| Machine | Task | Responsible person individual page Link |

|---|---|---|

| Laser Cutter | CAD Design | Ruganji Prince |

| Laser Cutter | Cutting and Assembly of the frame | Kwizera chris Felix Nyirigira |

| Laser Cutter | PCB Design and soldering | RUKUNDO JEAN CLAUDE and CHRISTIAN BIMENYIMANA |

| Machine | Task | Responsible person individual page Link |

|---|---|---|

| Arm Robot | Mechanism and Concept | Kawaida Lars |

| Arm Robot | CAD Design | Kawaida Lars |

| Arm Robot | Computer Aided manufacturing | Gedeon munyensanga evode |

| Arm Robot | PCB Design and soldering | RUKUNDO JEAN CLAUDE , CHRISTIAN and ERIC |

What is a Laser Cutter

A laser cutter is a computer-controlled machine that uses a powerful laser beam to cut or engrave various materials such as wood, plastic, metal, fabric, and more. The laser beam is focused by a series of mirrors and lenses onto the material, which is then burned, vaporized or melted away. Laser cutters can be used for a wide variety of applications, including creating intricate designs and patterns, cutting out complex shapes, engraving text or images, and even etching onto glass. They are commonly used in manufacturing, prototyping, engineering, and the arts and crafts industries.

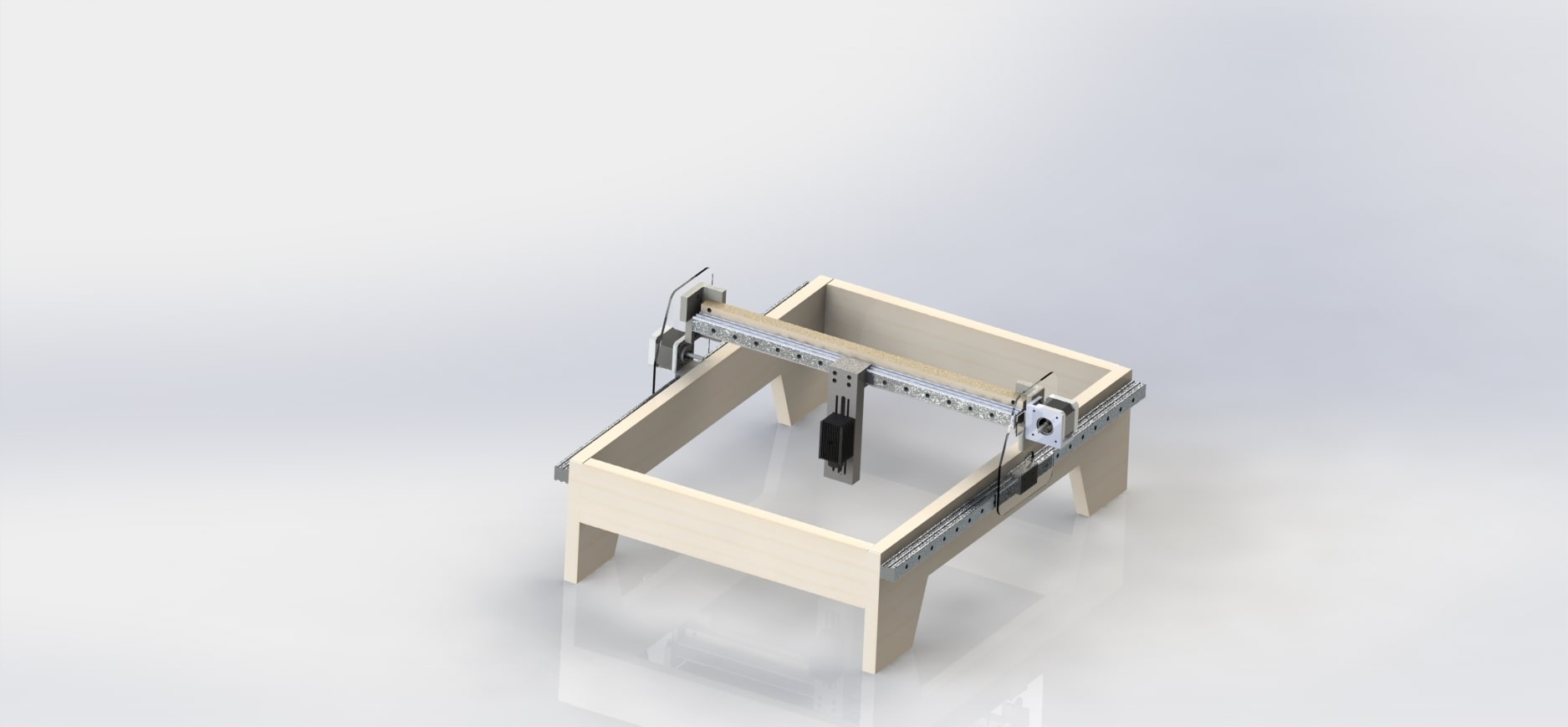

The laser cutter that we are going to design has the following characteristics

| ITEM | Characteristics |

|---|---|

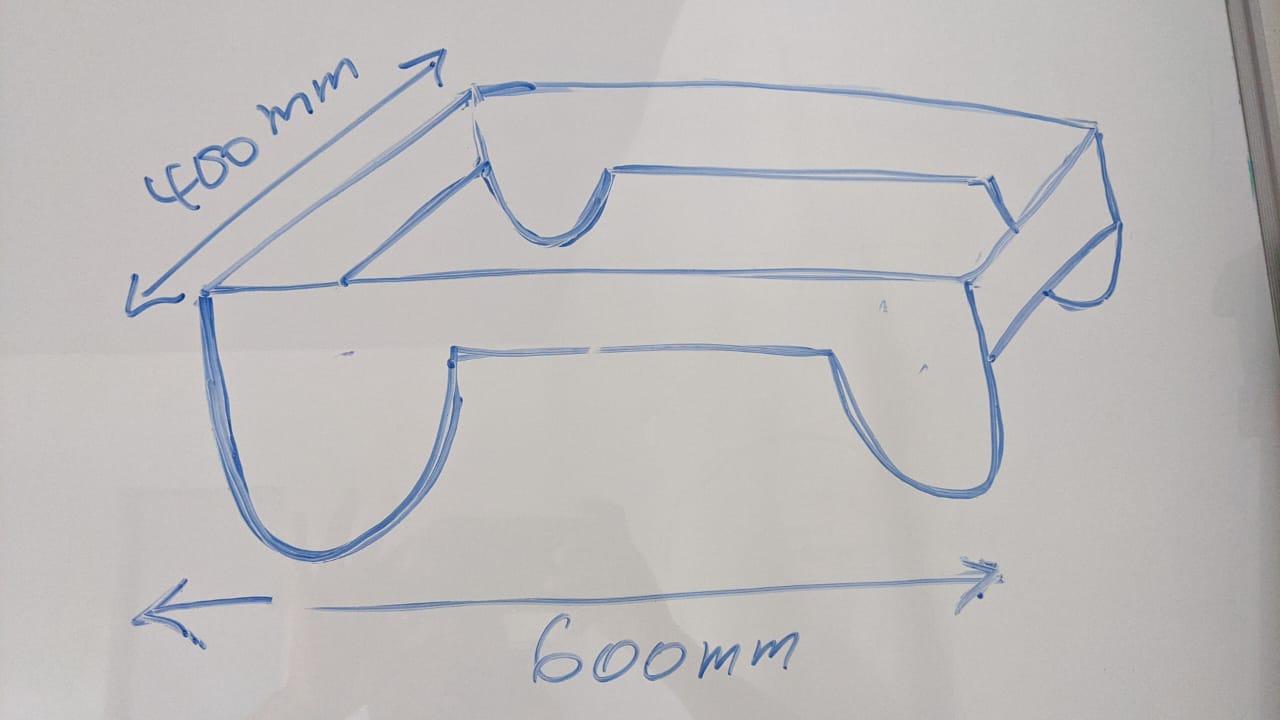

| Width | 400mm |

| Lenght | 600mm |

| Laser Power | Roland Mendel |

| Frames | The flame is made in plywood |

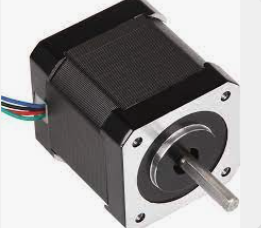

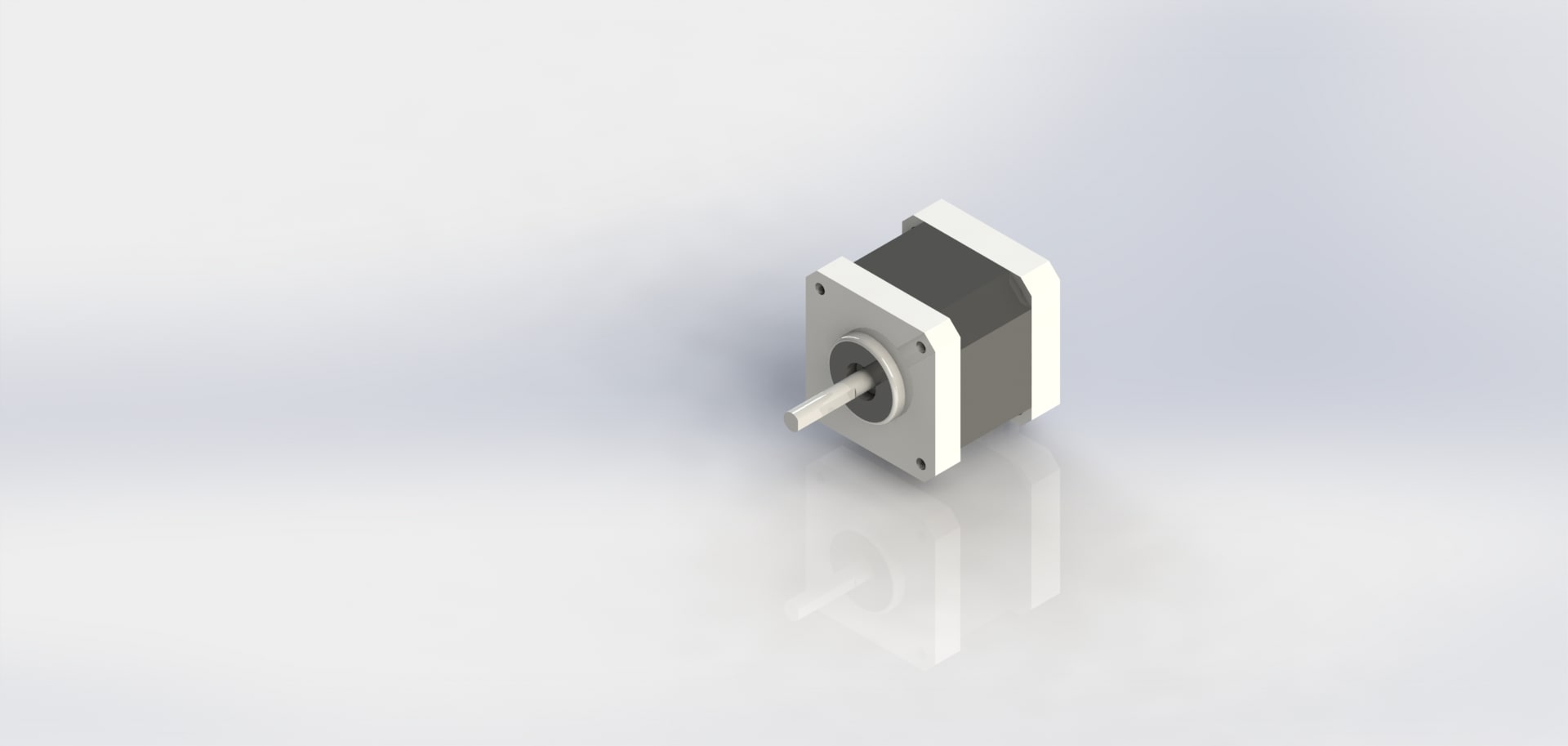

| Motors | We will use nema17 stepper motors to move our laser beam in X AND Y directions |

| Control Mechanism | We plan to burn GRBR firmware and control stepper motors with G-code |

