Week 10: Mechanical Design, Machine Design

Group assignment

Mechanical Design (part 1 of 2)

-

* Design a machine that includes mechanism + actuation + automation + application

-

* Build the mechanical parts and operate it manually

-

* Document the group project

Machine Design (part 2 of 2)

-

* Actuate and automate your machine

-

* Document the group project

The group assignment page is here on FabLab Rwanda web page

.Individual assignment

-

Below here, I am going to document the group project and my individual contribution

The first component of the project basically involves thinking about what our machine will perform and designing its mechanism. Use the device without any motors.

For this week we worked in two different groups, Group A worked on a Laser Cutter machine and Group B worked on Arm Robot. I was in the Group A:

A laser cutter is a computer-driven device that can cut or engrave a variety of materials, including wood, plastic, metal, fabric, and more. A sequence of mirrors and lenses concentrate the laser beam onto the substance, which is then burned, evaporated, or melted away. Intricate designs and patterns can be created, complex shapes can be carved out, text or images can be engraved, and even glass can be etched with a laser cutter. They are frequently employed in the manufacturing, engineering, prototyping, and creative industries. The qualities of the laser cutter that we are going to create are as follows:

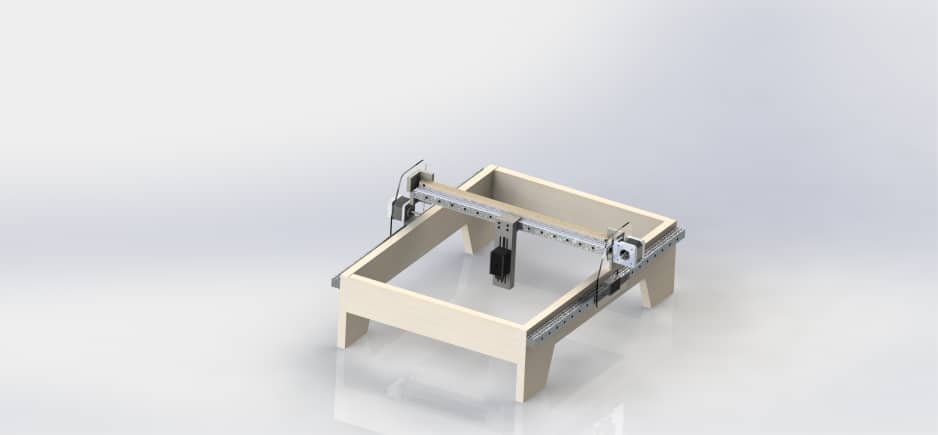

Below here are the designed parts of the Laser Cutter machine

|

|

The following is the simulation video:

Laser cutters are machines that use high-powered lasers to cut or engrave various materials, such as wood, plastic, metal, and fabric. The laser beam used in a laser cutter machine is produced by a process called stimulated emission.

A laser beam is a highly focused, narrow beam of light that is generated by exciting a laser medium, such as a gas, crystal, or semiconductor, with an energy source such as electricity or light. The excited atoms or molecules release photons of light, which bounce back and forth between two mirrors, amplifying and aligning the beam until it emerges as a highly concentrated, coherent beam of light.

In a laser cutter machine, the laser beam is directed onto the material being cut or engraved by a series of mirrors and lenses. The material is then melted or vaporized by the intense heat of the laser, which cuts through it with extreme precision. The laser cutter machine can be controlled by a computer program, allowing for highly intricate and precise cuts and engravings to be made.

One of the main advantages of using a laser cutter machine is the speed and accuracy of the cuts. The laser beam can cut through a variety of materials quickly and with very little waste, making it a highly efficient manufacturing tool. Additionally, the laser cutter machine can create complex designs and shapes that would be difficult or impossible to achieve with traditional cutting tools.

Overall, the use of a laser beam in a laser cutter machine offers a highly precise and efficient way to cut and engrave various materials, making it a valuable tool in many manufacturing industries.

