Molding and casting week. Group 2 Work.

Group members

Group work for week 12

We went over the following materials available at our Fab Lab.

- OOMOO 25

- Smooth-Sil

- Soma Foama 15

- Bera HS (metal casting)

The table below summarizes the material characteristics. The later sections go to details

| Material | Type | Color | Pot life | Cure time | Mixing ratio | Safety notes |

|---|---|---|---|---|---|---|

| OOMOO 25 | Silicone | Blue | 15 min | 75 min | 1:1 (volume) | Dispose cured |

| Smooth-sil 940 | Silicone | Navy Blue | 8-10 min | 24 hours | 1:1 (volume) | |

| Soma Foama 15 | Silicone | Platinum | 30 sec | 1 h | 2:1 (volume) | |

| Bera HS | Metal | Gray shiny | few sec | 10 sec | Alloy |

OOMOO 25

"Easy to use" soft silicone rubber compound. Tear strength is said to be limited on the product page.

Safety sheet review

Key takeaways:

- Basic chemical handling precautions

- Wear hand and eye protection

- Vinyl gloves only as latex gloves will inhibit the cure of the rubber

- Do not eat or drink in the room

- Also good idea to wear long sleeves

- Wear hand and eye protection

- Respiratory protection not required when used in properly ventilated space

- Wash hands after use

- In case of skin contact wash with normal soap and water

- Keep eye wash close

- Disposal on the safety sheet is put on the responsibility of the user

- It is understood that when cured it is safe to dispose of

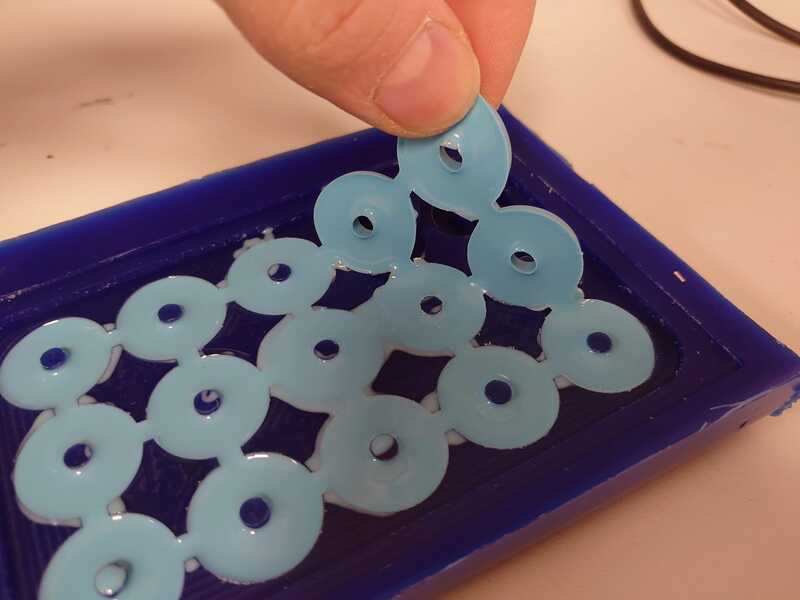

Test cast

As the group were mixing this material, Akseli's mold was already ready, so he casted to that directly.

The cast cured well and the result was as expected. This silicone compound is on the softer side and therefore might not be as durable. Good choice for negative molds.

Smooth-Sil 940

Safety sheet review

Safety sheet

Safety sheet for Smooth-Sil 940

Key takeaways: It appears that this is the same safety document as for the OOMOO and Soma Foama 15, so that the same key takeaways are true for this material as for the Smooth-Sil 940. Few additional notes:

Handling and storage: Use good general housekeeping procedures. Wash hands after use. Do not get in eyes, on skin or on clothing. Do not breathe vapors or mists. Use good personal hygiene practices.

Conditions for safe storage, including any incompatibilities Keep container(s) tightly closed and properly labeled. Store in cool, dry, well ventilated place away from heat, direct sunlight, strong oxidizers and any incompatibles. Store in approved containers and protect against physical damage. Keep containers securely sealed when not in use. Indoor storage should meet local standards and appropriate fire codes. Containers that have been opened must be carefully resealed to prevent leakage. Empty containers retain residue and may be dangerous. Avoid water contamination.

Hand Protection Wear any liquid-tight gloves such as butyl rubber, neoprene or PVC.

Eye Protection Safety glasses with side shields per OSHA eye- and face-protection regulations 29 CFR 1910.133 and European Standard EN166. Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or in conjunction with contact lenses.

Comments No eating, drinking, or smoking in the same area. Wash hands thoroughly after handling. If the area is not an open environment with adequate ventilation, also use respiratory protection.

Test casting

The cast cured well and the result was as expected.

Soma Foama 15

Soft, two-component platinum silicone flexible foam that is versatile and easy to use. product page. Expands 4 times its original volume and develops a uniform cell structure. Cured foam is high heat resistance (will resist up to 350°F/176°C), water resistant, UV resistant and resists oxidation and ozone degradation.

Safety sheet

Safety data sheet for Soma Foama 15

Key takeaways: It appears that this is the same safety document as for the OOMOO, so that the same key takeaways are true for this material as for the OOMOO. Few additional notes:

Handling and storage: Use good general housekeeping procedures. Wash hands after use. Do not get in eyes, on skin or on clothing. Do not breathe vapors or mists. Use good personal hygiene practices.

Conditions for safe storage, including any incompatibilities Keep container(s) tightly closed and properly labeled. Store in cool, dry, well ventilated place away from heat, direct sunlight, strong oxidizers and any incompatibles. Store in approved containers and protect against physical damage. Keep containers securely sealed when not in use. Indoor storage should meet local standards and appropriate fire codes. Containers that have been opened must be carefully resealed to prevent leakage. Empty containers retain residue and may be dangerous. Avoid water contamination.

Hand Protection Wear any liquid-tight gloves such as butyl rubber, neoprene or PVC.

Eye Protection Safety glasses with side shields per OSHA eye- and face-protection regulations 29 CFR 1910.133 and European Standard EN166. Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or in conjunction with contact lenses.

Comments Never eat, drink, or smoke in work areas. Practice good personal hygiene after using this material, especially before eating, drinking, smoking, using the toilet, or applying cosmetics. Wash thoroughly after handling

Bera HS

Key Takeaways: The product shall not be classified as hazardous according to the classification and labeling rules for substance and mixtures

Harmful if vapours from molten metal are inhaled or if the skin comes in contact with molten metal.

Prolonged exposure to welding smoke and particles constitutes a risk of developing asthmatic diseases, various respiratory disorders and cancer of the respiratory system. Harmful if vapours from molten metal are inhaled or if the skin comes in contact with molten metal.

Wear safety goggles if there is a risk of eye splash

Wear protective gloves which protect against contact and splashing from molten metal.

Test casting