15. Wildcard week¶

Part one : Assignments¶

Group assignment:

None

Individual assignment:

- Design and produce something with a digital fabrication process (incorporating computer-aided design and manufacturing) not covered in another assignment, documenting the requirements that your assignment meets, and including everything necessary to reproduce it.

Part two : What I did¶

Individual assignment:¶

For this week’s work, we chose to use a plasma cutter to make a fireplace using coal.

1. Presentation of the Plasma cutter in our Fab Lab¶

1.1. Presentation

In our Fab Lab, we have a model HTP-1530 from HITECCNC compressed-air plasma generator up to 168A.

A plasma cutter is a controlled machine that uses plasma cutting technology to cut all conductive materials. A plasma arc is formed when a gas, such as oxygen, nitrogen, argon or compressed air, is forced through the nozzle orifice. An electric arc generated by an external power source is then introduced to this high-pressure gas stream, more commonly known as a plasma jet. The plasma immediately reaches temperatures of up to 22000°C, enabling it to cut very quickly. The role of the plasma cutter is to cut sheet metal quickly and relatively precisely, and to produce different shapes. Plasma can be used to cut metal sheets in thicknesses ranging from 0 to 160 mm, with a precision of plus or minus 0.2 mm.

1.2. Specification

| Brand | Hiteccnc HTP-1530 |

|---|---|

| Working area | 1500x3000mm |

