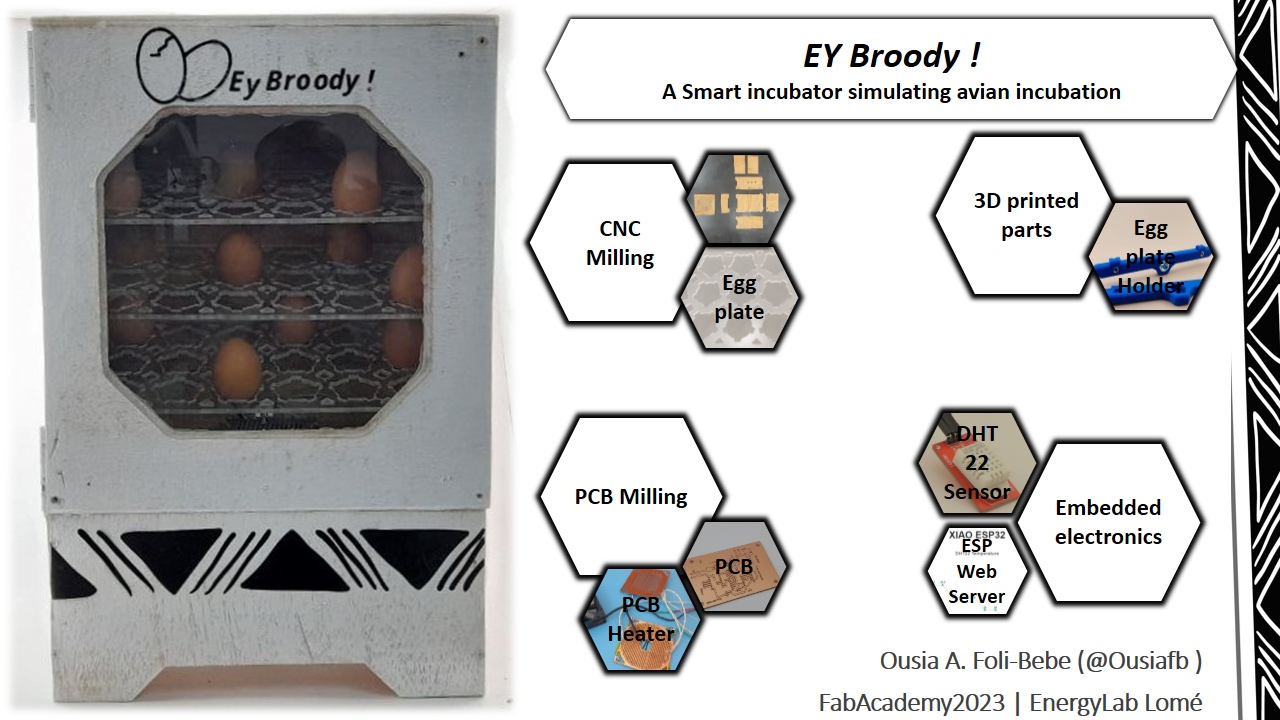

Hero Shot¶

3D design live Fusion 360¶

What does it do?¶

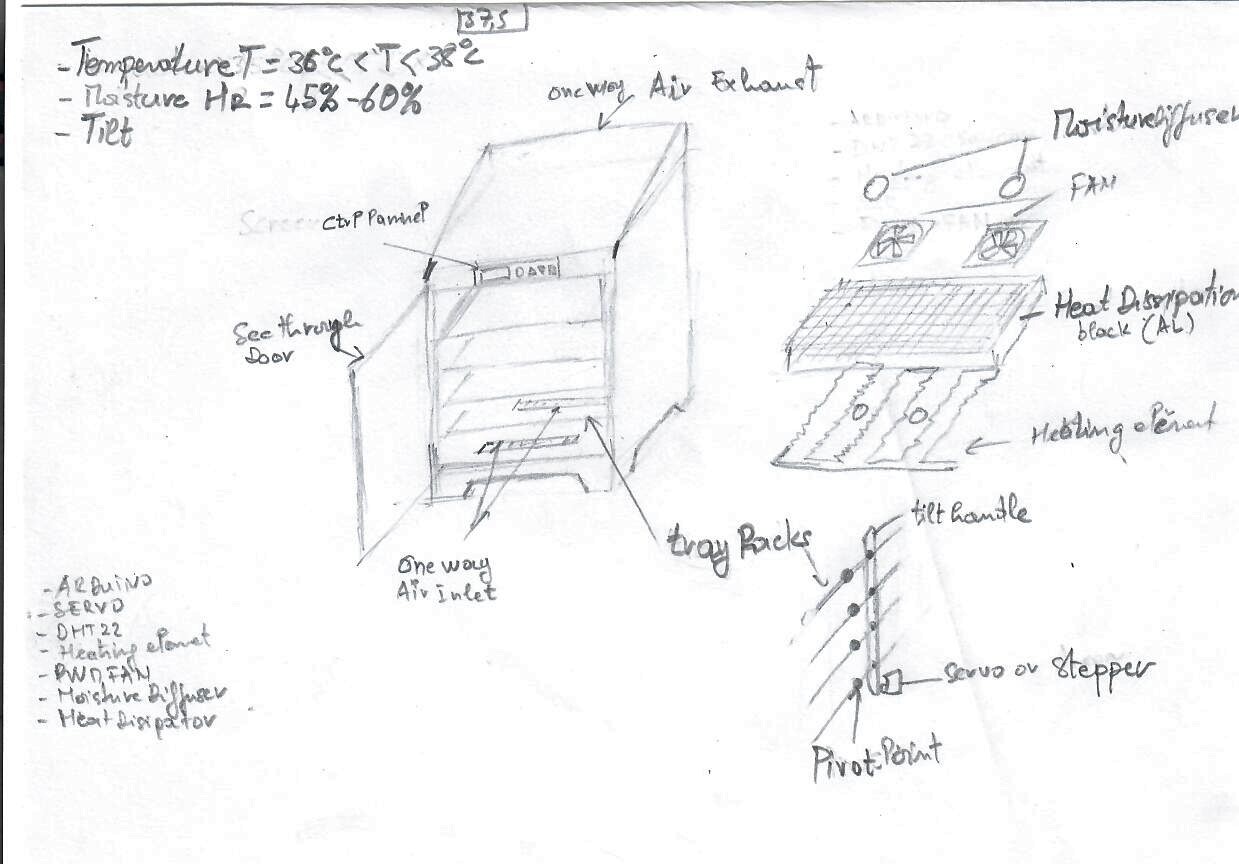

My project : EyBroody - Egg incubator for hatchery¶

My project is to make an Arduino controlled and possibly connected egg incubator. Egg incubators are machines that create the perfect conditions ( temperature, moisture, positioning) for an egg to incubate and hatch successfully. It’s designed to regulate incubation temperature and humidity at perfect levels there for playing the role of a broody hen.

