FabAcademy

FabAcademy is a fast paced, hands-on learning experience where students learn rapid-prototyping by planning and executing a new project each week, resulting in a personal portfolio of technical acomplishments.

Fab Academy is led by Neil Gershenfeld and its leassons are really helpful. Even when I knew about almost all the process I did learn many things from him. If you want to know more about this fabulous course you can click here.

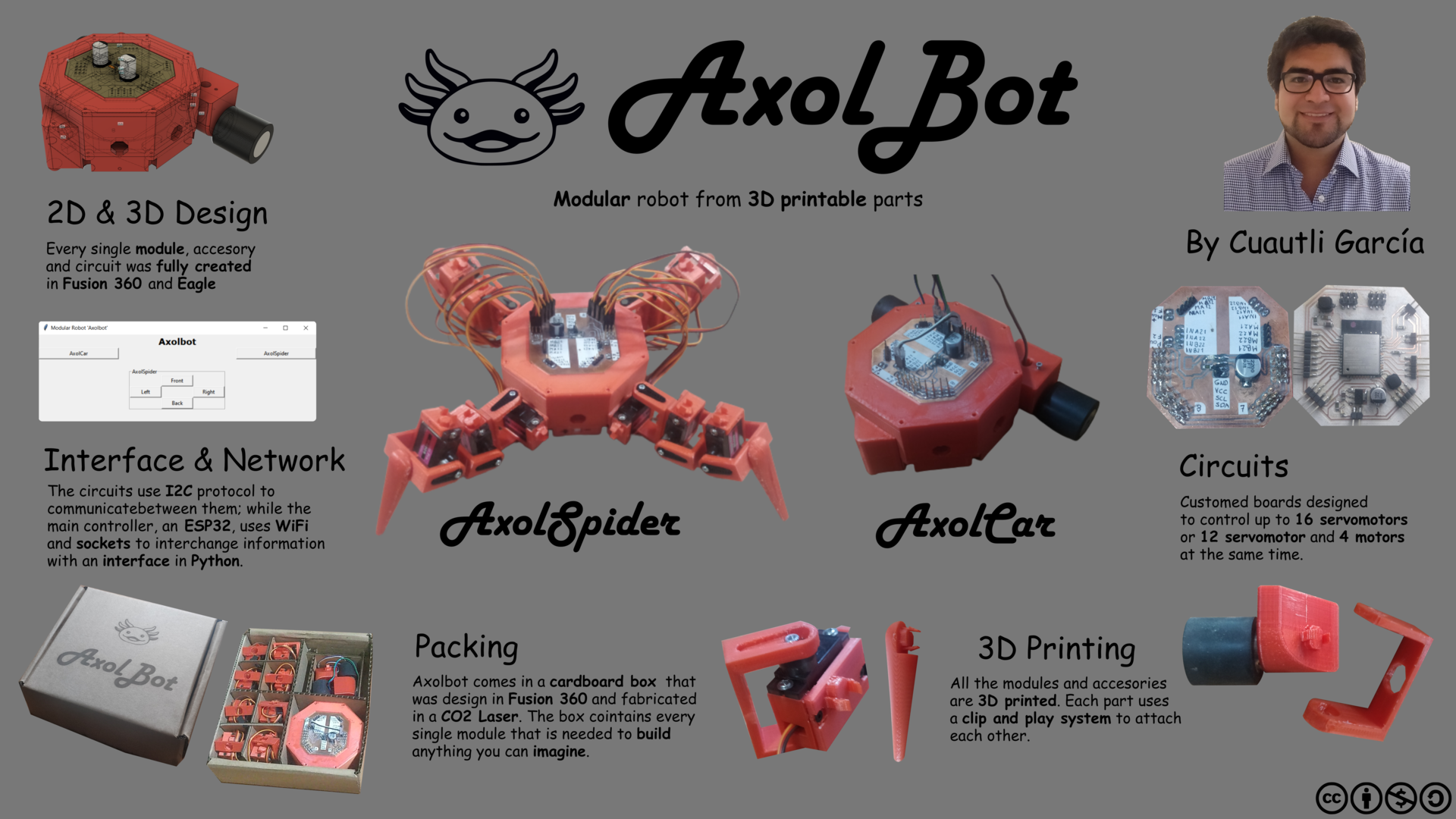

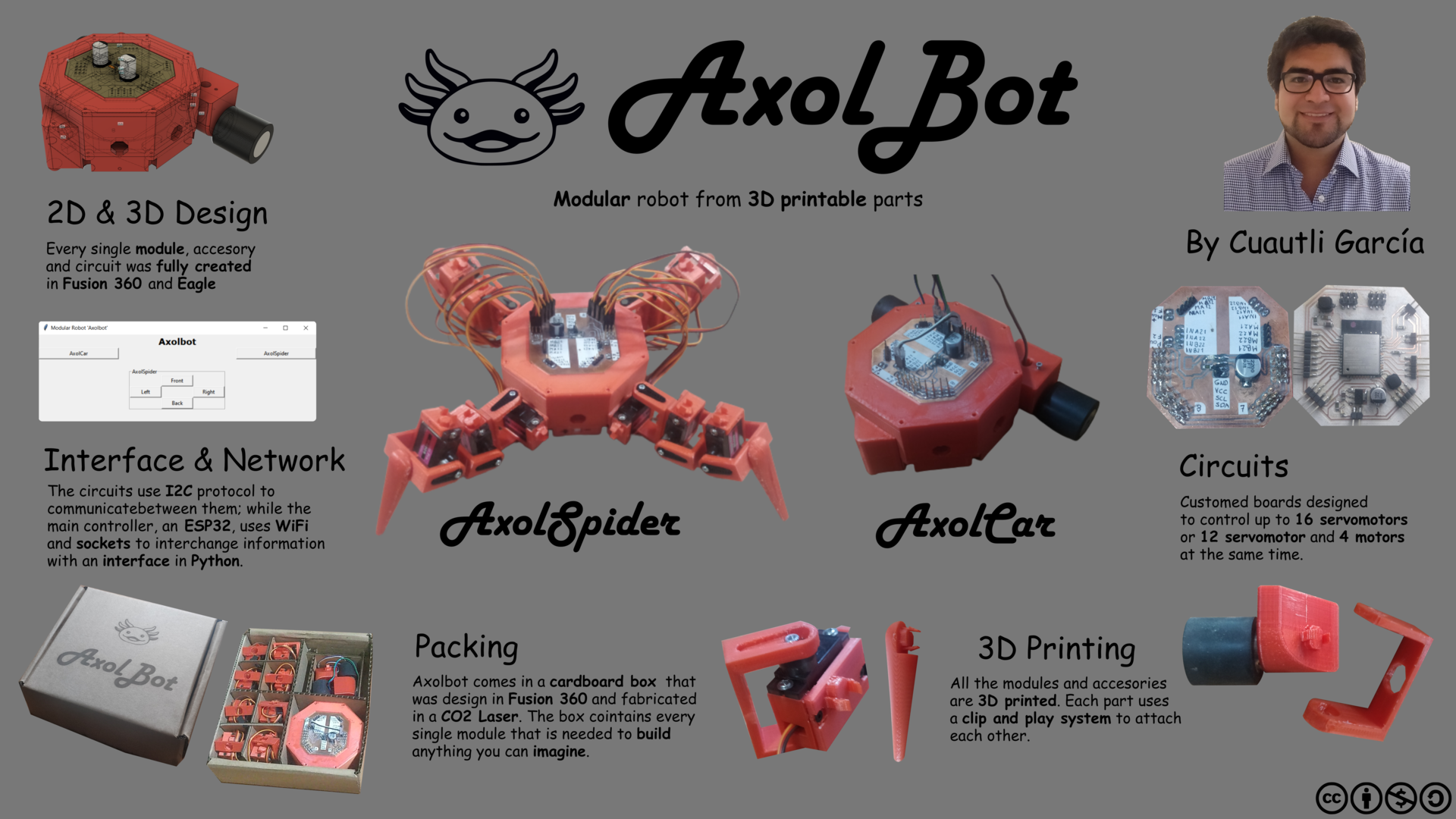

The picture above shows my final project which is a modular robot from 3D printable modules so you can have an idea about what you can build and learn in this course.

