WEEK 3 - Computer-Controlled Cutting

INTRODUCTION

I spent a very rich week on assignments, gained a lot of information, and learned on machines I had never worked on before.

Assignment Description

- characterize your lasercutter's focus, power, speed, rate, kerf, and joint clearance

- cut something on the vinylcutter.

- design, lasercut, and document a parametric construction kit.

group assignment:

individual assignment:

for the group assignment you can get it here

Let's Start with the individual assignment

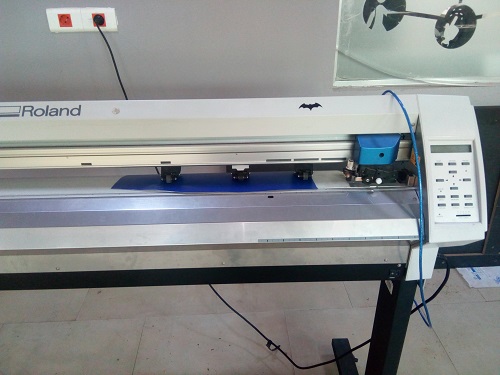

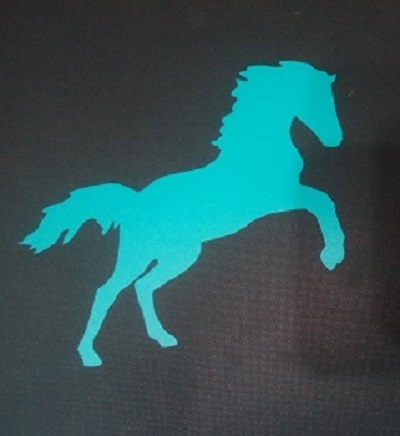

vinylcutter

First I had no experience cutting vinyl before,so let's take this journey together.

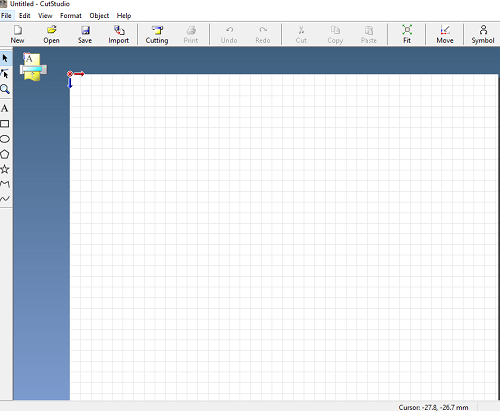

- I used CutStudio software, you can download it from here

- insall, and open it

- Now you have a very simple interface

- drag and drop your image here to convert it to vector.

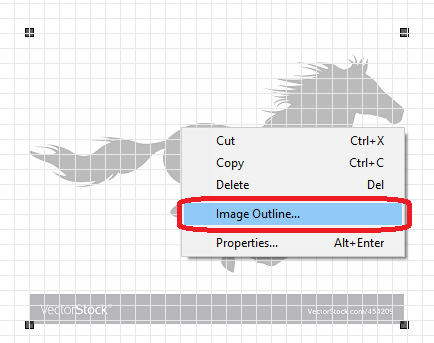

- Right click and choose"image outline"

