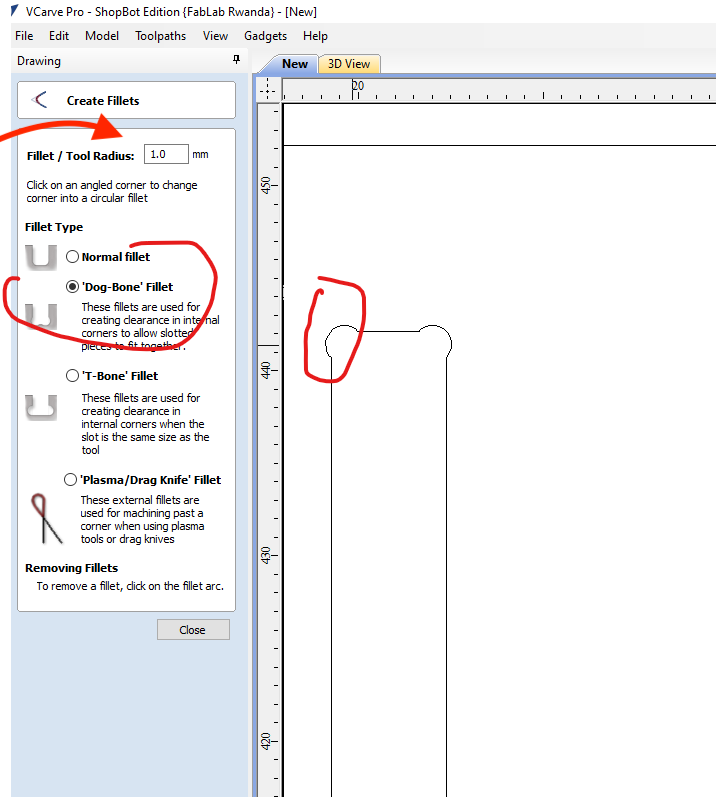

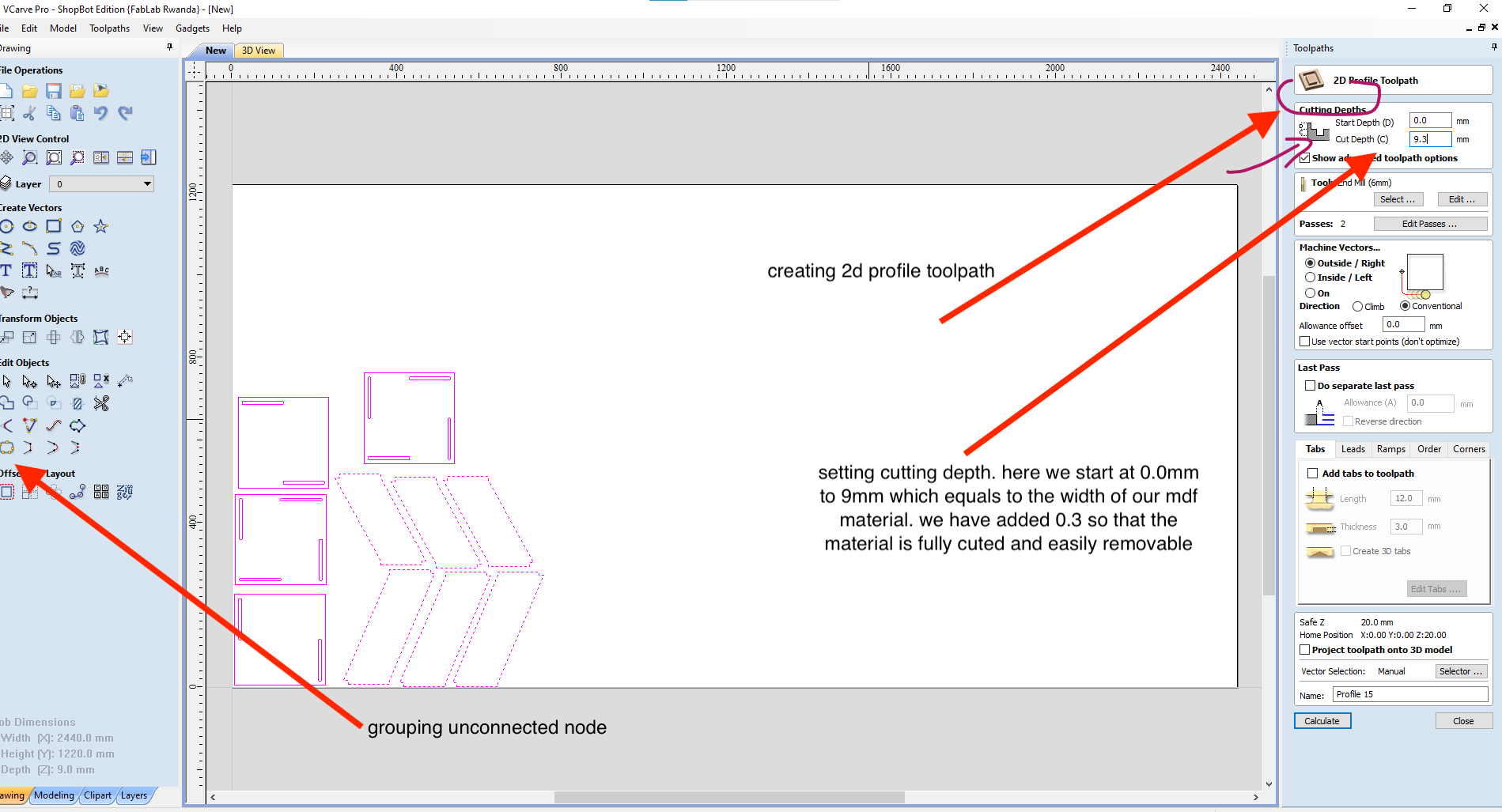

Creating Vectors in VCarve pro for CAM software

To cut the different parts of the material , we have to use CAM softaware

Automating a production process via the use of software and computer-controlled equipment is known as computer aided manufacturing (CAM). a CAM system requires the following three elements to operate:

- Software that creates toolpaths to instruct a machine on how to build a product.

- Industrial equipment capable of transforming raw materials into final goods.

- Toolpaths are translated into a language that machines can understand during post processing.

VCarve Pro is a software package designed for creating and producing CNC (Computer Numerical Control) toolpaths for a wide range of CNC machines, including ShopBot CNC routers.

VCarve Pro allows users to create 2D and 3D designs using a wide range of tools and features. we can import designs in various formats, including vector files, bitmap images, and 3D models. Once a design is imported or created, VCarve Pro allows us to manipulate and edit the design to create the desired output.

When used with a ShopBot CNC router, VCarve Pro allows users to generate toolpaths for the machine to follow. T hese toolpaths are based on the design created in VCarve Pro and provide instructions for the ShopBot CNC router to carve or cut the design into the material being used. VCarve Pro is able to generate toolpaths for a variety of operations, including profiling, pocketing, drilling, and v-carving.

