MOLDING AND CASTING

GROUP ASSIGNMENTFor this week's assignment we were tasked to design a mold around the process I will be using and use it to cast parts.. But what is molding and casting? Molding and casting are manufacturing processes where liquid or pliable materials are shaped into a desired form by using a mold or die. Molding often involves injecting or pressing the material into a mold, while casting typically involves pouring molten materials into a mold. The primary difference lies in the method of material introduction and the materials used. For more, visit.

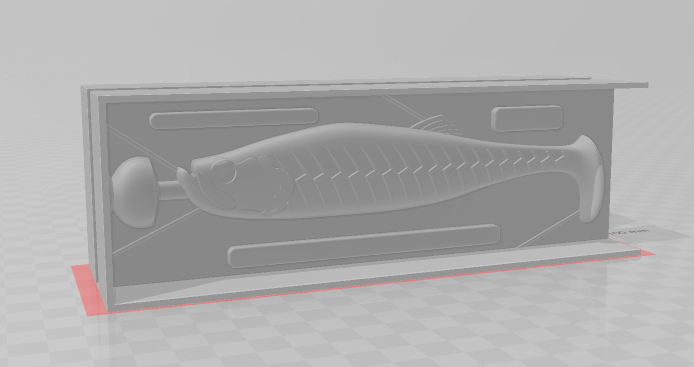

DESIGNING

Below is the design that I have come up with, that will be used to make a mold. The design was then sliced using a creality slicer and then 3D printed with creality K1 printer.

