11. Applications and implications¶

Assignment

- Propose a final project masterpiece that integrates the range of units covered, answering some questions.

- Your project should incorporate 2D and 3D design, additive and subtractive fabrication processes, electronics design and production, embedded microcontroller interfacing and programming, system integration and packaging, where possible, you should make rather than buy the parts of your project

- Your projects can be separate or joint, but need to show individual mastery of the skills, and be independently operable

This week I worked on defining my final project idea and started to getting used to the documentation process. I Propose a final project masterpiece that integrates the range of units covered.

Explaining the Project¶

In the project I am developing a 3D printer to decorate food, firstly I will try with potato puer, although I will also do tests with delicacy and decoration cream for cakes.

The way to operate will be, a design is made in some 3D design software, the STL file is extracted, the 3D slicer is used to create the gcode file, to be executed in the 3D Food Printer.

It is on a separate machine, but software developed by the REPRAP community will be used, such as the microcontroller firmware, calibration software and 3D slicer.

The design of the structure is entirely made with a 6mm plate initially with MDF, but later this will be replaced with acrylic, all parts are designed for laser cutting, but the extruder will be made entirely with PLA 3D printing pieces.

The electronics part will be designed on a tabletop router, with electronic components.

Together we used:

- Laser cut

- 3d print

- Table Router

Answering¶

What will it do?¶

I will make a 3D printer for food, my initial proposal was to work with mashed potatoes but doing the analysis with Design Thinking, I changed the proposal to focus on a different market; I will work in cake decoration, the 3D printer will decorate cakes with chantilly cream.

About the parts to design, I will design the following:

- X, Y and Z Movement Structure.

- Extruder for prepared food.

- Electronics based on Atmega2560 and A4988 controllers.

I will use the REPRAP Community:

- Firmware for 3D Printers, Marlin

- Pronterface Calibration Software

- Ultimaker Cura software to slice the design.

Who’s done what beforehand?¶

Yes, for example we have the Natural Machines makers, where it has a very nice machine but we also have other groups that do it as an amateur

But the most difficult would be to work with the extrusion of the material.

What will you design?¶

I will design a 3D printer for food, It will decorate cake, I will design all the pieces, for example X, Y and Z structures, the extruder and the electronic.

What materials and components will be used?¶

It will work on Reprap models, it will be used for the acrylic structure, stainless steel for the movement mechanics, and an electronics based on Atmega2560 and the work done on Reprap.org

Where will come from?¶

I will make it, all the design. To carry out this project we will divide it into the following parts:

- XYZ Structure

- FAB20 prototype sketch design

- Structure Design for movements in X, Y and Z axes

- Manufacture of structure for movements in X, Y and Z axes

- Assembly of structure of Movements in X, Y and Z axes

- Extruder

- Extruder prototype sketch design

- Extruder Structure Design

- Extruder Manufacturing

- Extruder Assembling

- Electronic

- CAD Electronic Designing

- Electronic Manufacturing

- Electronic Assembling

- Software

- Marlin Firmware Configuration

- Calibration with Pronterface software

- Ultimaker Cura Software Configuration.

- Testing

- Sample with chocolate delicacy

- Sample with cakes

- Sample with mashed potatoes

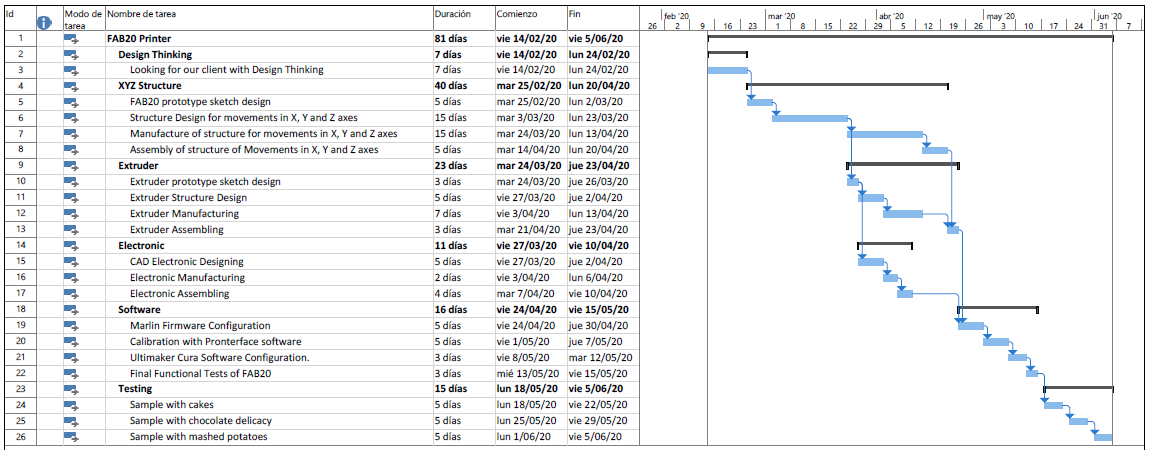

For the execution of this project, the following activities plan was prepared with the required times:

How much will they cost?¶

The cost is not fixed but if we have expectations that it has an average cost not to exceed 500 dollars.

What parts and systems will be made?¶

Most of the parts will be manufactured with the exception of: material syringe, electronics such as nema 17 motors, power stage, and display screen

What processes will be used?¶

I will use the machines: Laser cutter 3D printer PCB milling machine and Vinyl cut for decoration.

What questions need to be answered?¶

I wait find the printer speed about 20mm/s , I will just try it. Probably, the print size will be 200mm x 180mm x 150mm.

How will it be evaluated?¶

For the project test we carried out 3 tests with different materials:

- Chocolate delicacy

- Mashed potatoes

- Whipped cream for decoration

Where all the result was successful with its respective parameters.