| Power supply | Huayuan 160A |

| **Control system ** | CNC Starfire Control system with HYD Independent THC |

| Software | StarCAM |

| Resolution | ± 0.03mm |

| Command | G code (uoo,nc,mmg,plt) |

| Voltage | 380V, 3 phase,50/60HZ |

| **Consumble Parts ** | Cutting nozzle and electrode |

| Max working speed | 0-10000mm/min |

| Motor and driver | Leadshine stepper motor and driver |

2. Design¶

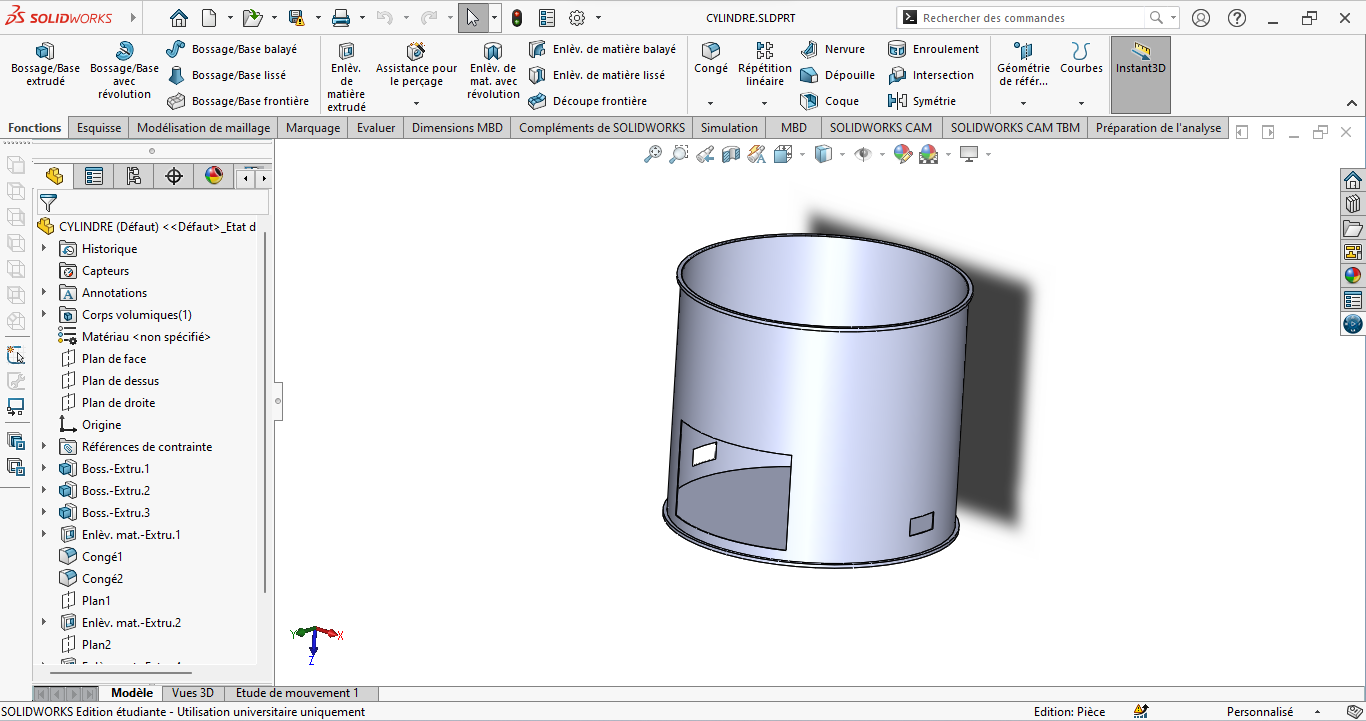

For the modeling of our parts we used SolidWorks. For more details refer to Week 2 (Computer Aided design). Here are the results of our modeling.

As you can see above, we have a 3D cylindrical part, but with the Plasma cutter we can only cut 2D parts. To do this, we calculated the various dimensions of our 2D rectangle using the formula L = 2 pi x r. here are the different parts of our 2D system. to download them, go to the file session at the end of this page.

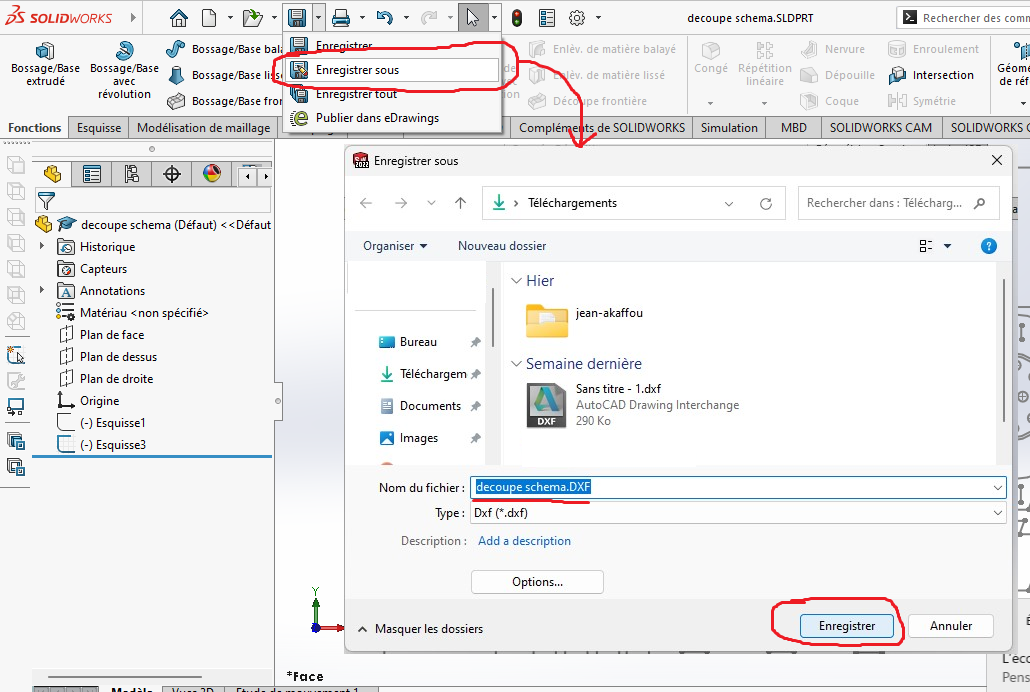

Once the modeling was complete, we exported our drawing to dxf as shown below.

3. Cutting path generation¶

For the generation of the cutting path we learned how to use a new software and the most important thing is that unlike laser cutting, the plasma cutter needs to initiate the cut by creating a hole in the part, which is why the cut starts either inside or outside the part. There are various starting forms, as shown below.

To generate the cutting path, we used the StarCAM software supplied with the machine.

