WILD CARD

Computarized embrodery Machine

this wildcard week was about to do something that was not done before. i prefered to use computarized embroidery machine, because its similarity with cnc and laser cutter both are computer controlled and it was not covered in what we have seen in the last weeks .

A computerized embroidery machine is a sophisticated piece of equipment designed to create intricate and detailed embroidery designs on various fabrics. It combines the traditional art of embroidery with modern technology to streamline and automate the embroidery process.

Here are some key features and components of a computerized embroidery machine

- Control Panel: The machine has a control panel or a computer interface that allows users to upload and select embroidery designs, control stitching parameters, and monitor the progress of the embroidery.

- Design Input: Designs can be created from scratch using computer software or obtained from digital embroidery design files. These designs are then transferred to the machine either directly or through a USB drive, memory card, or computer connection.

- Hoops: The machine typically includes a set of hoops or frames in various sizes that secure the fabric in place during the embroidery process. The hoops move along multiple axes to ensure precise stitching.

- Needles: Embroidery machines have multiple needles, usually between one and 15, that hold different thread colors. The needles move up and down and side to side, creating the desired patterns and designs.

- Thread Management: Computerized machines often have an automatic thread management system that cuts, trims, and changes threads as required during the embroidery process. This eliminates the need for manual intervention and ensures smooth stitching.

- Stitching Techniques: Computerized embroidery machines offer a range of stitching techniques, such as satin stitch, fill stitch, appliqué, cross-stitch, and more. These techniques can be combined to create complex and detailed designs.

- Speed and Precision: These machines are capable of stitching at high speeds while maintaining exceptional precision and accuracy. The computer-controlled movements ensure consistent stitch quality and alignment throughout the design.

- Customization and Editing: Computer software allows users to customize and edit embroidery designs according to their preferences. They can adjust the size, rotation, density, and stitch types to achieve the desired look.

- Multi-Functionality: Some advanced computerized embroidery machines offer additional features, such as sequin attachment, cording, quilting, and monogramming. This makes them versatile tools for various applications and creative projects.

it is really an interesting machine as it is used to print on clothes complex design that can not be made manually.

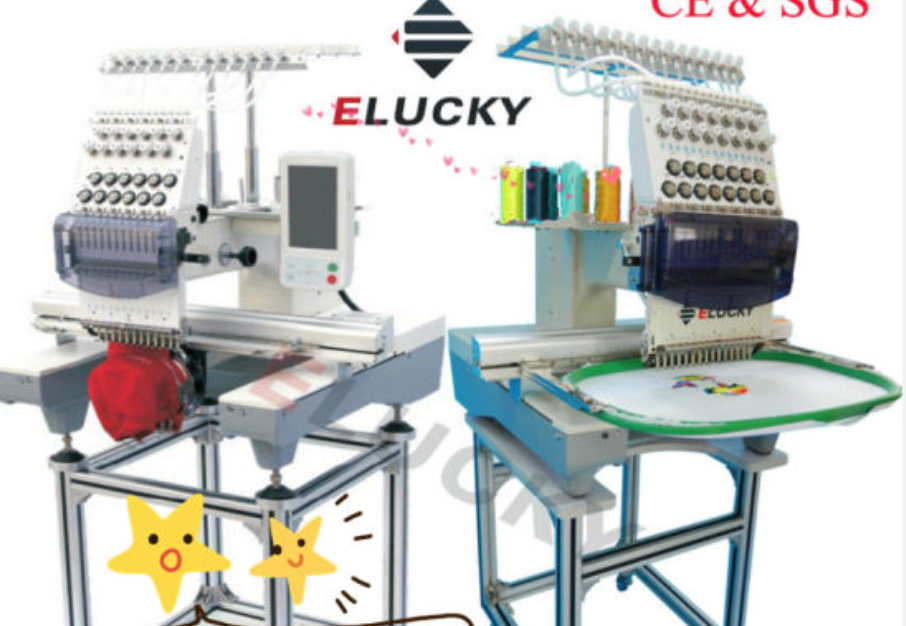

ELUCKY EMBROIDERY MACHINE USED

The machine i used is called elucky machine

it has max speed of 1500RPM with 140kg weight , workable sie is 360*200mm and it has 15 nodels

DESIGN PROCESS WITH ES CHENILLE SOFTWARE

The process i used is to take already designed logo image and create embrodery vectors using ES Chenille software.

to prepare the bag, we use circular shaped plastic material and we fix it in the embrodery under tools used to