Kindly see the below video showing the process of testing laser beam

The following is the simulation video:

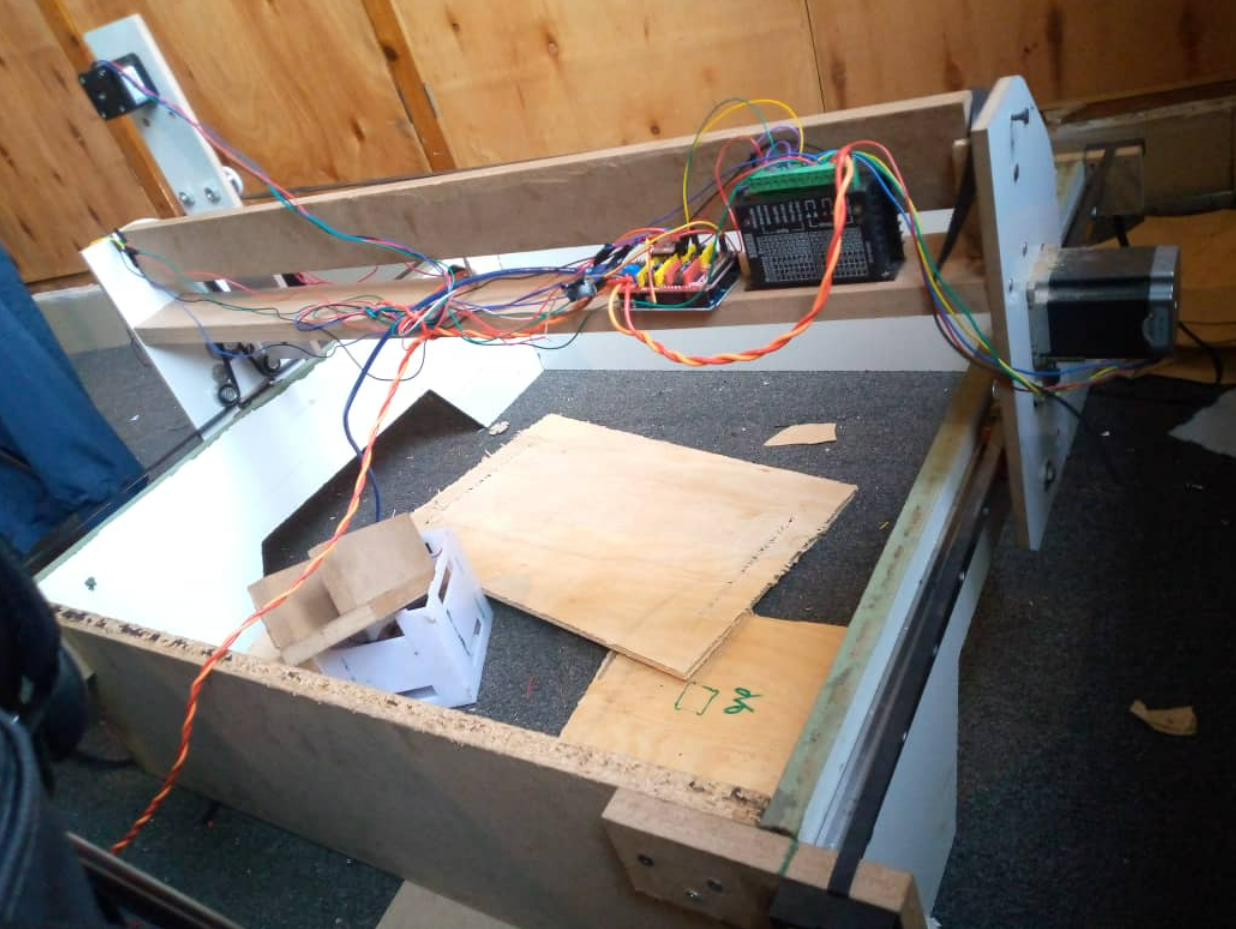

After constating that the laser beam is working, we did assembling of parts for our made Laser Cutter Machine:

After putting everything together, we tested the equipment to see if it was operating properly.Simply by engraving any text that was displayed on the computer, we took a sample. We carved it on a predetermined MDF just as a draft, as seen in the video below.

The following is the simulation video:

The finished product of the workpiece after engraving is shown below:

- Used file can be found here for Laser cutter.

© 2023 | Eric NDAYISHIMIYE | All Rights Reserved