Mechanical design, Machine design

Assignment to be done:

- design a machine that includes mechanism+actuation+automation+application

- build the mechanical parts and operate it manually

- document the group project and your individual contribution

Group assignment to be found here

Individual Assignment: Document the group project and your individual contribution

In my group we designed and build a Laser Cutter Machine

My contribution to this work was cutting all designed mechanical parts and their assembly in order to get the final working machine. Down here there are all procedures I passed through when cutting and assembling the parts toward the complete and working machine.

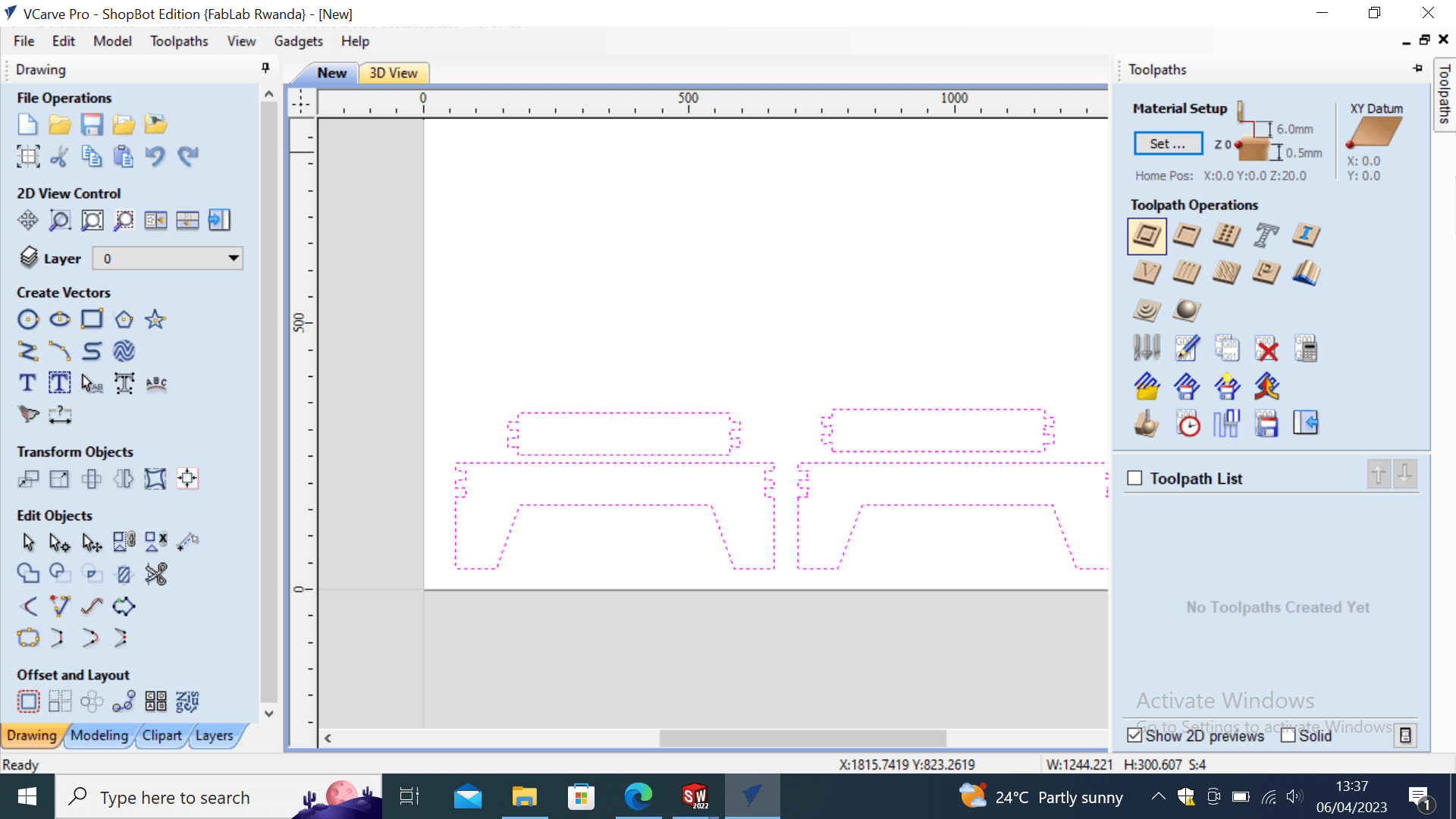

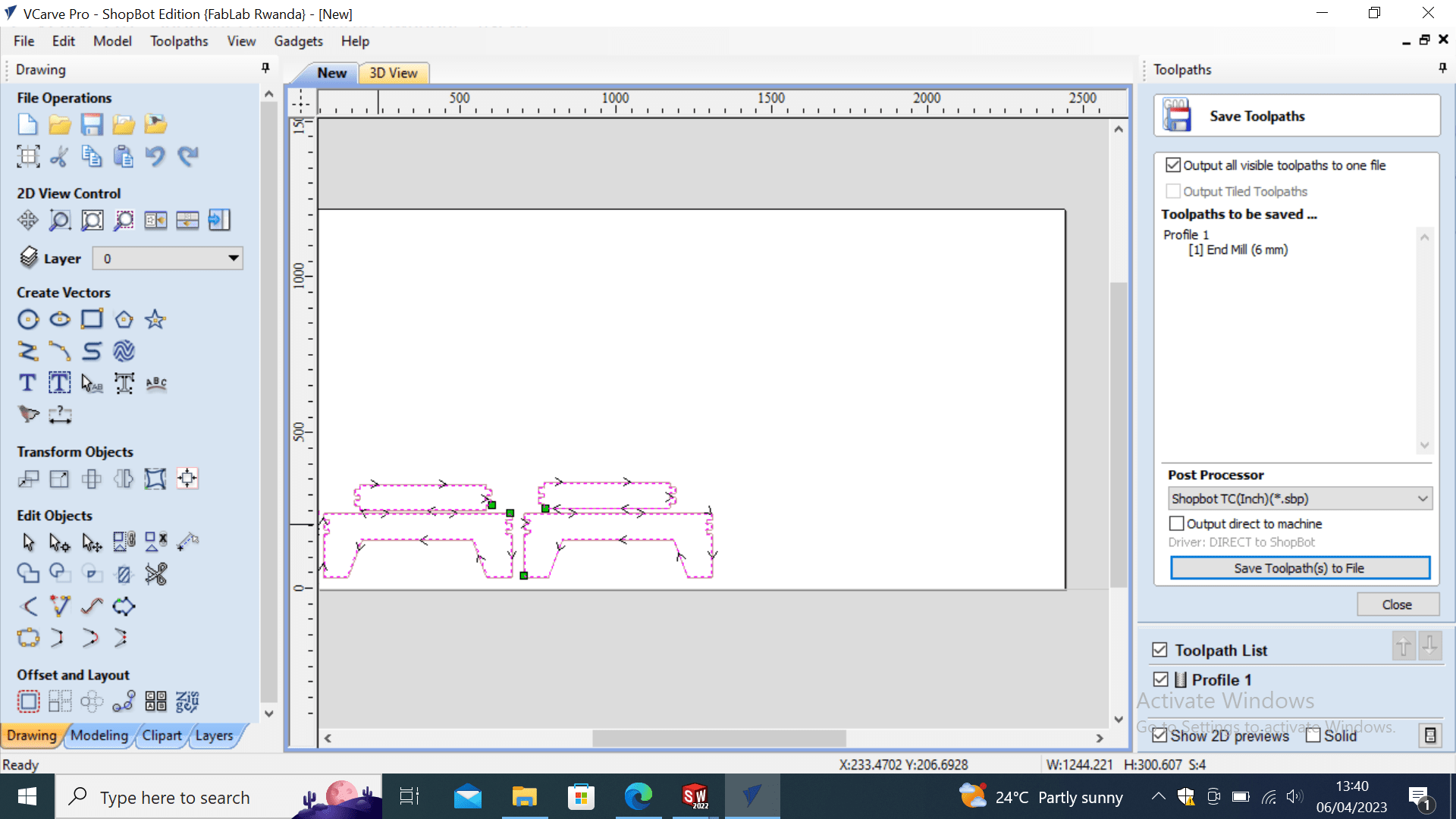

After having all files ready, I fixed the work piece to be cutted on the bed of my CNC shopbot machine.Here I made sure that the piece is well tighted on the bed so that will be no movement when a machine is cutting. As there was a piece of workpiece of previous work, I started by removing it.

Cutting the pieces to be used with CNC shopbot machine

Assembling the parts of our machine

Actually when assembling the machine, I started by fixing the four external parts of the machine in rectangular form!!! and made sure that they are well fitted and aligned. After this, I fixed the other smaller parts to support the belts and the laser head as well as the stepper motors for making motion or movement.

Normally, all parts need to be fitted in order to ensure their alignment and not causing the unstraight movement of the laser head.

This is also crusial as the frame will support the heavy stepper moters. If it is not it will cause the machine to not be precised. The belts also need to be very staight and well fixed sothat the movements be not zig zag.

Then the complete laser machine after assembling:

After the hardwork, we as group successfully completed the design and build our laser cutter machine and it works as expected now and more details can be found on group page through the link I shared on the top of this page

The files can be downloaded from here

2023 All Rights Reserved. Designed by Felix NYIRIGIRA