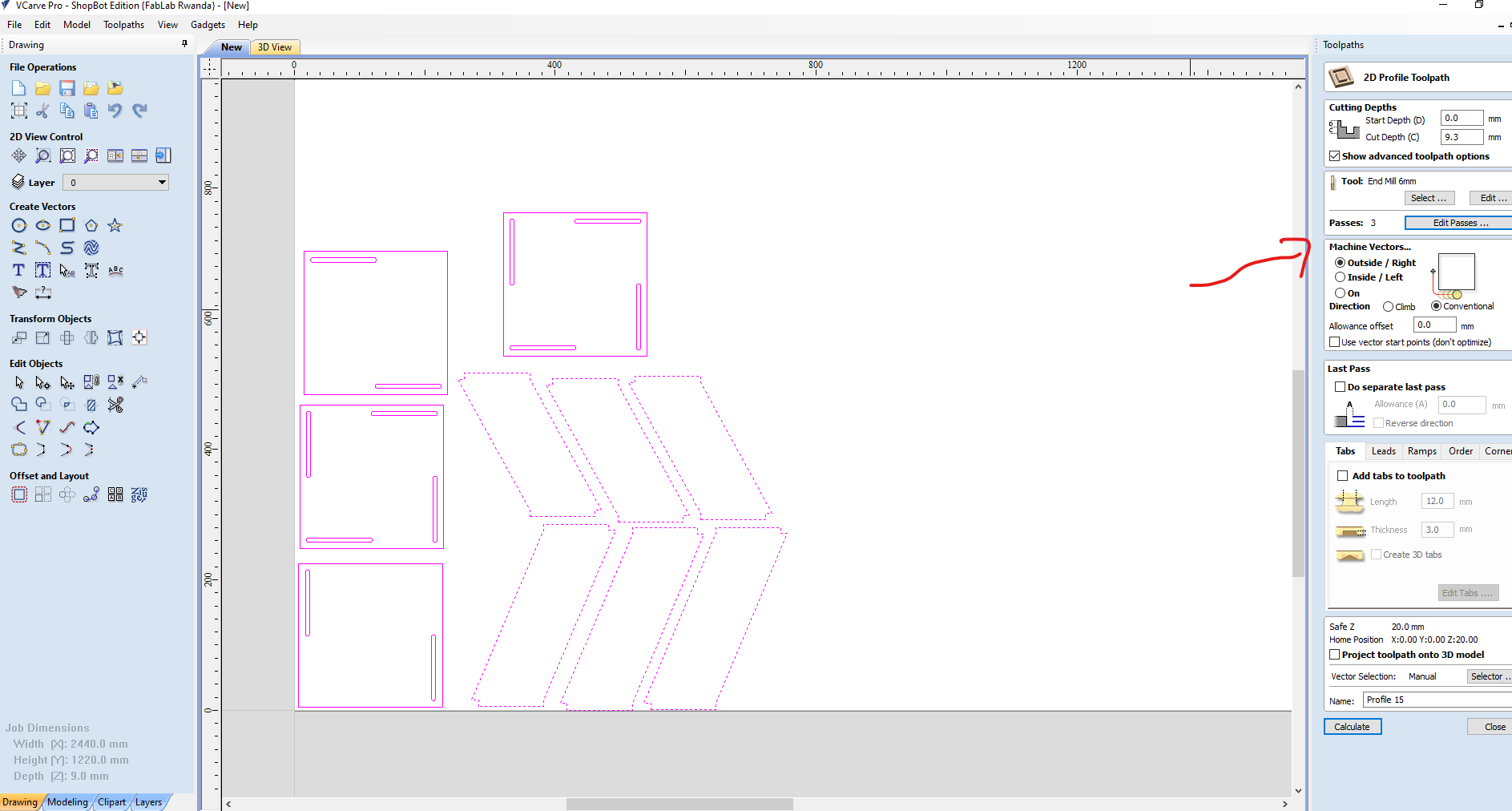

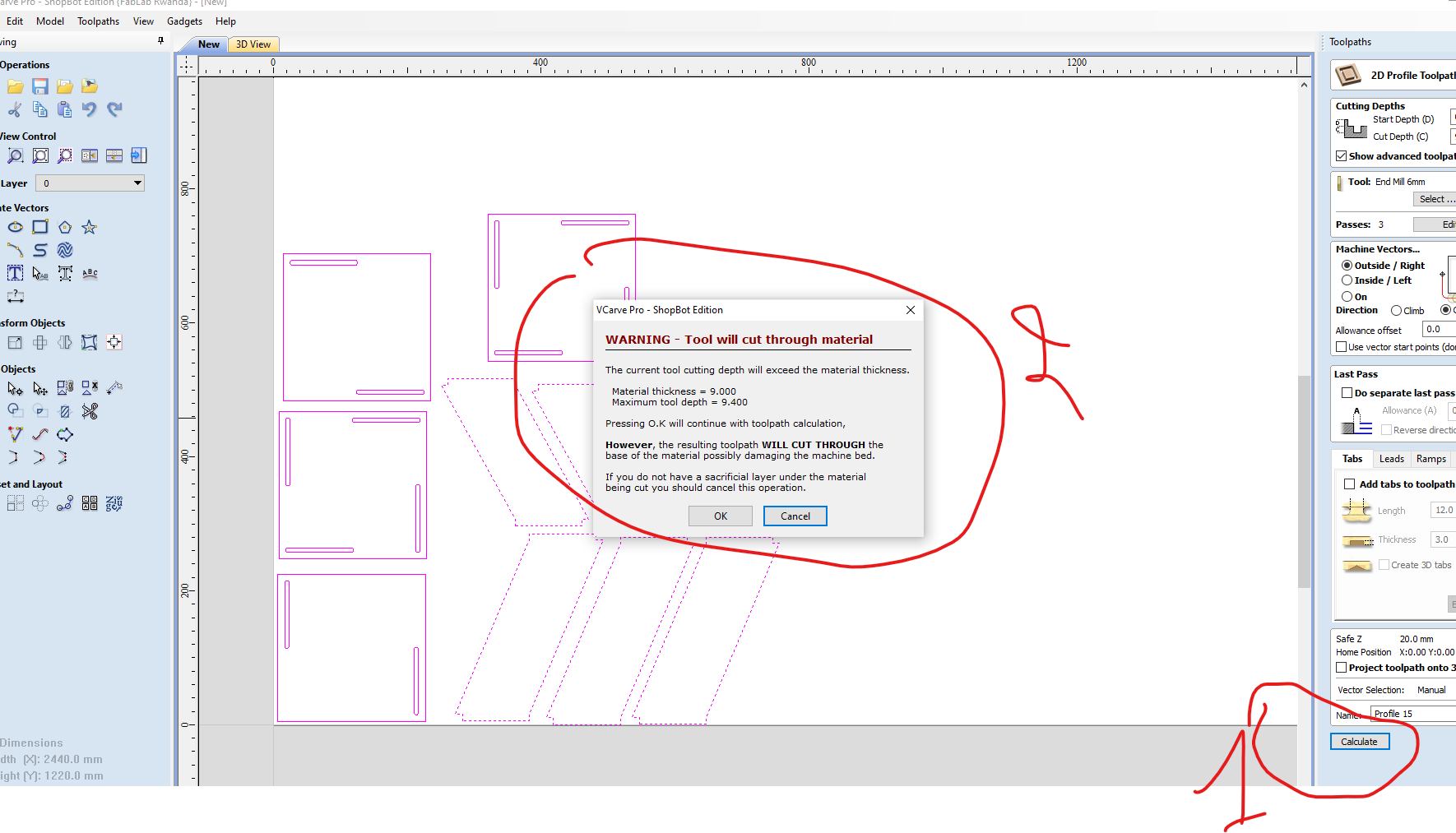

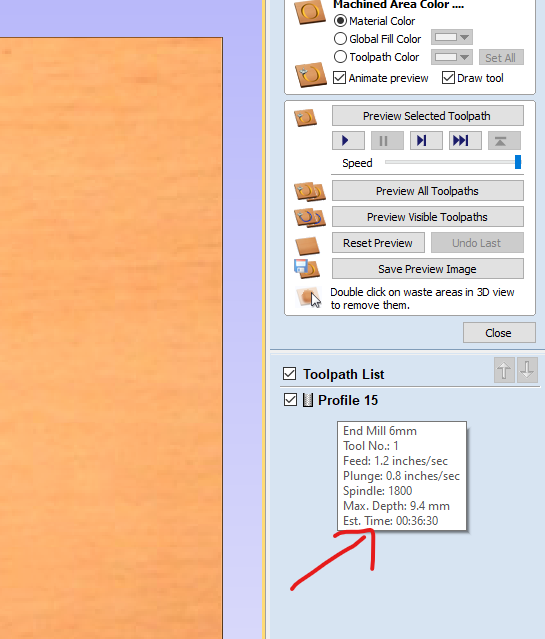

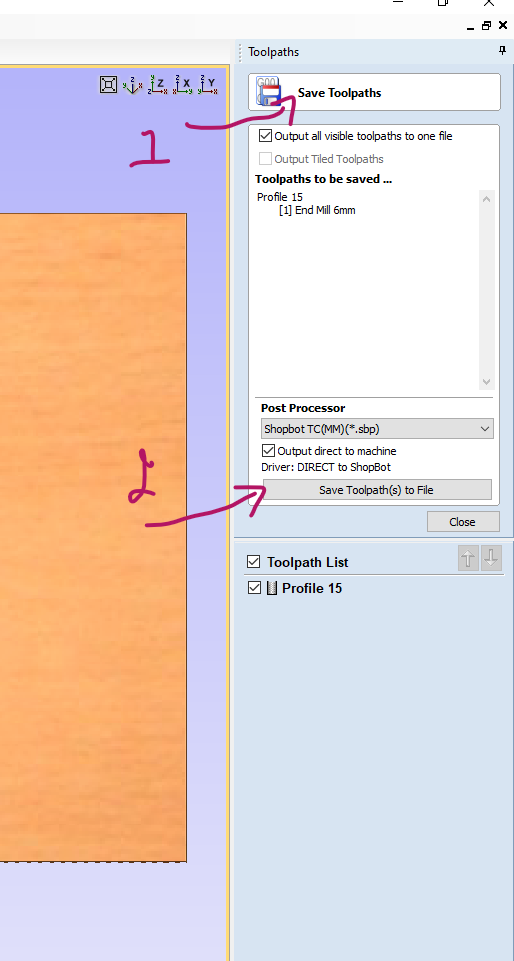

Using VCarve pro to create toolpath for my design

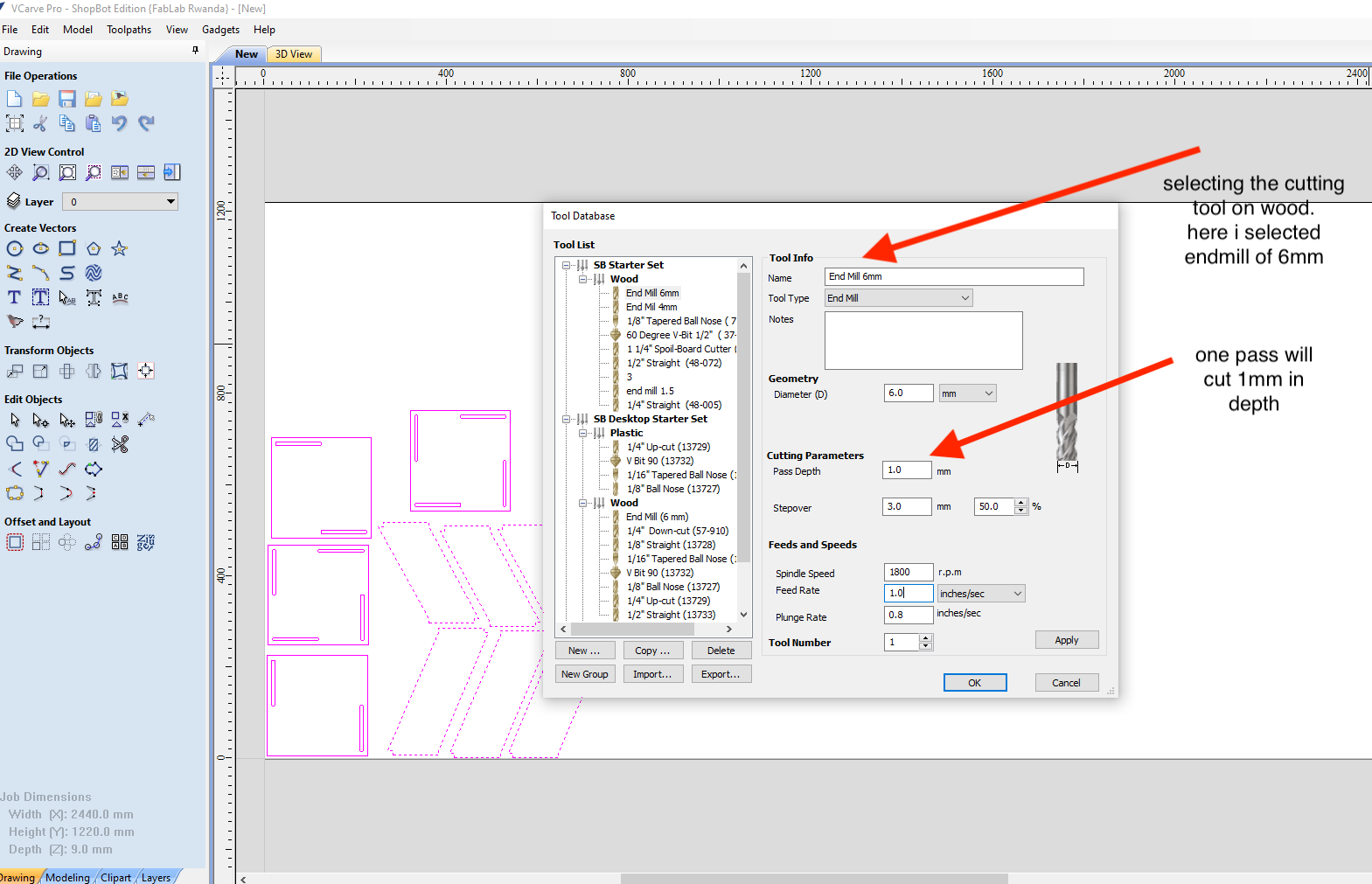

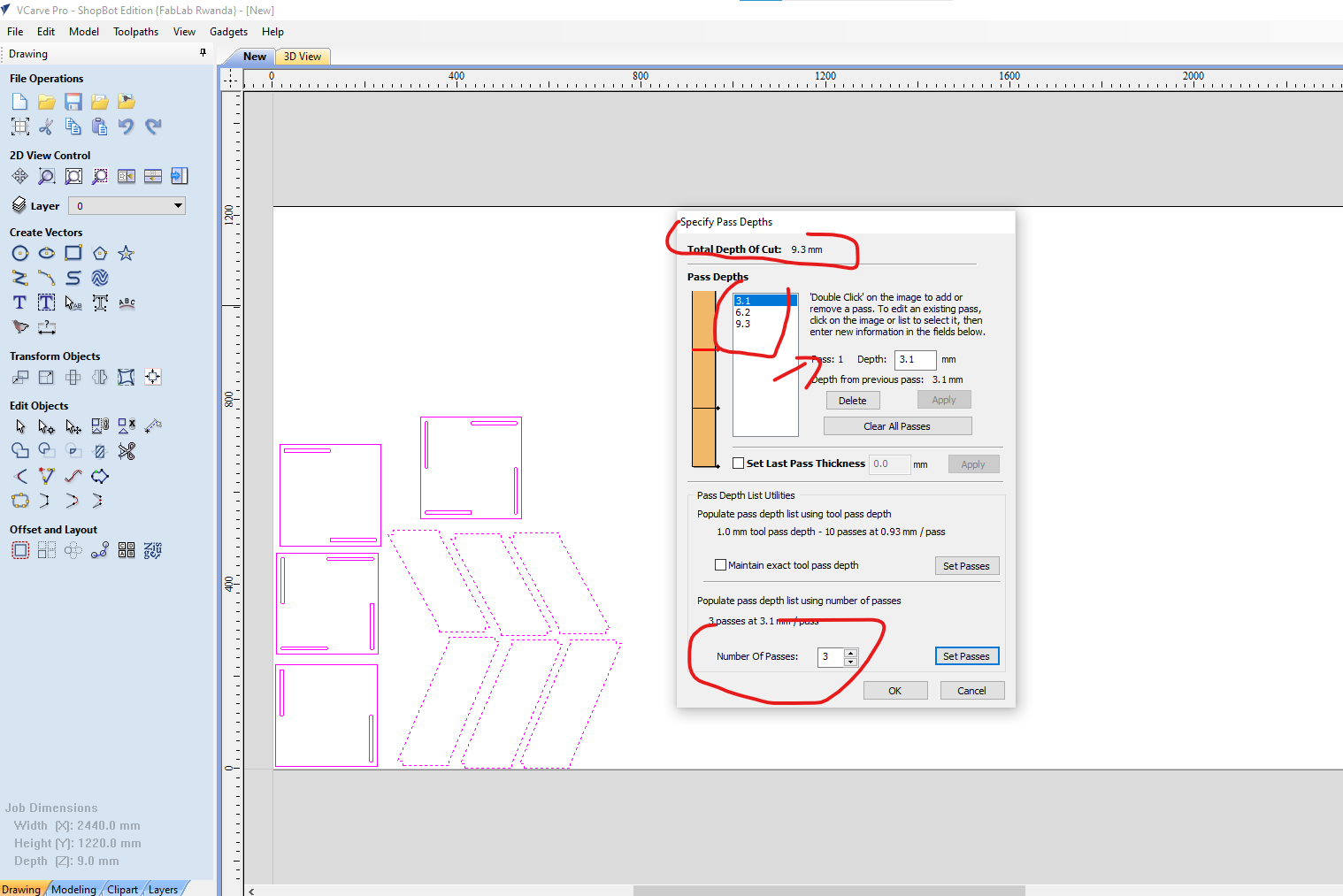

