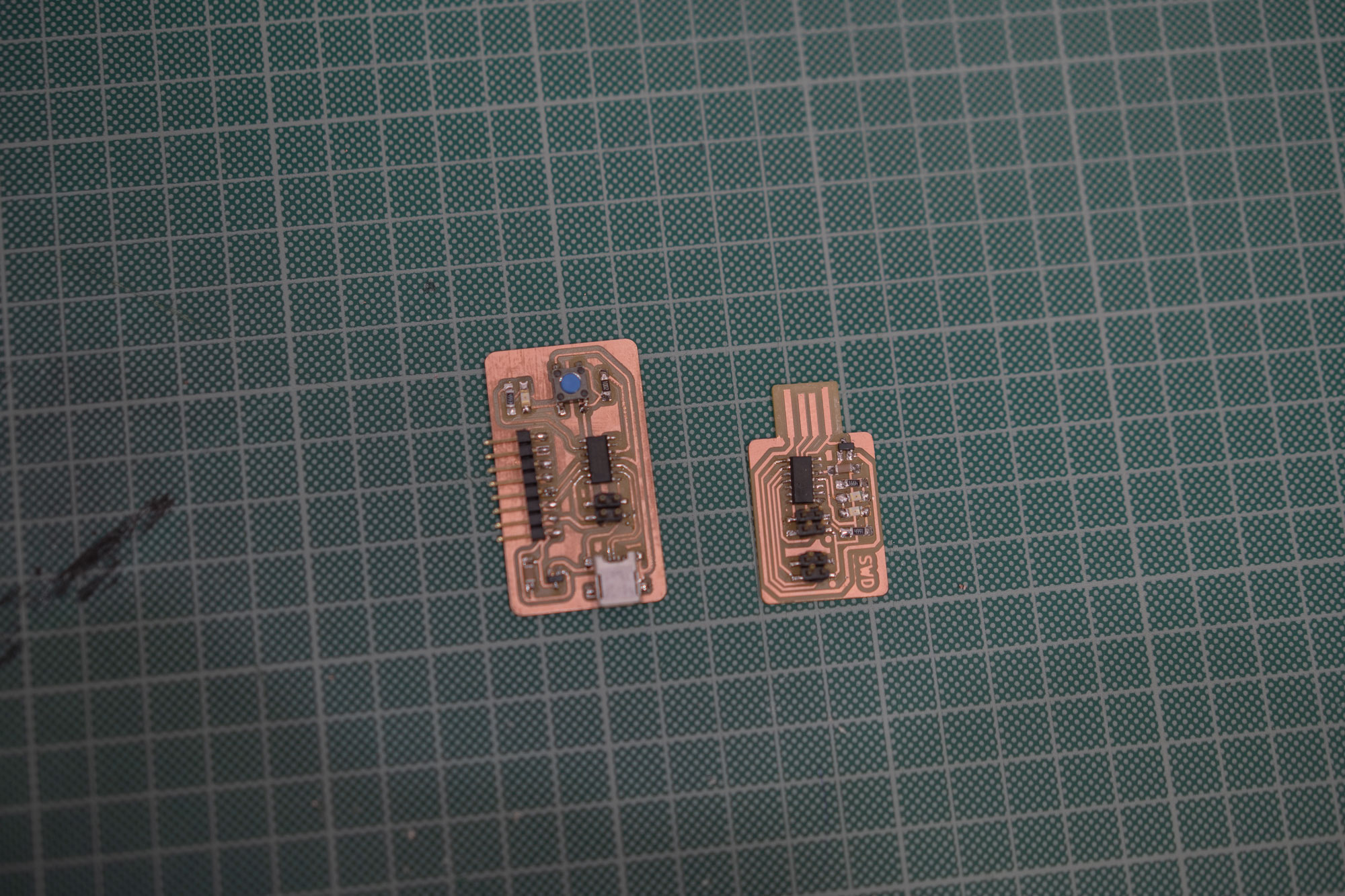

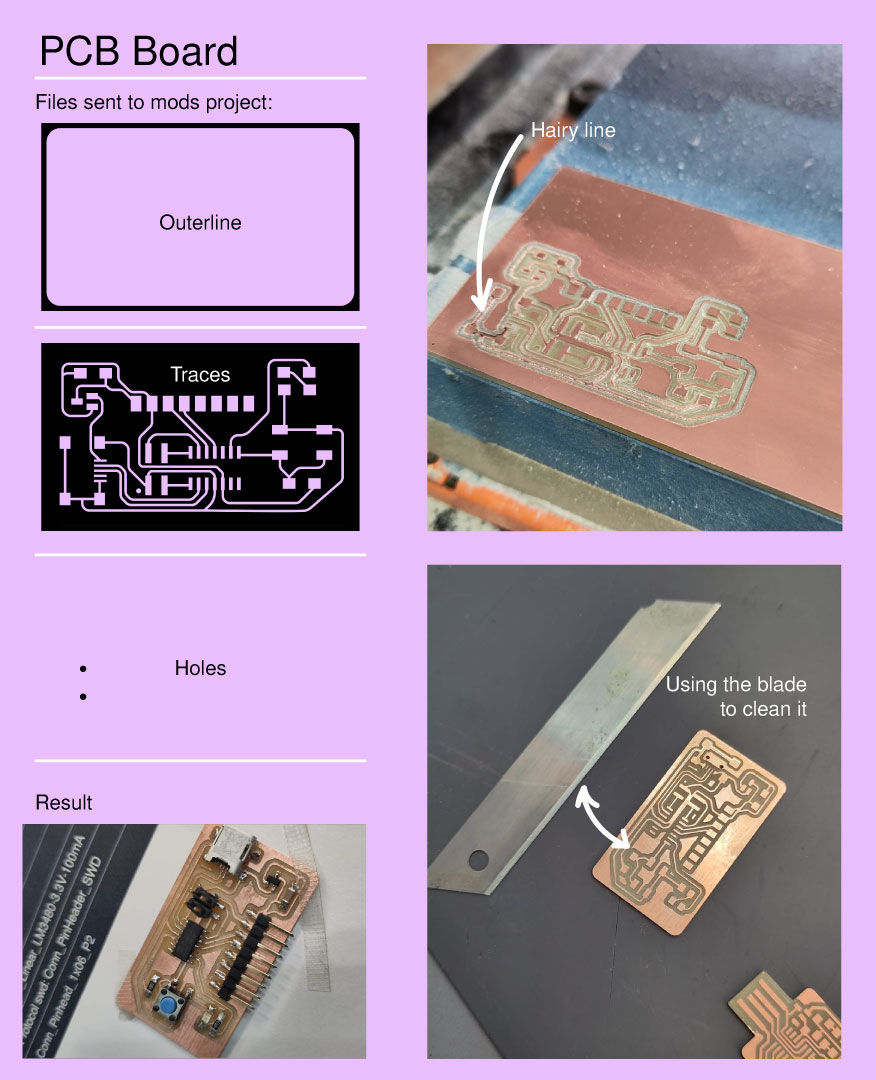

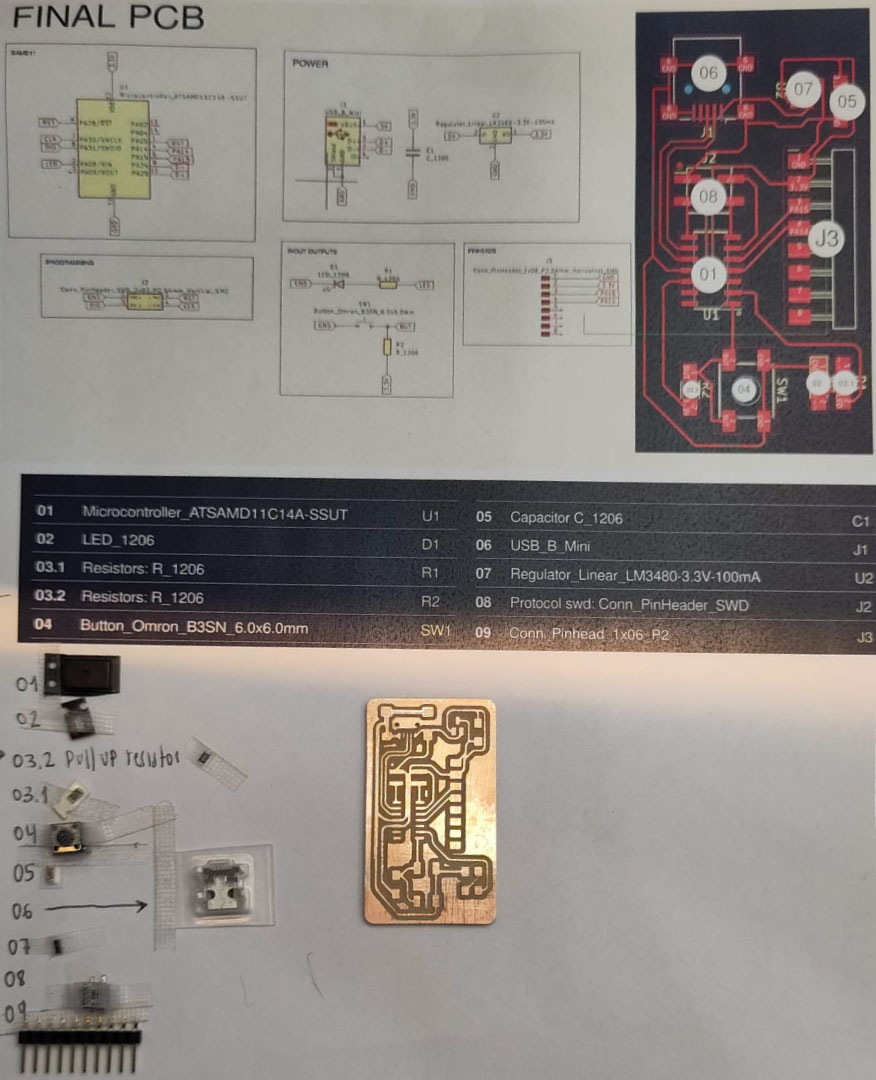

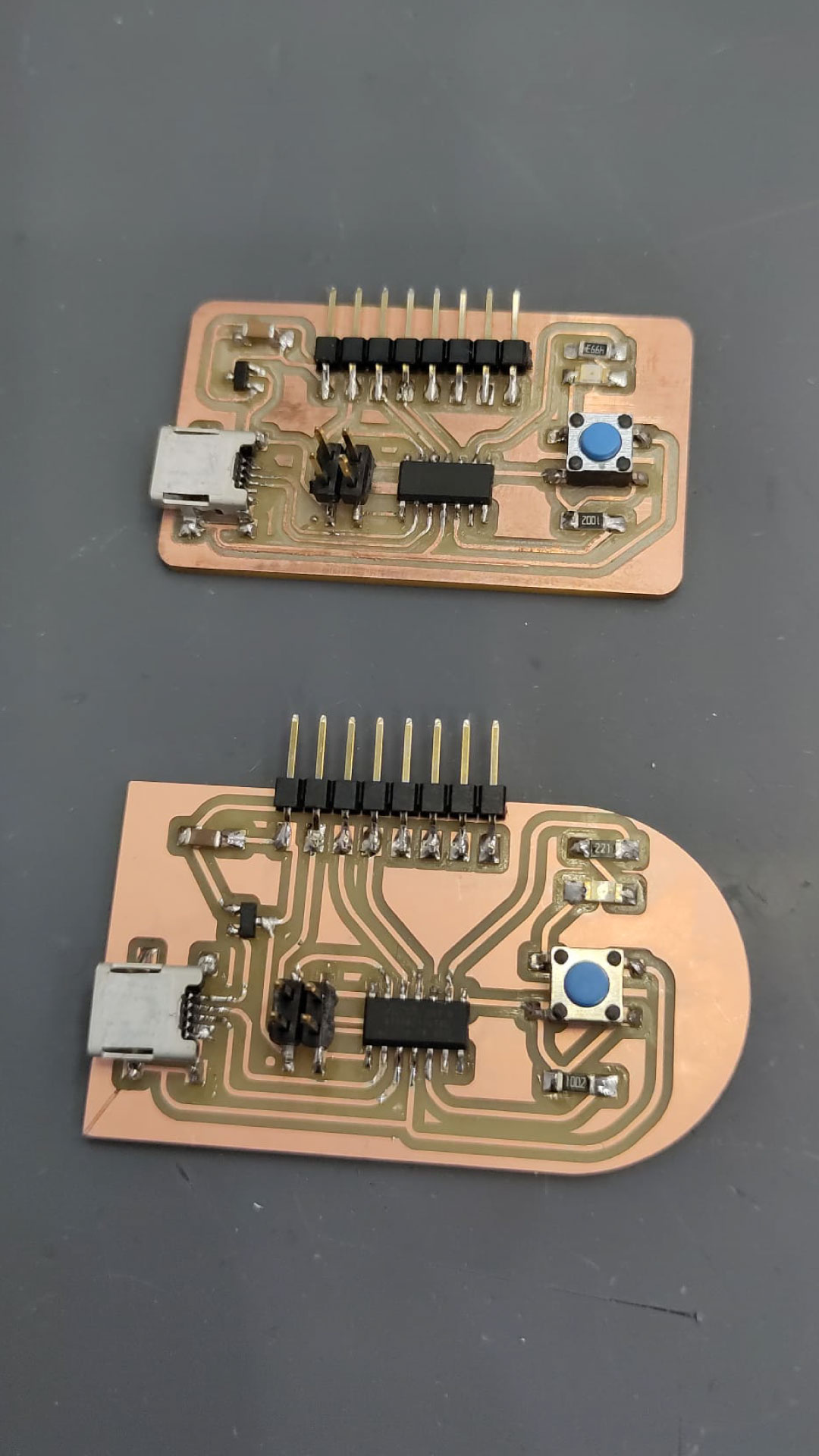

PCB printed circuit board, there are many types and process on how to produce them like with acid, cnc milling or cut it in the vinyl cutter.

The ones that we will be using are FR1: this mean the material inside the coper is phenolic resin. It is standard the amount of thickness through all the boards.