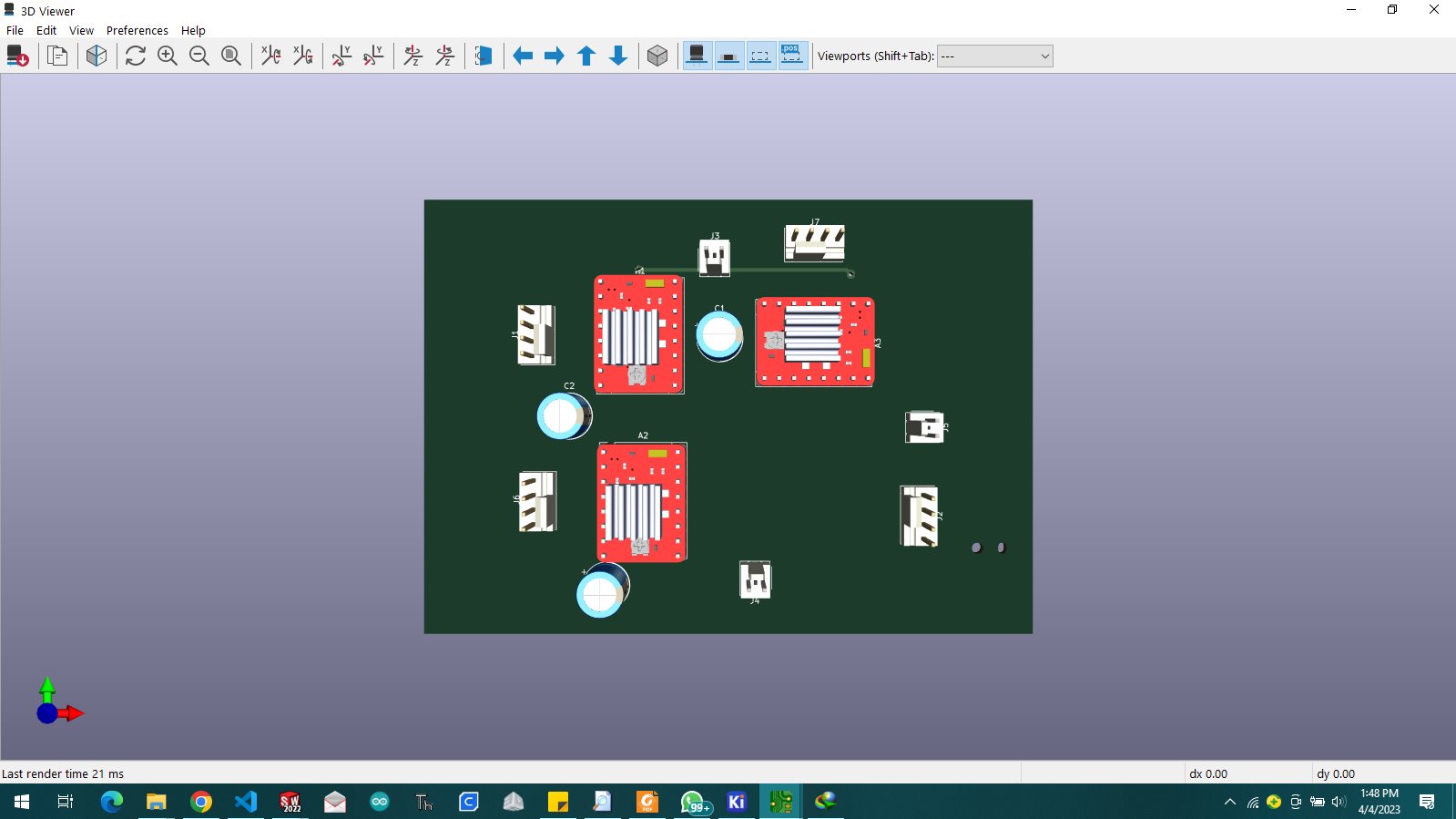

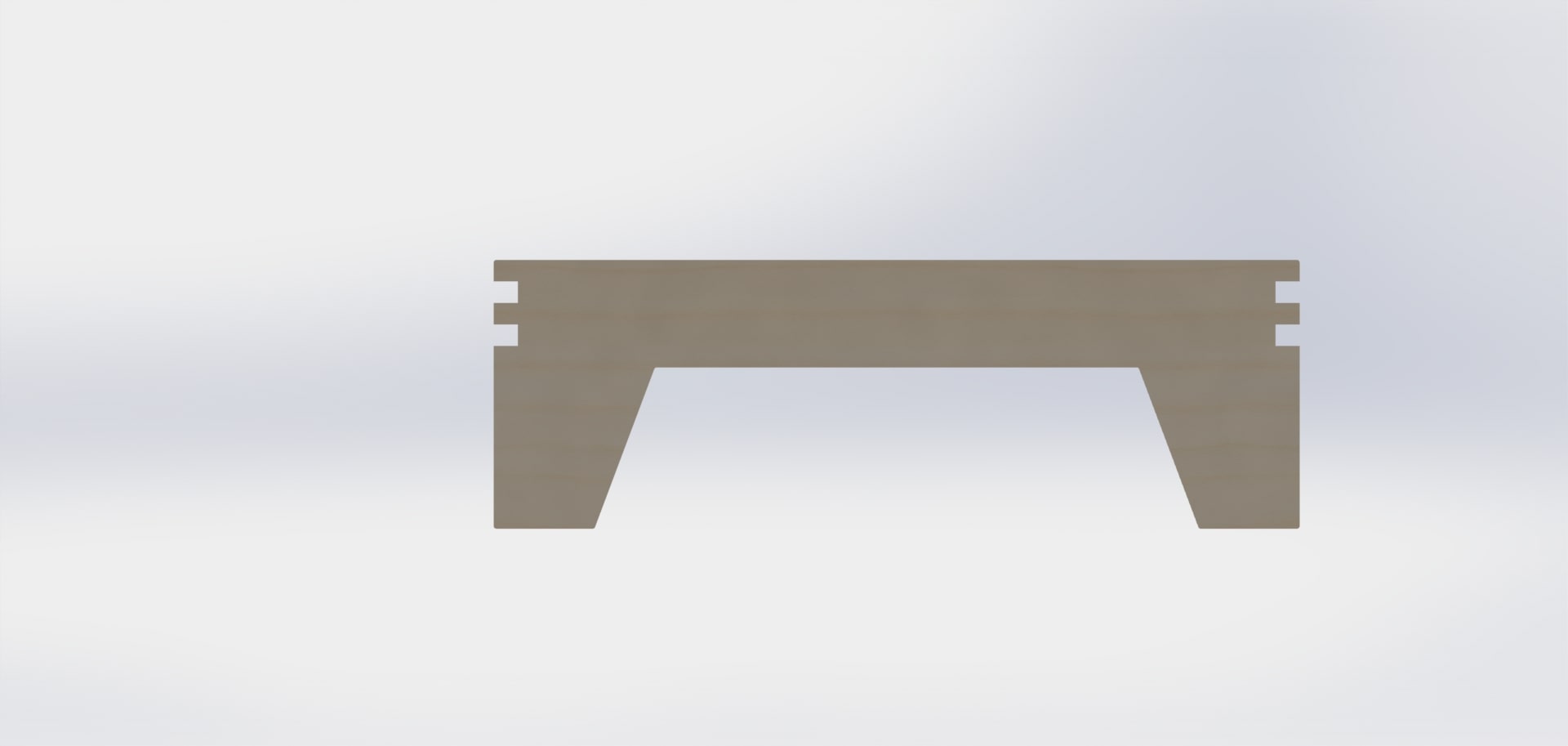

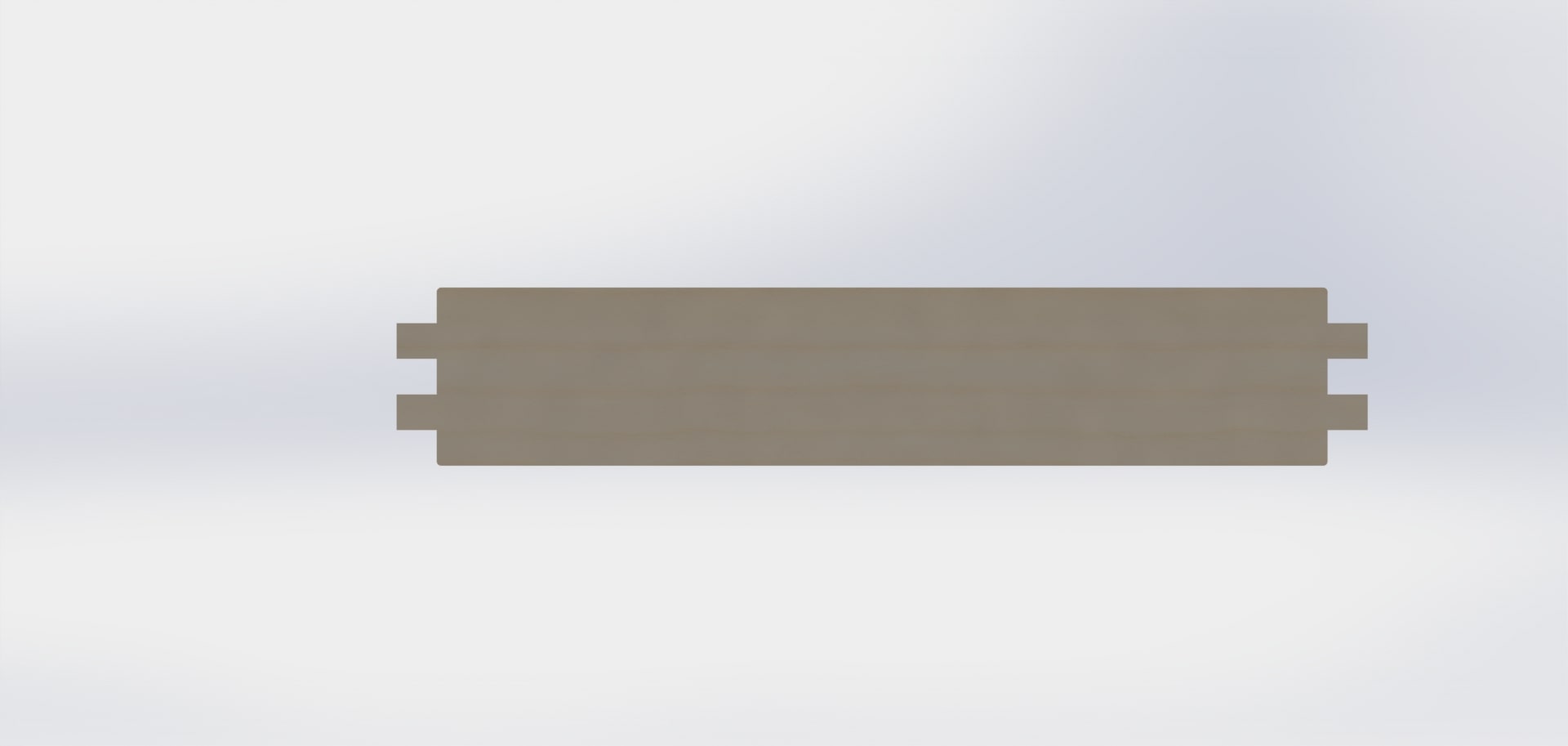

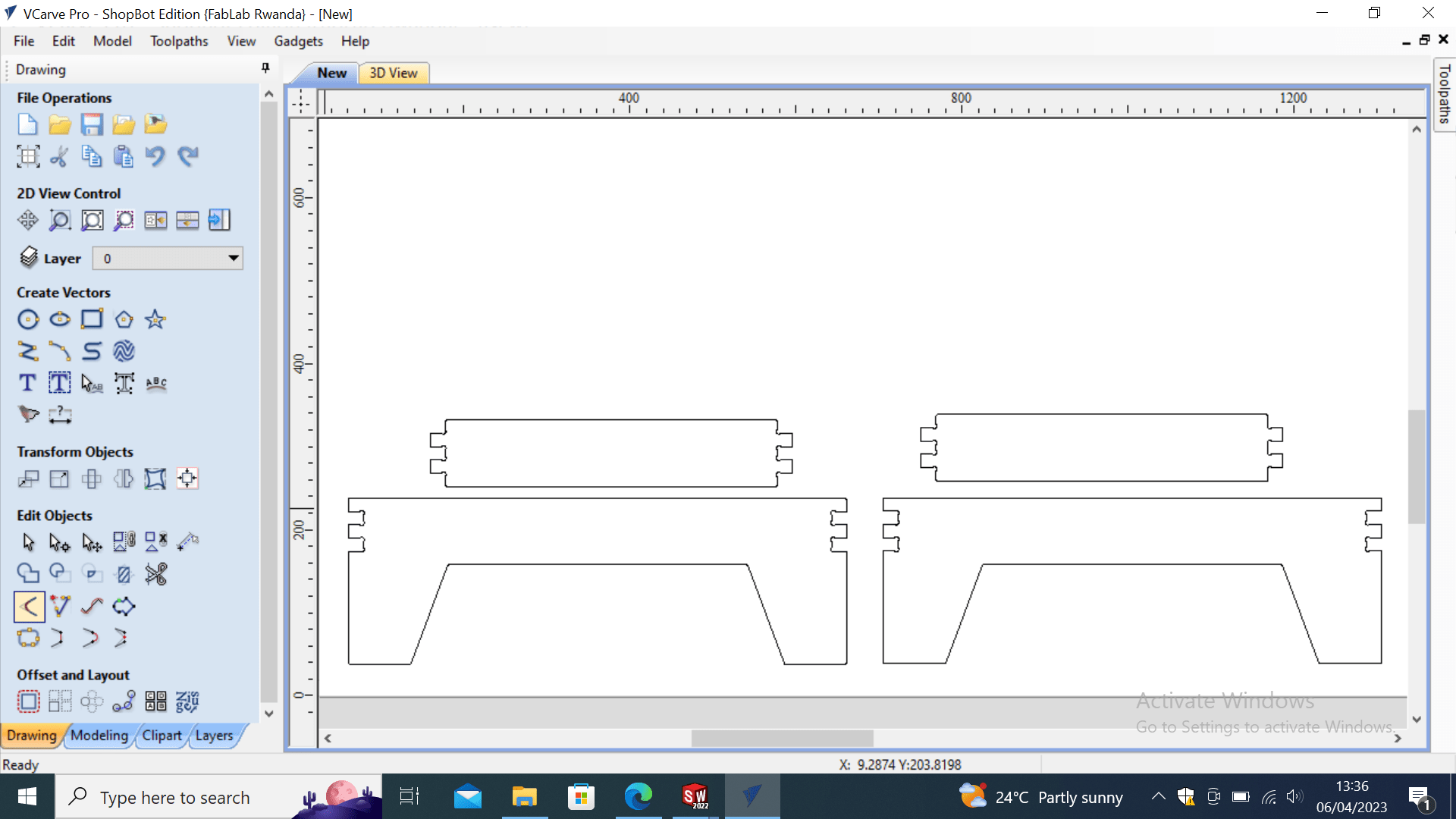

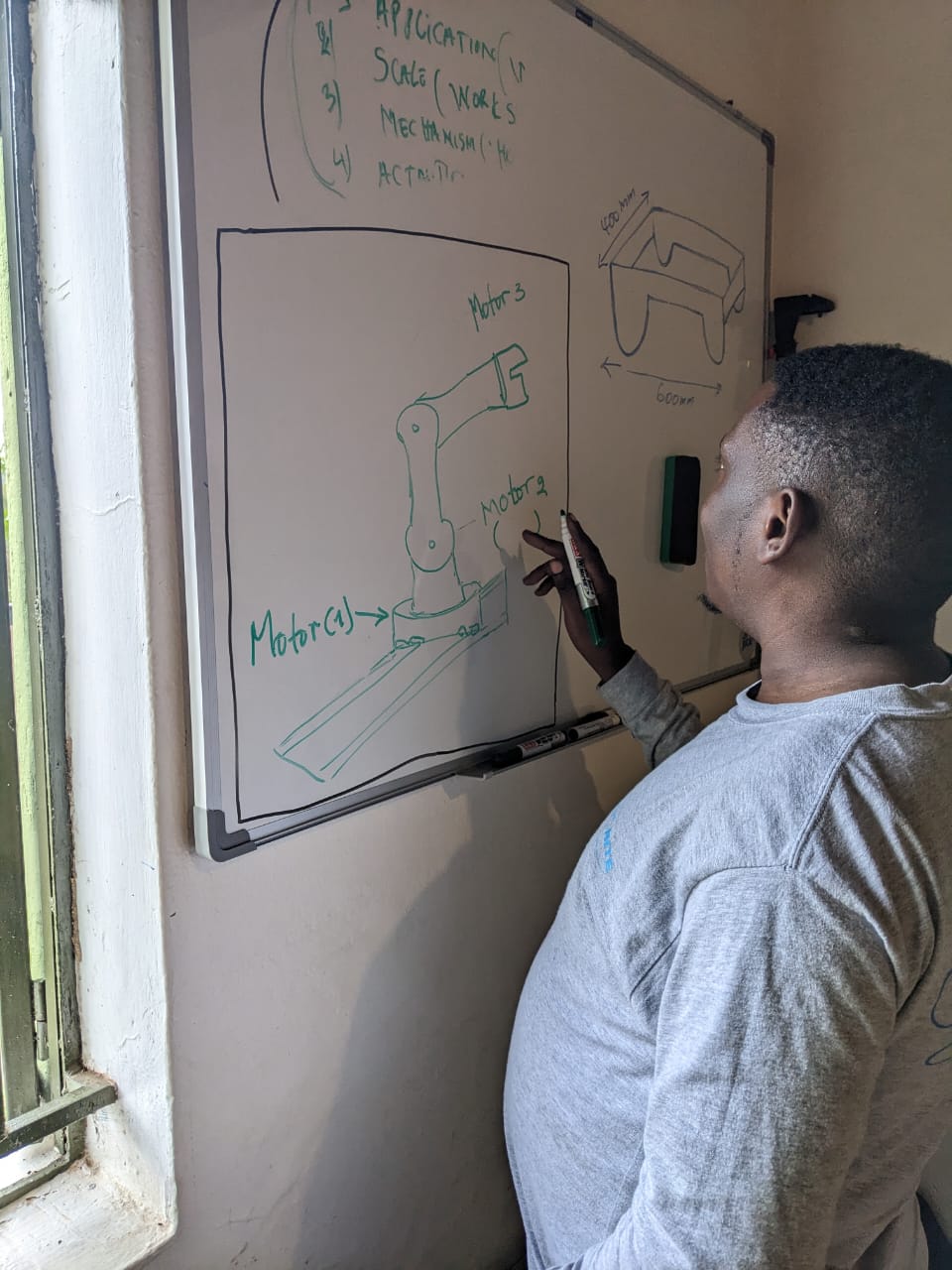

we did some sketching on the frame of the laser bet and it looks like the following