Cutting parameters :

| Parameter | Definition |

|---|---|

| Number of Passes | The number of times the tool will cut over the same area. |

| Pass Depth | The depth that the tool will cut into the material during each pass. |

| Stepover | The distance the tool will travel side-to-side in between each cut. |

| Spindle Speed | The speed at which the spindle or router will rotate. |

| Feed Rate | The speed at which the tool moves through the material during cutting. |

| Plunge Rate | The speed at which the tool moves down into the material at the beginning of a cut. |

Furniture Manufacturing with CNC shopbot

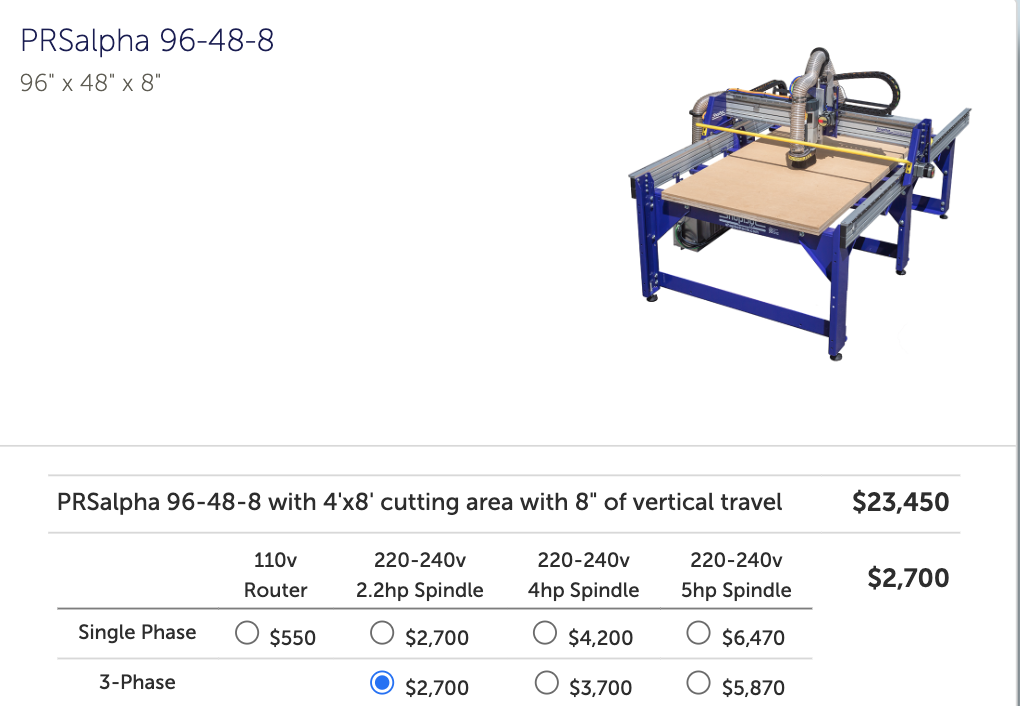

PRSalpha shopbot Specifications

| Specifications | Values |

|---|---|

| Work Area | 96" x 48" x 6" (2438mm x 1219mm x 152mm) |

| Spindle | 3.0hp HSD Spindle |

| Spindle Speed | 7,000 - 24,000 RPM |

| Cutting Speed | 600 inches per minute (25 meters per minute) |

| Repeatability | +/- .001" (.025mm) |

| Drive System | Precision Ball Screws |

| Control System | ShopBot PRSalpha Control System |

| Software Compatibility | PartWorks3D, VCarve Pro, Vectric Aspire, Fusion 360, and more |