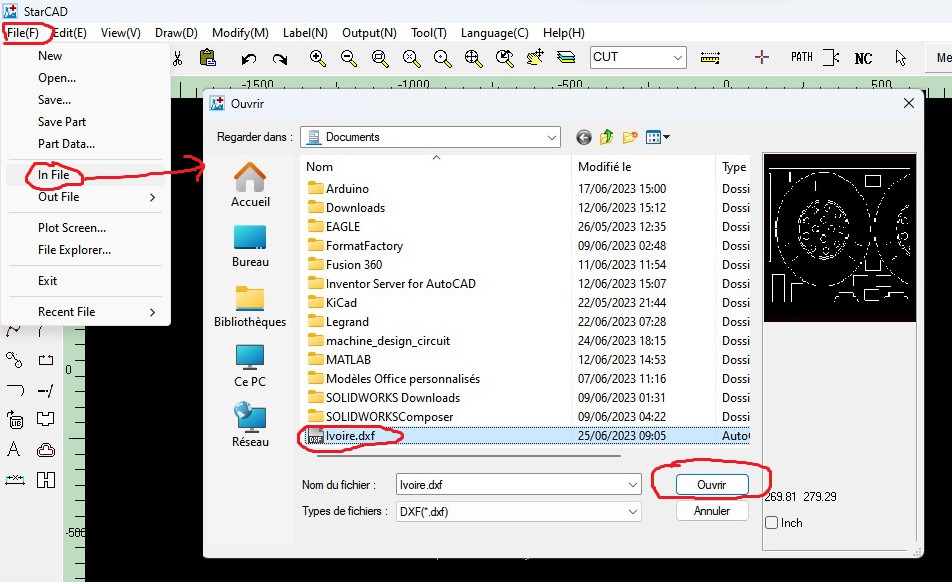

Step 1 : open the software and click on StarCAD.

Step 2 : Once StarCAD was open, we imported our DXF file as shown below

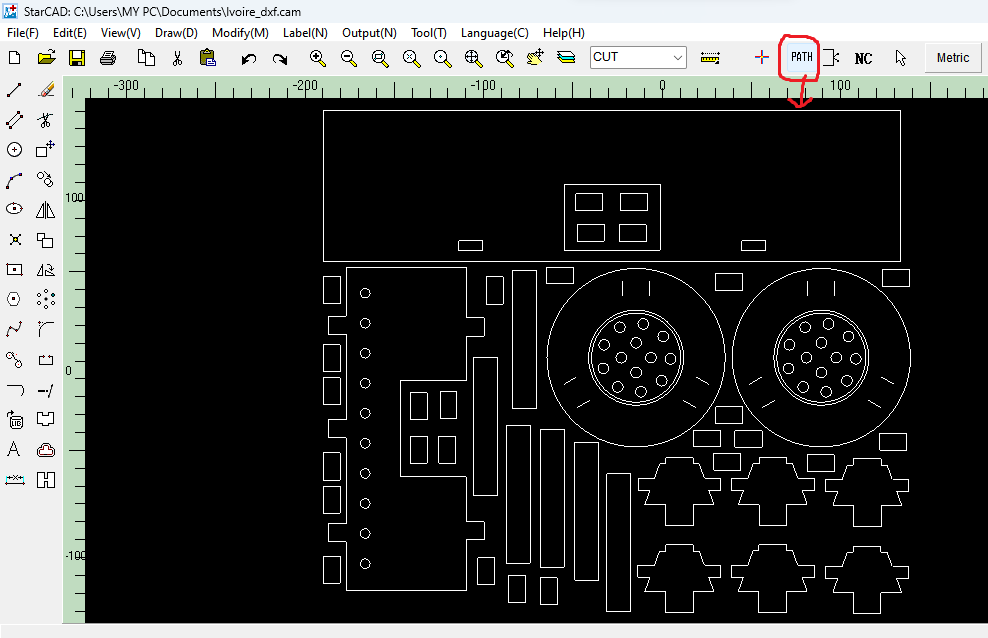

Step 3 : Click on “Path” to generate the cutting path

Step 4 : click on “NC” to save it as shown below.

