Assignment week eleven is also a creative week.This week, we have to create an object in 3D softwear that can be milled into a positive mold. This requires us to make a negative mold and a positive item.This week, Niel explained to us in detail the molding and casting processes as well as the many materials that are utilized in these processes. To go through all the steps is interesting.

The safety data sheets for each of the molding and casting materials in our lab must be reviewed as part of the group project. With each of them, create test casts to compare.Talk to the group members about the parameters. We separated the materials and tested their properties for the group assignment in our lab, which has a variety of materials including HydroStone, Silicon Rubber, FlexWax, Machinable Wax, Epoxy Resin, and Paraffin Wax.For testing purposes, one of our members also tried using Medimix soap.

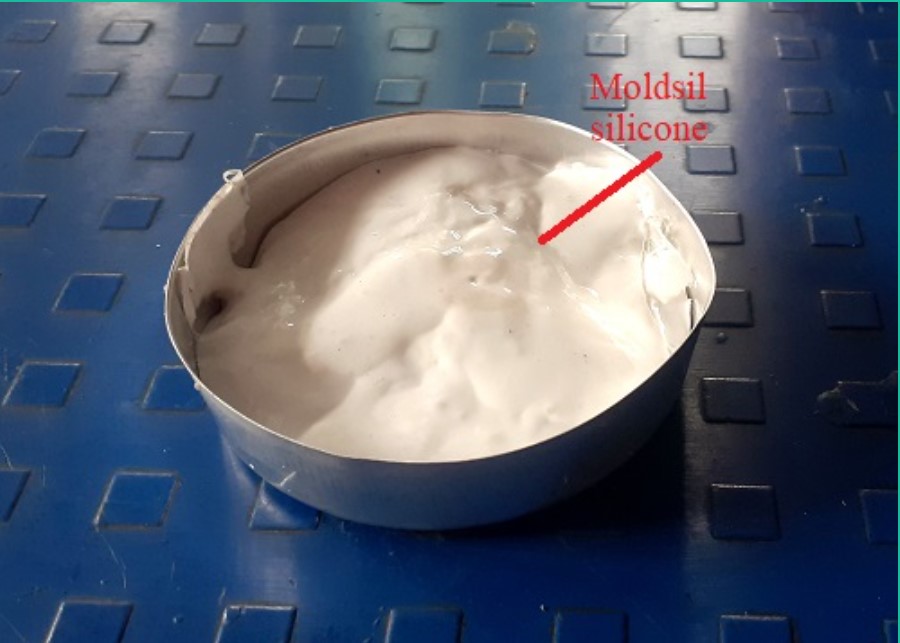

Molding and casting material.

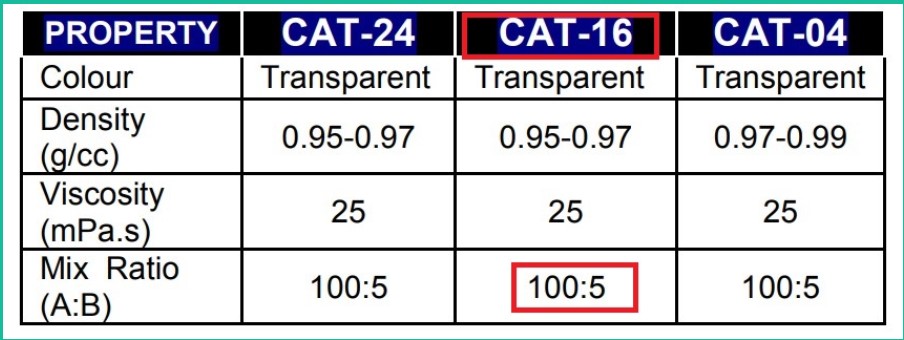

The choice of catalyst depends on the application method and the speed of cure needed. Moldsil-15 can be cured in to elastomeric products using the following cure options:

Catalyst

mouldsil-15 PLUS contains constituents that have been found to be safe. Hence special handing precautions except general industrial hygiene need to be followed. Catalysts (CAT-24, CAT-16 and CAT-04) contain organo-tin compounds and are flammable and might cause irritation upon contact with eyes and skin. Adequate protective measures are recommended. Refer to Material Safety Data Sheet (MSDS) for safe use of the product.

result of mixture

A wax-plastic material for making molds quickly, easily, and inexpensively. Simply melt it, then brush it on or dip the object into it. Flexwax melts at 120°F (49°C) , a comfortably warm temperature. It cools in a few minutes to form a tough, flexible mold.

wax materials

wax materials

wax materials