It is used by farmers and used by farm providers to produce and sell chicks to farmers.

The functionalities I taught of :¶

Make an incubator that :

- Can set and efficiently control the temperature inside the incubator

- Can set and efficiently control the moisture inside the incubator when required ()

- Ensure energy efficiency through proper insulation and energy use.

- Have a programable cycle depending on the type of egg.

- is connected for live monitoring

- Log data for later analysis and use.

Who’s done what beforehand?¶

- Lucio Pentagna tried something similar on his fabAcademy Journey.

- ESP32 Web Server for Live date plotting Based on Random Nerd Tutorials

- NTP client to get date and time on Random Nerd Tutorials

- Use of telegram bot sensor monitoring

- Heater PCB trace Calculation

- Tilting Mechanism inspired By Quentin Bolsee’s beehive-axes

Research¶

To understand how incubators work and the required manipulations I have searched for and read through the following:

- Agromisa Agrodok No 34 PDF this gives me most of the needed information

- A professional Agricultural equipment seller website

- DIY Build on Youtube for a same similar project

First spiral¶

functionalities :¶

- Confirm a Heating element design choice

- Regulate the heating

- Implemented egg plat tilting function mechanism

- Value sending online

What did you design?¶

I have Designed:

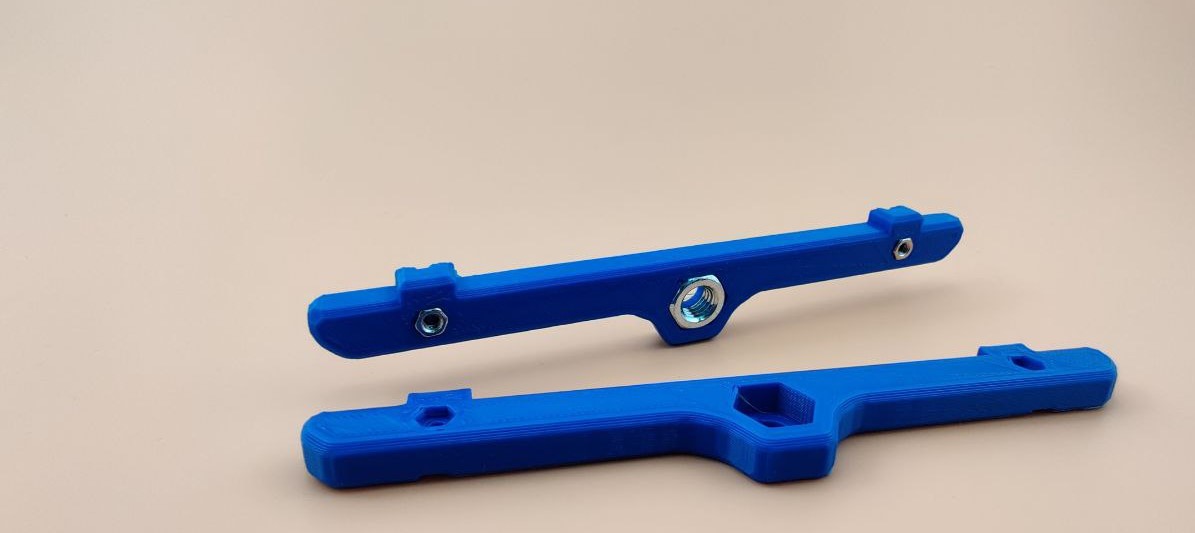

- the 3D printed parts for the tilting mechanism

- Tray,

- Tray holder;

- Stepper Mount;

- Mechanism Shaft;

- Stepper Spacer,

- The frame

- The PCB board

- The Logo

What processes were used?:¶

- 2D/3D design

- CNC Milling

- Electronic Design

- Electronic Production

- 3D Printing

- Solder (Reflow and Soldering iron)