4. Cutting¶

When cutting our parts, we’ve learned that it’s not possible to cut with plasma because of the items listed below. and the most important thing of all is the air compressor. if the air tank is small like ours, we often have to pause the cutting process to avoid cutting jumps or the machine stopping on its own during cutting.

A Huayuan LGK-160IGBT plasma source.

Air compressor

Water pump station

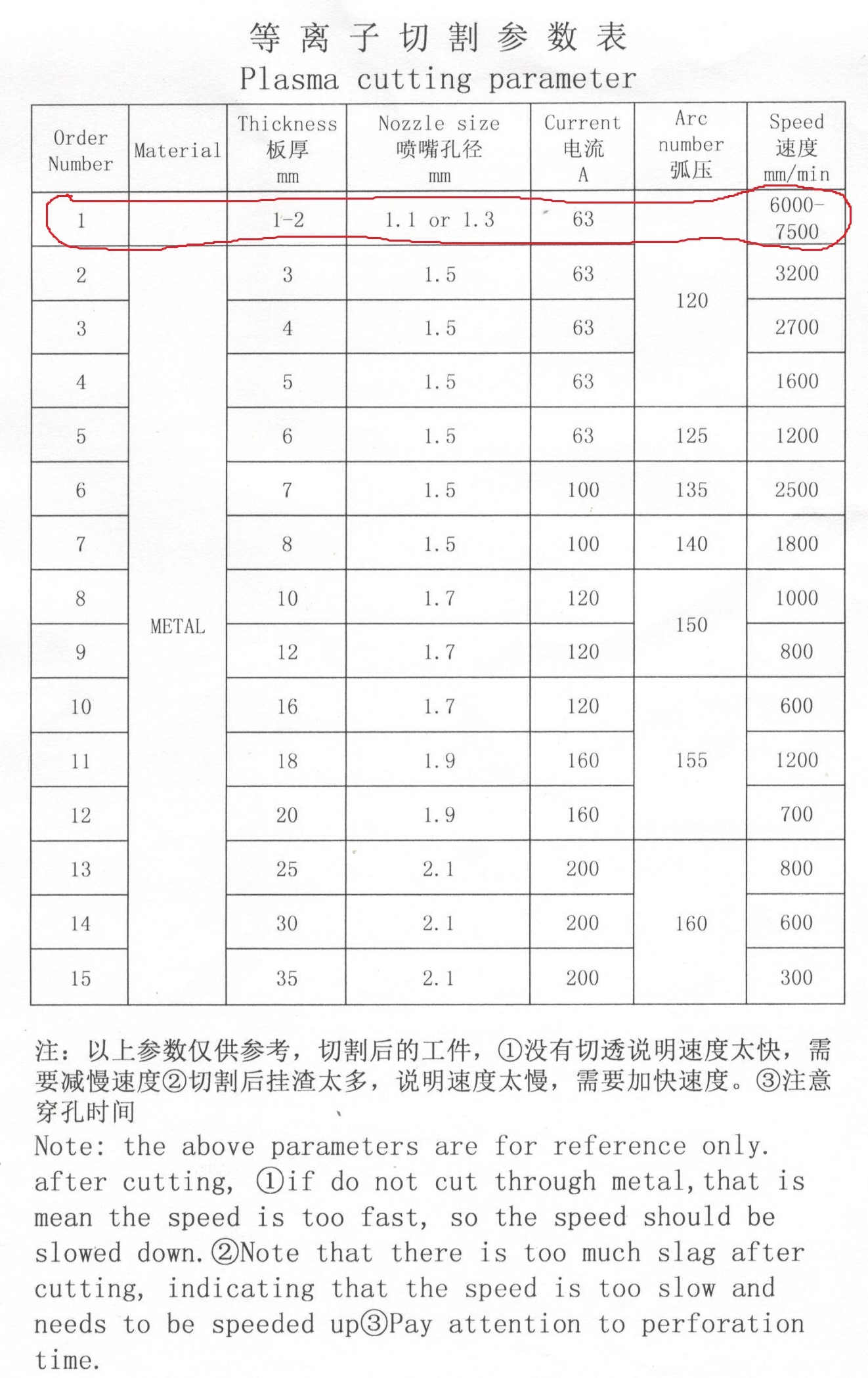

Before starting any work on the machine, we first had to determine the machine settings, i.e. arc current, arc voltage, cutting speed and the appropriate cutting nozzle. To do this, we referred to the table below, supplied by the manufacturer, which defines all the above parameters as a function of the thickness of the material to be cut.