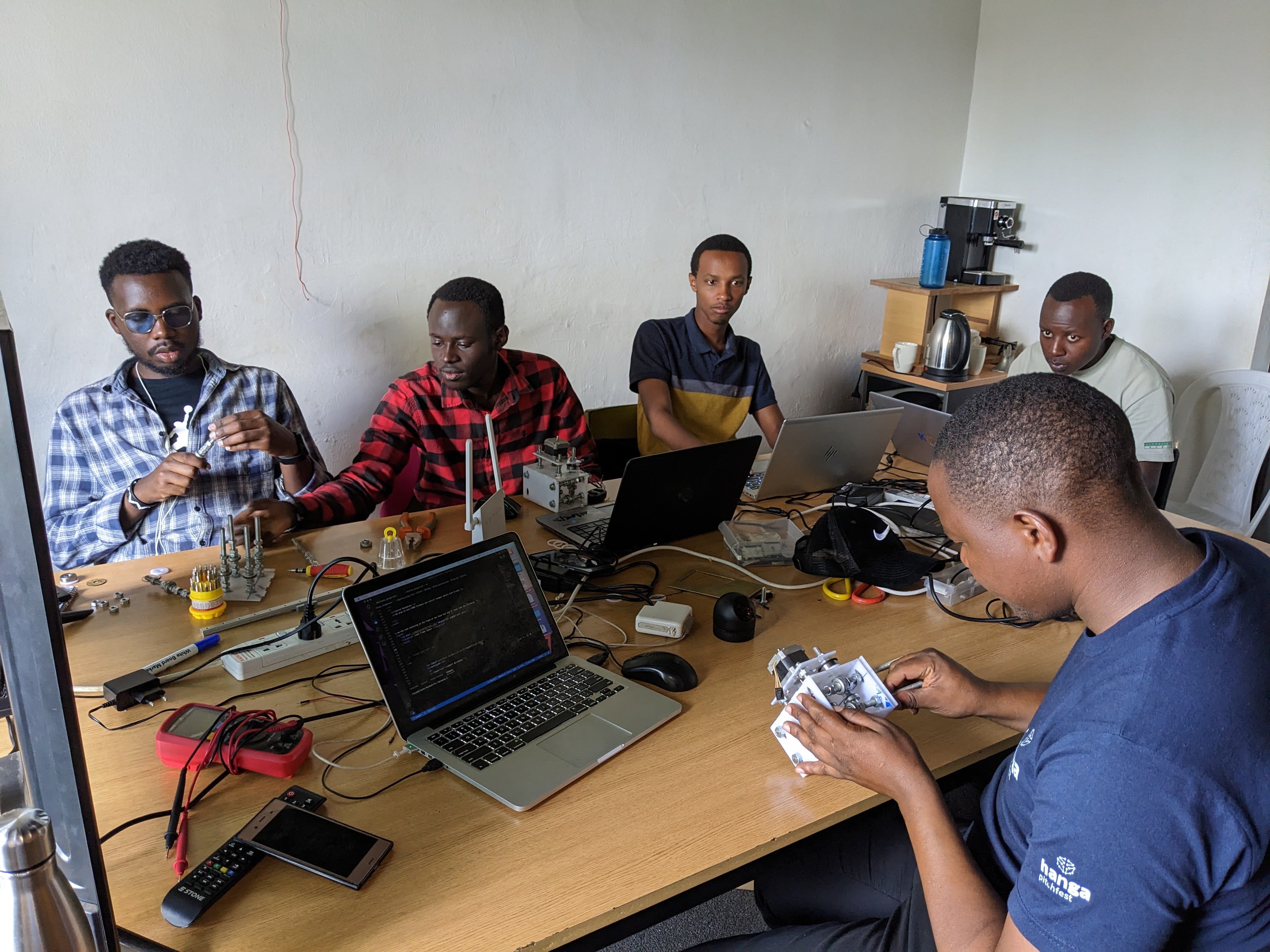

We have two teams , one working on laser cutter machine and other working on Arm robot

| ITEM | QTY | Characteristics | Picture |

|---|---|---|---|

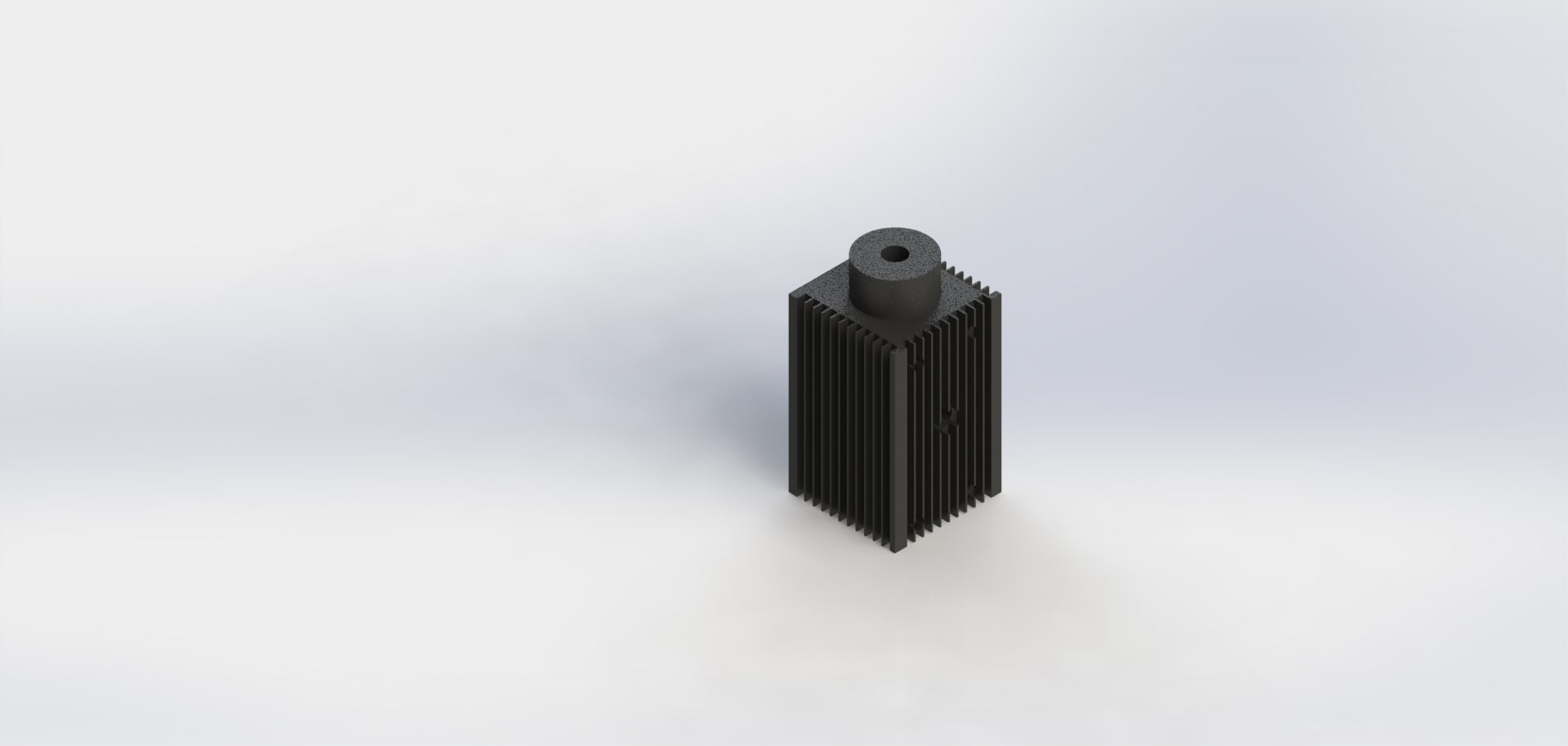

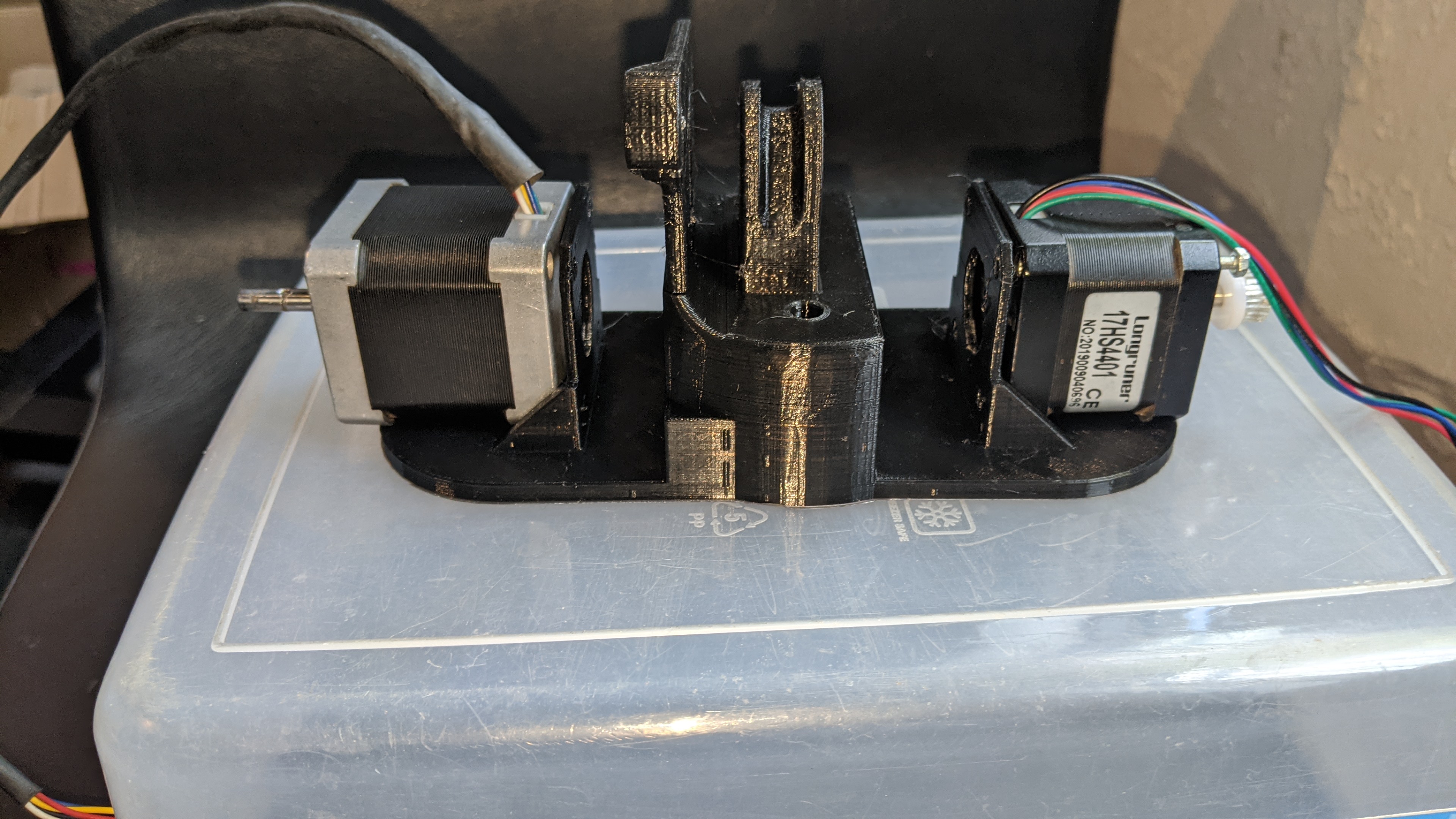

| Stepper motors | 2 | We will use NEMA 17 stepper motors:

|

|

| Stepper motor drivers (2) | 2 | the A4988 stepper motor drive characteristics and working principle cn be found here

|

|

| Power supply | 2 | We will use 5V power supply having output current of 5A maxim | |