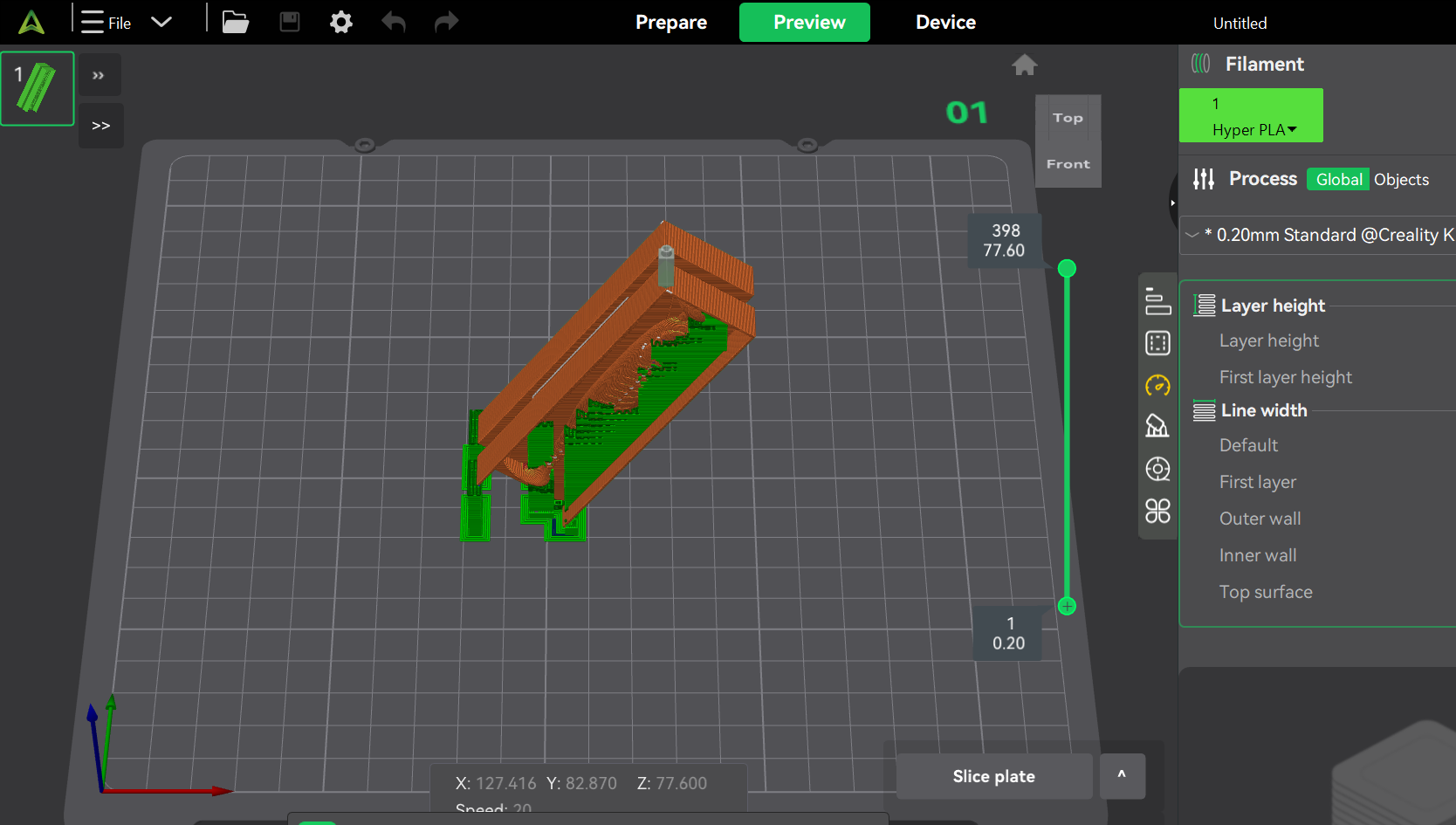

SLICING

Used creality print to create printer g-code.

3D PRINTING

Then used a creality K1 to print the design.

