general safety rules are Never wear loose clothing, gloves or any type of garment that can become entangled in any moving machinery. Tuck in shirttails and roll up sleeves, or wear a close-fitting industrial garment (such as coveralls, an industrial apron or a shop coat) that cannot be entangled by a moving machine part or the workpiece .based on that the safety training and story of yole Univesity student for her accident in the shop we summurized the safety training out come in the following paragraph

Definition and classifiction of hazard :A hazard is any source or situation that has the potential to cause harm, damage, or injury to people, property, or the environment. Hazards can come in many forms, such as physical, chemical, biological, or psychological. Examples of hazards include:

we have learned that It's important to identify and assess hazards in order to prevent accidents, injuries, and illnesses. This is typically done through risk assessments, which involve analyzing the likelihood and severity of a hazard, and implementing controls or measures to reduce or eliminate the risk.

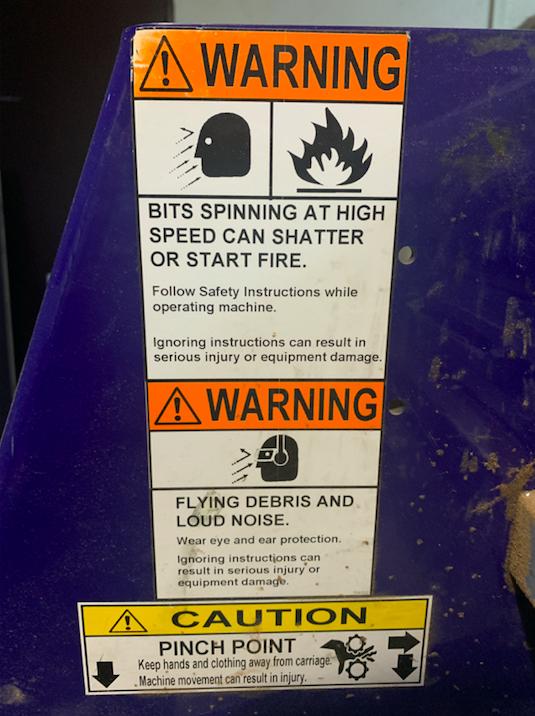

Here are some safety measures that should be followed when using a ShopBot CNC Router Machine:

1. Wear appropriate safety gear:

Before operating the machine, make sure to wear appropriate safety gear, such as safety glasses, earplugs, and closed-toe shoes. Long hair and loose clothing should be tied back or tucked in to avoid getting caught in the machine.

Here are some safety measures that should be followed when using a ShopBot CNC Router Machine:

1. Wear appropriate safety gear:

Before operating the machine, make sure to wear appropriate safety gear, such as safety glasses, earplugs, and closed-toe shoes. Long hair and loose clothing should be tied back or tucked in to avoid getting caught in the machine.

2. Familiarize yourself with the machine::

Read the operator's manual and familiarize yourself with the machine's controls, emergency stop button, and safety features.

Read ShopBot User Guide here

2. Familiarize yourself with the machine::

Read the operator's manual and familiarize yourself with the machine's controls, emergency stop button, and safety features.

Read ShopBot User Guide here

3.Use dust collection:

The ShopBot CNC Router Machine generates a lot of dust and debris during operation. Use a dust collection system to keep the work area clean and to prevent dust from becoming a health hazard.

3.Use dust collection:

The ShopBot CNC Router Machine generates a lot of dust and debris during operation. Use a dust collection system to keep the work area clean and to prevent dust from becoming a health hazard.

4.Use Emergency stop switches

Emergency stop switches are an important safety feature for any CNC router, including the ShopBot CNC Router. In the event of an emergency or malfunction, an emergency stop switch can quickly shut down the machine to prevent injuries or damage.

4.Use Emergency stop switches

Emergency stop switches are an important safety feature for any CNC router, including the ShopBot CNC Router. In the event of an emergency or malfunction, an emergency stop switch can quickly shut down the machine to prevent injuries or damage.

B.test runout, alignment, fixturing, speeds, feeds, materials, and toolpaths for your machine

1.Runout :

Runout refers to any wobbling or vibration of the cutting tool. To test runout, you can use a dial indicator to measure any movement in the cutting tool as it rotates.

B.test runout, alignment, fixturing, speeds, feeds, materials, and toolpaths for your machine

1.Runout :

Runout refers to any wobbling or vibration of the cutting tool. To test runout, you can use a dial indicator to measure any movement in the cutting tool as it rotates.