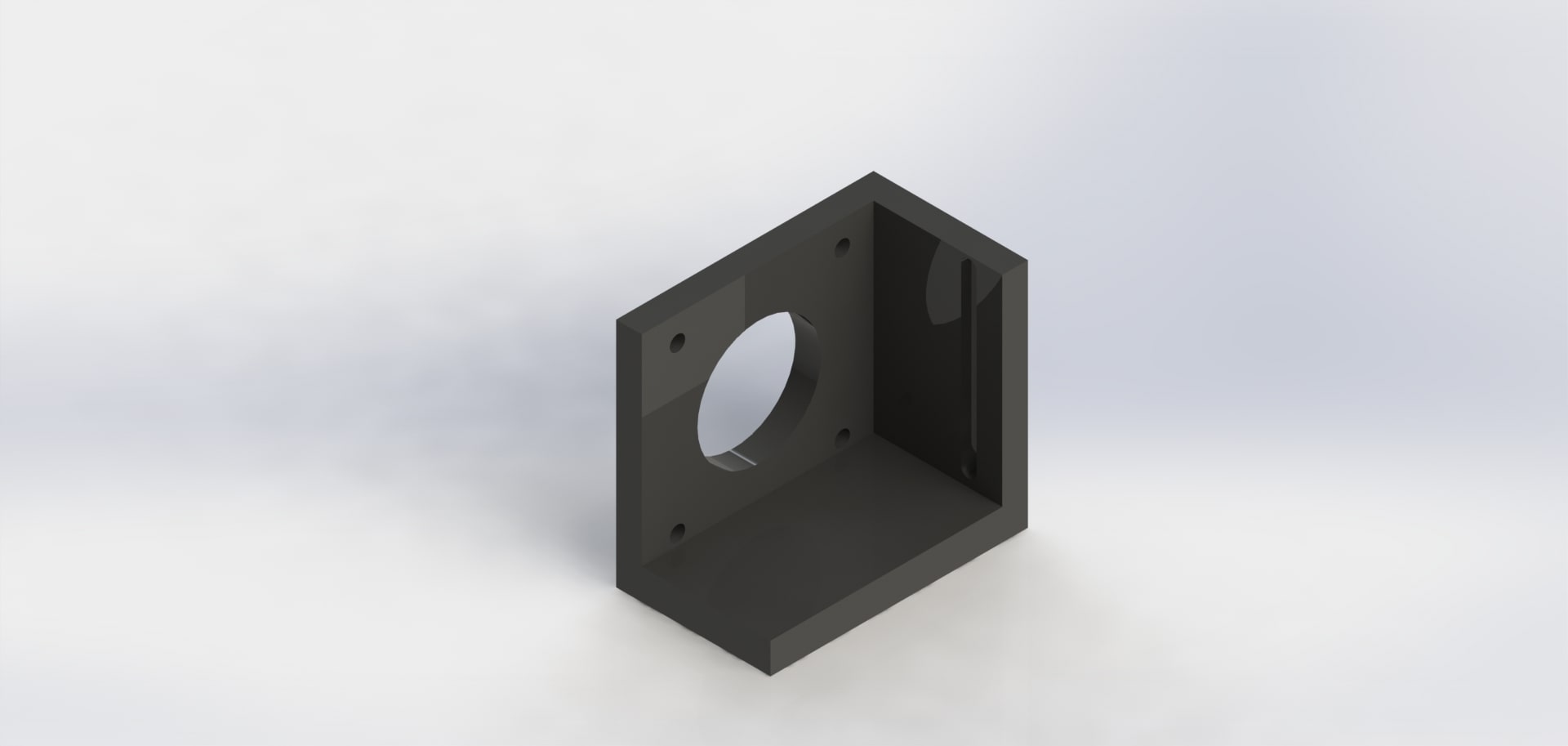

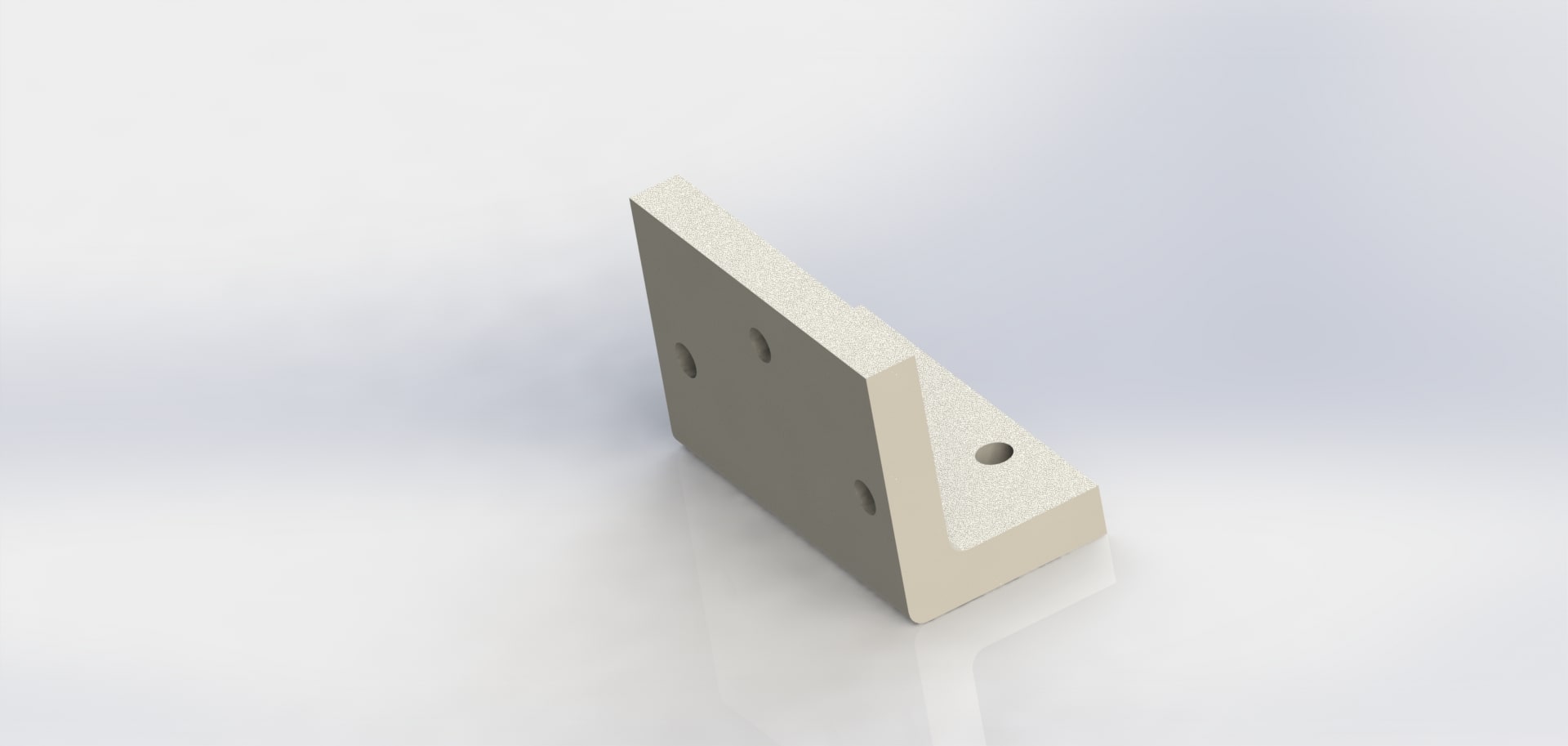

| Aluminium Linear Guides | 2 | The flame is made in plywood |  |

| Laser Tube | 2 | we will use laser tube having xx watts of laser power | |

| Frame | 2 | We plan to burn GRBR firmware and control stepper motors with G-code | |