FINAL PRINT

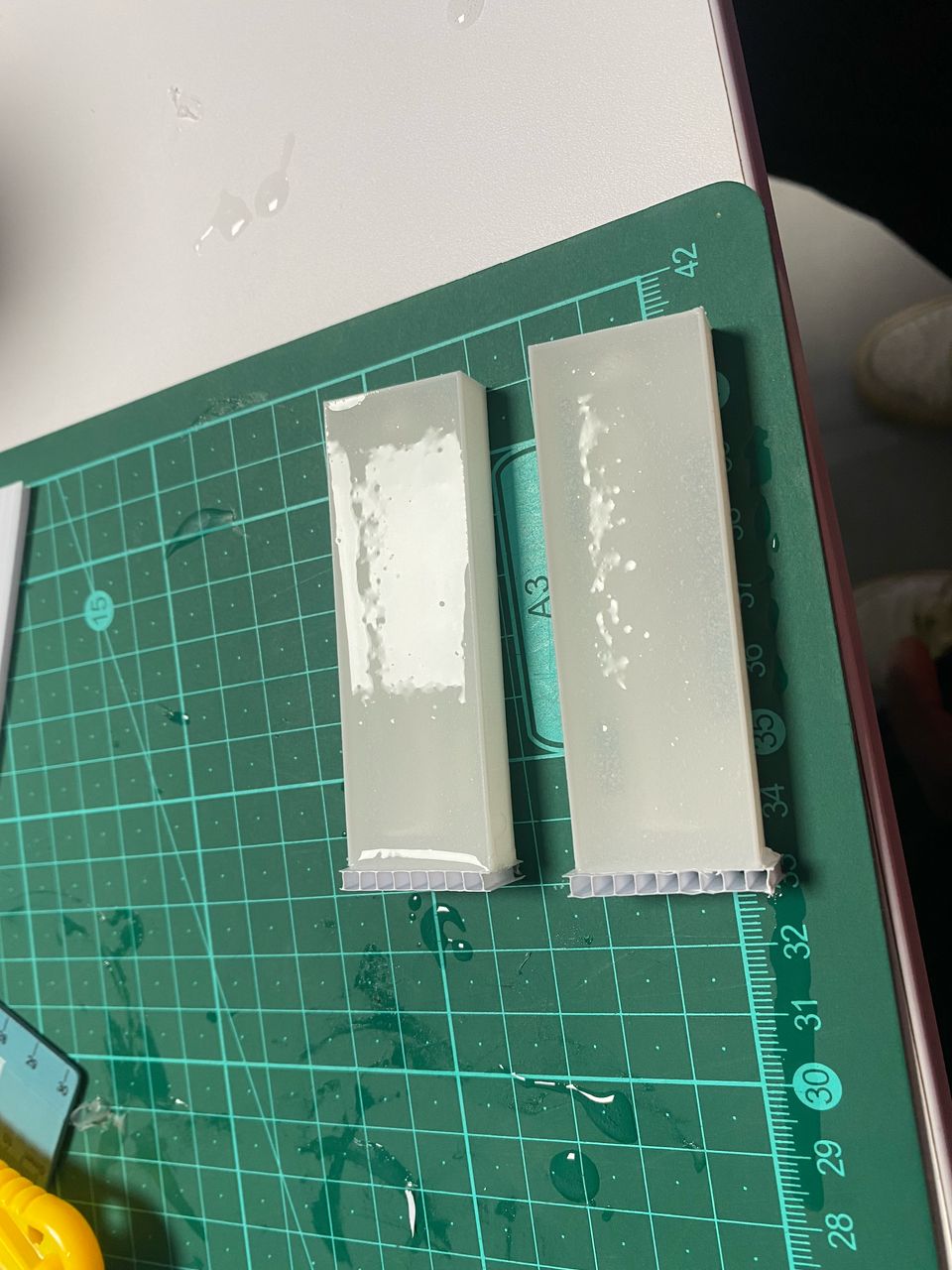

Because the design was not enclosed, I had to compromise and close it up with a correx piece to avoid the silicone to spill out.

POST PROCESSING