2.Alignment :

Alignment refers to the positioning and calibration of the cutting tool relative to the workpiece. Proper alignment ensures that the tool cuts exactly where it's supposed to, resulting in accurate and consistent cuts. The alignment of the cutting tool should be checked regularly and adjusted as needed.

2.Alignment :

Alignment refers to the positioning and calibration of the cutting tool relative to the workpiece. Proper alignment ensures that the tool cuts exactly where it's supposed to, resulting in accurate and consistent cuts. The alignment of the cutting tool should be checked regularly and adjusted as needed.

3.Fixturing :

Fixturing refers to the methods used to hold the workpiece in place during cutting. Proper fixturing is important to ensure that the workpiece doesn't move or shift during cutting, which can result in inaccurate cuts or damage to the machine.

3.Fixturing :

Fixturing refers to the methods used to hold the workpiece in place during cutting. Proper fixturing is important to ensure that the workpiece doesn't move or shift during cutting, which can result in inaccurate cuts or damage to the machine.

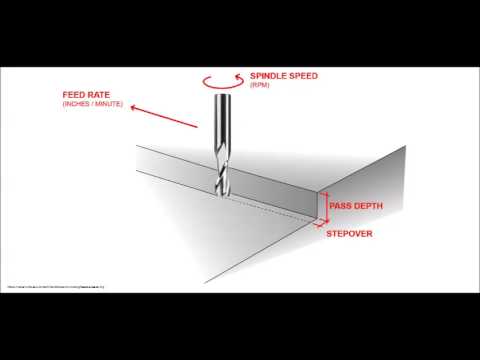

4. Machine speed :

:Lower the speed if working with hard surfaces and medium speed for high frictional material. Otherwise, the tool will break.

4. Machine speed :

:Lower the speed if working with hard surfaces and medium speed for high frictional material. Otherwise, the tool will break.

.png) 5. Feed rate:

Feed rate means how fast the CNC os running to take the next line. It's better to have it at a low rate like 15% or 30% depenting on the material.

5. Feed rate:

Feed rate means how fast the CNC os running to take the next line. It's better to have it at a low rate like 15% or 30% depenting on the material.

5. Feed rate:

Feed rate means how fast the CNC os running to take the next line. It's better to have it at a low rate like 15% or 30% depenting on the material.

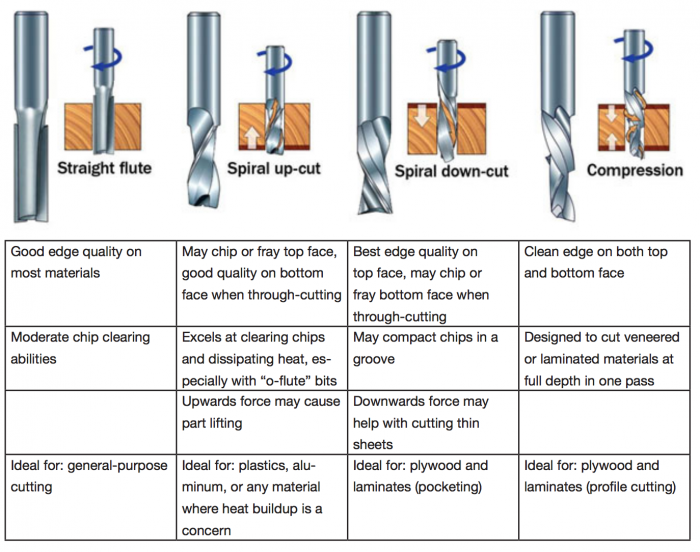

6. Materials:

materials: the istructor explain the virious type of material to be used on our machine such Wood (MDF, Plywood, cherry, mapple,OBS...) Metal (aluminum thin layers) Plastic.

6. Toolpaths:

Toolpaths used with our machine: toolpaths for our machine Pocket profile drill 3d rough, smooth Vcarve and mamy others

5. Feed rate:

Feed rate means how fast the CNC os running to take the next line. It's better to have it at a low rate like 15% or 30% depenting on the material.

6. Materials:

materials: the istructor explain the virious type of material to be used on our machine such Wood (MDF, Plywood, cherry, mapple,OBS...) Metal (aluminum thin layers) Plastic.

6. Toolpaths:

Toolpaths used with our machine: toolpaths for our machine Pocket profile drill 3d rough, smooth Vcarve and mamy others