- Embedded programming

- Network and communication

Design and fabrication results¶

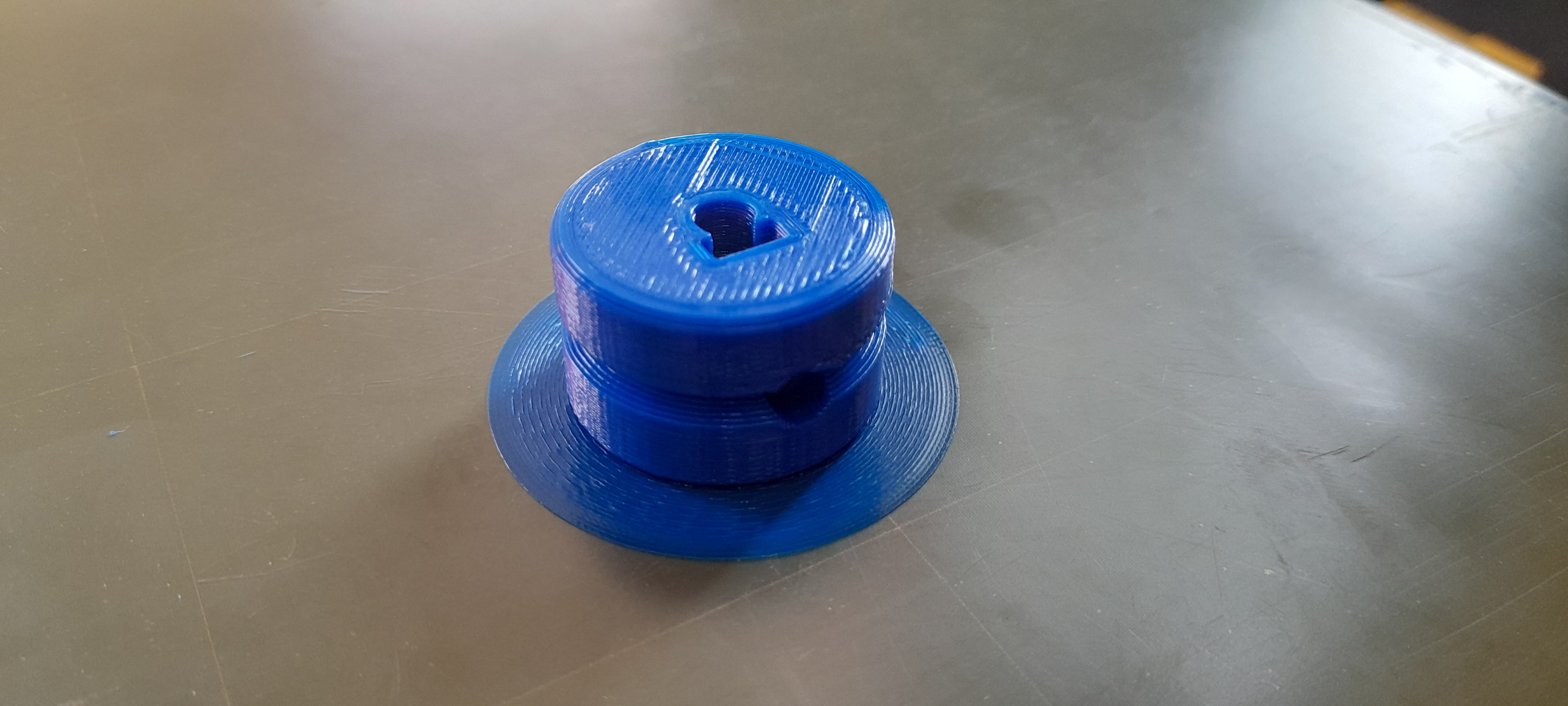

3D Design and printing¶

This part is the Shaft for the tilting Mechanism. It goes on the stepper axis and host the fishing line that used for the tilting mechanism.

Stepper shaft, mount and spacer design process

Bellow the egg Holders (3D designed and printed) that support the plate and host the fishing line for the tilting mechanism.

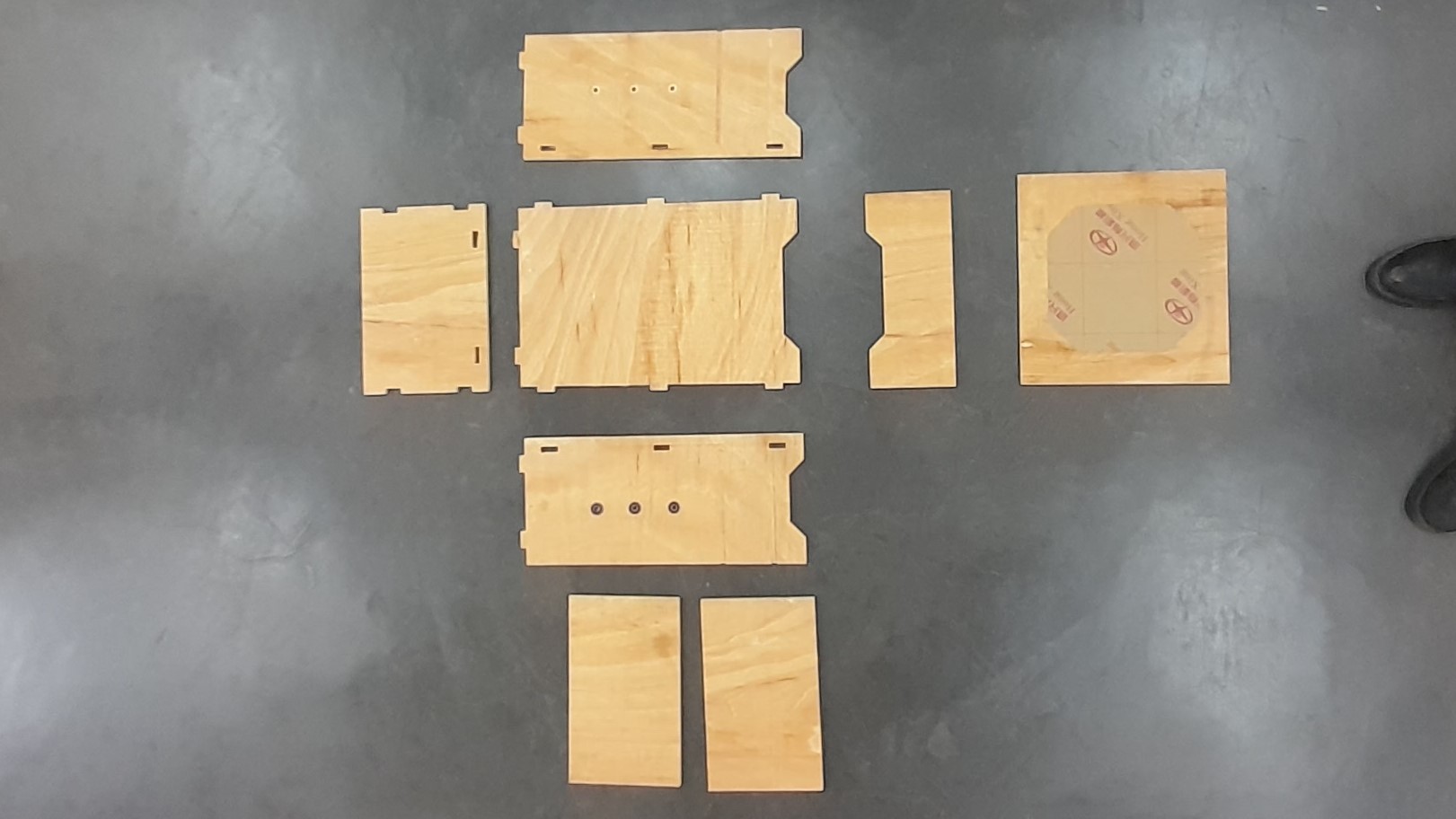

Milling¶

Frame¶

The egg incubator frame designed and Cuted as process shown on ‘Week 07 - Computer controlled machining’

Video of the steps for my 3D design

Egg plate Holder¶

the transparent plate is the parametric egg plate design milled with a CNC. It serves as tray to hold the eggs.