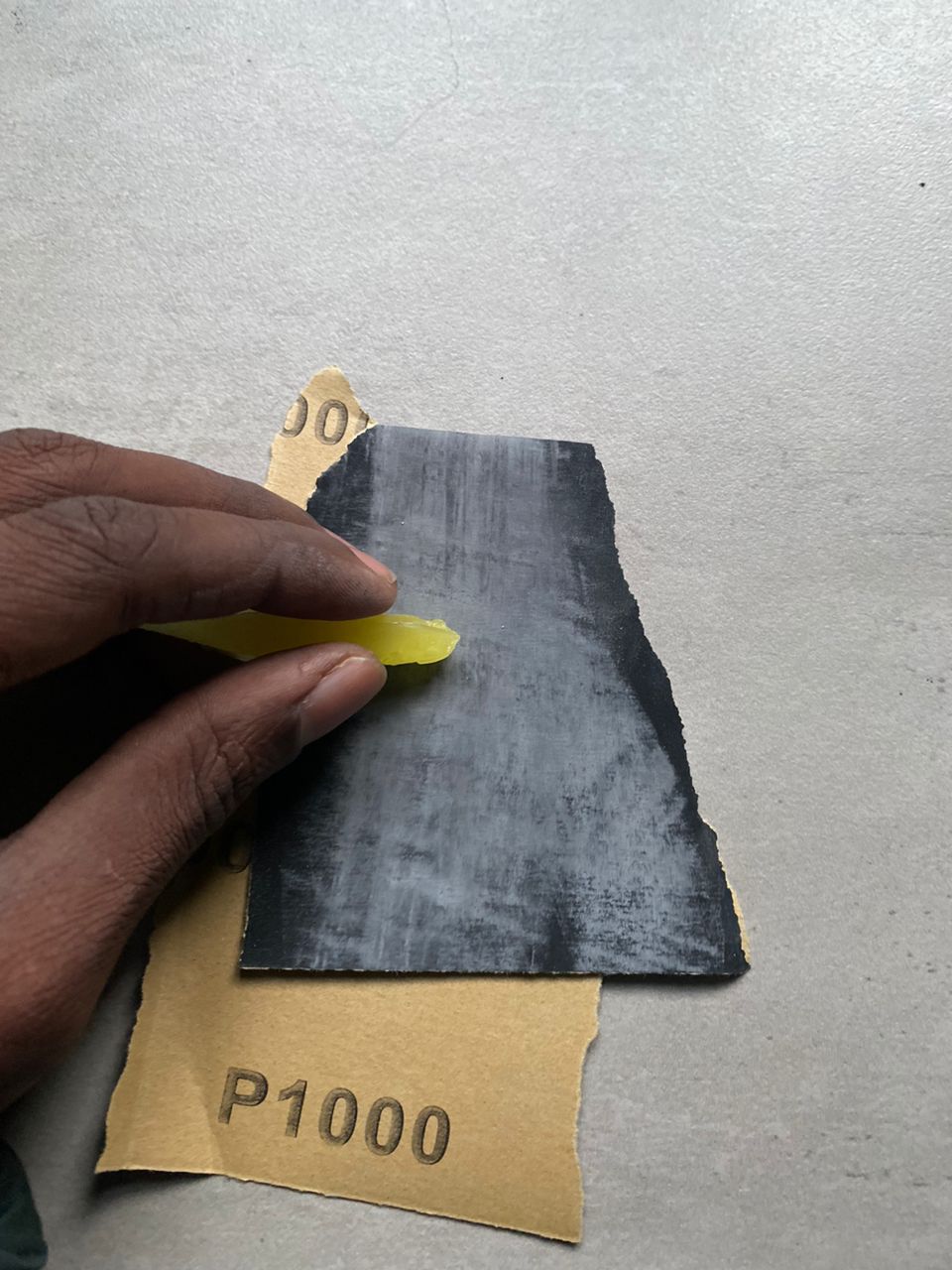

After printing, I used the abrasive paper to abrade and smoothen the edges of the printed model. This was to make sure the mold made is smooth.