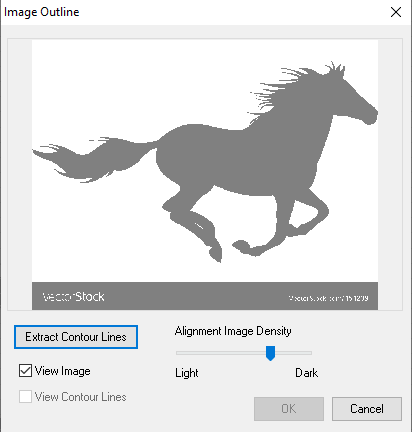

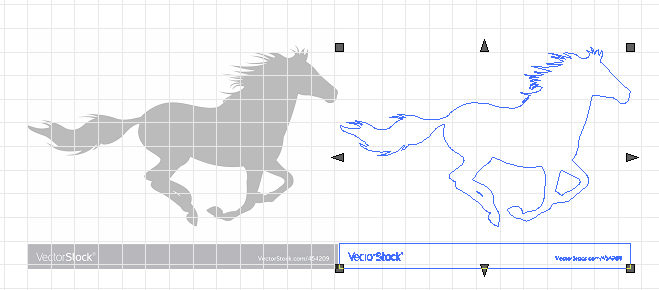

- click on extract contour lines, then ok

- now delete the image source

Now! let's go with Vinylcutter

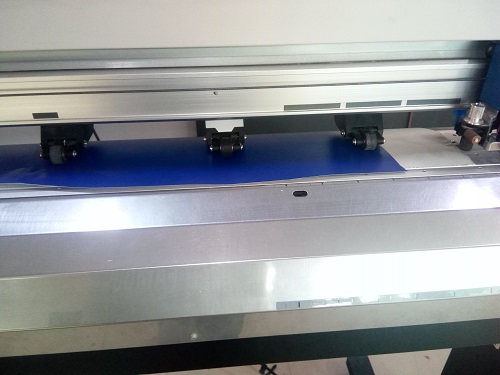

- On the machine we have clamps to install the workpiece, and to define the locations of the sensors

- The first clamp should be placed in front of the first sensor, and the last at the end of the workpiece in front of the sensor

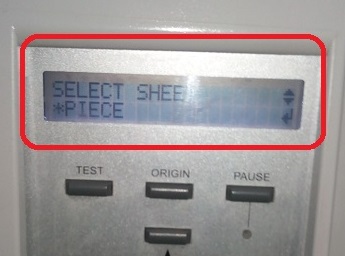

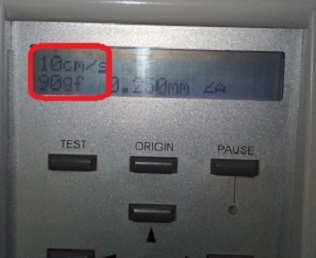

- Turn on the machine, place your work piece with clamps, then choose the "piece" option, and i worked with 90gf for force