Given that our material is 2 mm thick, here are the parameters we have selected.

Cutting parameter¶

| Materiel | Metal |

|---|---|

| Thickness (mm) | 2 |

| Nozze size (mm) | 1.2 |

| Current (A) | 63 |

| Arc number | 120 |

| Speed (mm/min) | 6000 |

To start cutting we proceed as follows:

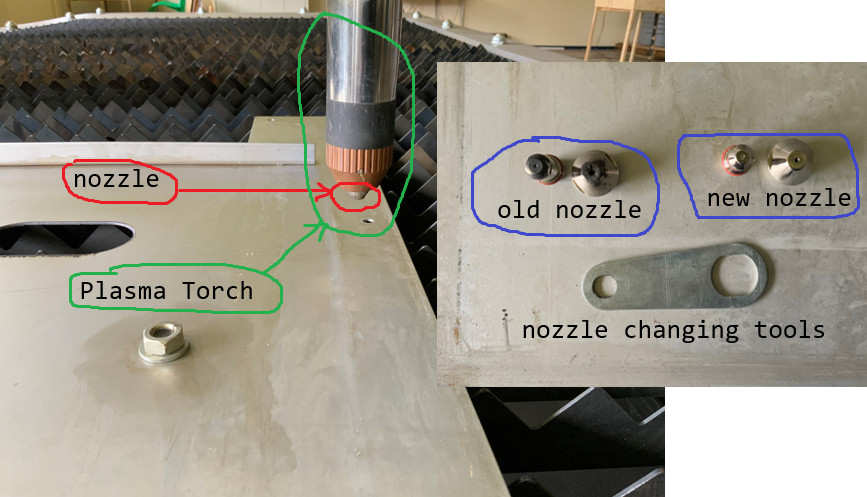

- First, we changed the nozzle as shown below

-

switch on plasma source, air compressor and water pumping station.

-

we set the plasma source to 63A as recommended above

-

we inserted the USB key containing the cutting file into the plasma cutter’s control panel as shown below

- Finally, we launched the cutting process with the green button as shown below and then pressed the Enter button.

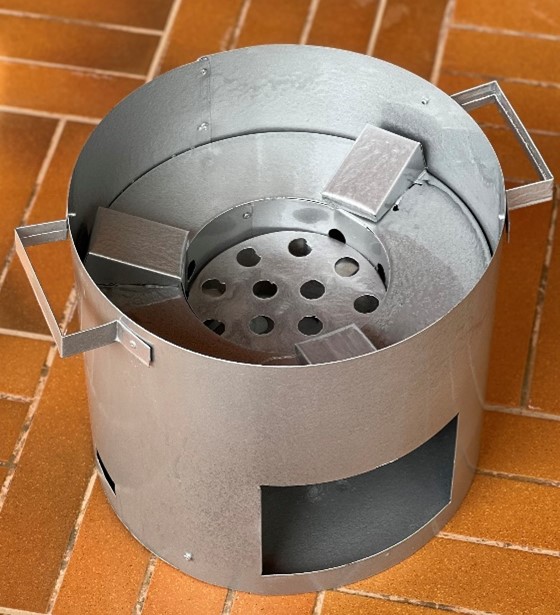

- Here are the different pieces we cut out after folding and bending them.

- The final result is

5. Conclusion¶

Plasma cutting is an interesting technology. We found it difficult to implement because we rarely use this machine and the documentation is in Chinese. Thanks to the “wildcard week” we improved our knowledge of this technology.

We will continue to use this technology by improving our ecological stoves or ecological fireplaces for low-income households. We have made other prototypes.

The idea is to improve our prototype and think about marketing it.