| Power Requirements | 220 VAC, Single Phase, 30 Amp |

| Weight | 1,500 lbs (680 kg) |

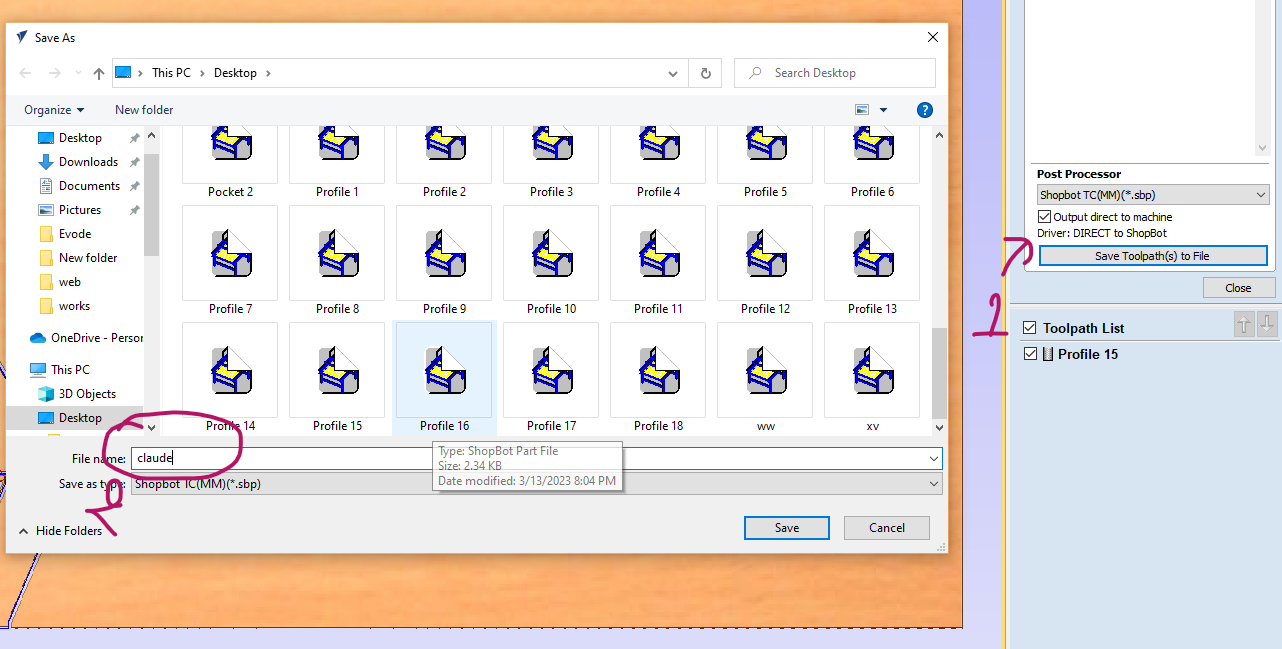

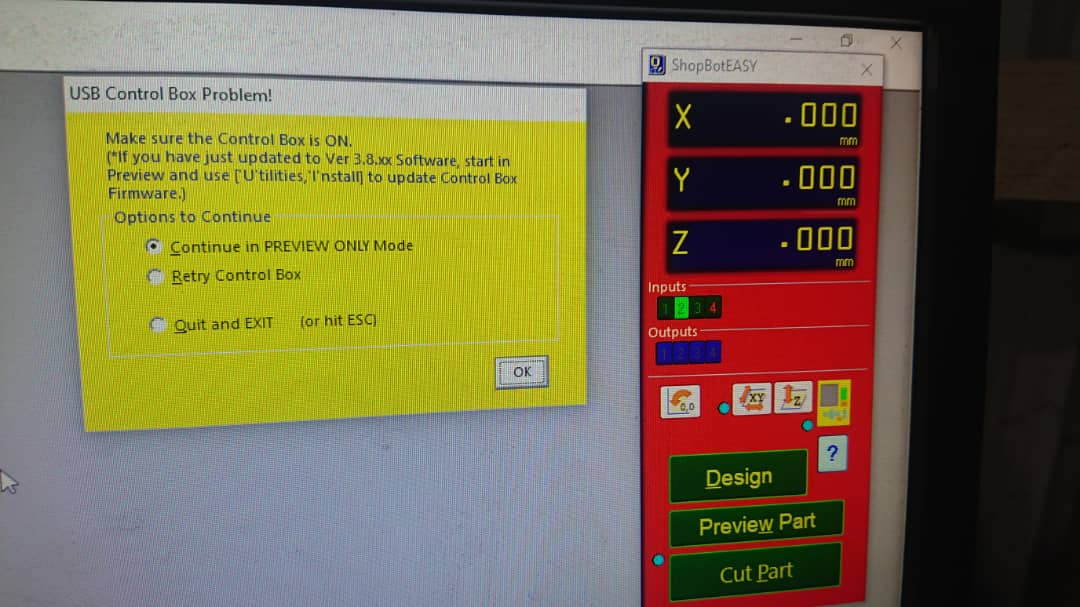

Shopbot Control Software

The ShopBot Control Software is a proprietary software package developed by ShopBot Tools, Inc. It is a CNC control software