Week4group

Group Assignment:¶

Q. Characterize your lasercutter’s focus, power, speed, rate, kerf, joint clearance and types.

Fablab Mandala have divided the students into two groups: A & B, because of the covid situation in the country.

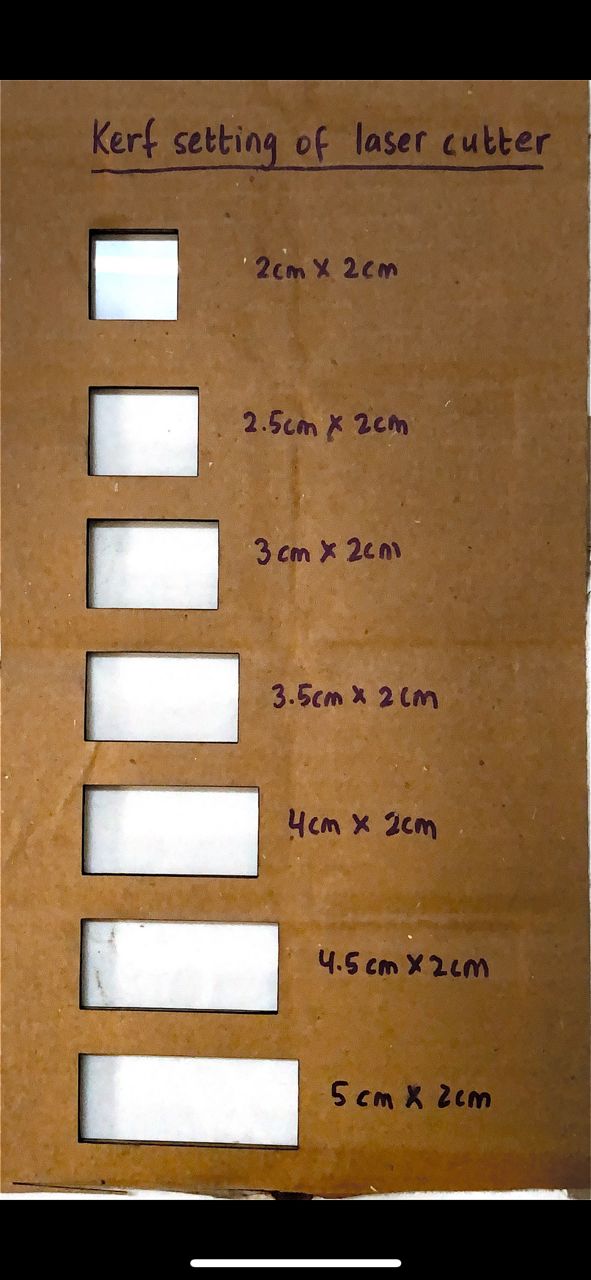

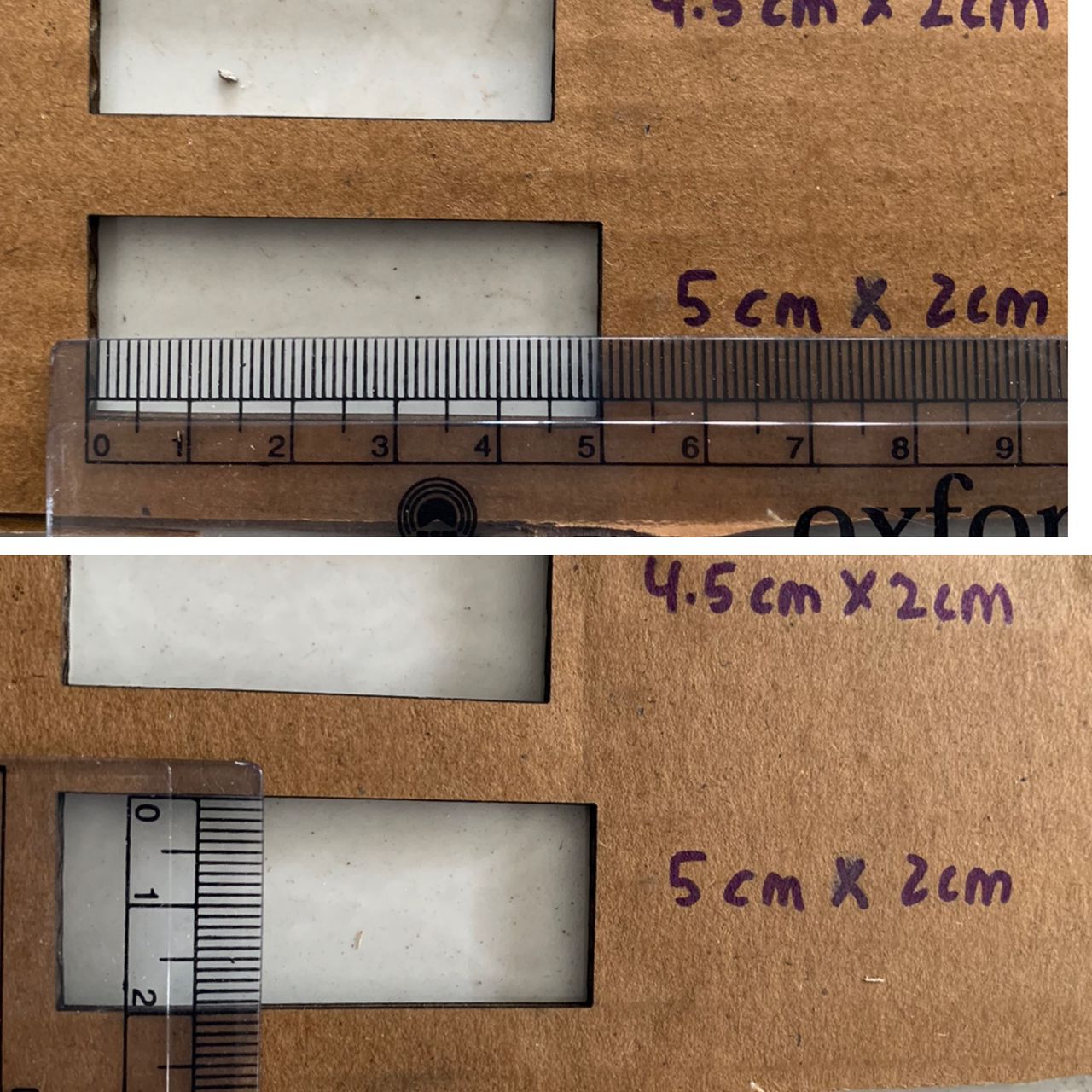

To start our group assignment, we made a design in fusion 360 with cut outs length ranging from 2 cm to 5cm to test the kerf of laser cutter.

Next, we exported the sketch in .dxf file and opened it up on coral draw for cutting.

# characterize lasser cutter’s settings.

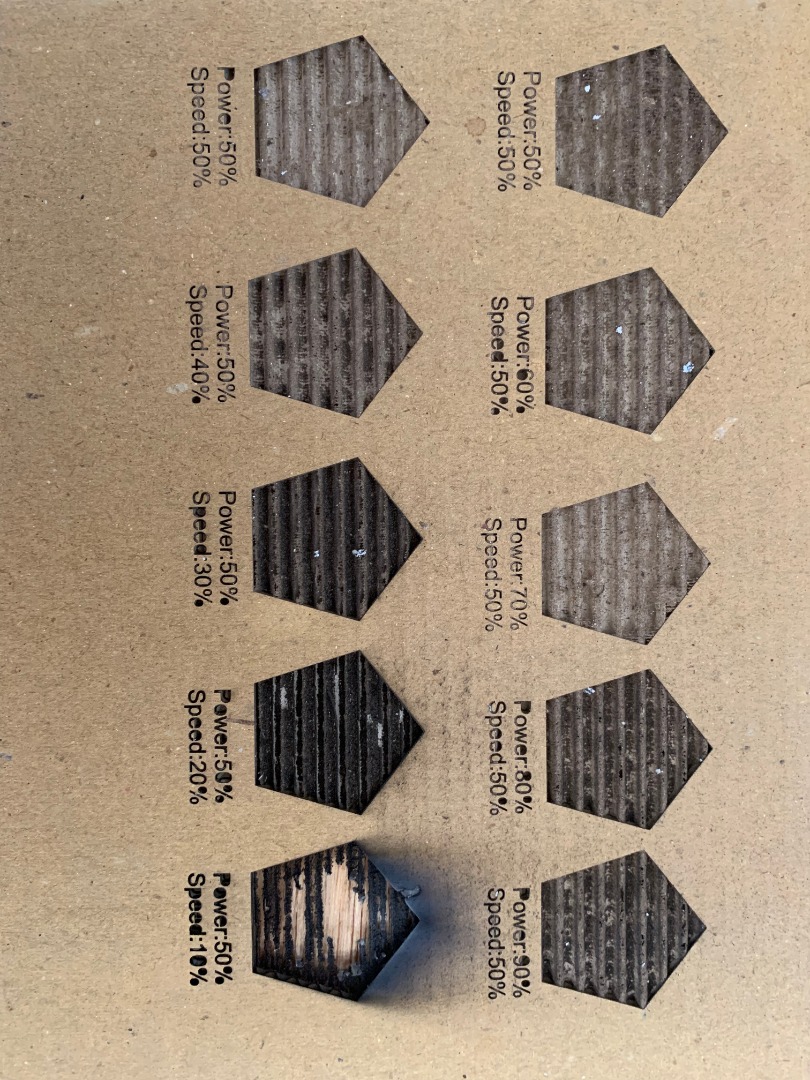

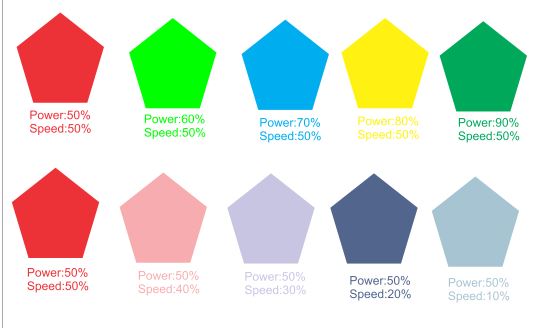

To characterize laser cutter’s setting, for the first set we kept the speed constant and changed the power of laser and for the second part we kept the power constant and changed the speed.

To test the Lasser cutter’s setting we used rubber wood as our material. As rubber wood is hard and quit thick we couldn’t find much differences in constant speed .

When the power was kept constant and speed varied, we can see the differences even on the rubber wood.

Next, we changed the material to cardboard to see the laser cutting setting. Now, we can see the differences of different setting as shown in the image.

Next, we changed the material to cardboard to see the laser cutting setting. Now, we can see the differences of different setting as shown in the image.