16. Applications and Implications¶

This week our task was to propose a final project masterpiece that integrates the range of units covered. I had already started with planning and constructing the final project (current status is shown here).

My Final project¶

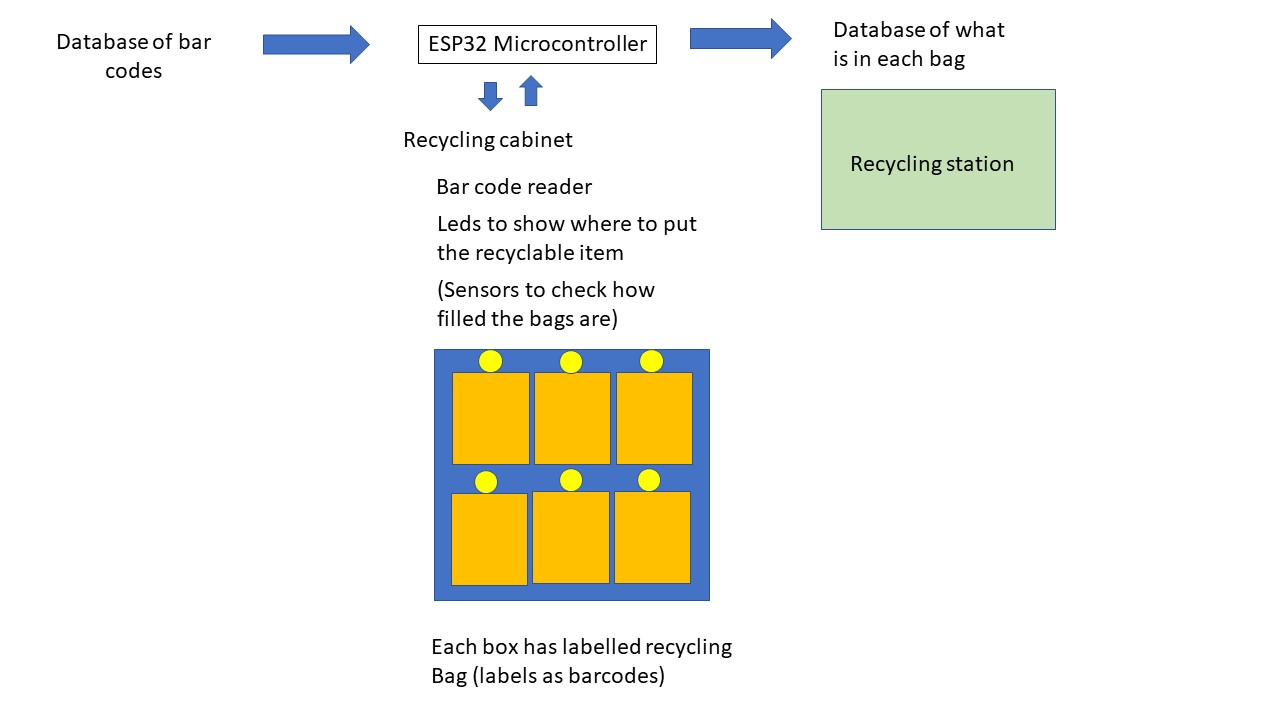

My final project is a Smart connected recycling storage cabinet

Questions and answers¶

We needed to answer the following questions regarding the final project:

What will it do?¶

The smart recycling storage cabinet will read the barcode of the packaging of used product. It read a database of bar codes, and it will indicate in which recycling bag(s) to put the packaging material(s). The recycling bags in the cabinet will be labeled, and the cabinet will send information on what exactly is in each bag to another database, that can be read by a recycling center. In this way, the recycling center can know exactly what material is in each labelled bag, when the bag arrives to the recycling center.

Who’s done what beforehand?¶

When I started looking information on the similar previous projects, I found that Mennatallah Moustapha had previously built a very nice recycling storage device. My device extends this idea by using databases to receive information on the bar codes to use it for accurate sorting, and transmitting the exact information on what is in each bag to the recycling center.