The video shows how the abrading was made.

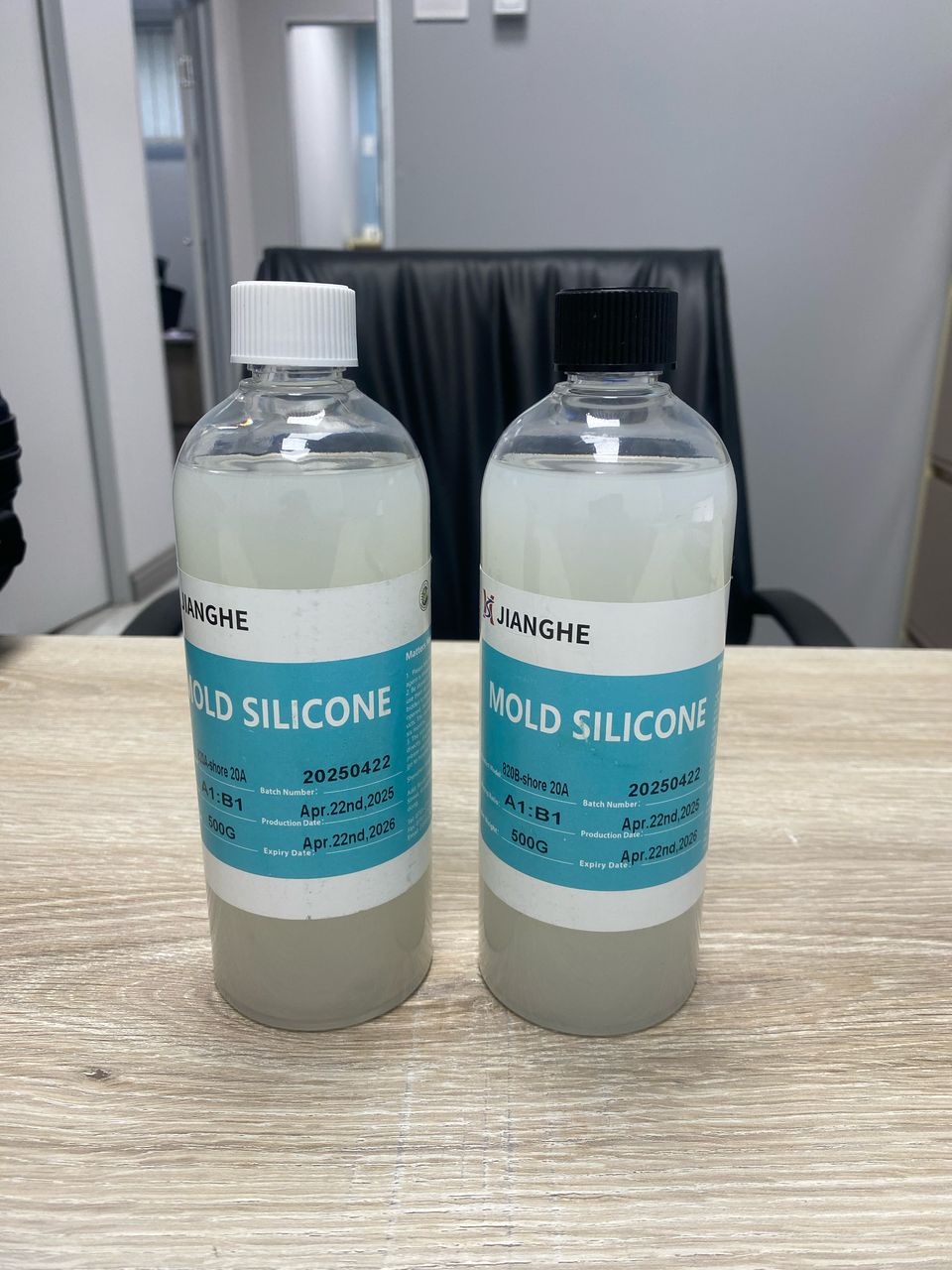

MOLDING

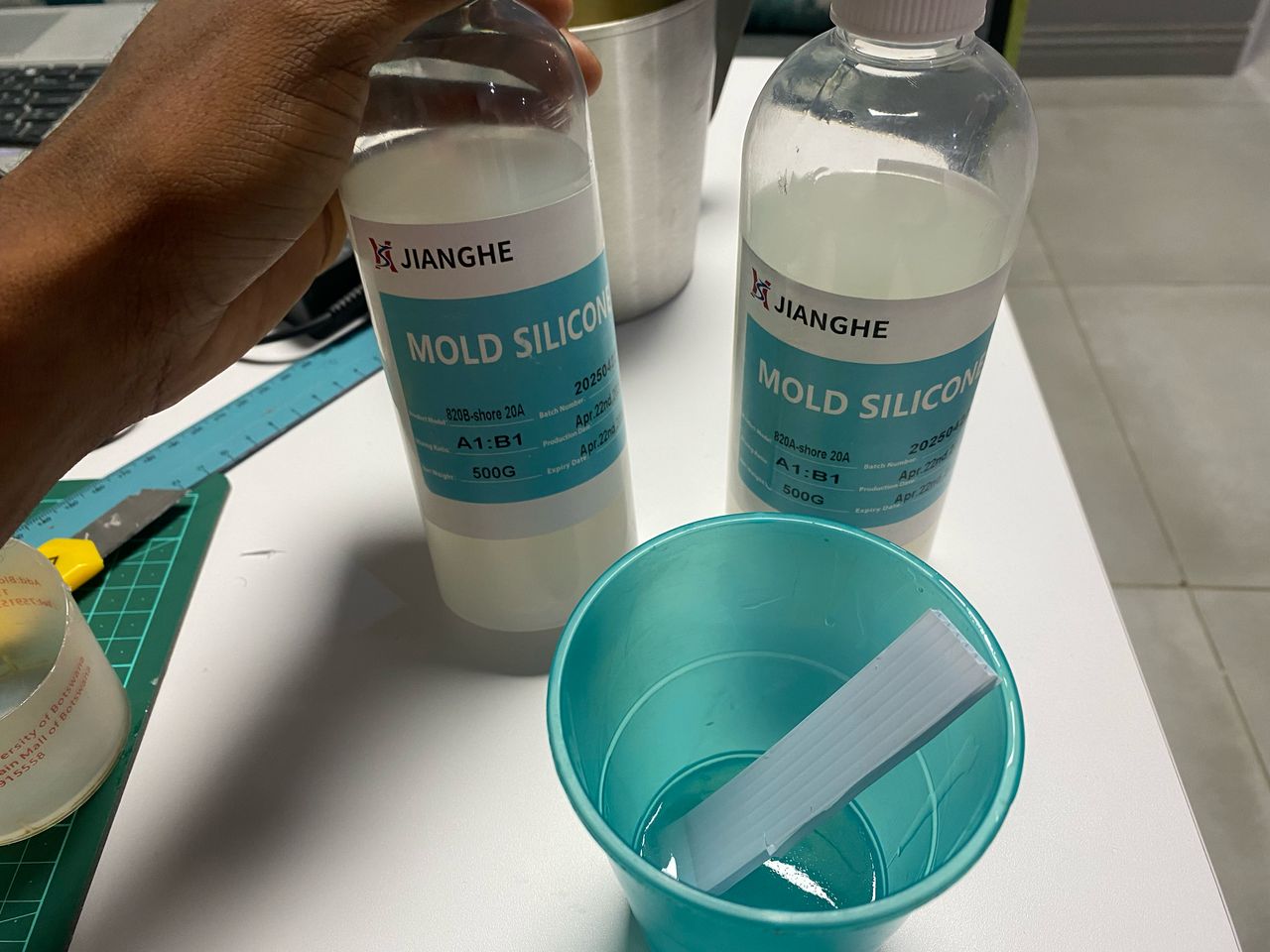

The products used for molding.

