Molding is used to create a negative impression of an original object, while casting involves pouring a material such as molten metal or plastic into the mold to create a duplicate of the original.

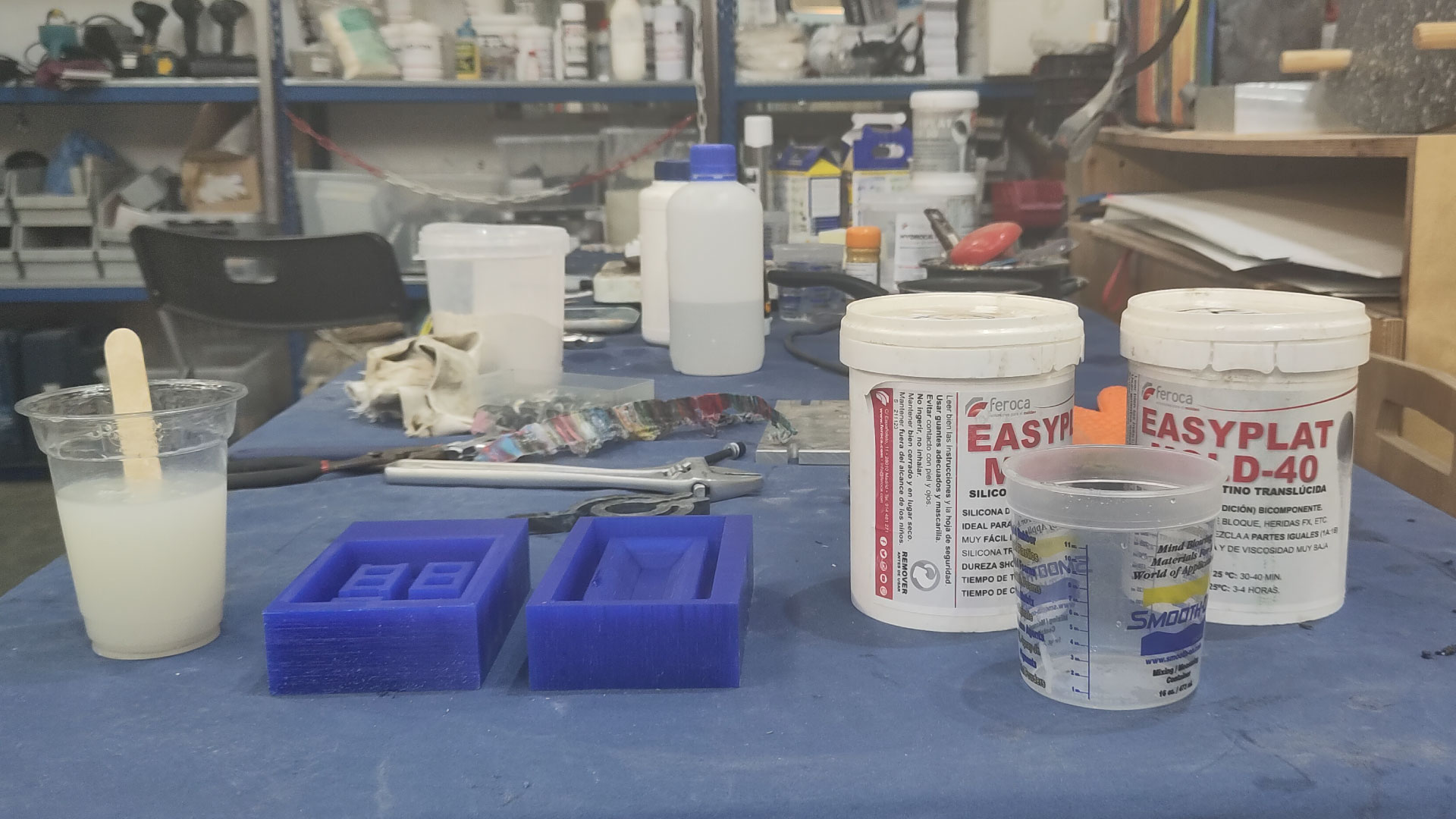

So we will use silicone to create the mold because of its properties, it doesn't stick to anything and then we will be able to unmold it. The downside of it is not easy to reuse once is casted.