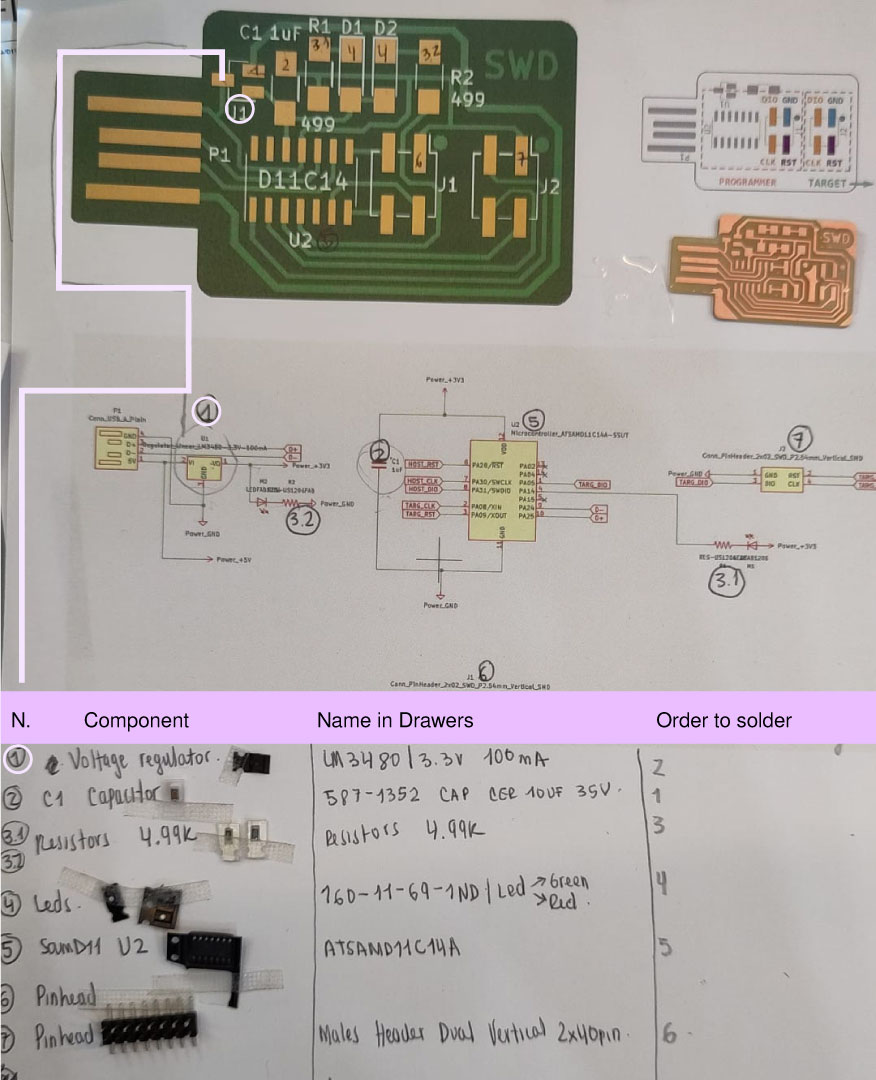

Design Rules:

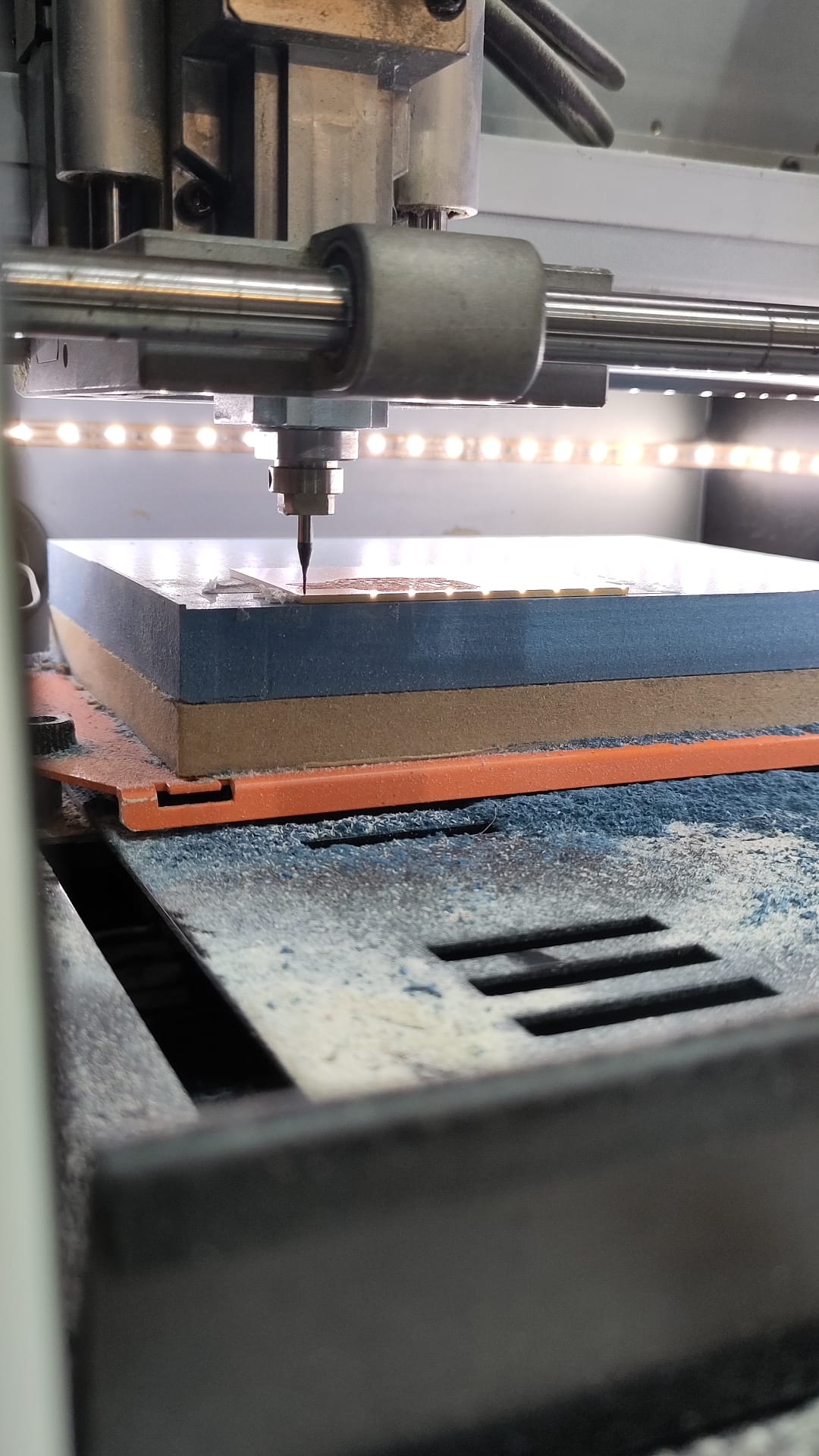

The distance between the traces needs to be at least the size of the end mill. We are using two different ones.

1. 1/64 inch (0.4mm) for doing traces * This is why in kicad, we were designing considering the clearance of the end mill.

2. 1/32 inch (0.8mm) for the holes and outlines.