| Microcontroller | 2 | Atmega328p |  |

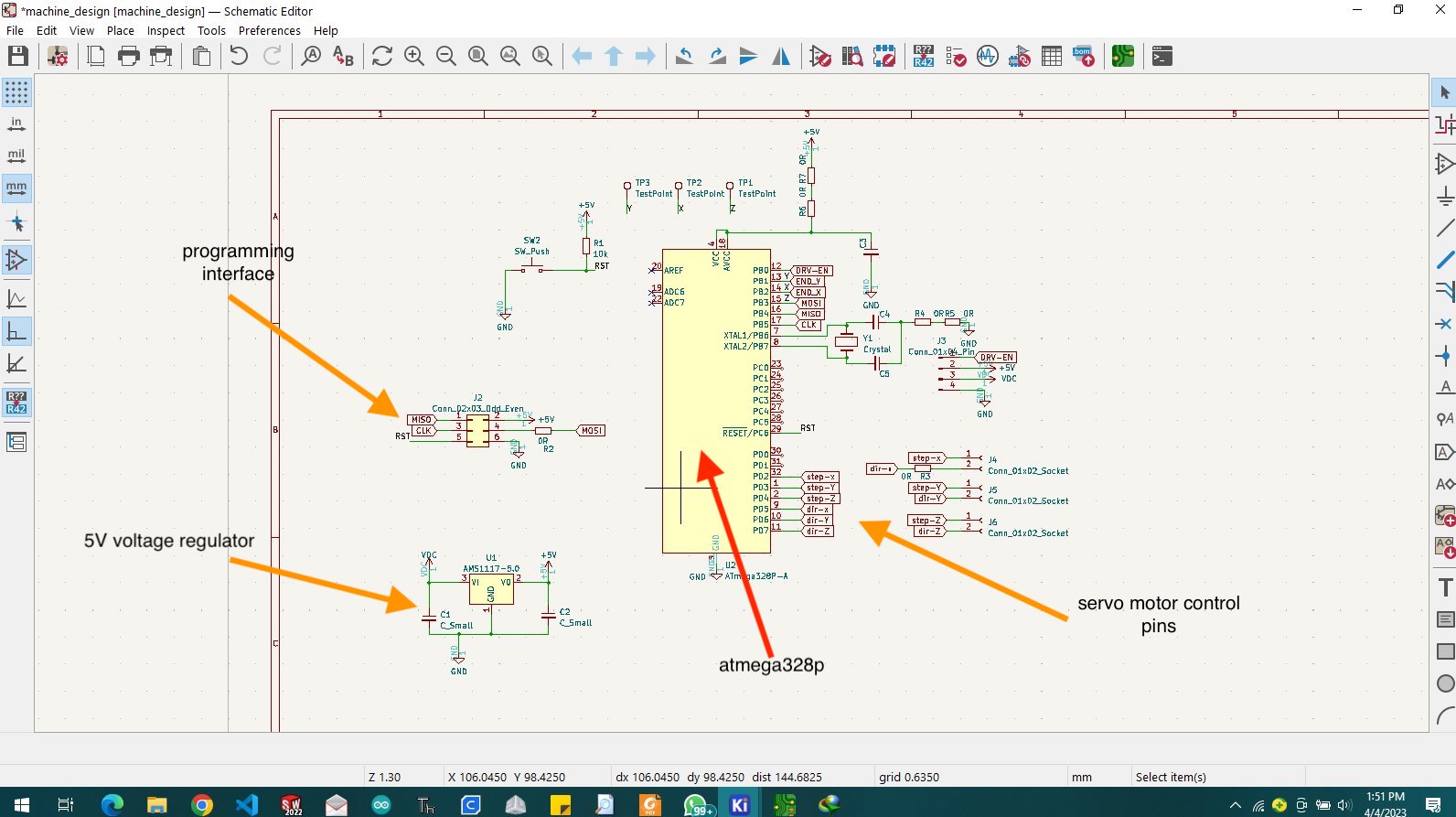

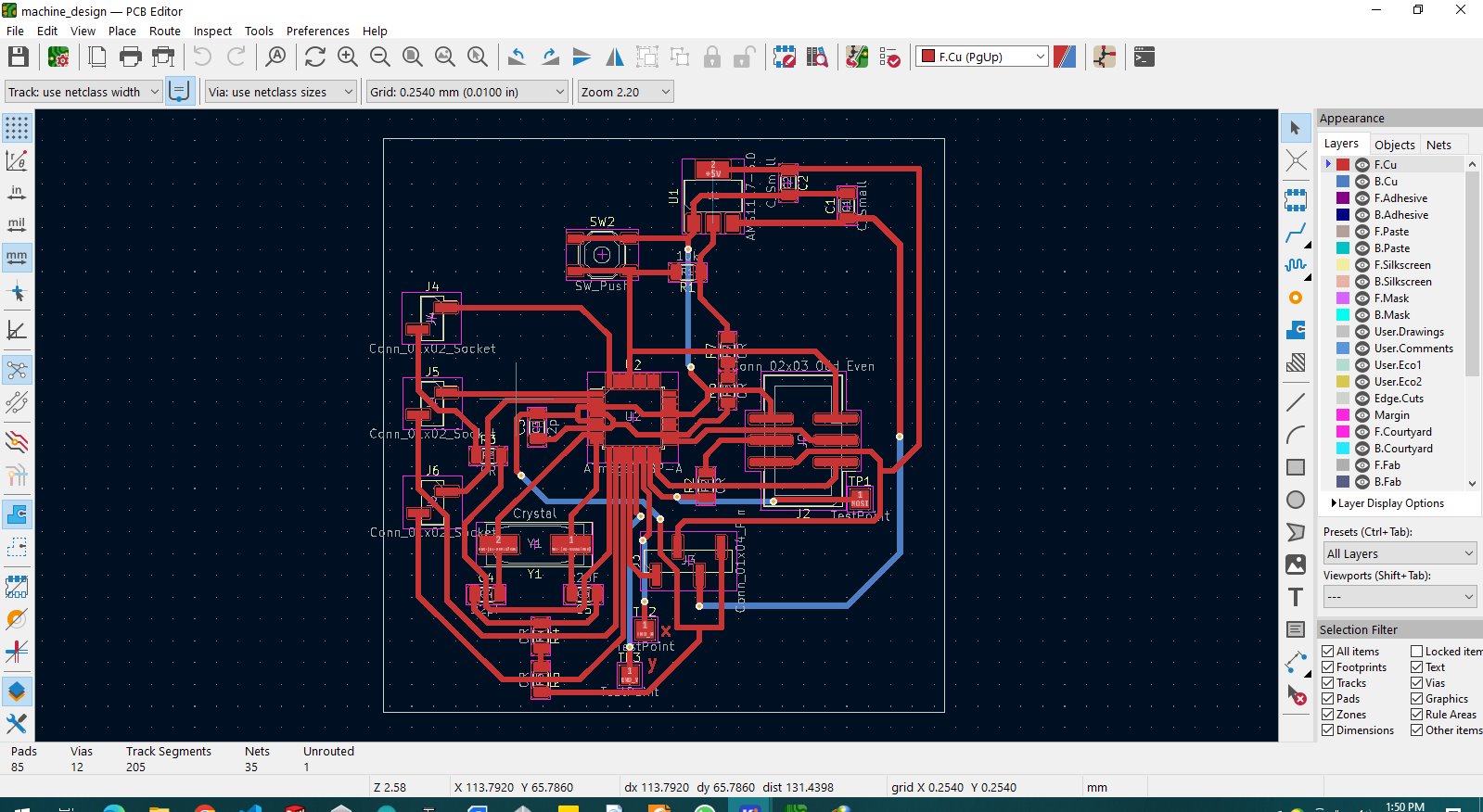

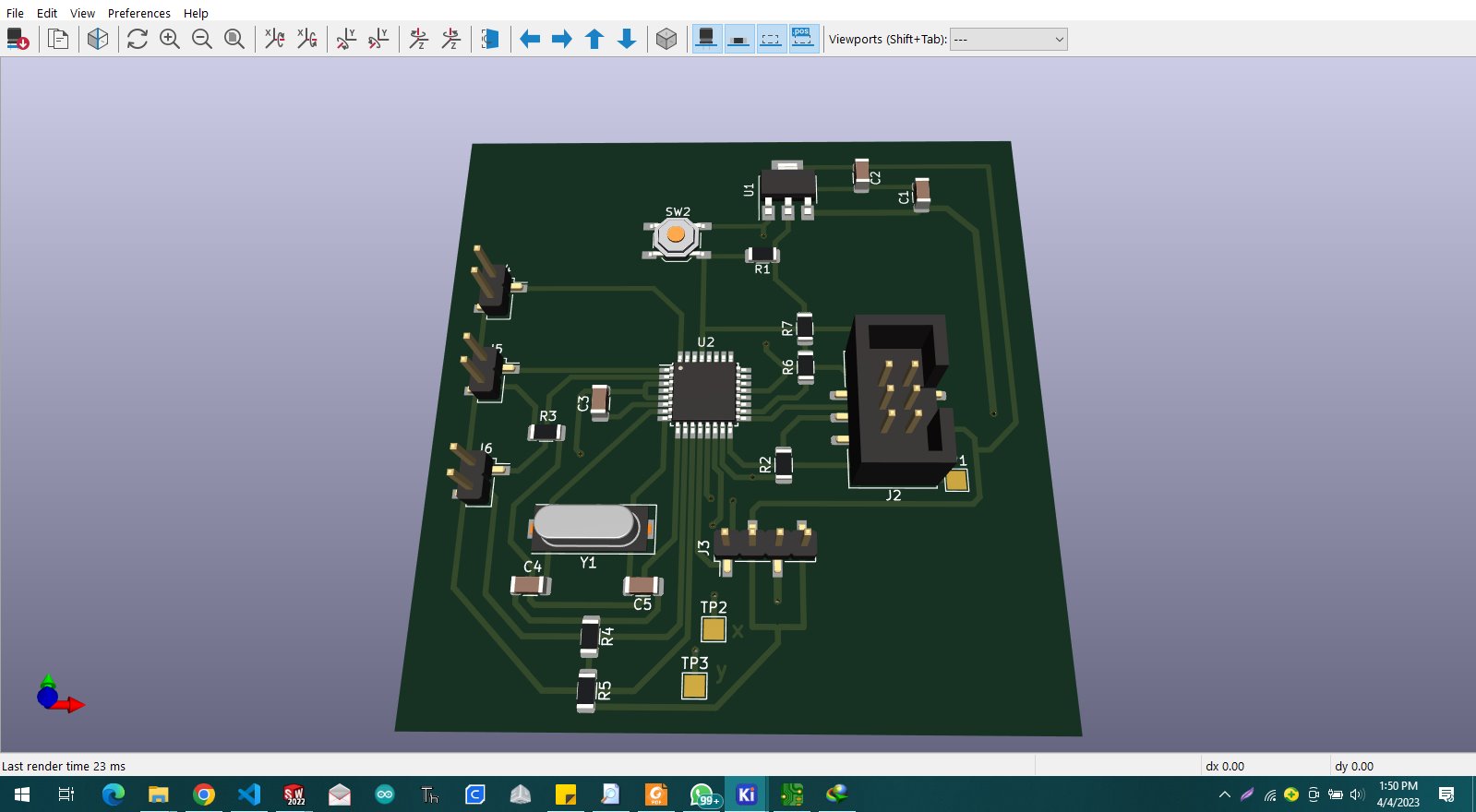

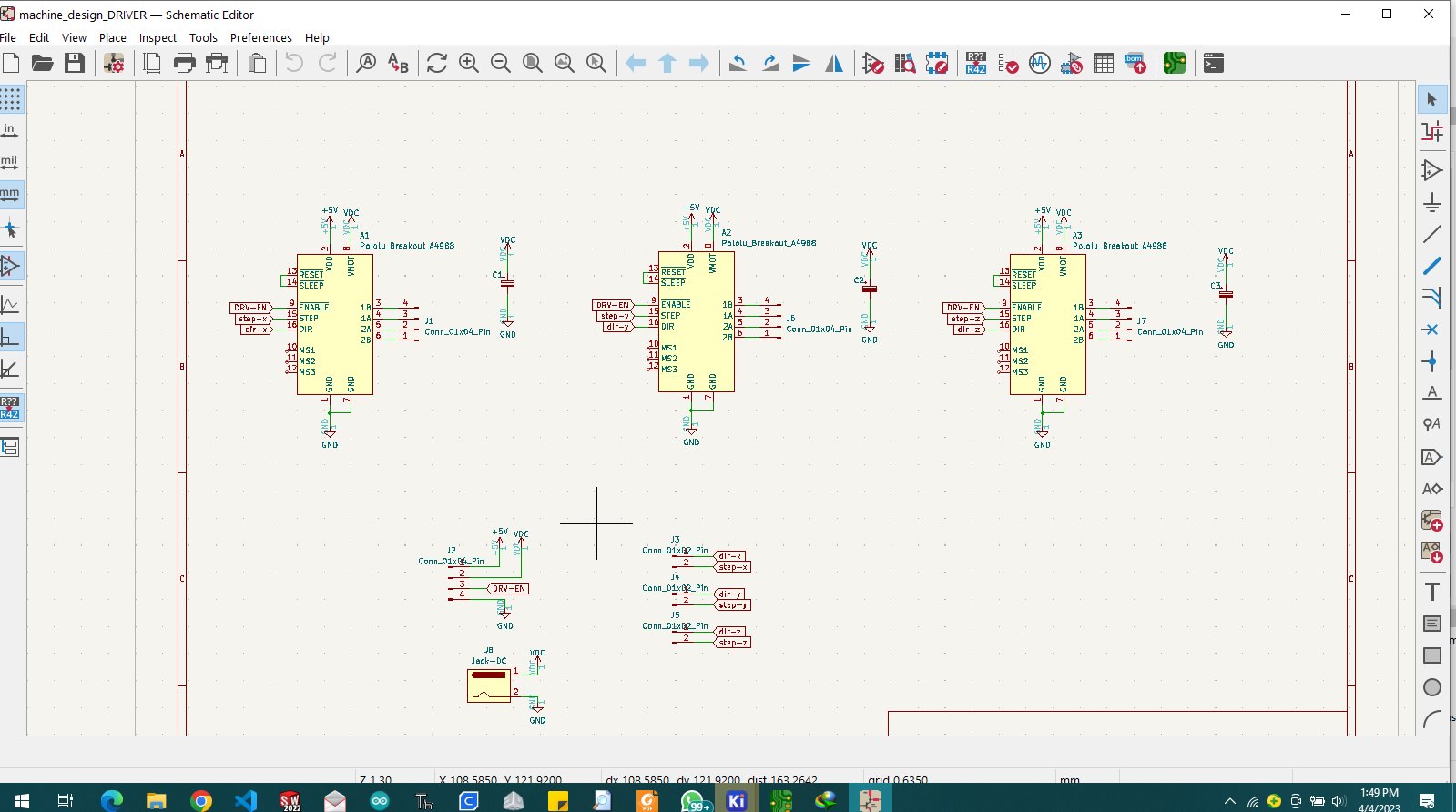

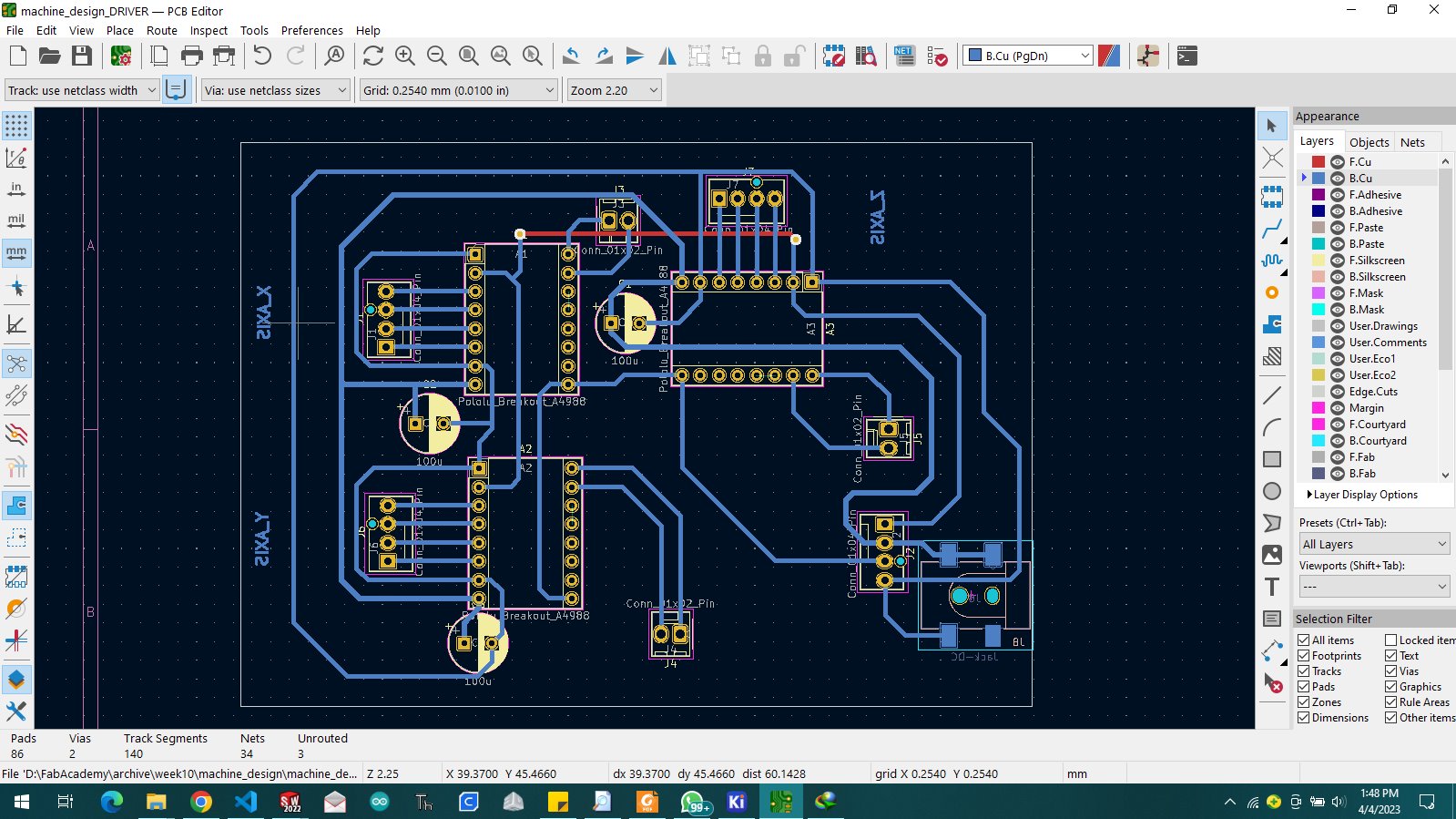

To be able to control the servo motors with G-code firmware, we built a control circuit around the atmega328p and another circuit for controlling servo motors

Making of control circuit with atmega328p

To be able to control stepper motors, motor control board is needed . we made a control board based on A4988 stepper motor drive BOARD

The following video shows the testing we did atfer flashing GRBL firmware in Atmega328p then we send the G-code in the MCU to see if there is a coordiinated motion

We tested the laser heat to our 12V power supply and any given pwm signal and it is working as intended

The following video shows how the final design looks like before final assembly of the mechanical part