In the fab academy pages, there was an idea for a final project for automatic recycling.

I also found an article on an internet publication referring a talk of Prof. Gershenfeld on a topic of including information on electronic products for achieving efficient recycling, which is a bit similar, in the sense that the information is transported alongside with the waste, to allow for efficient recycling. My device uses a bit similar concept of transferring the information, but it is managed by using the bar codes and labelling the recycling bags.

In a published peer reviewed article, it was discussed “that waste sorting capacity is driven by environmental attitudes, perceived convenience, social norms and economic drivers”. The planned device could aid in the convenience. Also economic drivers could be introduced in the sorting, since the device keeps track on how much waste is being recycled. It would be possible to give refund based on the recycling activity, since the recycling bags are labelled and it is possible to keep track on how much people recycle, and also to check that the bag actually contains the recycled things when they arrive to the recycling station.

What will you design?¶

I have designed and milled the cabinet outer structures. I also designed and laser-cut the interior shelves. I designed holder pieces and 3D-printed them. I designed the electronics schematics, and a circuit board, which includes the routings for the connections. I also designed the program which I uploaded to the RP2040 and ESP32C3 microcontrollers.

What materials and components will be used?¶

OBS board for the outer structues, HDF board for the inner structure (shelves). PLA for the holder parts. RP2040 microcontroller for interacting with the bar code reader, and EPS32C microcontroller for communicating with the databases. OLED screen to display textual information, USB host connector (I cut a piece from usb extension cable that had female connector), Neopixel leds and FR1 circuit board material. I had bought the bar code reader as used from a finnish second hand selling platform tori.fi for two euros.

Where will come from?¶

All the materials were available from the fab lab Oulu, except for the bar code reader (which I bought as used for 2 euros) and some screws that I used to attach the parts.

How much will they cost?¶

The costs are not big, some tens of euros:

| Qty | Description | Price | Link | Notes |

|---|---|---|---|---|

| 1 | OBS board | 40 euros | Obtained from fab lab | |

| 1 | ESP 32 | 7.95 euros | Obtained from fab lab | |

| 9 | Neopixel leds | few euros | from fab lab | |

| 1 | barcode scanner (used) | 2.00 euros | used from tori.fi | |

| 1 | HDF board | 20.00 euros | from fab lab | |

| 1 | FR1 Circuit board material | 1 euro | from fab lab | |

| 1 | OLED screen | 11 euro | from fab lab |

What parts and systems will be made?¶

Outer structure, inner structure, holder pieces, I am creating circuit board and connect the electronic components to it. I will use the following components: microcontrollers, led system (neopixel leds) to indicate in what bags to put the trash and OLED screen to show the textual information and the web server address to the user. The web server will be provided by the ESP32C3 and connectivity will be achieved using MQTT system provided by the ESP32C3 to achieve transmitting data from the recycling cabinet over network, so the data could be received by the database that could be used by the recycling center. The connections are shown in the final project documentation page.

What processes will be used?¶

CNC milling, laser cutting, 3d printing, electronics design, embedded programming, electronics production (circuit board milling), output and input devices, interfaces and applications, networking and communication.

What questions need to be answered?¶

I think I have solved most of the problems that I had. I was concerned on how to design the interior structures and how to keeps the pieces together. Also, I was worried how to connect the bar code reader to the microcontroller. I managed to solve these problems and I only need to proceed with making the remaining construction.

I will still need to think a bit how to package the electronics, but I think it is not of a big problem.

I will also need to figure out how to make the connection to external database. I am thinking to use MQTT service with the ESP32C microcontroller.

If I get the first cycle ready, I will think about improving it by trying to make my own bar code reader using ESP32C, camera and opencv.

How will it be evaluated?¶

The functionality: The device should be able to conveniently sort the trash to different bags. The connectivity: It should be able to provide connectivity to at least from the device to the database of the recycling center.

Planned time schedule:¶

- Week 1: Assembly of structures

- Week 2: PCBs and electronics

- Week 3: Connectivity and interfaces

- Week 4: Packaging