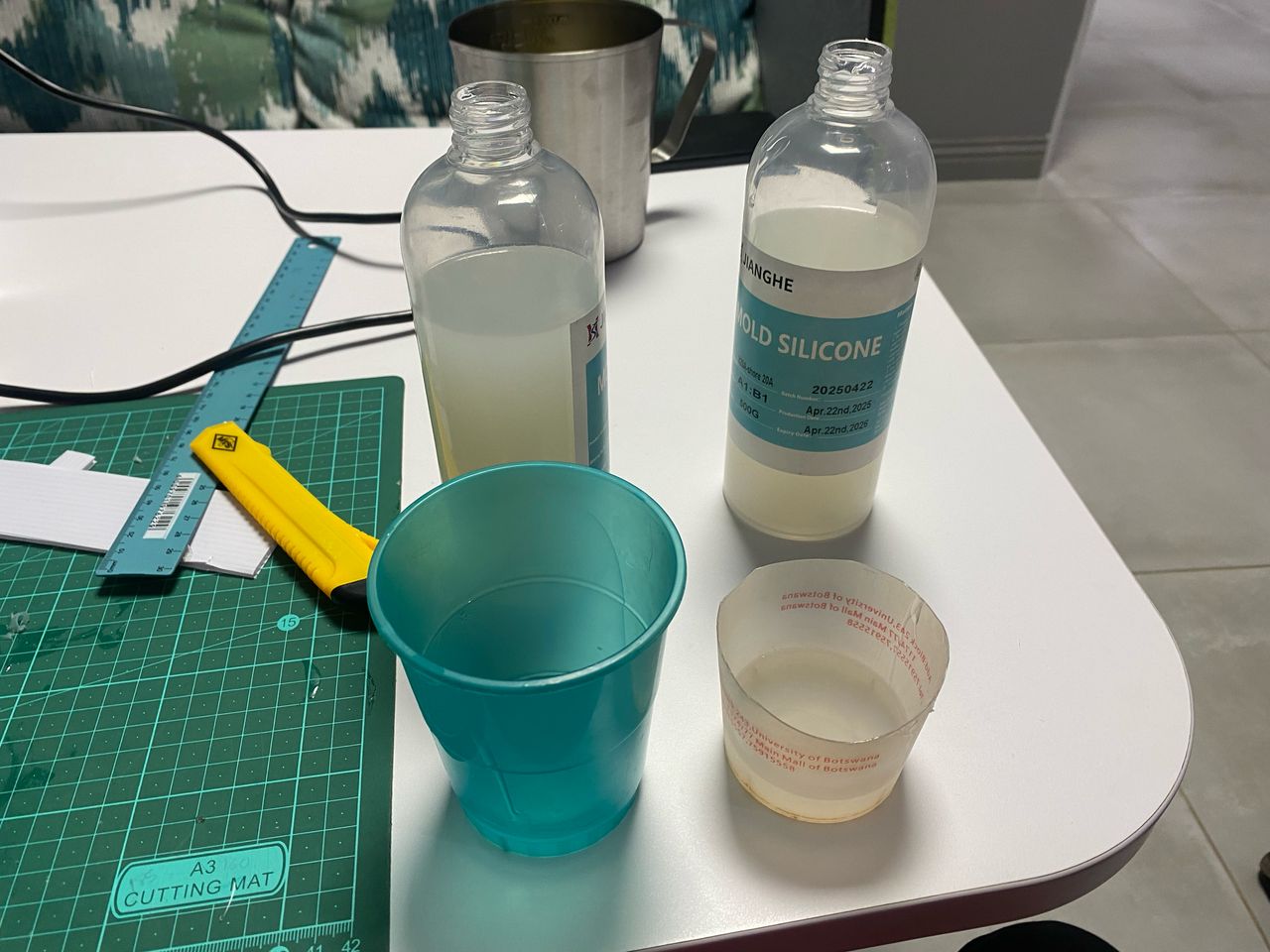

I then mixed the curing and the main silicone agent (mold silicone) together with a ratio 1:1.

MIXING

POURING THE SILICONE INTO THE DESIGN

The mixed silicone was then poured into the 3D printed design and let to set. This was to create a mold.

FINAL MOLD

The mold was then removed from the 3D printed parts.

I then fixed the the two molds together with a selotape to create a cavity that i will poured the molten candle wax in.

CASTING

I then melted the candle using a hot air gun, the molten candle is the one that I will be casting in my mold.

After melting the candle wax I then poured it into my mold and let it set.

FINAL PRODUCT

After it has set, i then removed it from the mold.

I then abraded with a sand paper to smoothen the rough edges of my final product.

FILES