Egg plate design steps

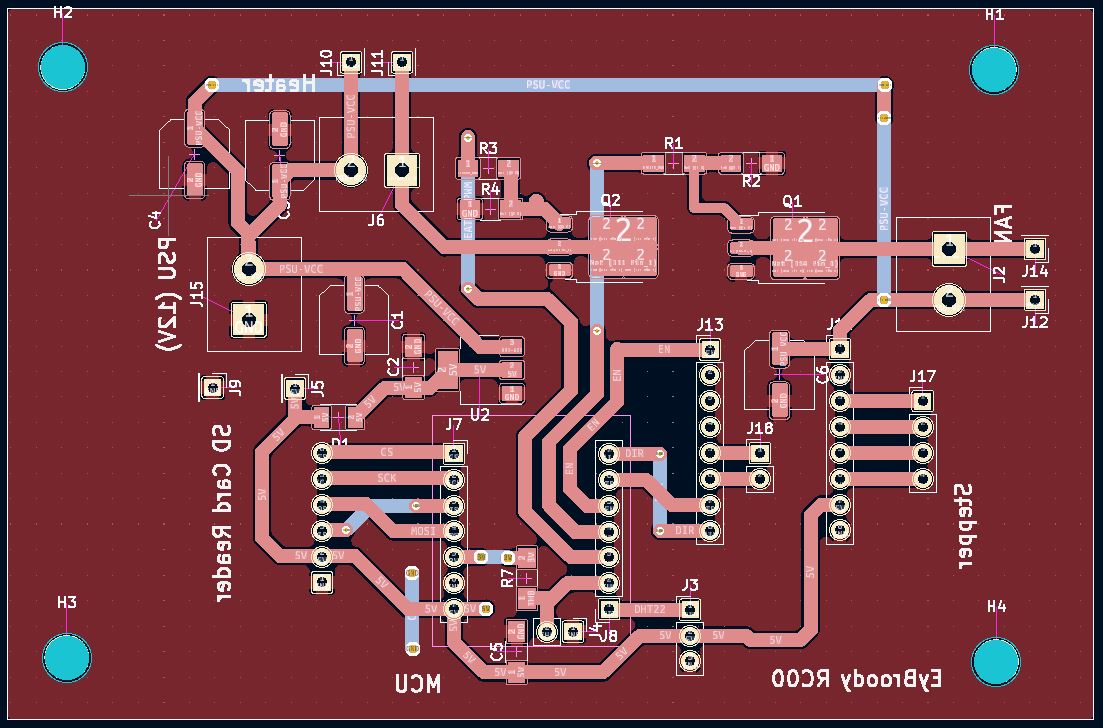

PCB Milling¶

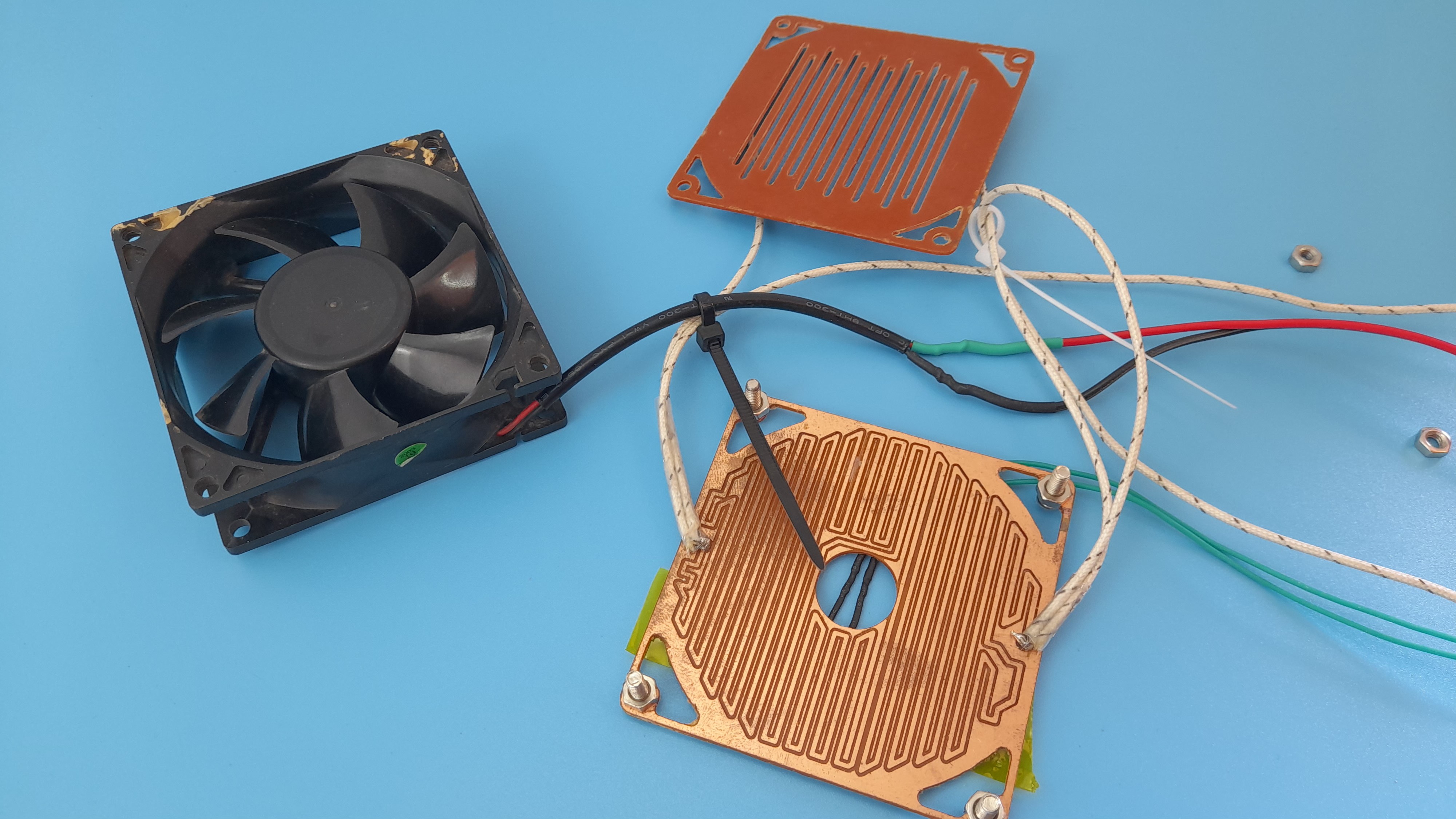

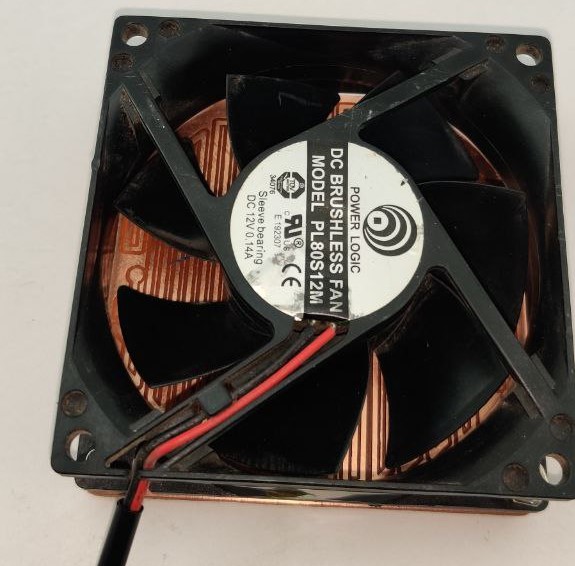

PCB Heater¶

PCB heater board design with KiCad and milled with a 3018 CNC

The heater system ready to be assembled

Partial assemble of the heater system

Complete assembly of the heater system