About me

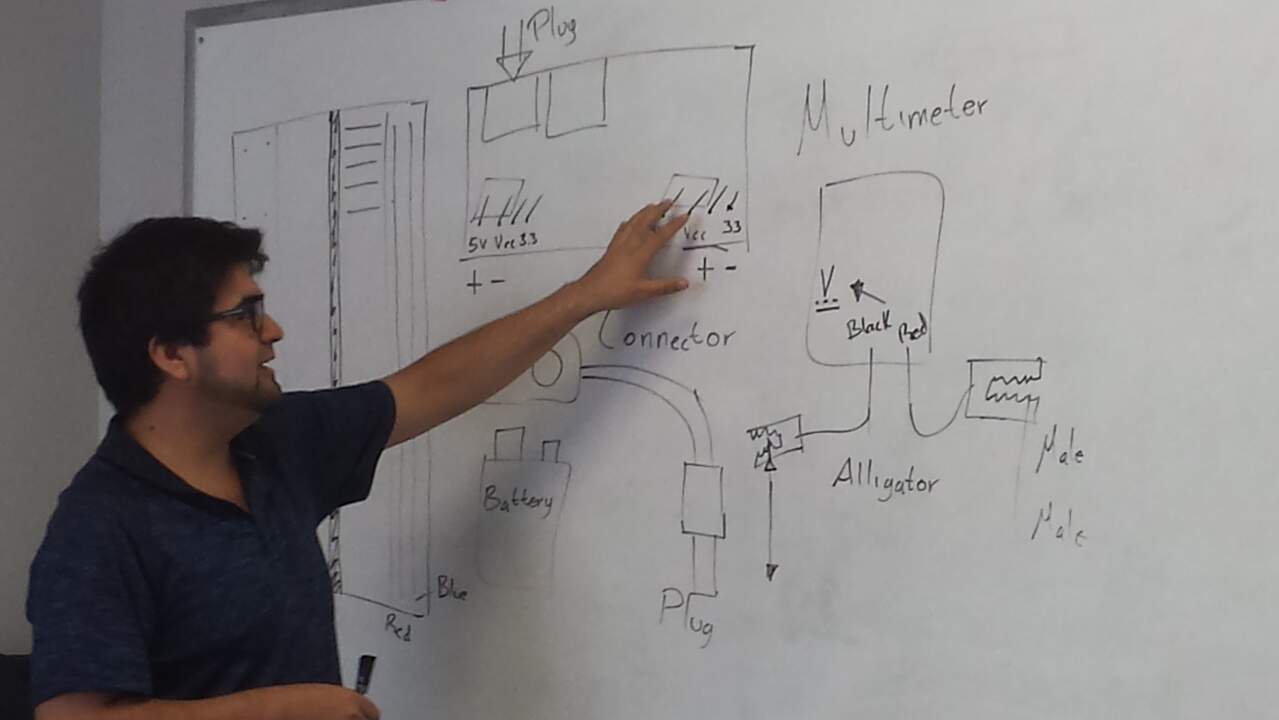

Hi! I am Cuautli and I am a mechatronics engineer with a master in electrical and computer engineer. I was born in Mexico City where I studied high school and where I discovered my biggest passion robotics. At that age, I wanted to be an architect but I discovered a robotics club at my high school and a few years at my University I was going to national and international robotics competitions. Since then, I always took every opportunity to acquire new knowledge, as a matter of fact I took the double of the required courses for my masters because I wanted to keep learning :D. I also have had the opportunity to teach robotics, electronics, soldering, programming and 3D printing at the University of Ottawa and at FabLab ONAKI in Canada. This FabLab is really special for me, because it is an indigenous FabLab and the best part is that not only they learned from me but I also learned from them. Thanks to those experiences, I discovered Fab Academy and the fabulous network that exists around the world.

At the end of my University, I moved to Monterrey where I worked for more than three years with CNC machines such as, routes, CO2 laser, fiber laser, plasma and plotters.

The project that I fell more proud about is a robot for inspecting gas pipes of different diameters. The robot is composed of three modules, two driving modules and one control module which are linked by a passive joint. The driving module has eight actuators: four gearmotors to propel the robot along the pipe, and four servomotors to control the radial position of the robot in the pipe and maintain the robot's balance. A Raspberry Pi is used to control the actuators, acquire sensors feedback, and receive commands from a remote wireless user-controlled GUI. If you are interested you can find a paper about the robot here.

Assignments

- Principles and Practices

- Project Management

- Computer-Aided Design

- Computer-Controlled Cutting

- Electronics Production

- 3D Scanning and Printing

- Electronics Design

- Computer-Controlled Machining

- Embedded programing

- Mechanical design

- Input Devices

- Molding and Casting

- Output Devices

- Networking and Communications

- Interface and application programming

- Wildcard week

- Applications and Implications

Invention, Intellectual property, and income

Invention, Intellectual property, and income

- Development of Final Project

Final Project

Final Project

Contact