- connect your machine with the laptop

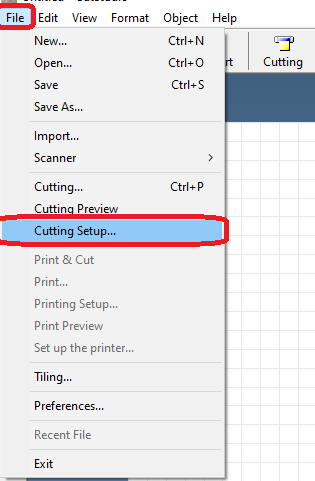

- click on file, then cutting setup

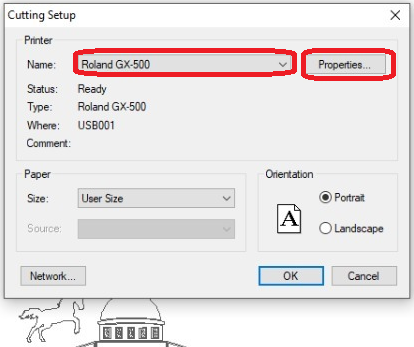

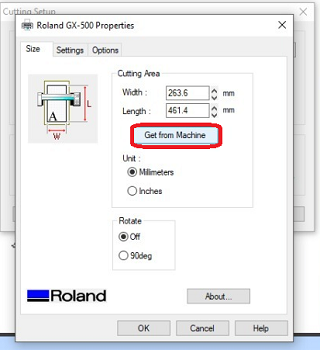

- choose your machine, then get your dimension

- put your design on correct place, and press on cutting

- Get your product and remove everything you don't want

- Apply tape to the product and pull it vertically

- Then put it as you like, then slowly pull the tape at a small angle

finally

our machine is Roland GX-500

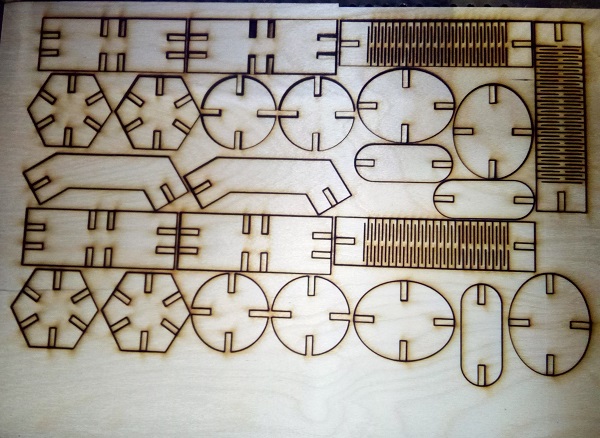

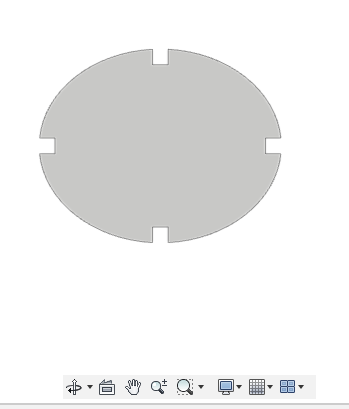

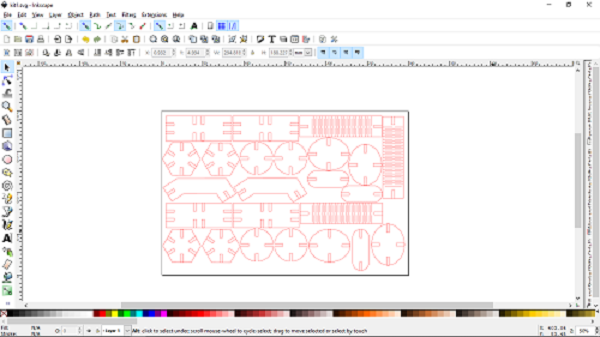

parametric construction kit

What is a Parametric Modelling?

Parametric is a term used to describe a dimension’s ability to change the shape of model geometry as soon as the dimension value is modified. Feature-based is a term used to describe the various components of a model. For example, a part can consists of various types of features such as holes, grooves, fillets, and chamfers. A ‘feature’ is the basic unit of a parametric solid model. for more details here

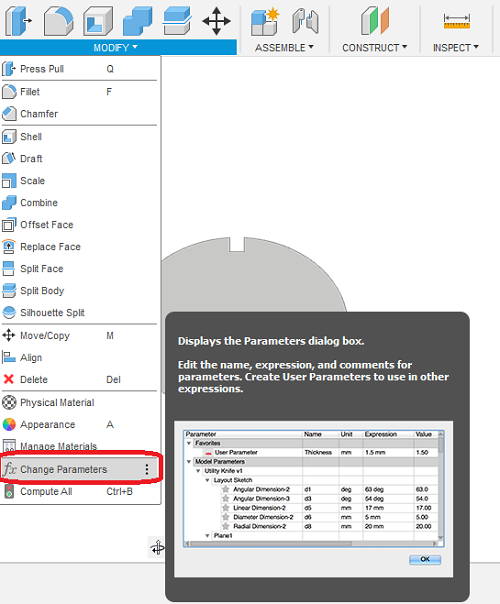

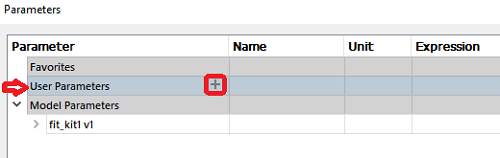

I used Fusion 360

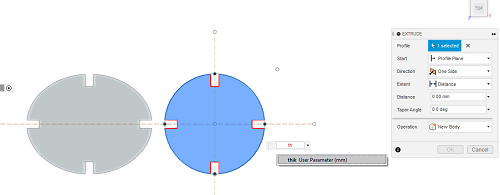

- Design the first piece as a new component

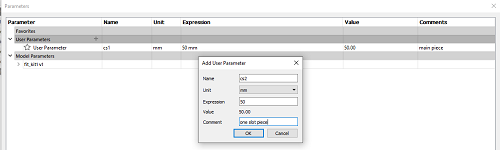

- choose change parameters from modify

- choose user parameters, press on "+"