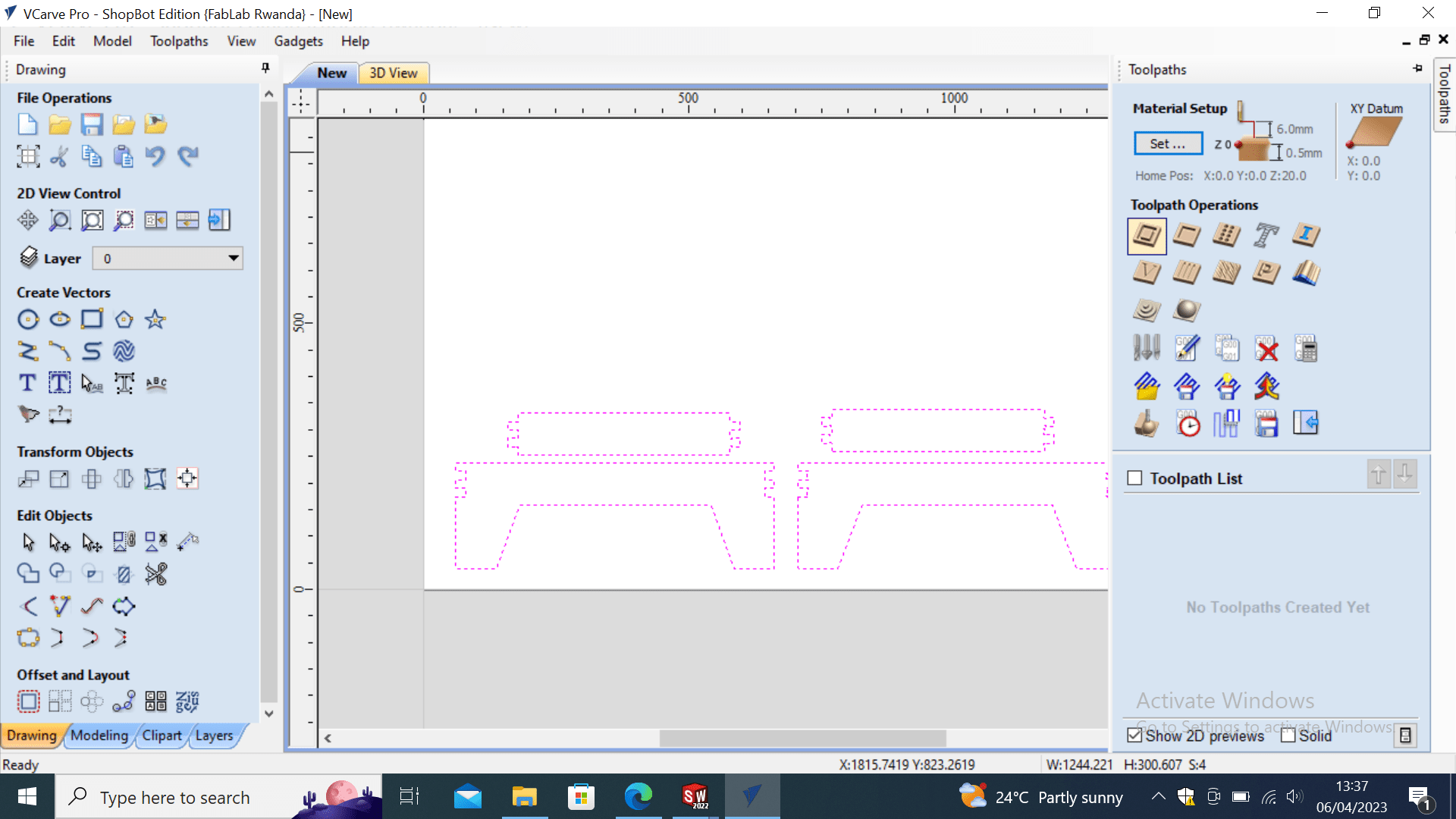

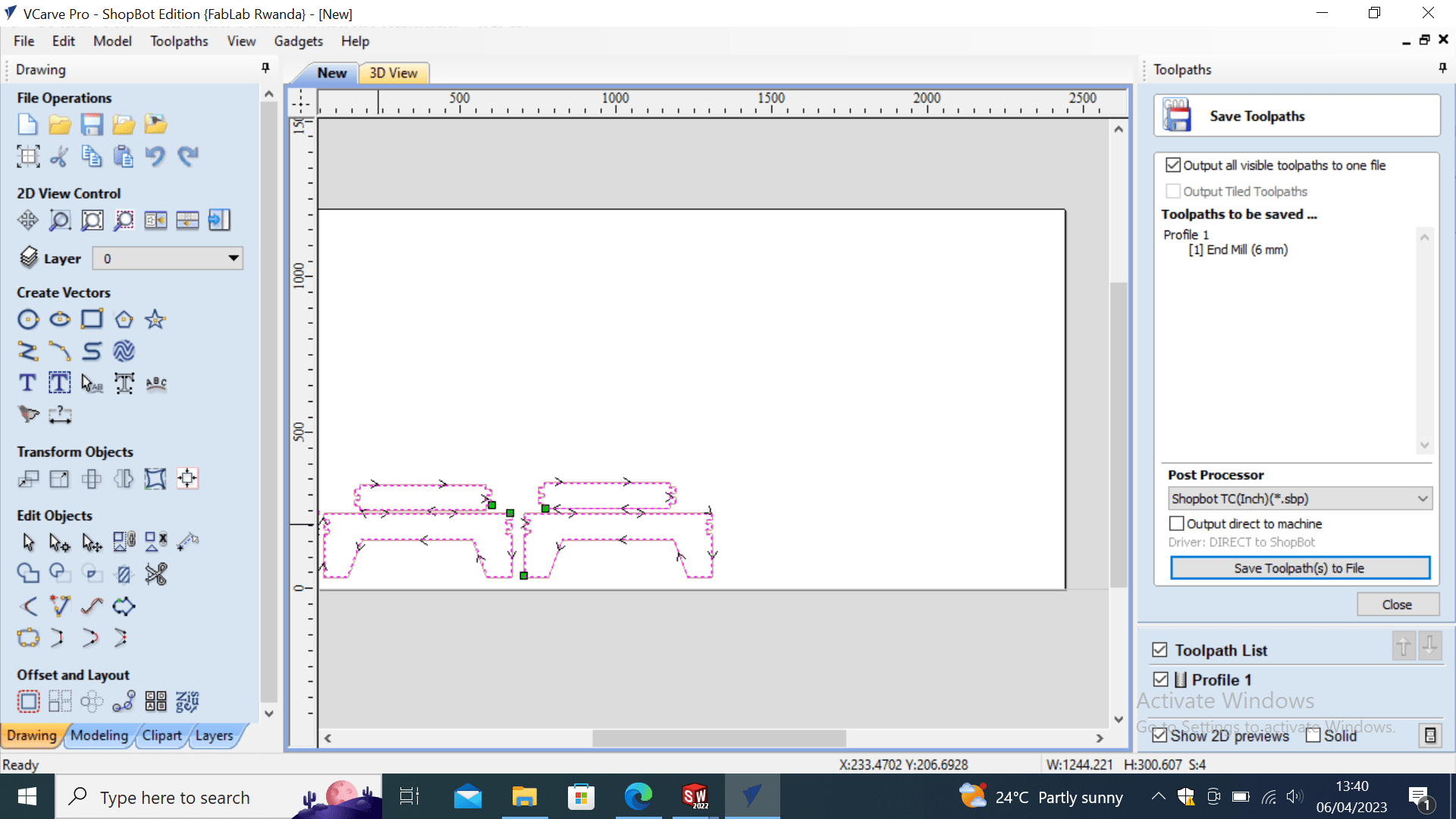

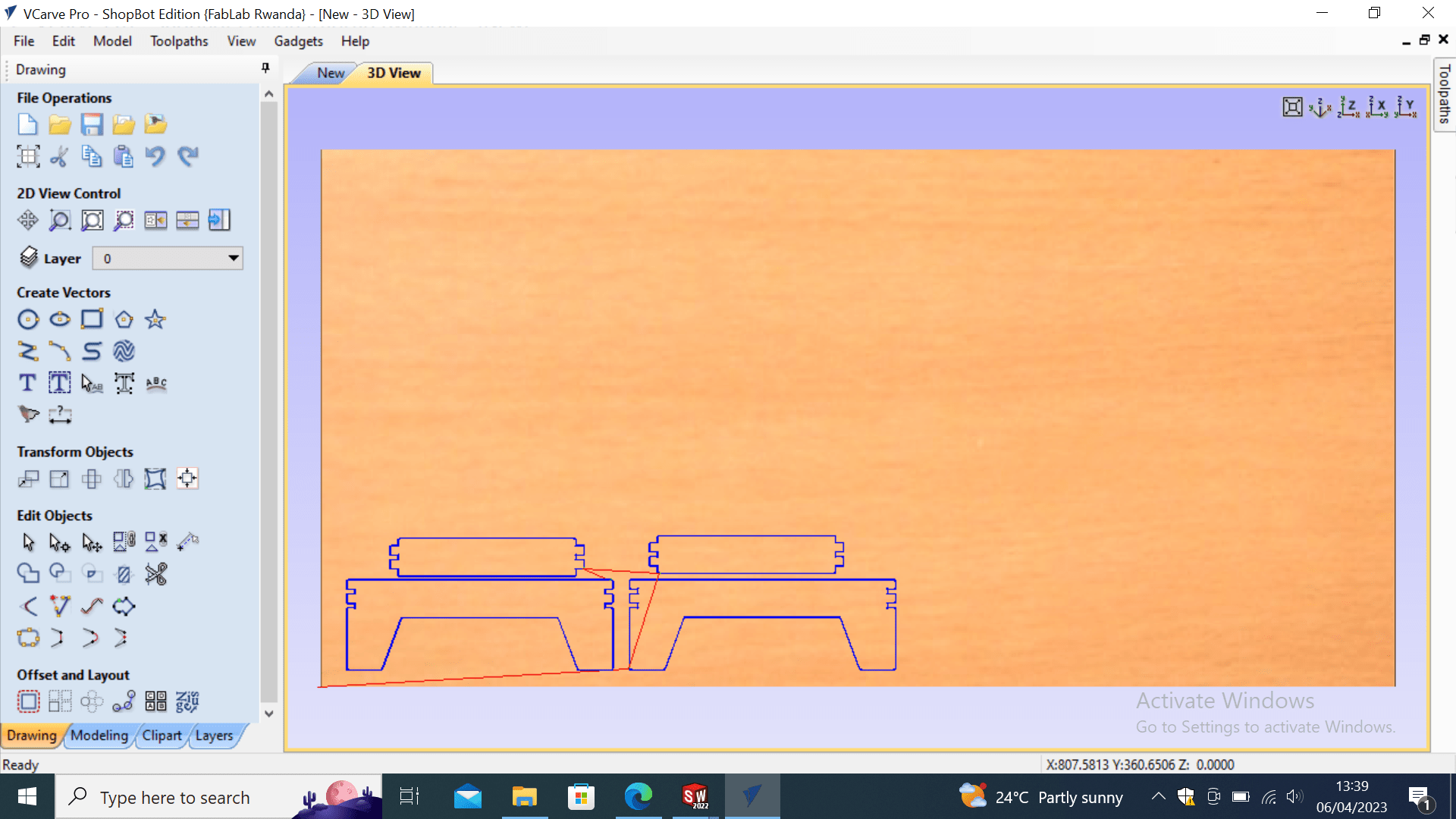

After design of the mechanical parts , the next is to produce those differents parts. we cutted those parts in MDF with cnc router with vcarve pro software

