20. Project Presentations¶

Document a final project masterpiece that integrates the range of units covered, answering:

- What does it do?

- Who’s done what beforehand?

- What did you design?

- What materials and components were used?

- Where did they come from?

- How much did they cost?

- What parts and systems were made?

- What processes were used?

- What questions were answered?

- What worked? What didn’t?

- How was it evaluated?

- What are the implications?

- Prepare a summary slide and a one minute video showing the conception, construction, and operation

Your project should incorporate 2D and 3D design, additive and subtractive fabrication processes, electronics design and production, embedded microcontroller interfacing and programming, system integration and packaging where possible. You should make rather than buy the parts of your project.

Projects can be separate or joint, but need to show individual mastery of the skills, and be independently operable

Present your final project, weekly and group assignments, and documentation

Presentation of my project¶

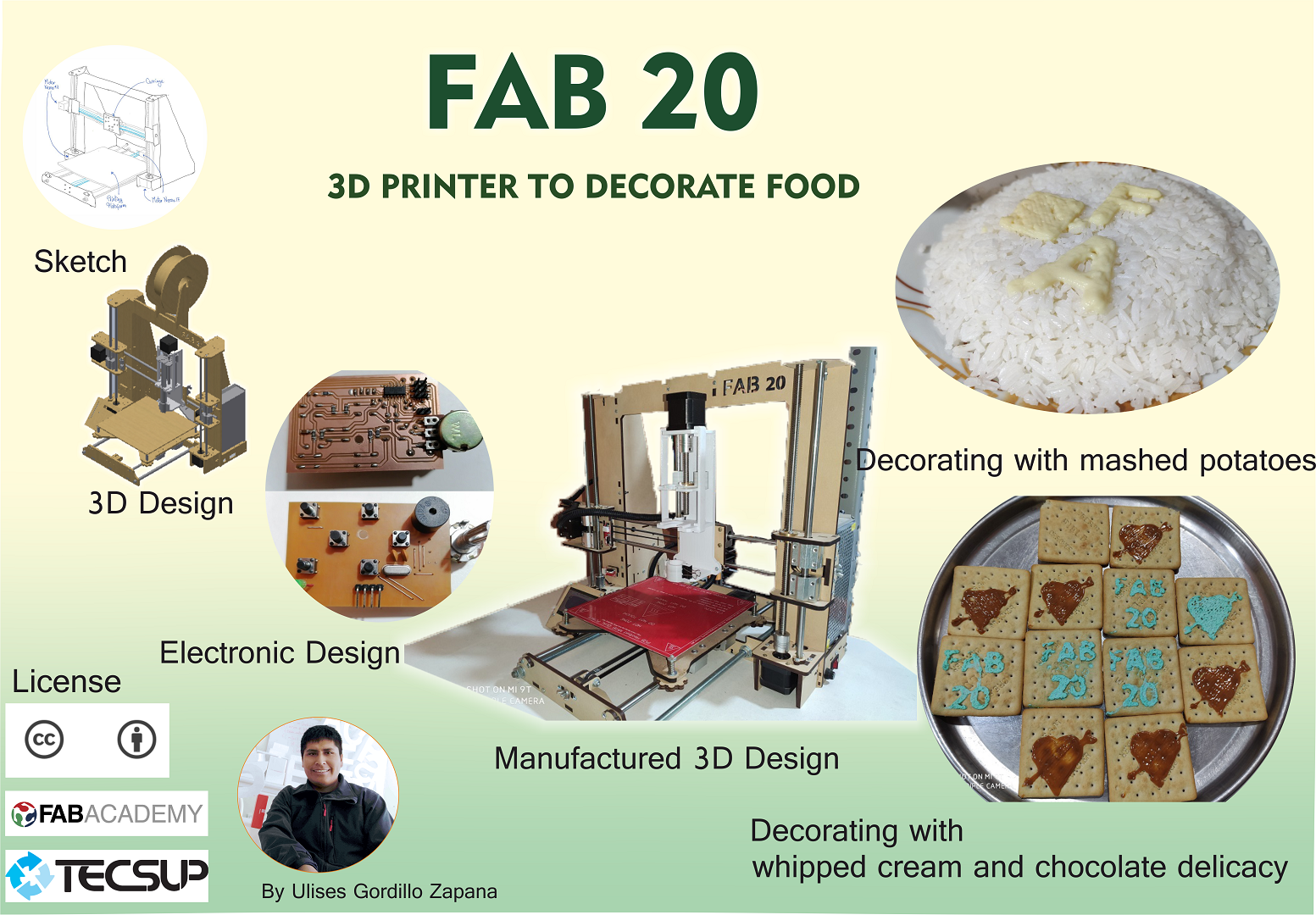

The master slide

We also can see here:

The project video

We also can see in youtube:

Describing my project¶

For the presentation of my project I will answer some of the questions:

What does it do?¶

The project is a 3d printer for decoration of cakes or dishes.

Who’s done what beforehand?¶

I saw that they carried out in other companies privately, I also saw that there were works with alticipation in the FabAcademy, but I propose a new design that has the characteristics of hardware and free software.

What did you design?¶

For this project I designed the following parts: Structure, Electronics and injection system; and modify the Reprap community software for 3D printer operation

What materials and components were used?¶

For the project, laser cutting machines were used with the MDF material, but for subsequent designs we will use accepted material for food preparation, in addition, 3D printing was used to manufacture the decoration material injector; and electronics based on an Atmega2560 and A4988 stepper motor drivers, and finally we used software like Marlin Firmware, Pronterface software to calibrate and Ultimaker Cura slicer software.

Where did they come from?¶

Both materials and supplies are bought in local stores or imported from abroad, some from China, the United States or Europe.

How much did they cost?¶

The materials had a cost of:

- 2 MDF sheets at 24 dollars.

- 1 roll of 3D Filament at 80 dollars.

- The mechanics integrated to 200 dollars.

- Integrated electronics at 400 dollars.

What parts and systems were made?¶

They were designed: - Movement structure in XYZ axes - Extruder structure - The Integrated Electronics of the Atmega2560 and the RAMPS 1.4

What processes were used?¶

- Laser cutting was used for the structure.

- 3D printing was used for the extruder

- The tabletop router was used to manufacture electronic boards

What questions were answered?¶

- The first question I had to answer was how the decoration material would inject

- The second question would be what material would have to change to make it commercial and to be accepted for food use.

What worked? What didn’t?¶

What worked was:

- The structure of motion in XYZ

- Injection of decoration material

- The impression from CAD design to physical fabrication

What didn’t work was:

- We did not obtain a way to eliminate the temperature control, what was done was control at room temperature but running the risk that it was failing in certain environments.

How was it evaluated?¶

For the project test we carried out 3 tests with different materials:

- Chocolate delicacy

- Mashed potatoes

- Whipped cream for decoration

Where all the result was successful with its respective parameters.

What are the implications?¶

This project will help the different food preparation companies to automate the decoration process, standardizing the finish, dosage and presentation.