- enter your parameter name and value, then click ok

- and when you need to set dimensions, just write the name of parameter

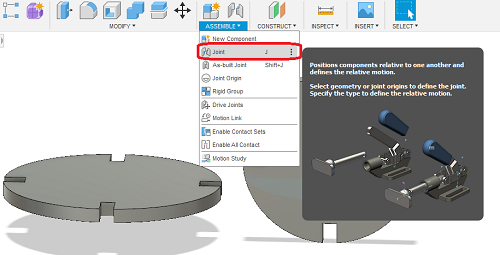

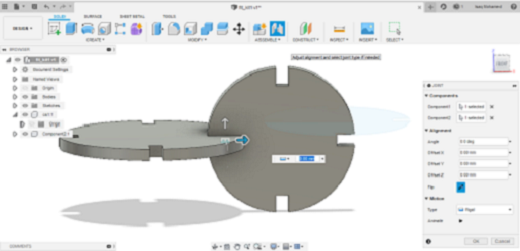

- you can try to assembly your kit, go to assembly, press on join,then choose the places you need to join together

- export your file as a dxf file

- i used inkscape programe

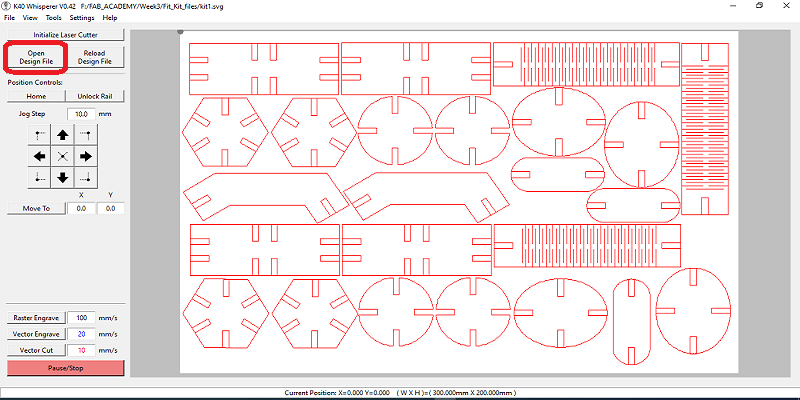

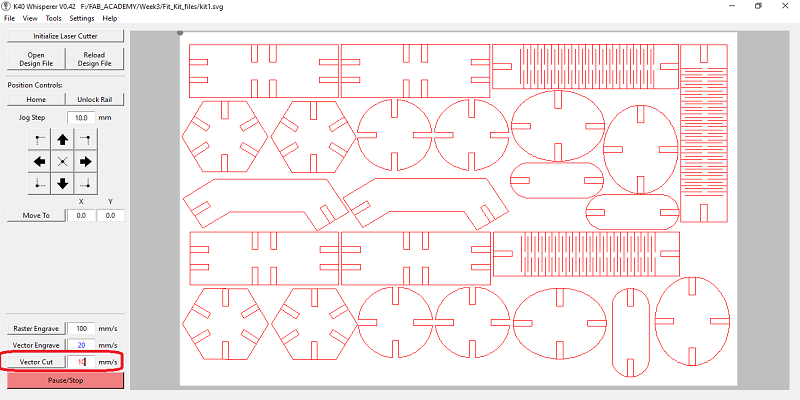

- I used K40 software for my machine, you can download it from here

- easy to use, open it, and upload your SVG or DXF file (from open design file button)

- I have set the power vector cut on 10

- enjoy

laser cutting