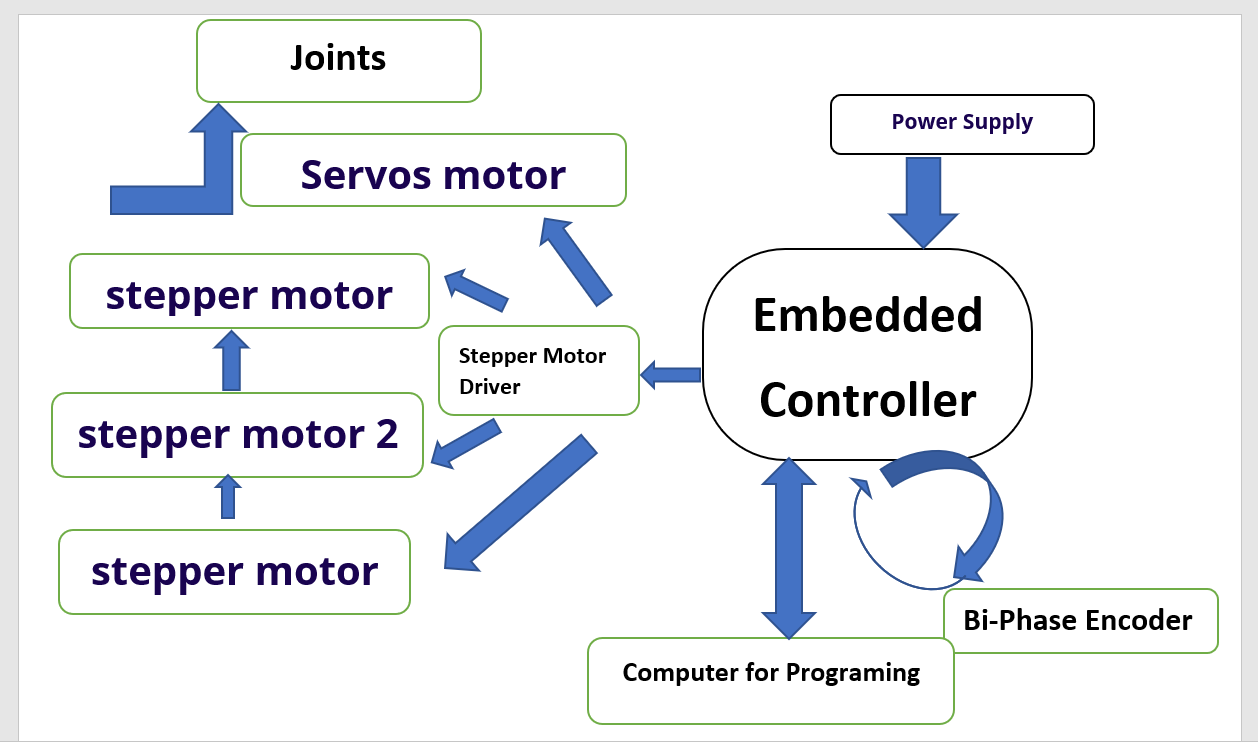

Block Diagram of Arm Robot

Block Diagram of Arm Robot

Here is group brainstoming how Arm Robot will works

Here is group brainstoming how Arm Robot will works

Our Robot composed with the following parts

Our Robot composed with the following parts

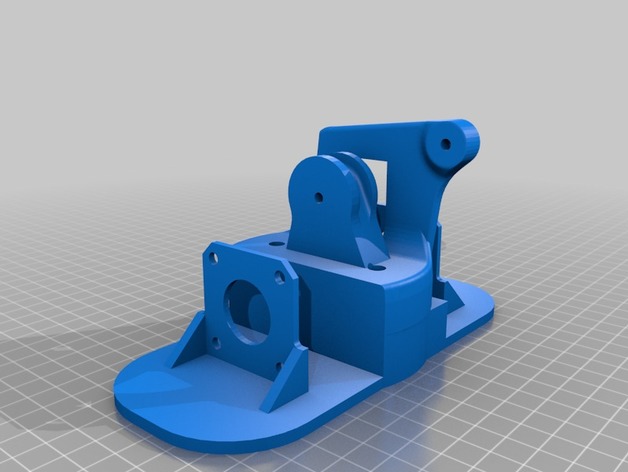

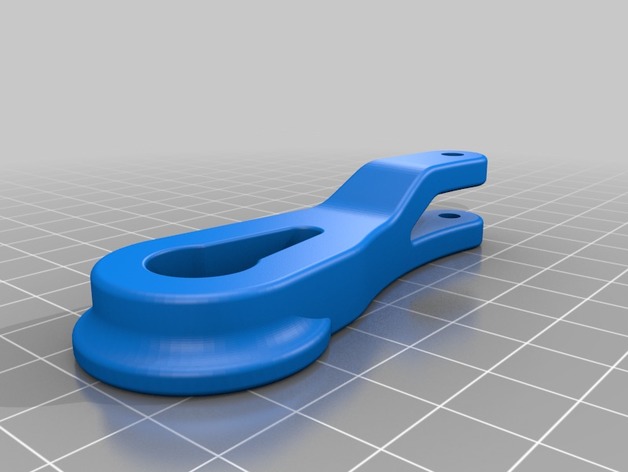

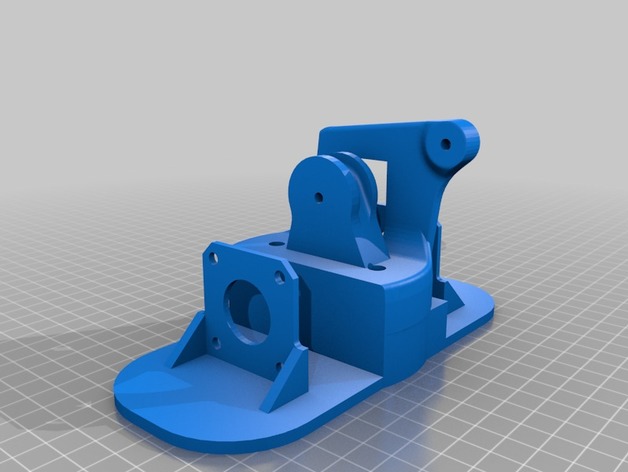

.jpg) 1. Base Arm Design

1. Base Arm Design

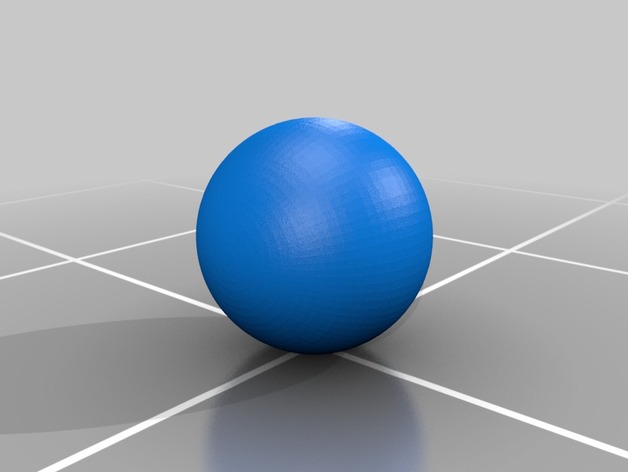

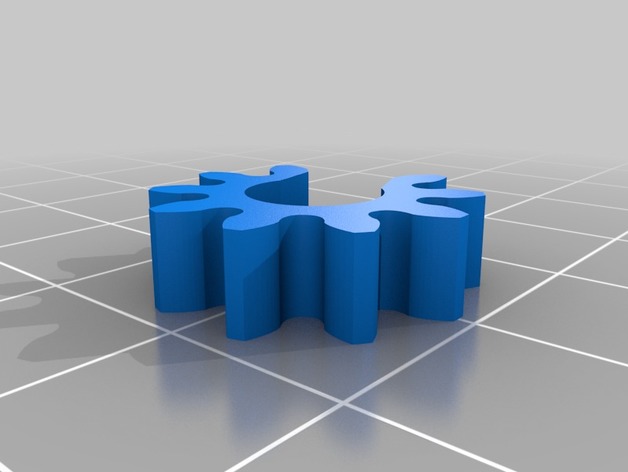

2. Base_Bearing_Ball

2. Base_Bearing_Ball

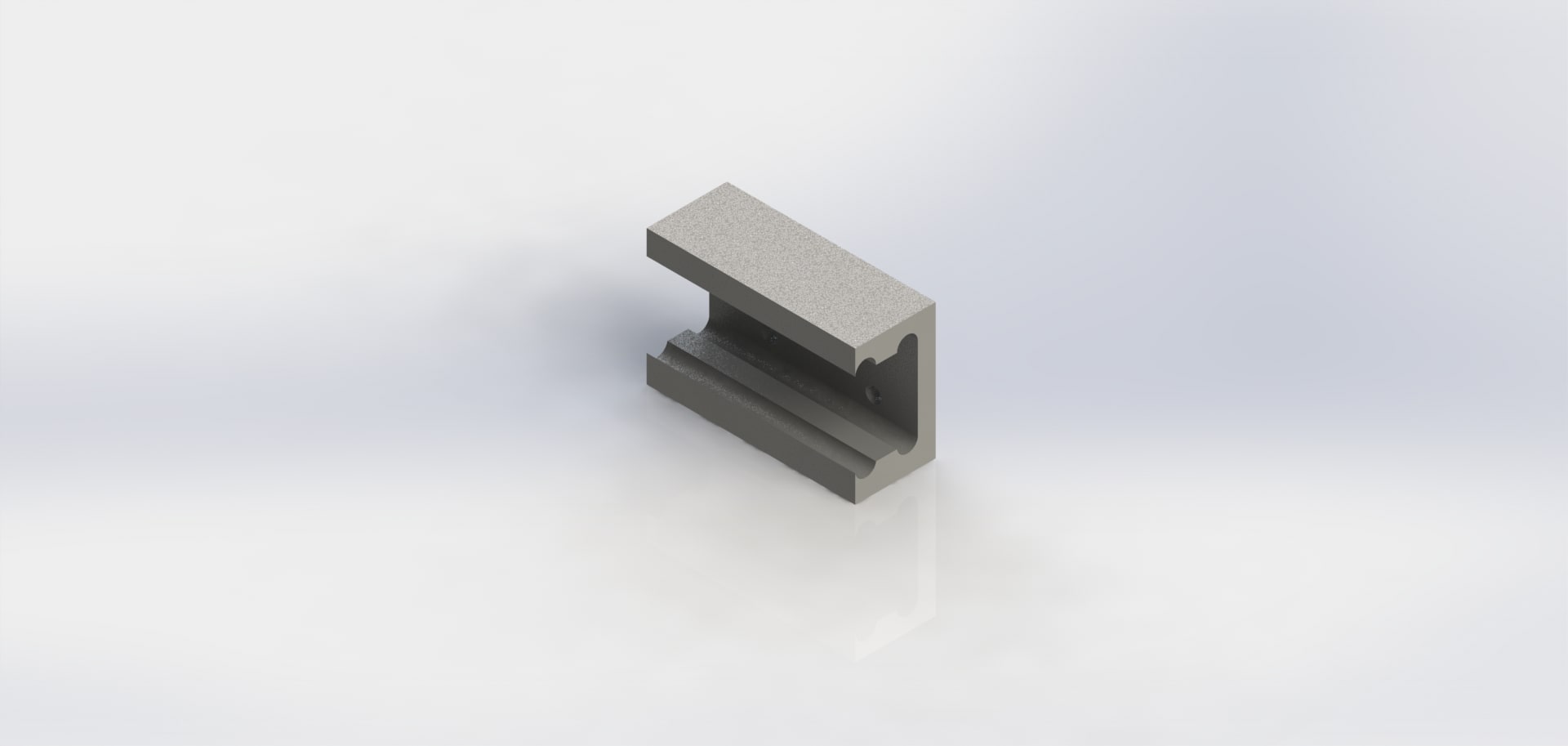

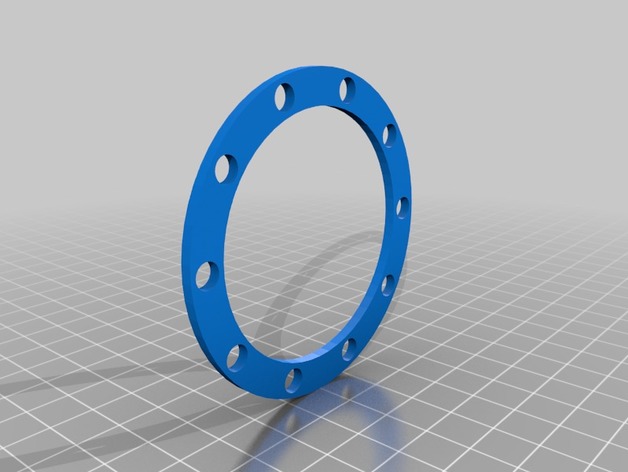

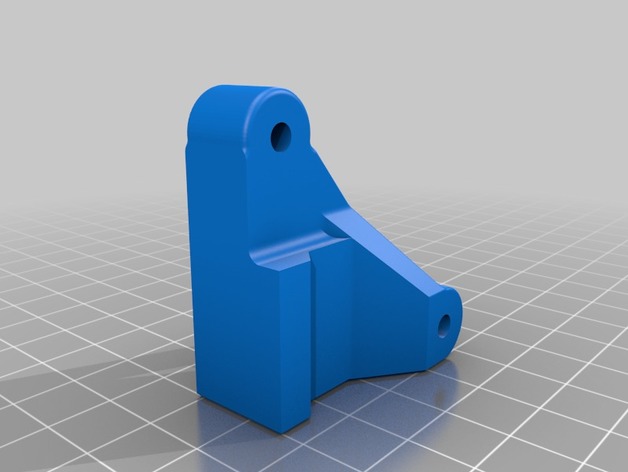

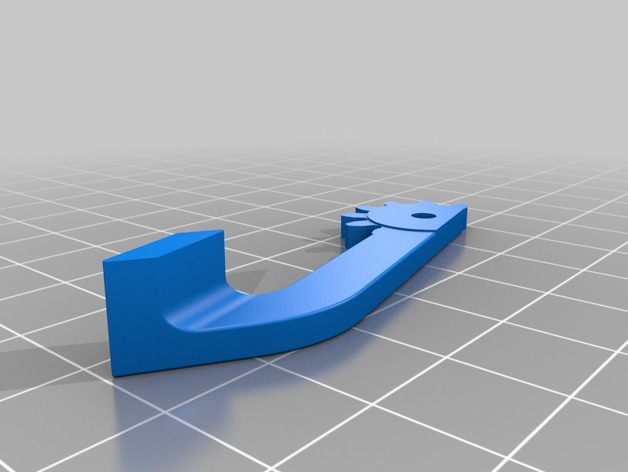

3.Base_Bearing_Holder

3.Base_Bearing_Holder

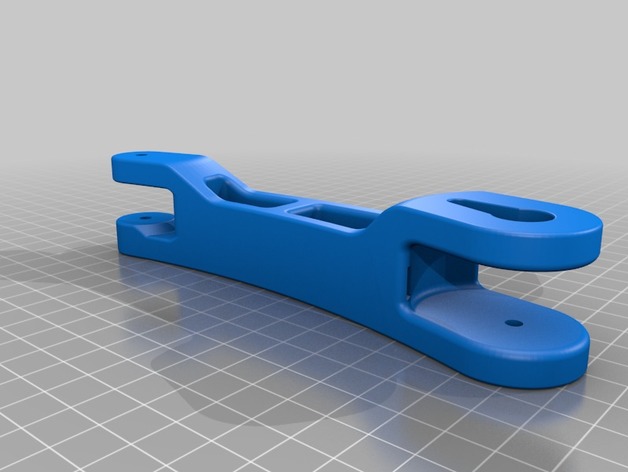

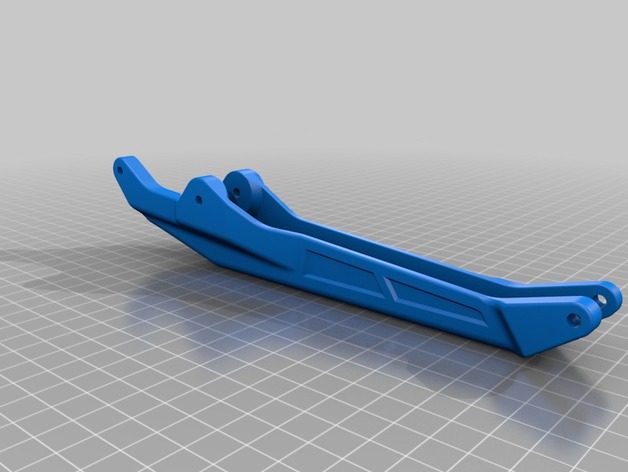

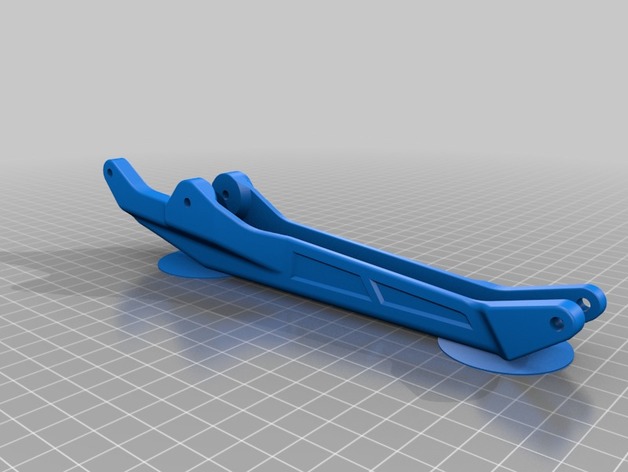

4.Main Arm of Robot

4.Main Arm of Robot

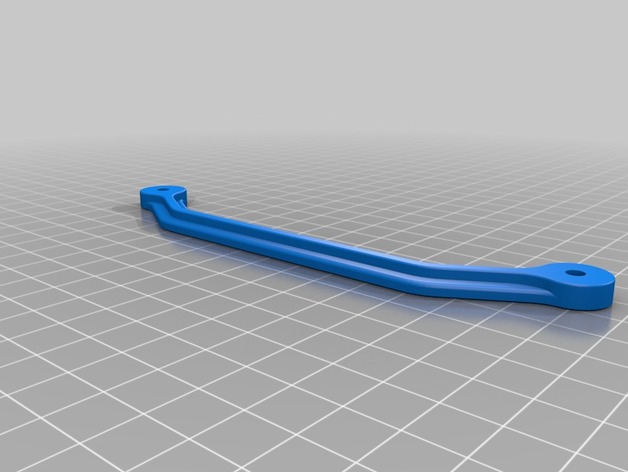

5.V_Arm

5.V_Arm

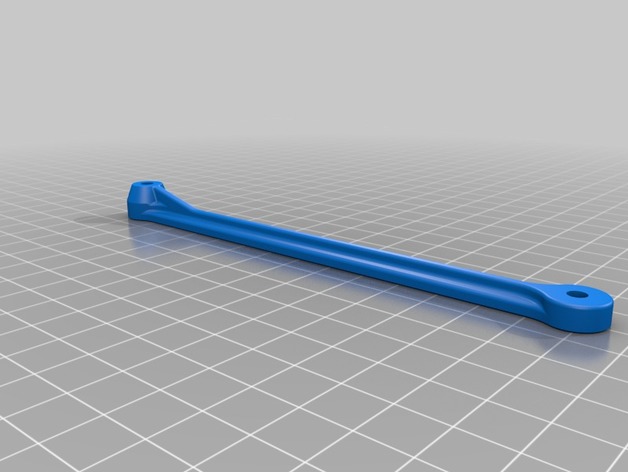

6. Links

6. Links

7. Horizontal Arm

7. Horizontal Arm

8. Horizontal Arm Plate

8. Horizontal Arm Plate

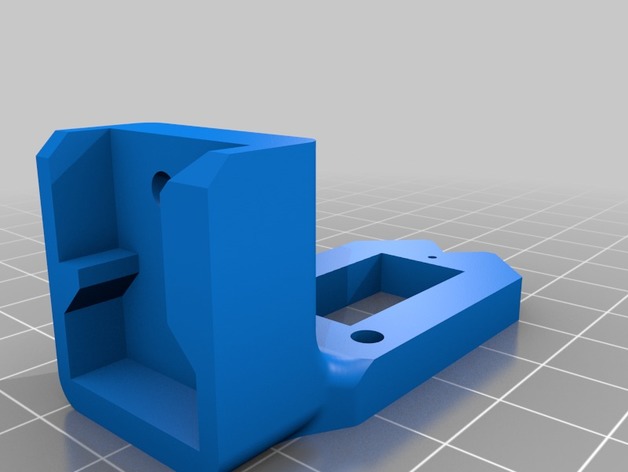

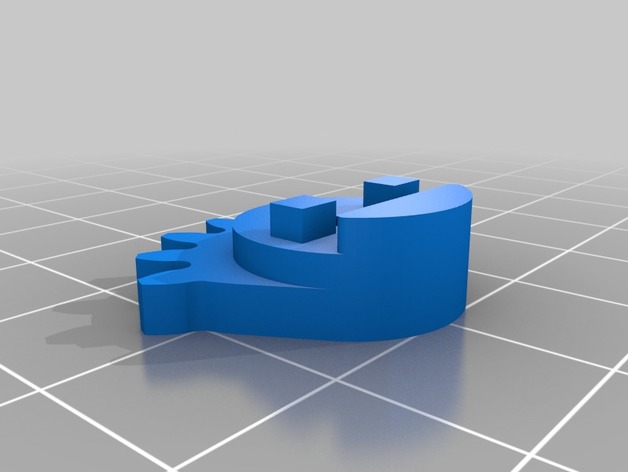

9. Claw Base