In order to cast, first we need to pour a liquid material into a mold which contains a hollow cavity of the piece that we design, then this liquid solidifies into the part created. There are several process in order to get the cast piece.

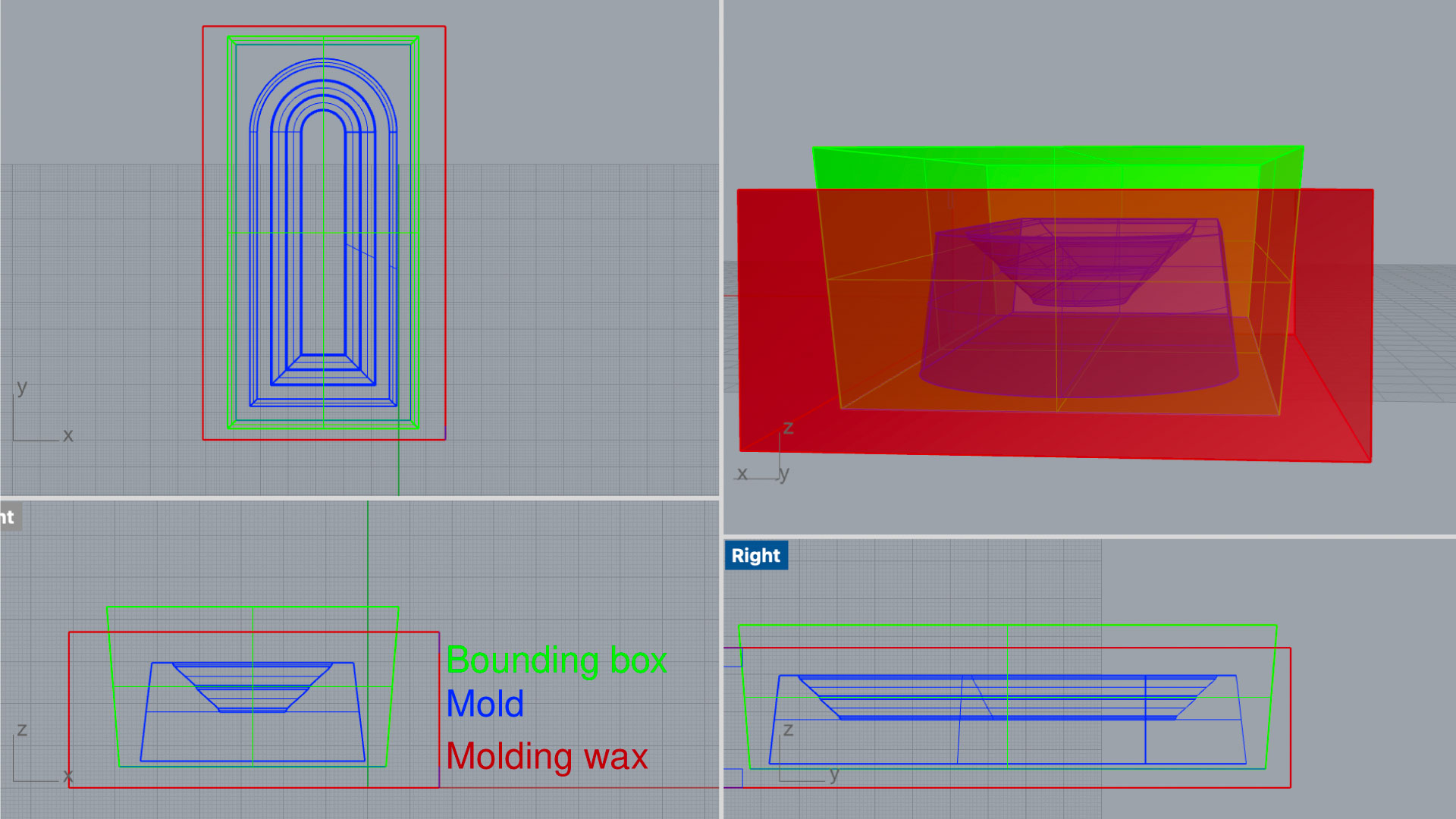

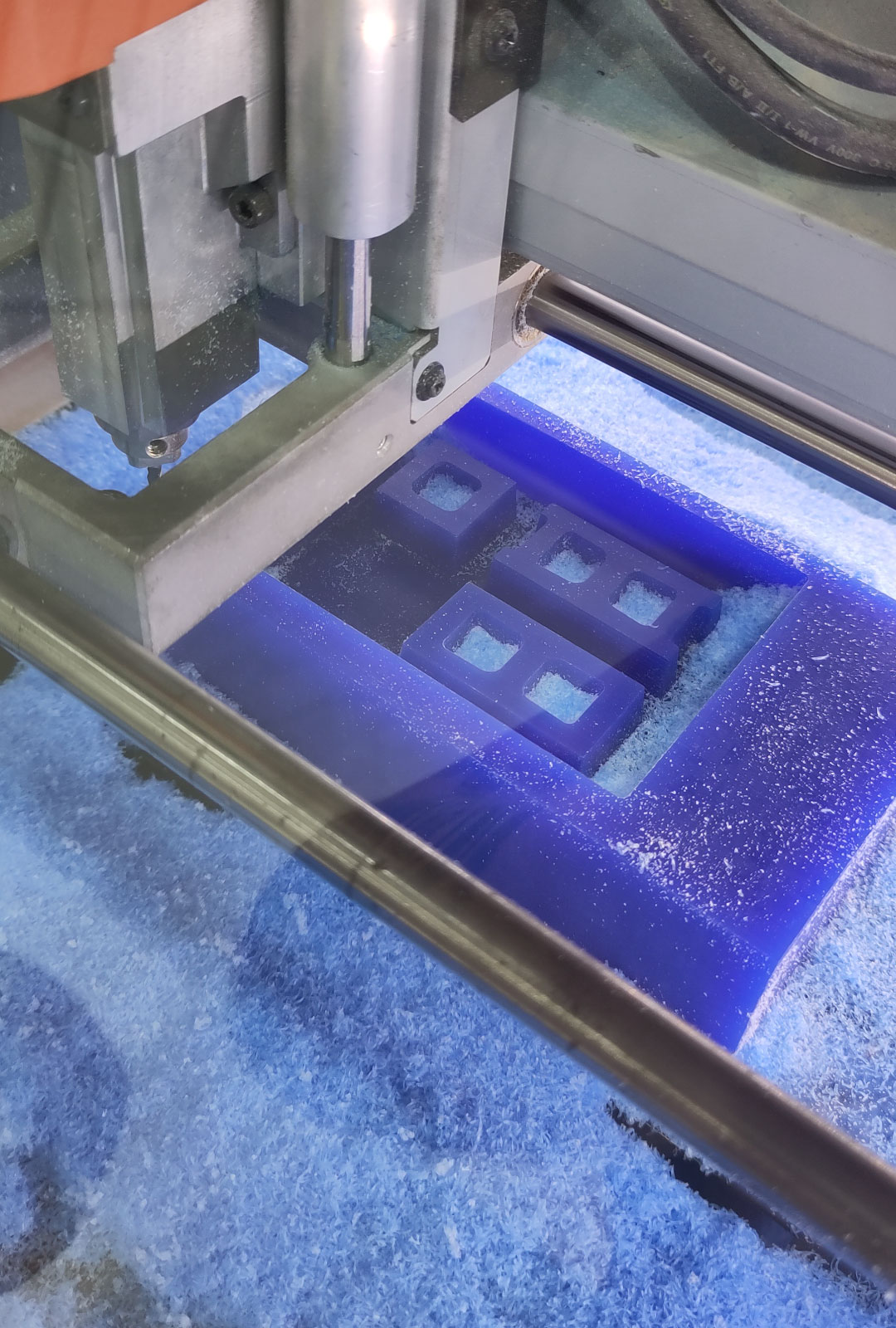