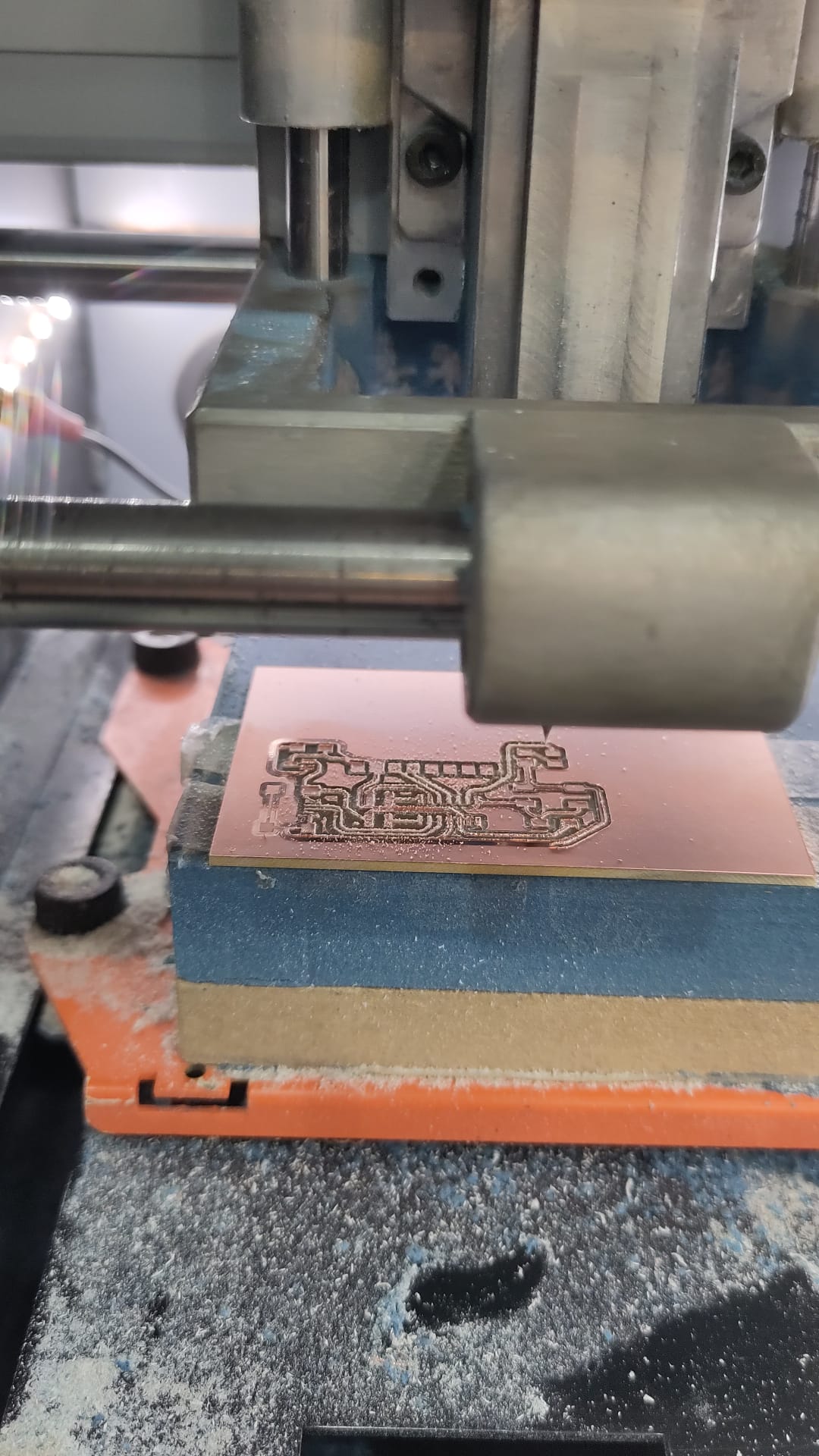

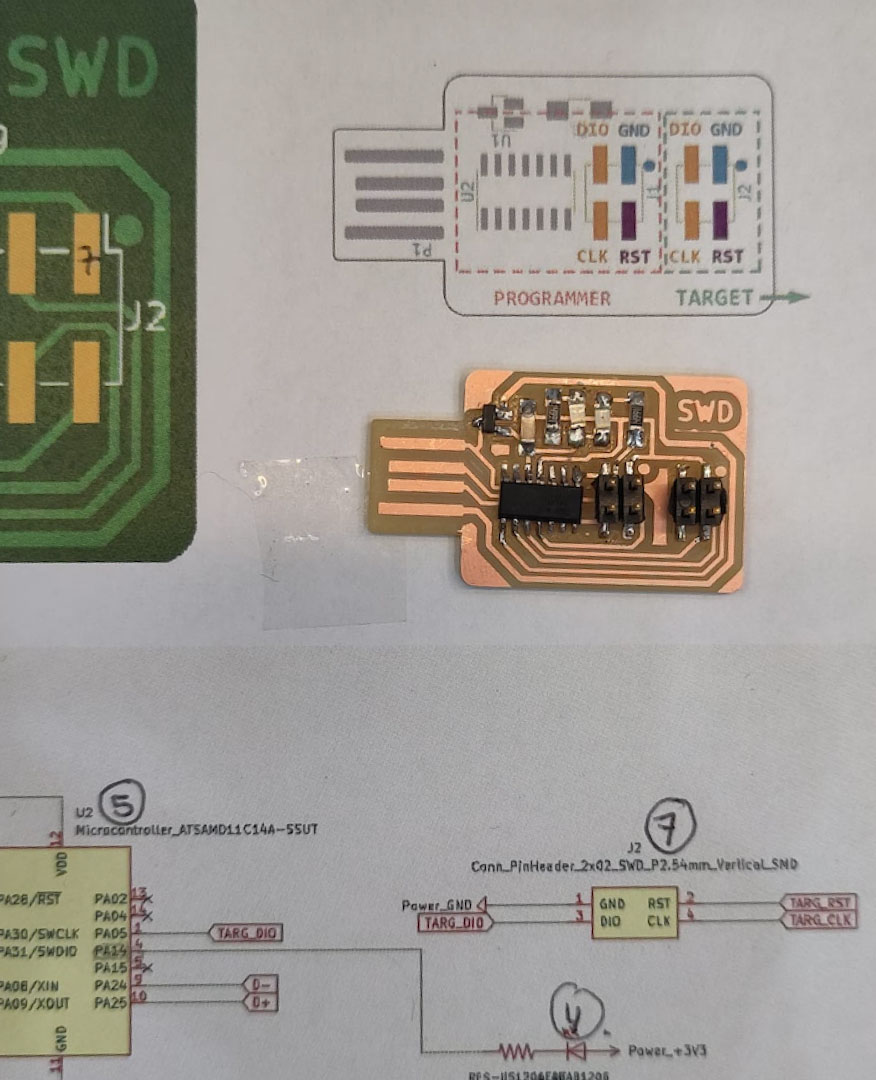

Prepare the files from kicad and Mods

1. We need to export as SVG from the PCB Editor in kicad, then a pop up window comes and we need to choose what to export, in this case the copper layer, the edge cuts, black and white for print mode and the board area only for the svg page size.