9. Claw Base

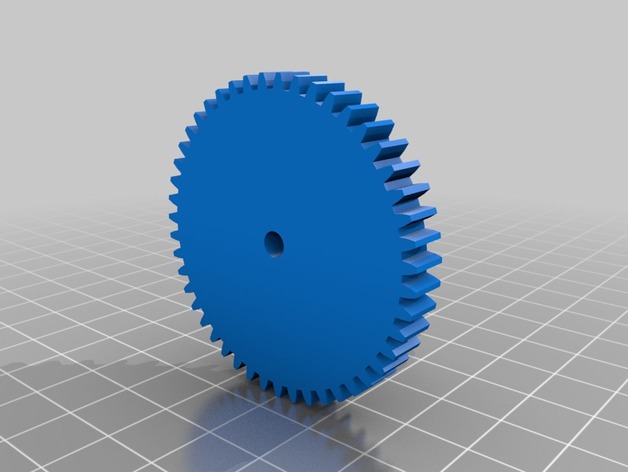

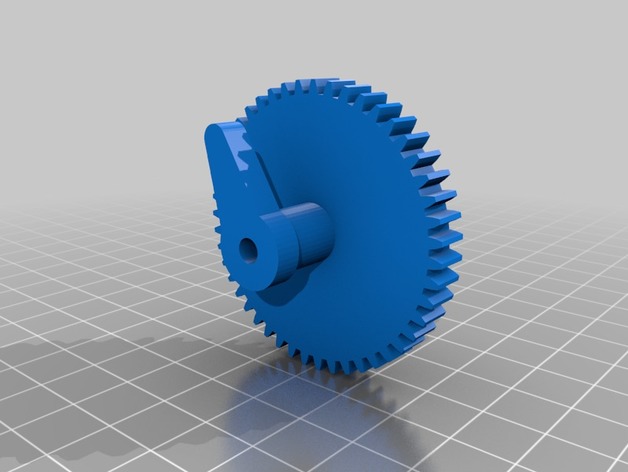

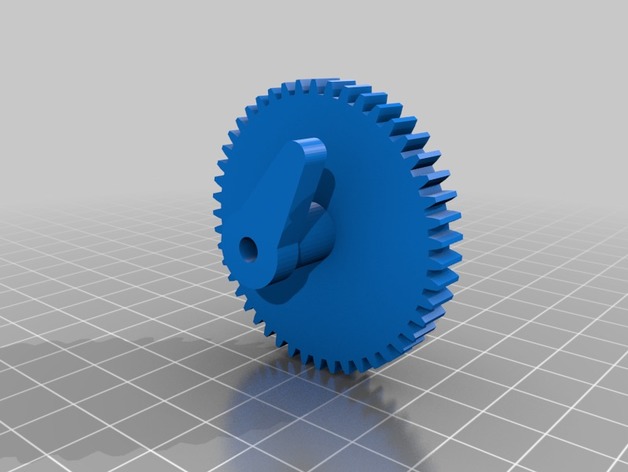

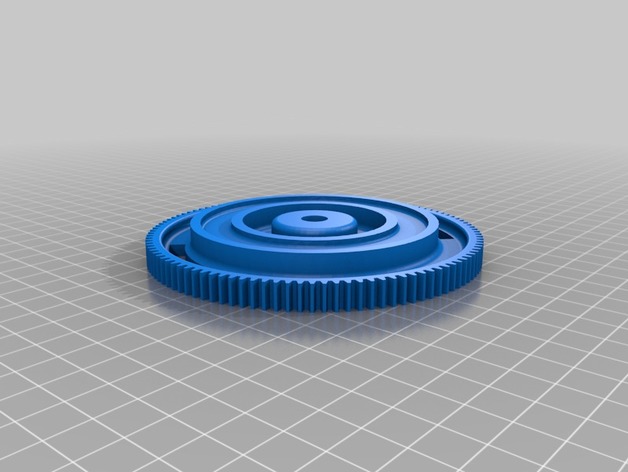

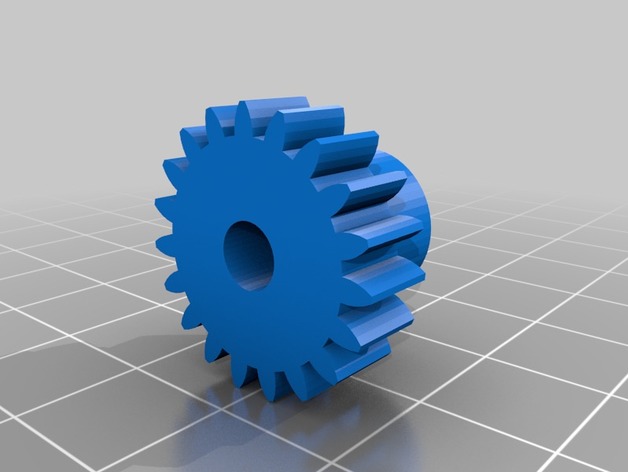

9. Gears

9. Gears

10. Robot Assemblely

10. Robot Assemblely

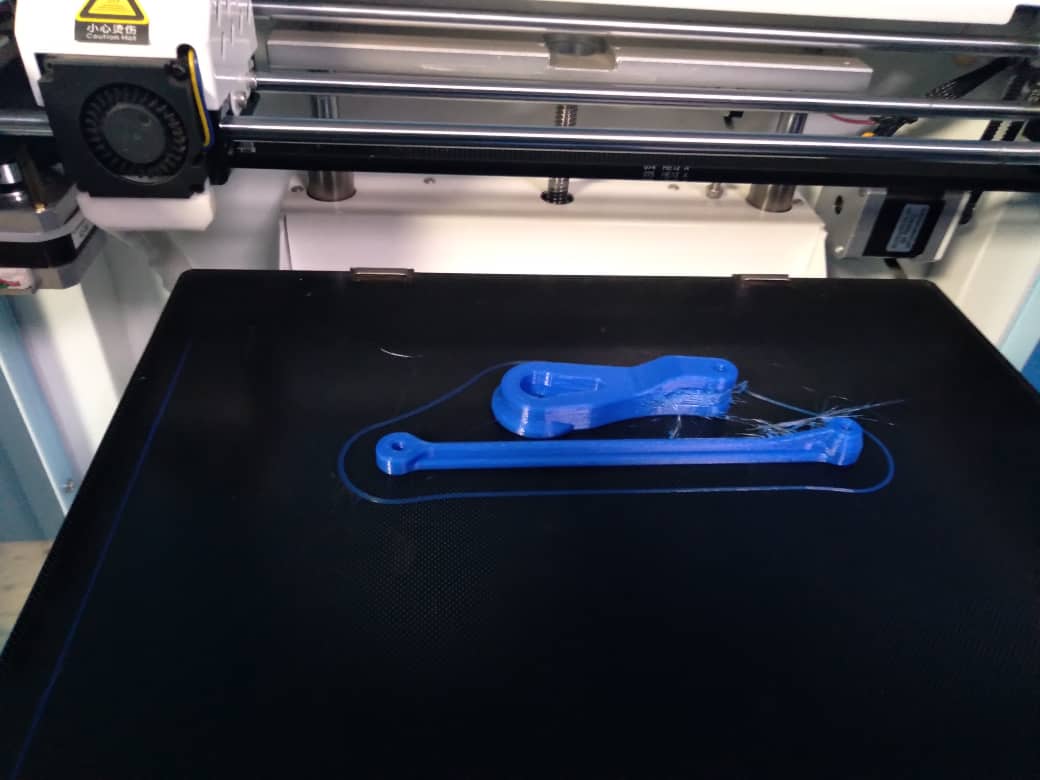

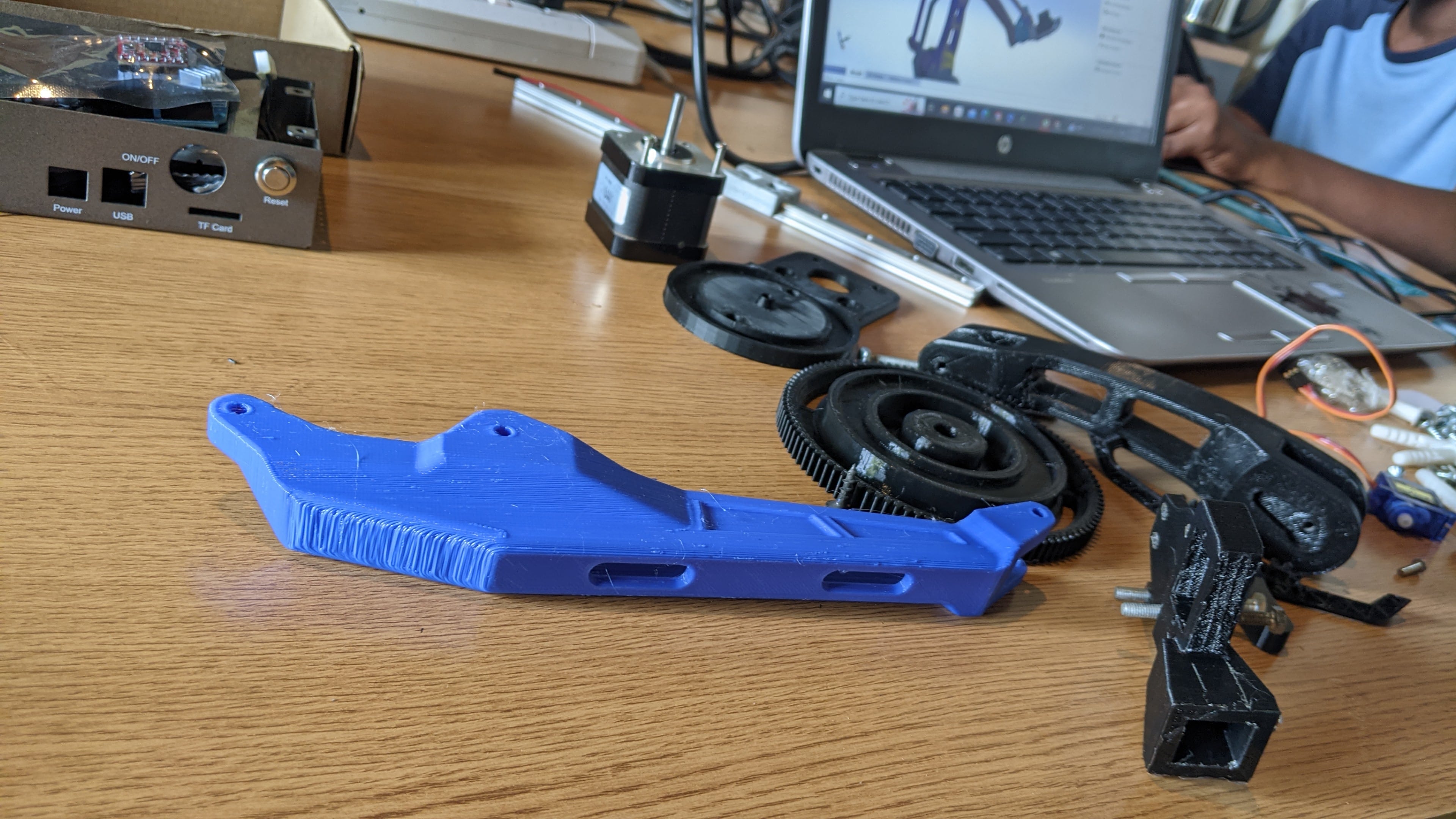

.jpg) We started Printing some parts with 3D Printer

1. Base Arm Design After Printing

We started Printing some parts with 3D Printer

1. Base Arm Design After Printing

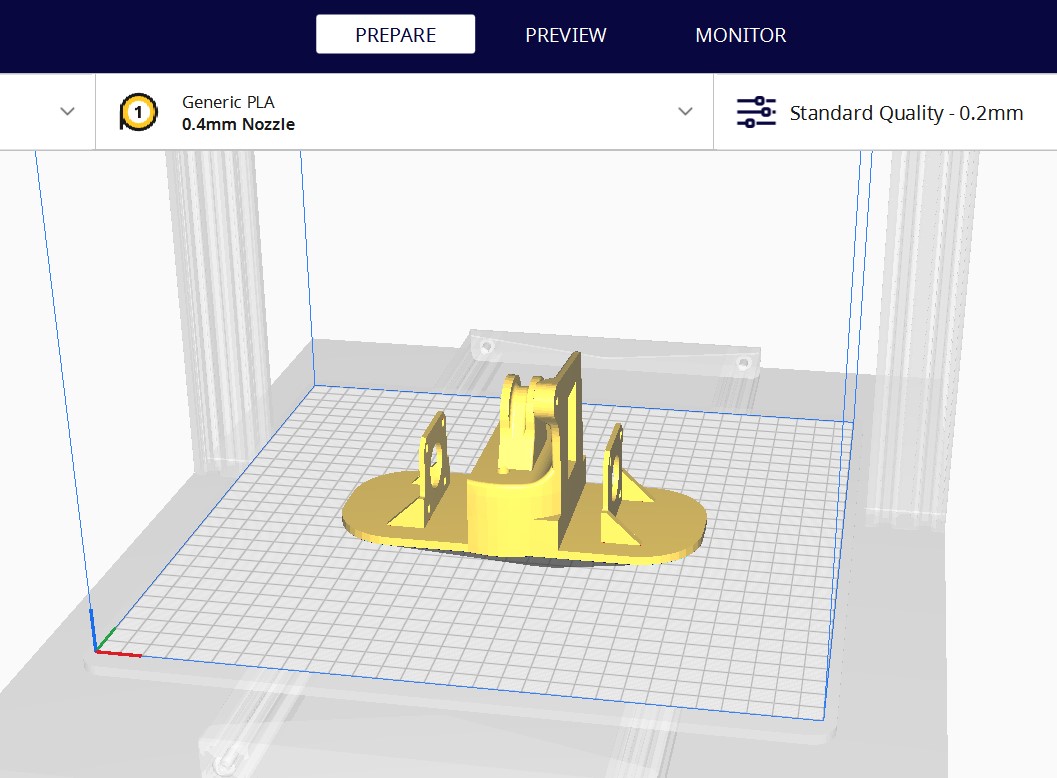

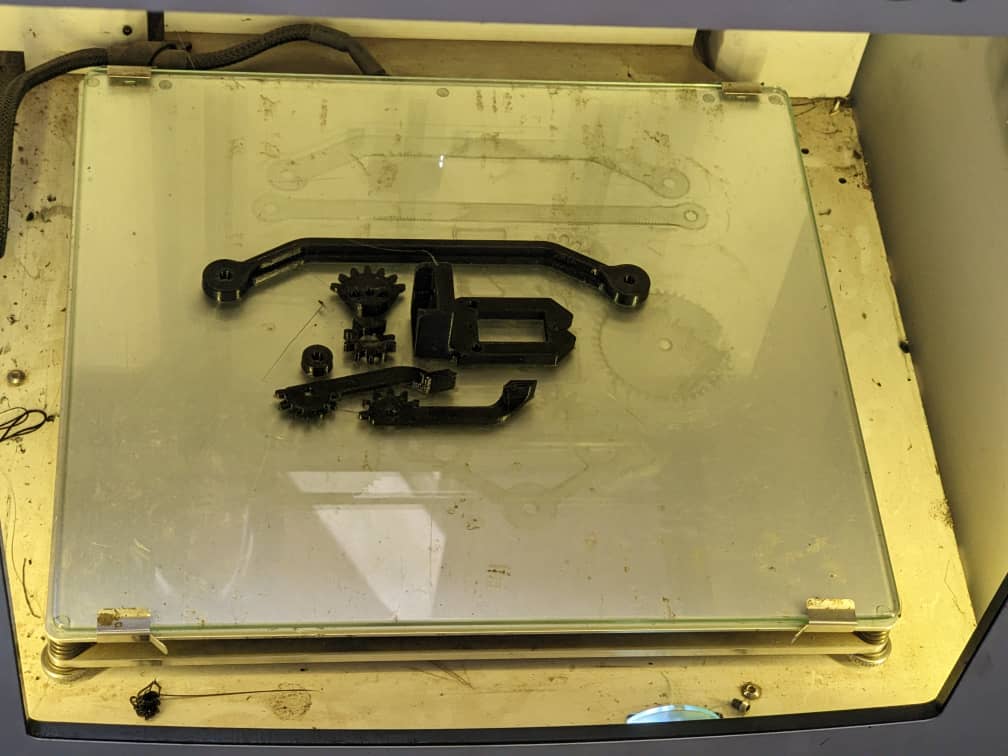

2. Printing other Parts of Robot

2. Printing other Parts of Robot

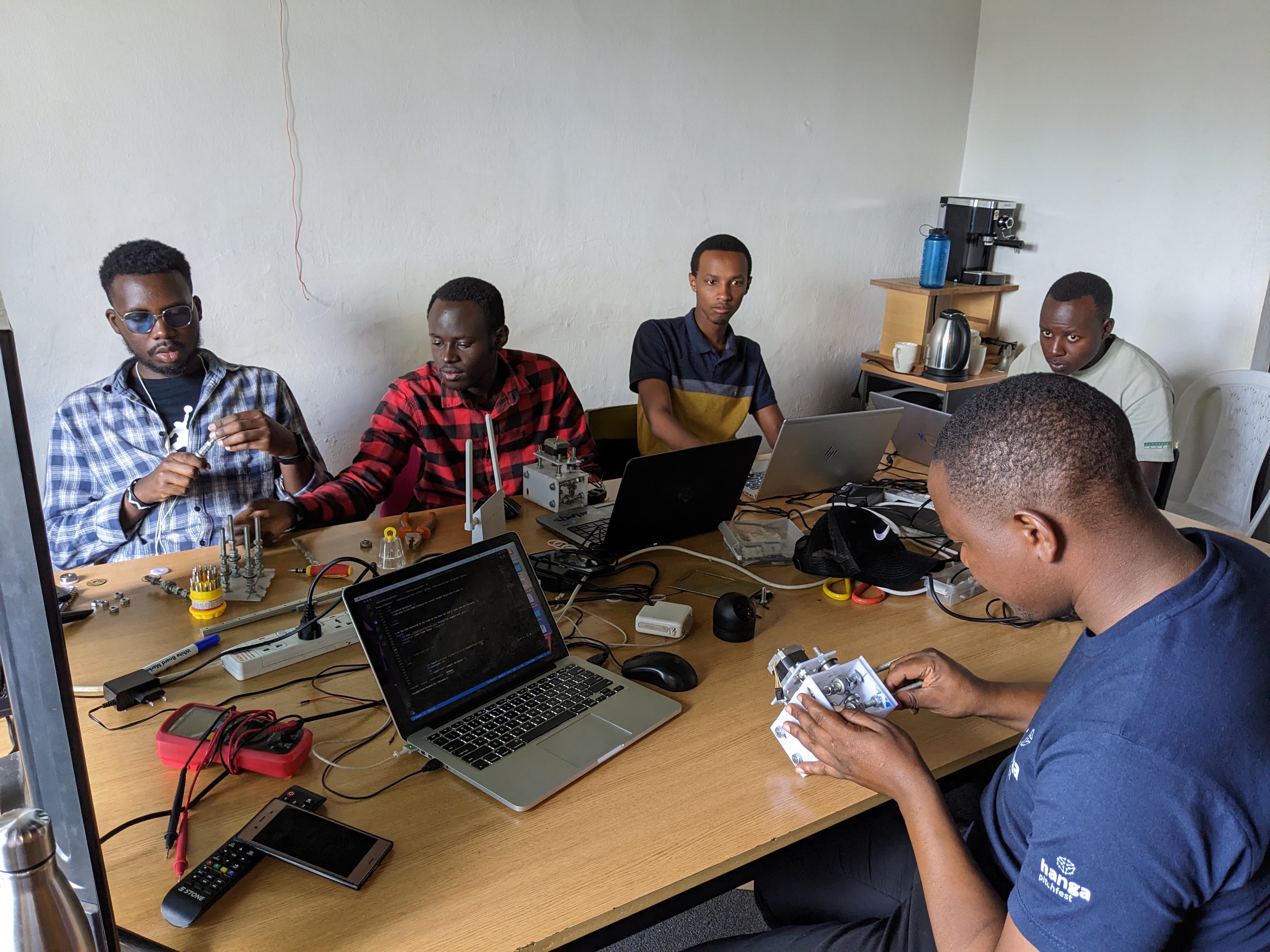

We started Assembly Part by Part of Robotic

We started Assembly Part by Part of Robotic

We encoutered with the issue of our 3D printer which broken after printing several parts of the robot arm. some gear are not working well and we are still finding alternatives.

We have also meet with the issue of Stepper motor driver circuit that was not working well which delayed the machine building process. we hope to finish machines as soon as possible because issues must be fixed and our instructor is looking for alternatives togather .