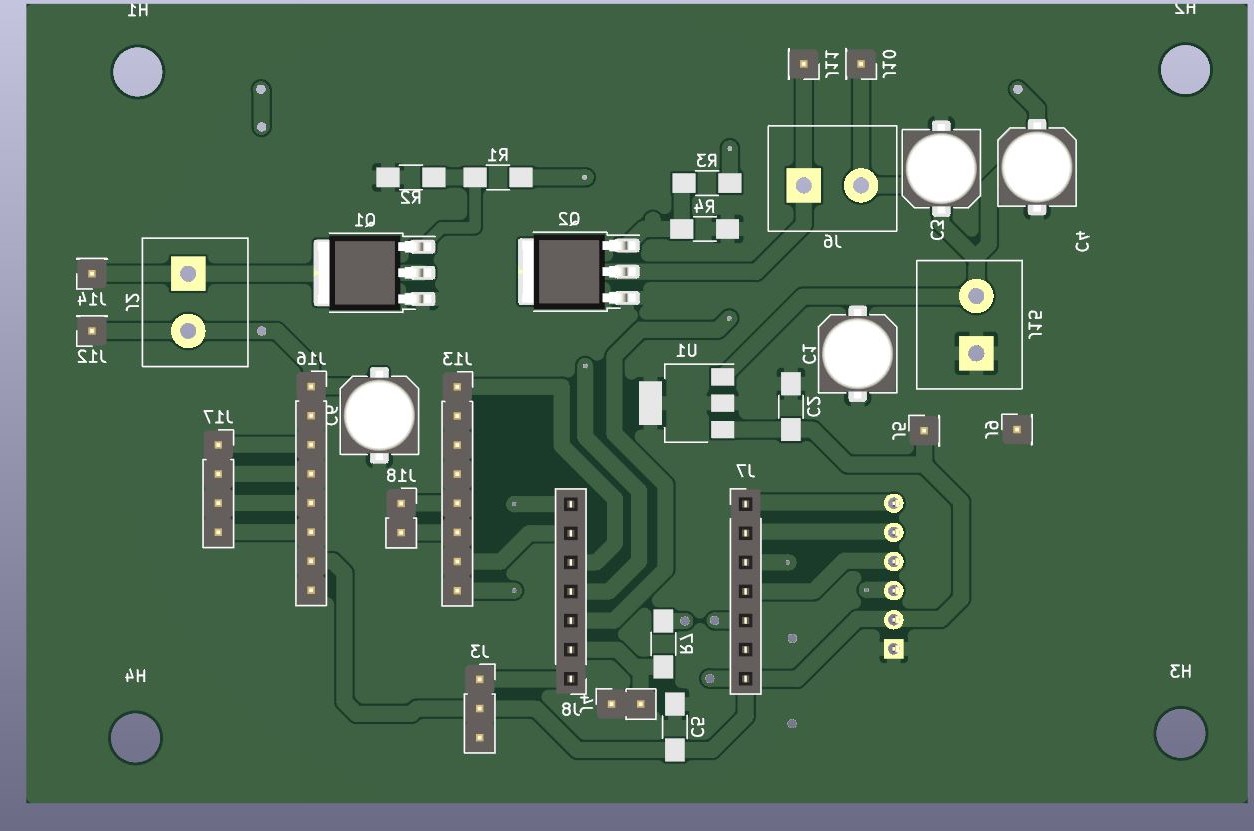

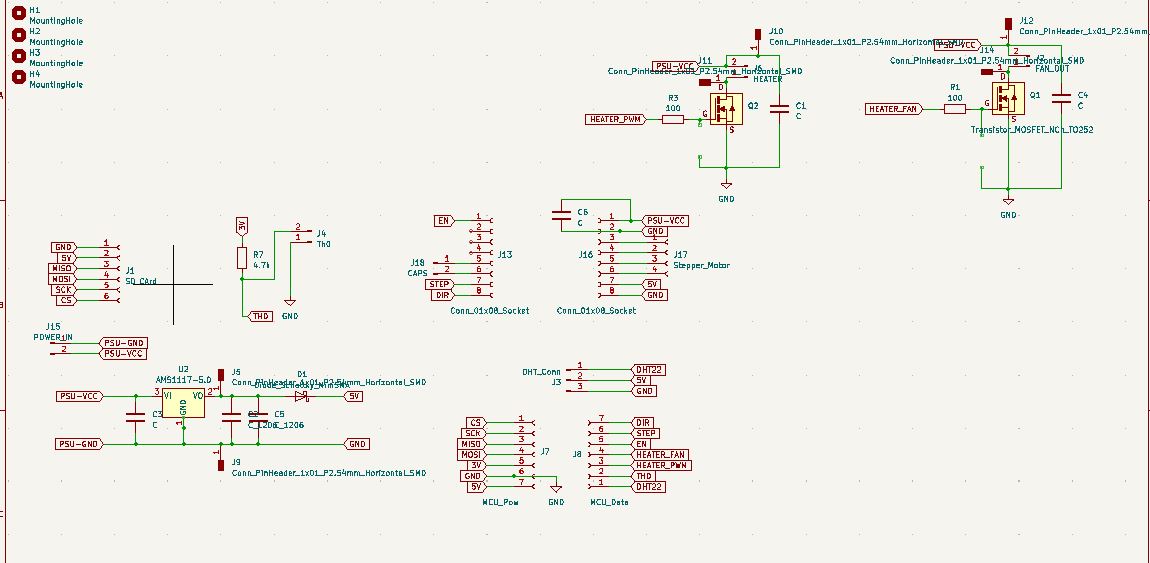

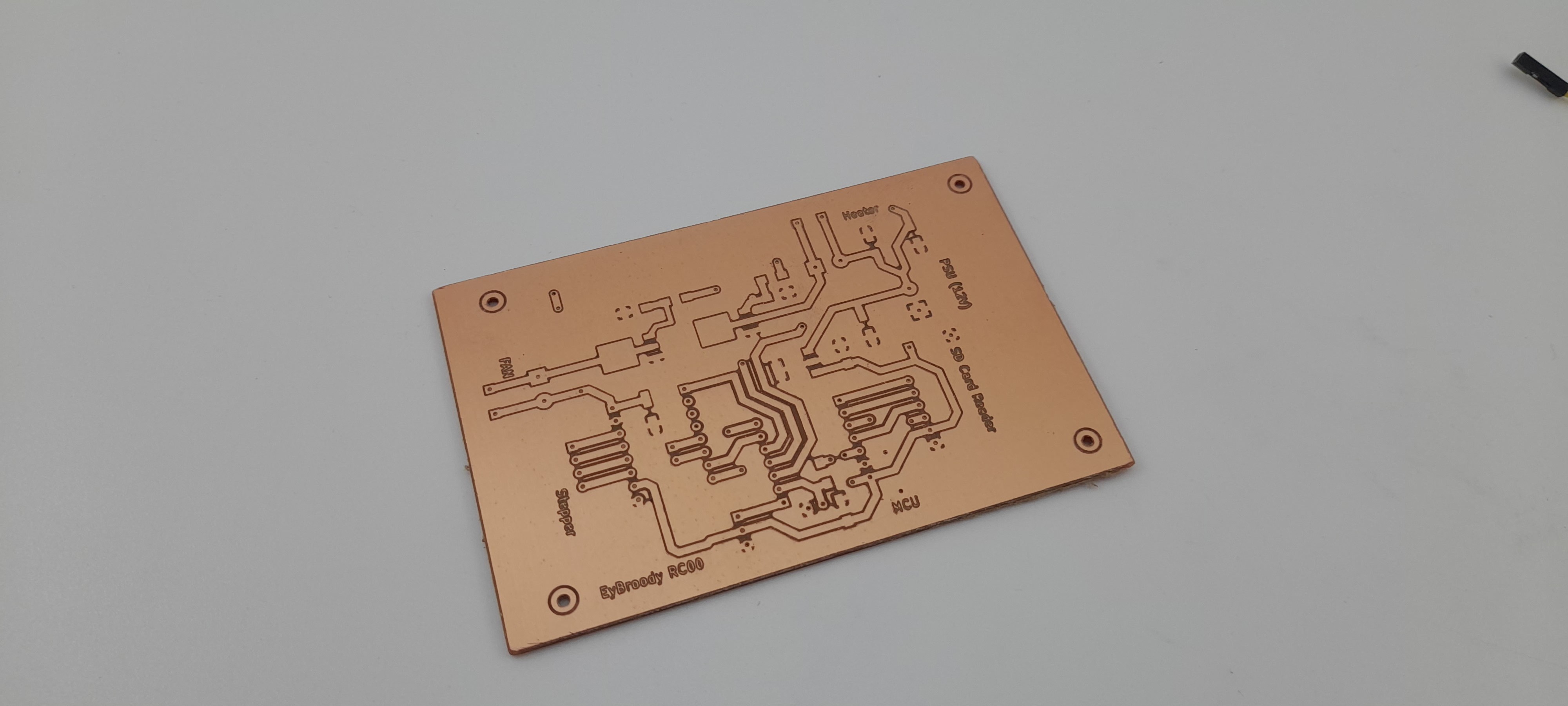

Electronic design-KiCad¶

Control board was design in KiCad

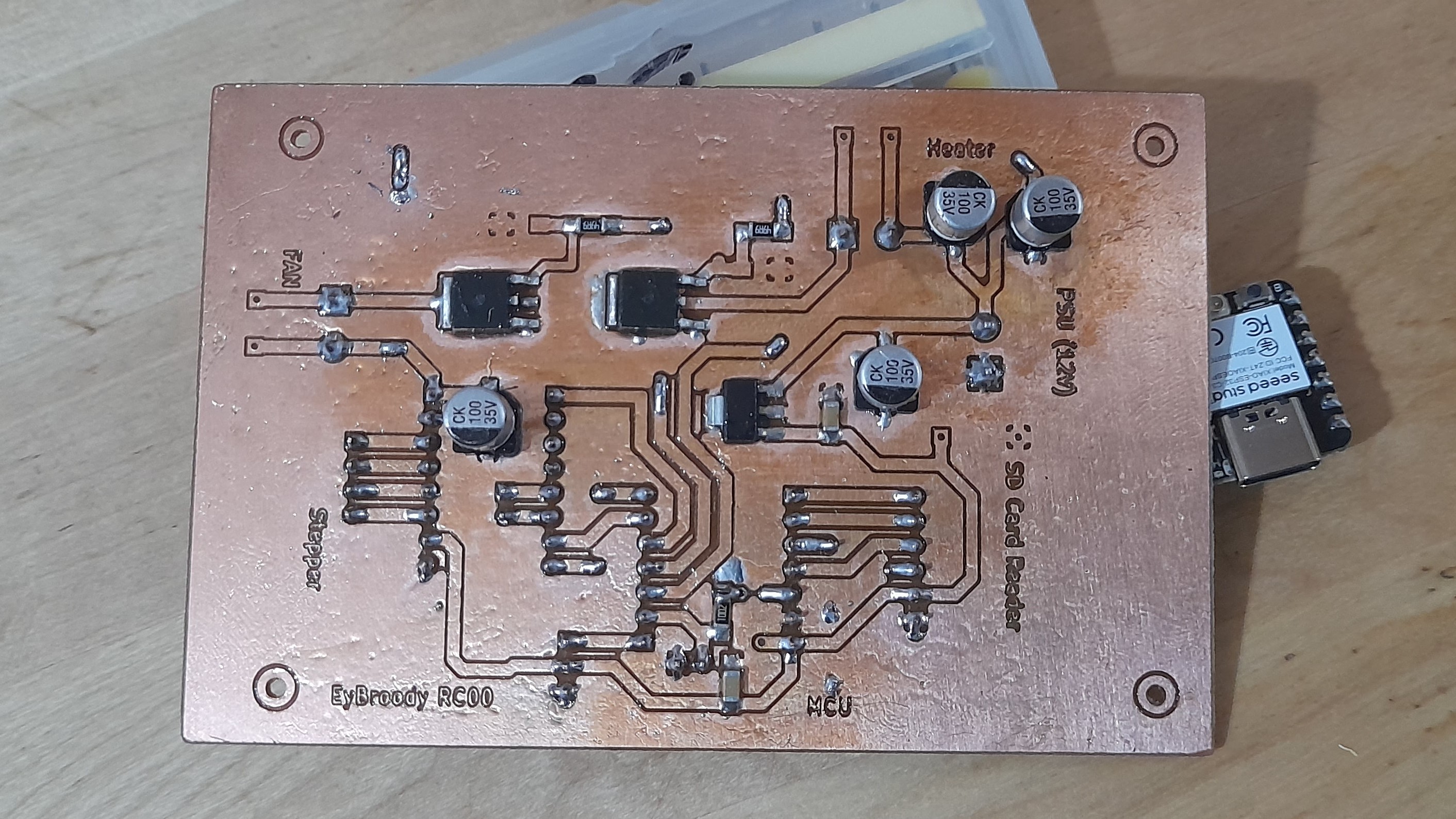

A picture of the milled PCB board

Picture of the Board after SMD component soldering (bottom Side)

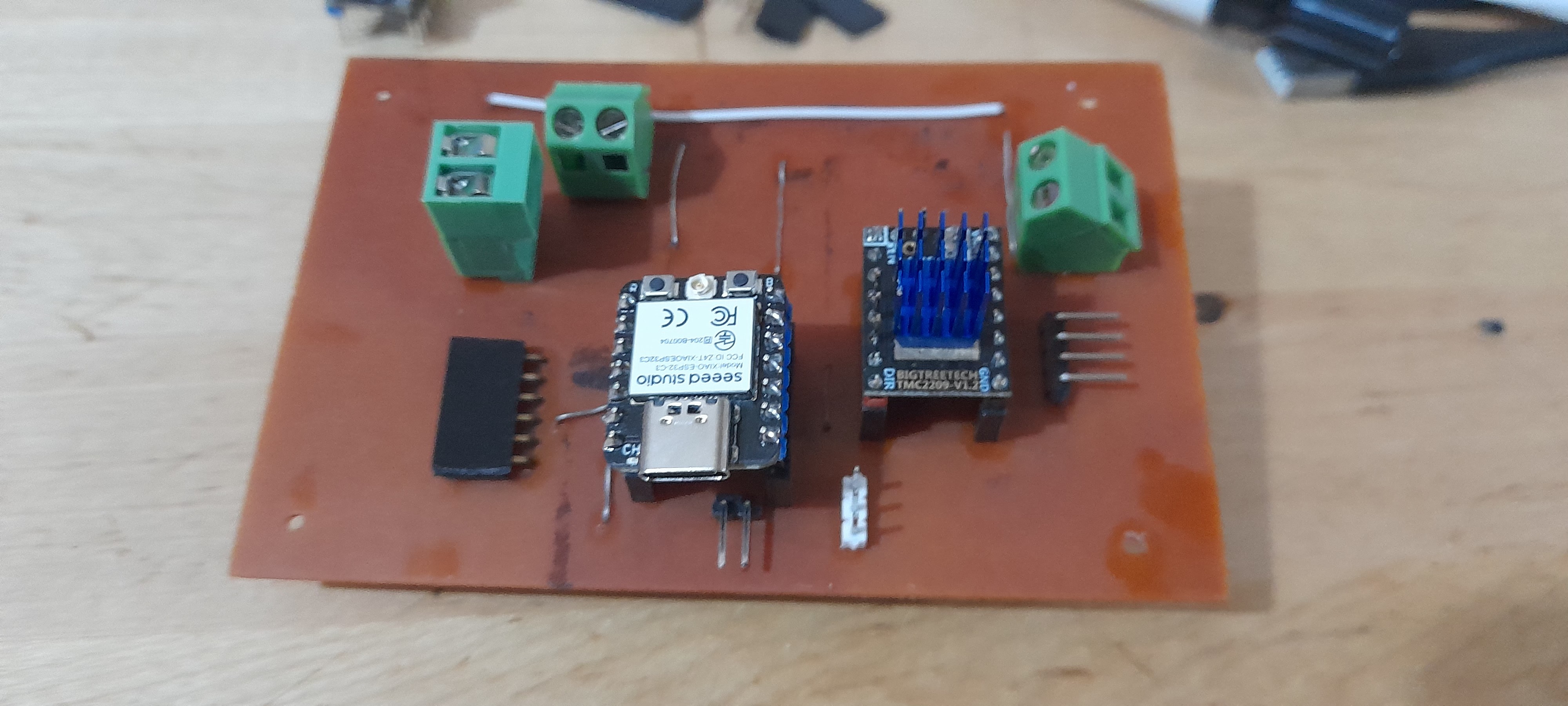

Picture of the board with the Trough Hole Components (Top Side)

Plate Tilting Mechanism¶

Link to weeks that contributed to the finale project:¶

- on ‘Week 02 - Computer Aided design’: I have made My logo Design to be cutted wih the vinyl cutter as Sticker. and I have design the Parametric Egg plate and started the design of my Frame

- On ‘Week 04 - Embedded programming’: I have confirmed the use of telegram bot as a way to interact with my incubator.

- On Week 07 - Computer controlled machining’: I have Cutted a design of my frame with the CNC and got Joinery feedback From professor Neil

- On Week ‘08 - Electronics production’: I have tried the PCB heater.

- On Week ‘09 - output devices’: I have Milled stepper output and a Mosfet PWM board to test their use on my project.