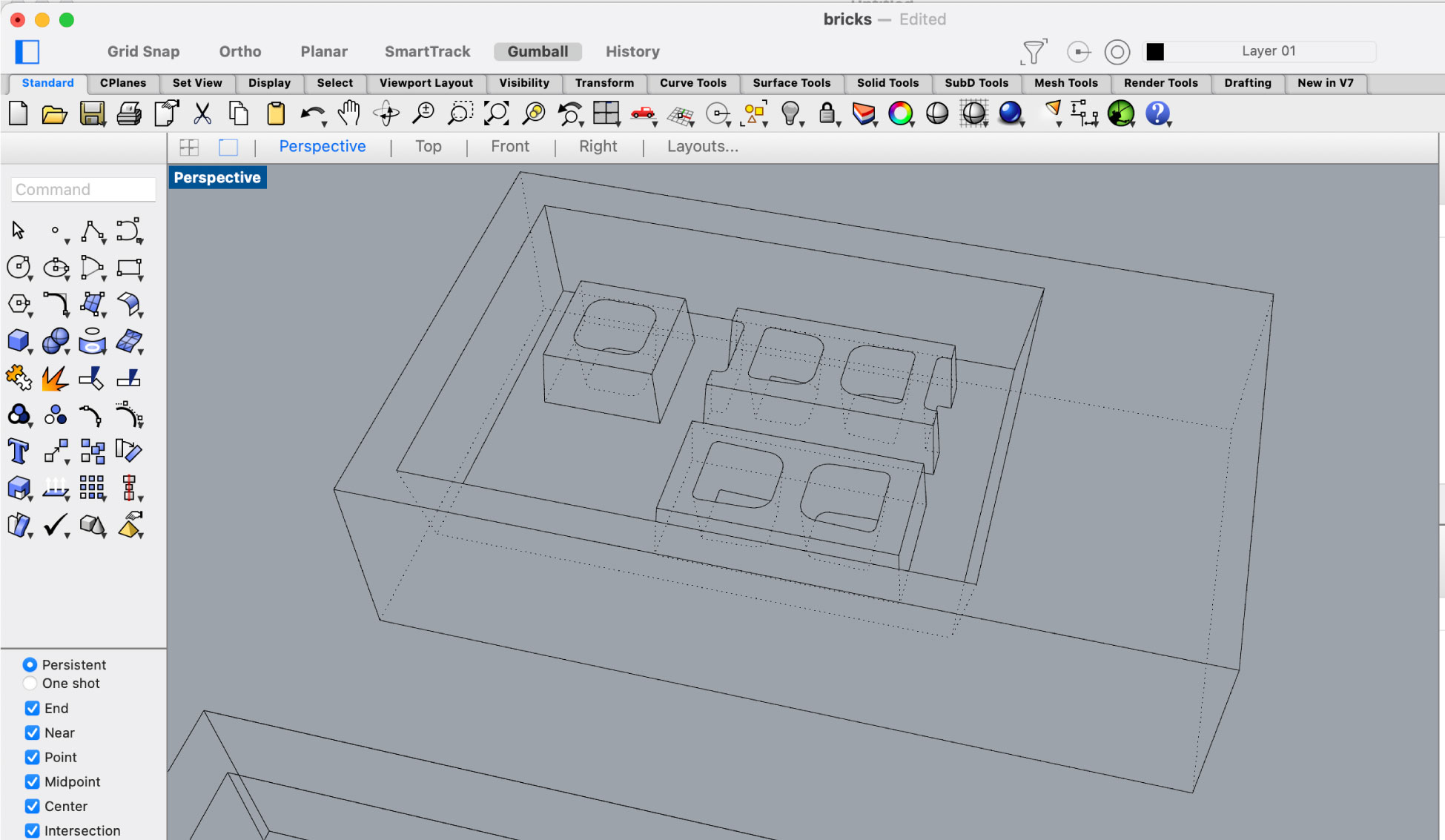

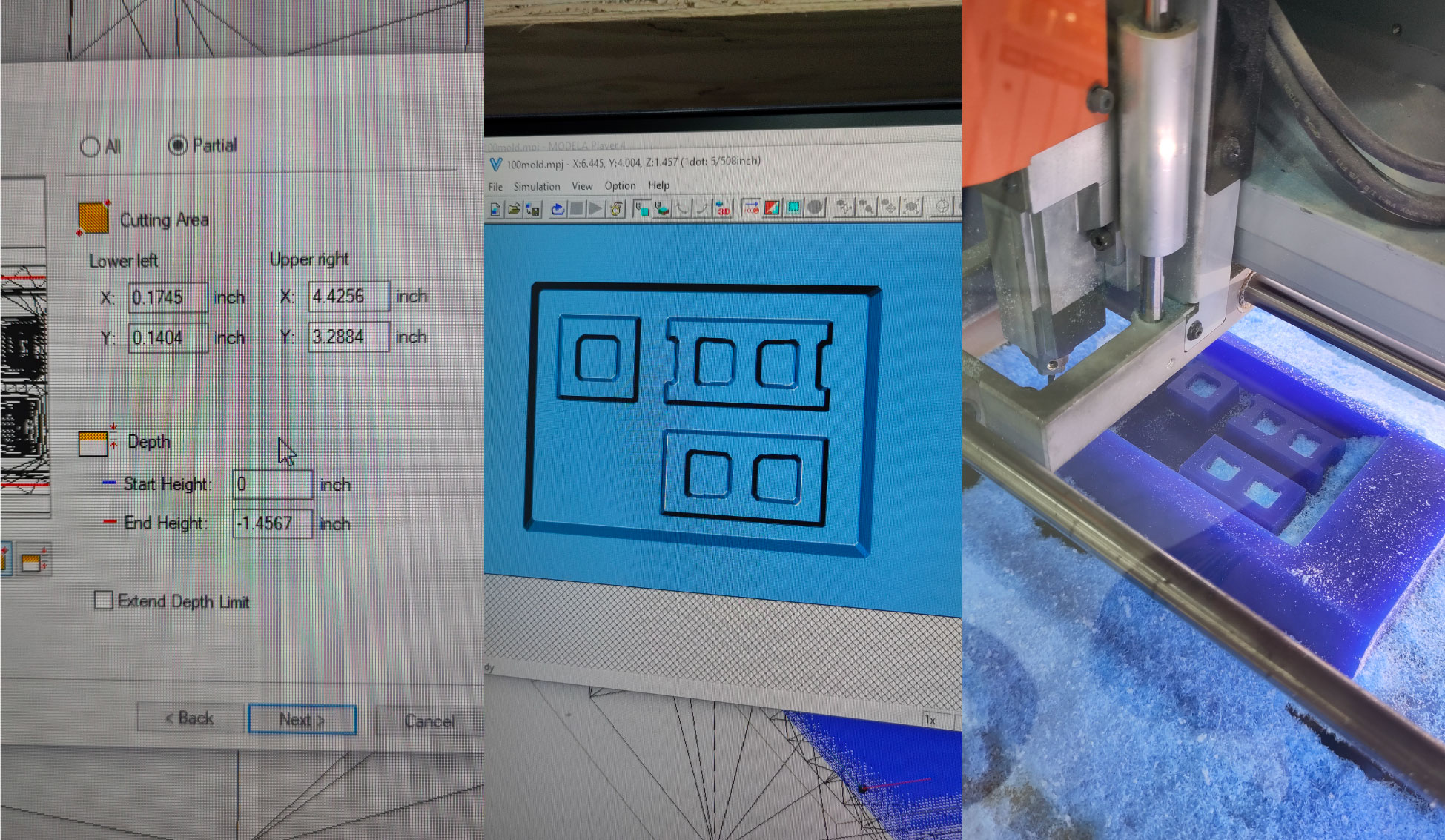

Creating a Mold:

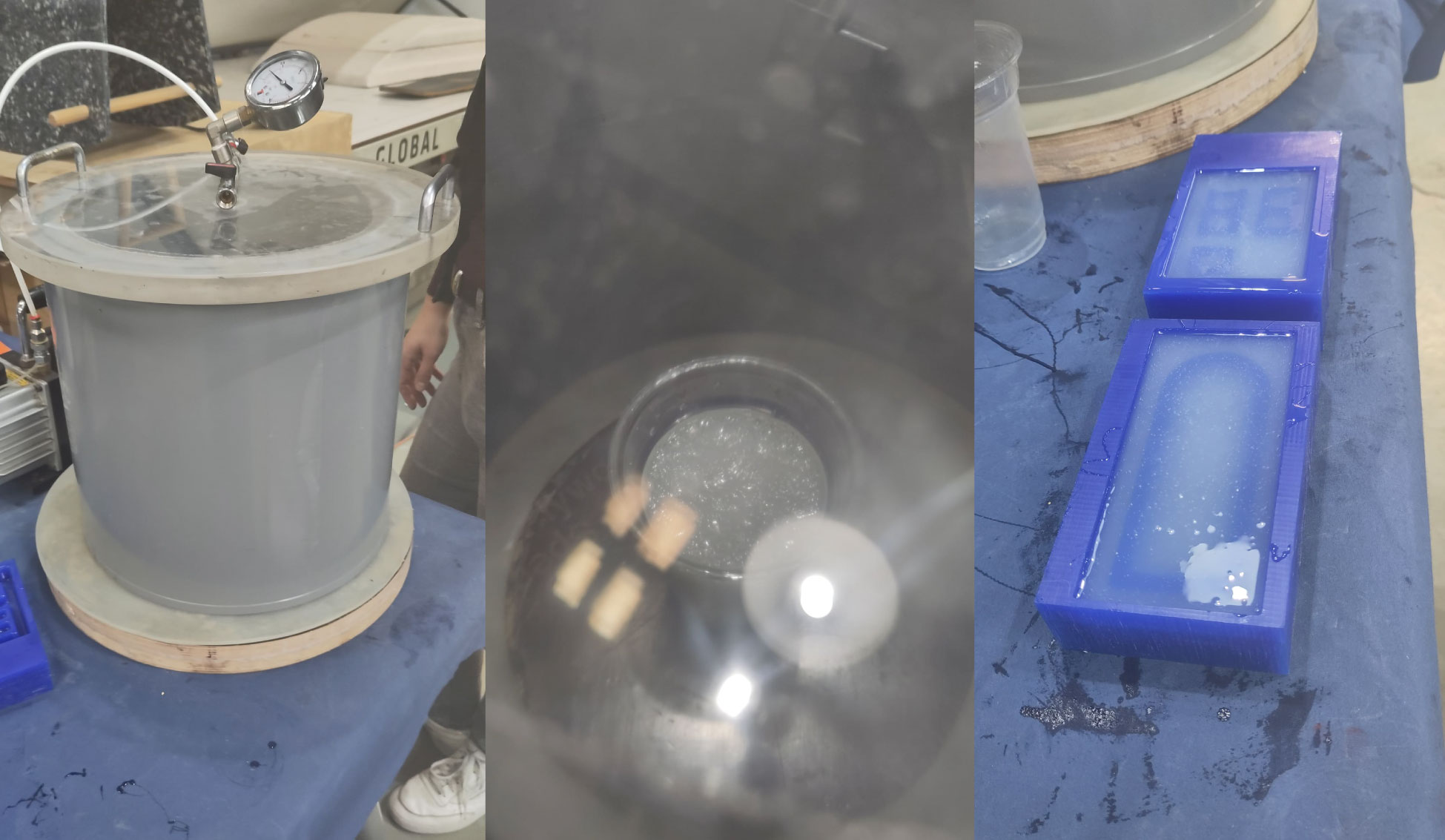

First, the original object or pattern is created or obtained.A mold-making material, such as silicone rubber or plaster, is prepared and poured or applied around the original object.

The mold-making material is left to set and cure, forming a negative impression of the original object within the mold.

Casting:

1. The mold is prepared for casting, which may involve applying a mold release agent (Jar A / B named over the cap to know the difference) to prevent the casting material from sticking to the mold.