2. Export to illustrator as the svg to divide the files into inner lines, holes and outer cut. Whatever is in white we are going to keep it and whatever is in black gets cut.In the case of the inner lines I added more radius to the corners so it will look more smooth.

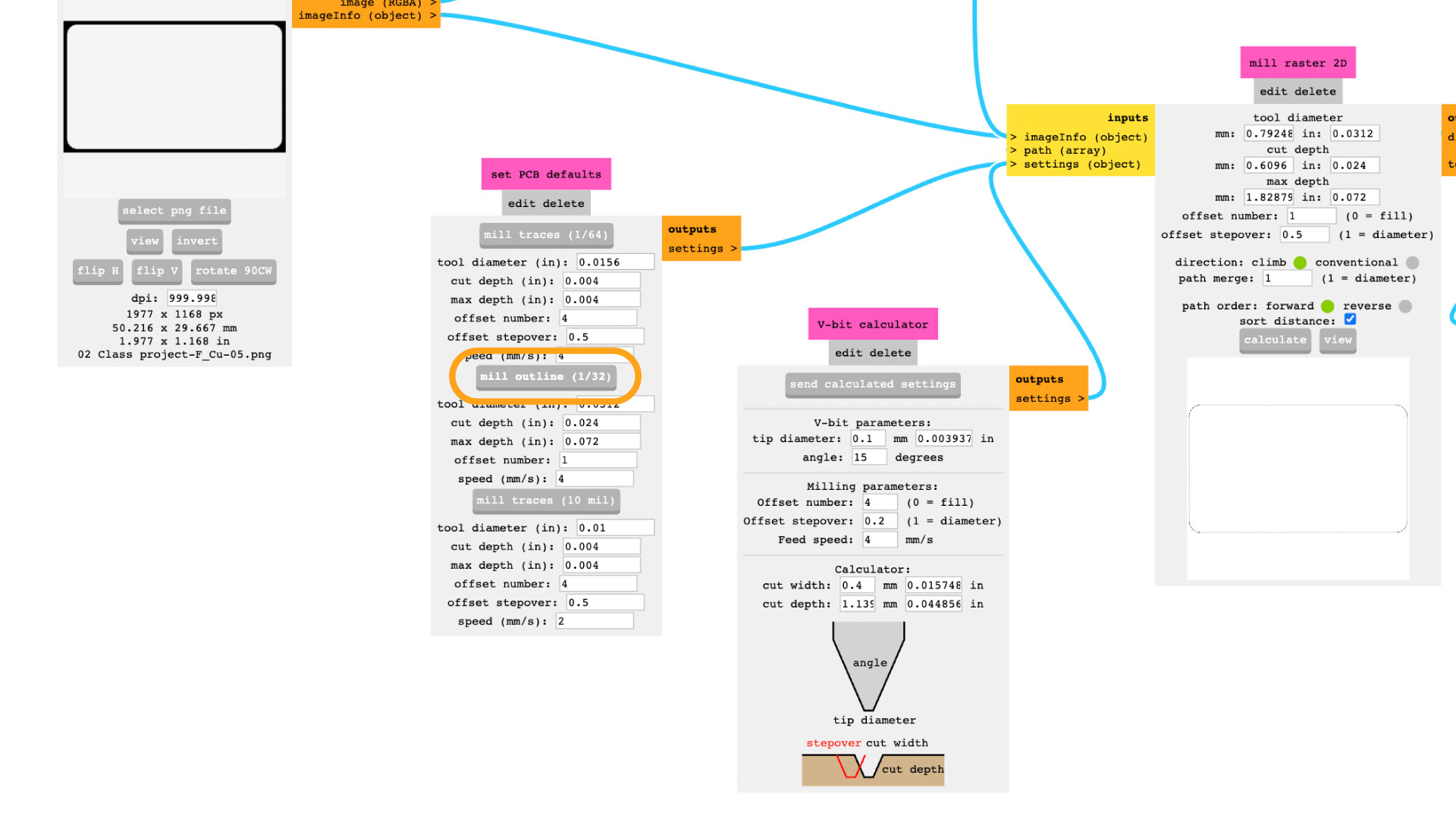

3. Mods to export the files for the SMR-20