- On ‘Week 14 - Interface and application programming’: I have confirmed the live data plotting with the ESP server

- On ‘Week 14 - Interface and application programming’: I have confirmed the live data plotting with the ESP server

- On ‘Week16 - Applications and Implications’: I have checked my plans for the project and improved the BOM

- On ‘Week 17 - Invention, Intellectual Property and Business Models’: I have decided the license for my project

For next spirals:¶

- Moisture regulation system implementation

- SD Card Data logging

- Telegram bot for feed Back and remote control

- …

What materials and components were used? # Where did they come from?# How much did they cost?¶

Bill of materials¶

| index | name | Qty | Cost | Total | Description | Origin |

|---|---|---|---|---|---|---|

| 1 | Plywood sheet | 0.5 | $ 18.35 | $ 9.18 | For the frame | Local Market |

| 2 | Plexiglass sheet | 0.25 | $ 30.03 | $ 7.51 | for the see trough part and plate | Local Market |

| 3 | XIAO ESP 32 Board | 1 | $ 1.95 | $ 1.95 | MCU | www.amazon.com |

| 4 | Resistor (2x4.7k and one 10K ohms ) | 3 | $ 0.40 | $ 1.20 | PCB | www.digikey.com |

| 6 | Capacitor 35V 100uF | 6 | $ 0.30 | $ 1.80 | PCB | www.digikey.com |

| 6 | N-Ch Mosfet ( SUD50N03-06AP-E3) | 3 | $ 1.00 | $ 3.00 | PCB | www.digikey.com |

| 7 | Dht 22 | 2 | $ 9.50 | $ 19.00 | PCB | www.aliexpress.com |

| 8 | 10K NTC thermistor | 1 | $ 2.00 | $ 2.00 | PCB | www.aliexpress.com |

| 9 | 80 mm 12V DC Fan | 3 | $ 4.00 | $ 12.00 | PCB | www.aliexpress.com |

| 10 | handle and hinges | 1 | $ 8.00 | $ 8.00 | PCB | Local Market |

| 11 | Stepper Driver TMC2209 | 1 | $ 7.00 | $ 7.00 | PCB | www.aliexpress.com |

| 12 | 0.42N.m 40mm Nema 17 Stepper Motor | 1 | $ 25.00 | $ 25.00 | Tilting Mechanism | www.digikey.com |

| 13 | M8 bolt | 6 | $ 0.80 | $ 4.80 | Tilting Mechanism | Local Market |

| 14 | M3 bolt | 12 | $ 0.10 | $ 1.20 | Tilting Mechanism | Local Market |

| 16 | 12V30A PSU | 1 | $ 24.00 | $ 24.00 | PCB | www.aliexpress.com |

| 17 | DC Connector screw plug terminal | 4 | $ 1.25 | $ 5.00 | PCB | www.aliexpress.com |

| 18 | Dupont Pin Headers 2.54mm | 6 | $ 0.60 | $ 3.60 | PCB | www.aliexpress.com |

| 19 | Fused AC Power Socket | 1 | $ 4.50 | $ 4.50 | PCB | Local Market |

| 20 | hinges | 3 | $ 0.60 | $ 1.80 | For the frame | Local Market |

| 21 | Screws | 24 | $ 0.10 | $ 2.40 | For the frame | Local Market |

| 22 | 608 ZZ ball bearing | 6 | $ 0.30 | $ 1.80 | Tilting Mechanism | www.aliexpress.com |

| 23 | 3D printing filament | 1 | $ 10.00 | $ 10.00 | 3D printed parts | www.aliexpress.com |

| 24 | ||||||

| Total | $ 156.73 |

What parts and systems were made?¶

Things we made¶

| index | name | Qty | Cost | Source |

|---|---|---|---|---|

| 1 | PCB heater | 1 | 6 | |

| 2 | egg holder system | 1 | 9 | |

| 3 | Stand off PCB Fixture | 1 | 1 |

What questions were answered?¶

The goals for our first spiral were all reached.

- Confirm a Heating element design choice

- Regulate the heating

- Implemented egg plat tilting function mechanism

- Value sending the web server

What worked? What didn’t?¶

- While milling my board a have mirror it so the trough hole components sit o top of the non coper surface but flipped it on the wrong Axis and had to re-o it. Appart of that the rest was okay.

- We have to optimize our PWM Mosfet control for the heating system and redesign a better PCB heater.

- From feedback From my Instructor and Professor Neil I have to optimize my PCB Heater Tracks width

How was it evaluated?¶

The evaluation were made on the following criteria:

- The heating system is working

- the heating is being regulated

- The egg plate is tilting

- Value are being plot on the web server

What are the implications ?¶

To make this product marketable here in Africa we need to optimize it final cost and material use that make it look of quality but at an affordable price. but the FacAcademy achievement are already a very good start to build on.

Project Licence¶

Project under CC BY-SA.

Under the CC BY-SA license, anyone is free to share, adapt, remix, and build upon the licensed work for any purpose, even commercially. This license encourages the creation of derivative works by permitting modifications, translations, or adaptations of the original material.

SA: However, it requires that the resulting work be distributed under the same license terms, meaning that any modifications or adaptations must be shared under the CC BY-SA license as well.

BY: The license requires attribution, so anyone using the work must give appropriate credit to the original creator. This ensures recognition of the original author’s contribution and provides transparency regarding the source of the work. Additionally, the license requires that any public distribution or display of the work includes a copy or a link to the license itself.

The CC BY-SA license promotes the principles of collaboration, openness, and sharing, enabling a vibrant ecosystem of creativity and knowledge. It fosters a community where individuals can freely contribute to and build upon the creative works of others, facilitating the growth and dissemination of culture and ideas.

Project Files:¶

3D designs For¶

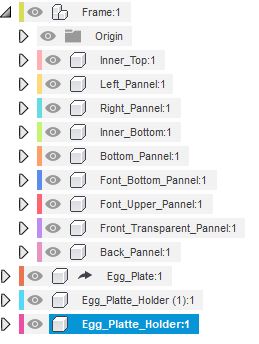

- 3D design Fusion360 file splitted in two parts zip file: Part 01 of 02 and Part 02 of 02 Contains:

- The frame (Frame wooden parts and Transparent acrylic panel Both can be CNC Milled or Laser cutted)

- The Egg plate (Laser Cutting or CNC milling)

- The Egg plate holders (3D printed)

3D Design file hierarchy in picture Bellow:

Electronic design and PCBs¶

- PCB Control board design KiCad Archive

- PCB Heater_Bottom board design KiCad Archive

- PCB Heater_Top board design KiCad Archive