that runs on a PC and is used to control ShopBot CNC r outers and other ShopBot CNC machines. The software includes a graphical user interface (GUI) that allows the user to interact with the machine and create, edit, and run CNC programs.

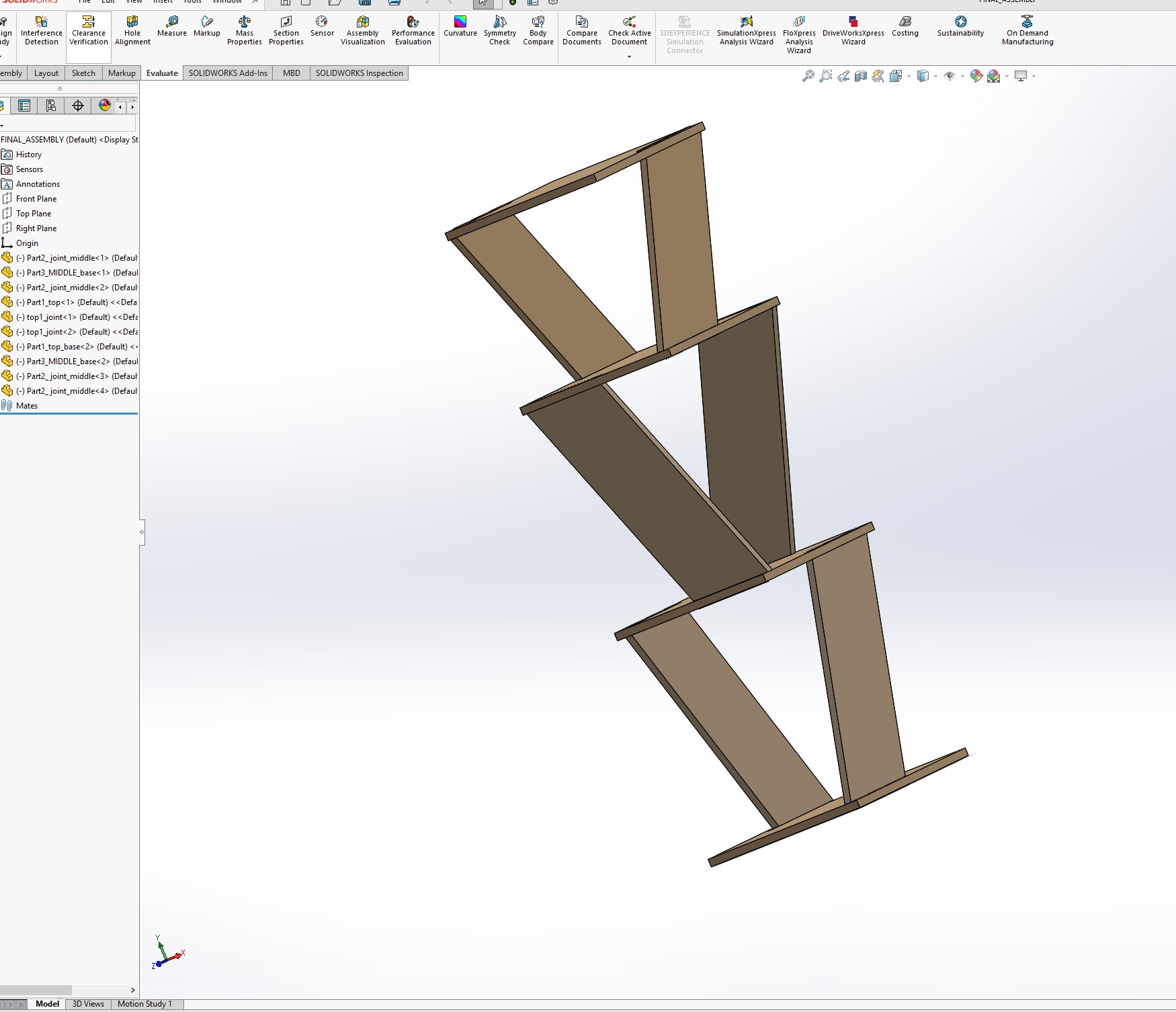

Final Manufacutred Hanging material