2. The casting material is prepared and poured into the mold.

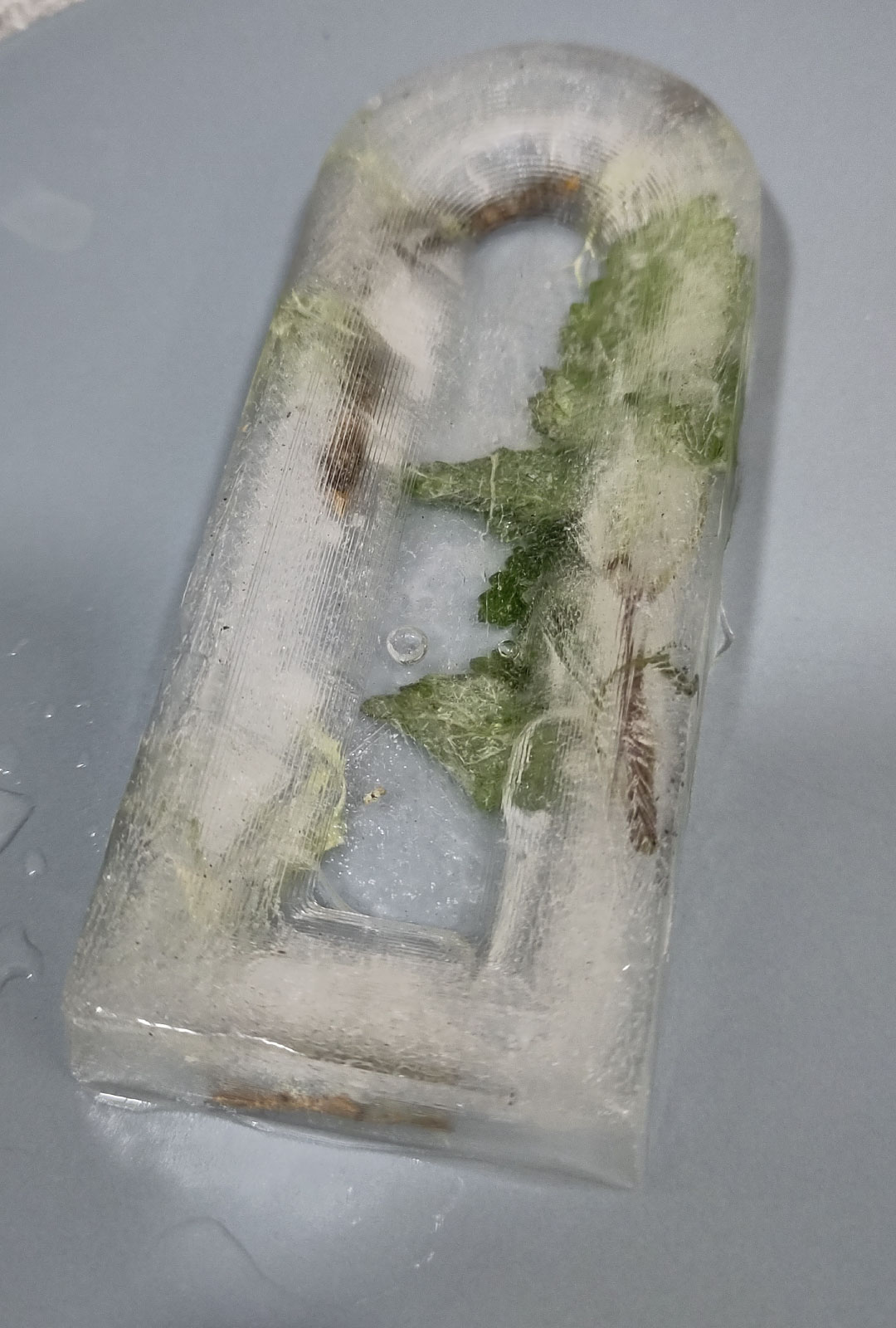

3. Then, left to cool down.

4. Once the casting material has hardened, the mold is removed from the casting, revealing the final duplicate piece.