Week15-Wildcard Week

Since my company happens to have a project that requires aluminum alloy, I’d like to try using the CNC machine to mill 6061 aluminum alloy for this week’s assignment.

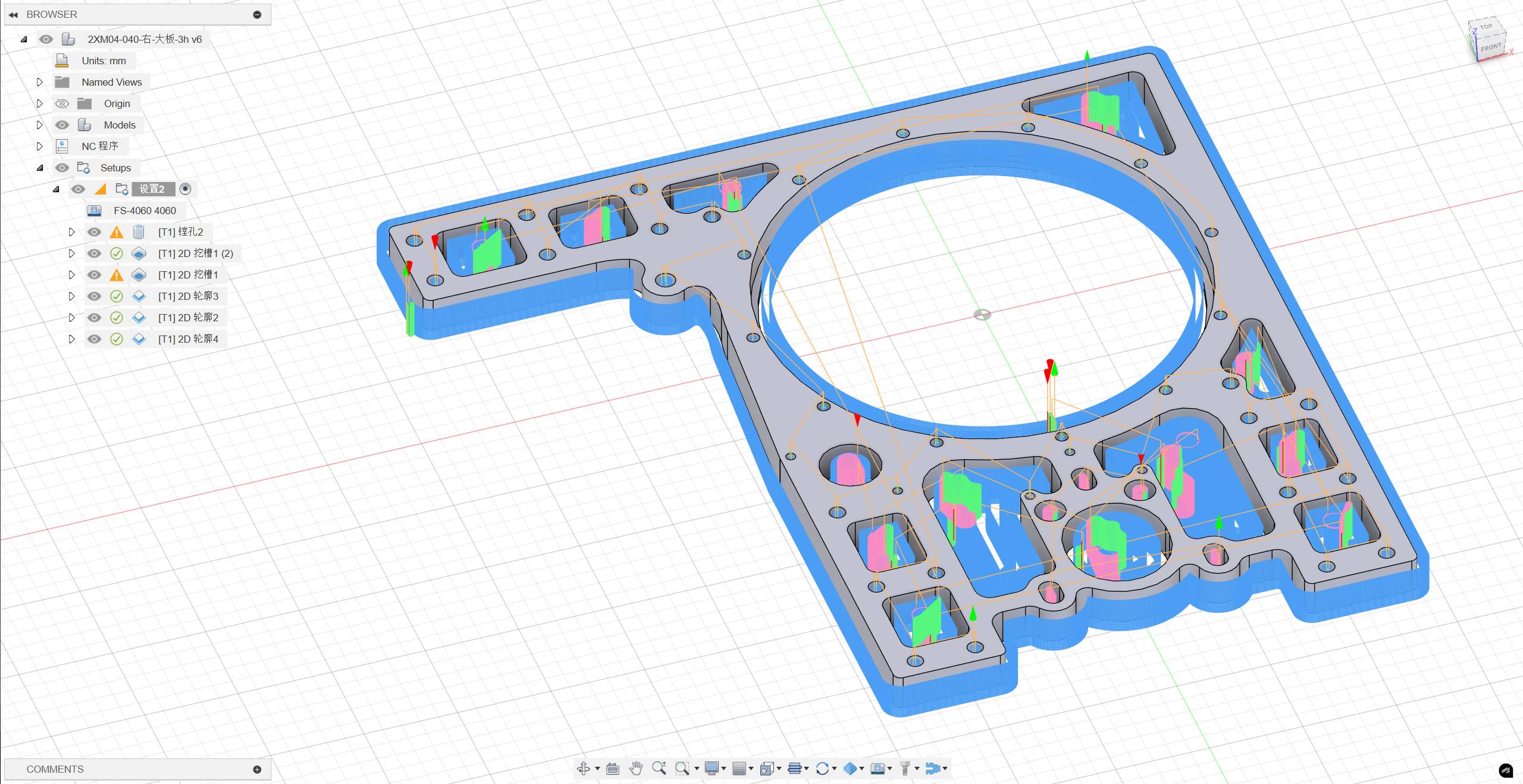

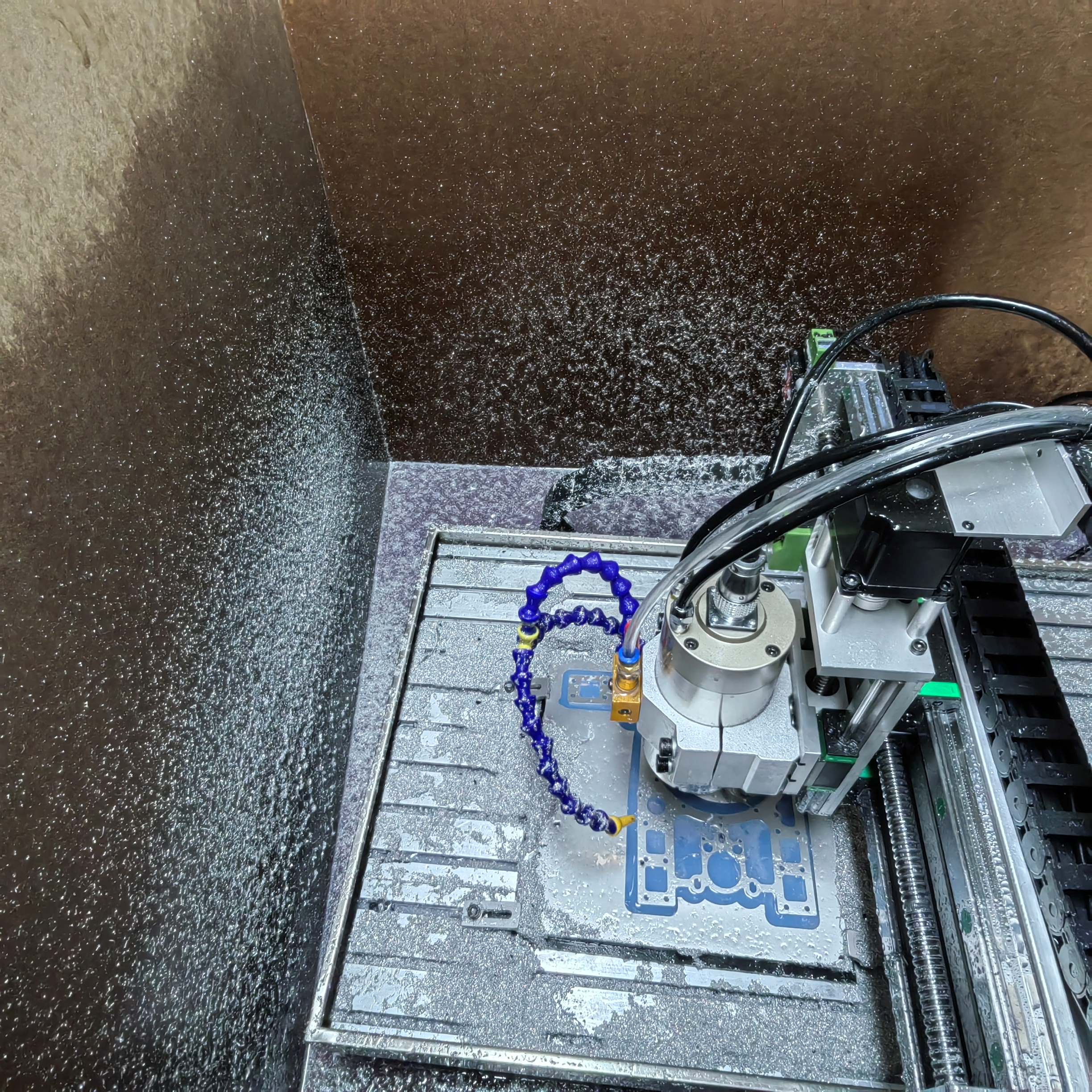

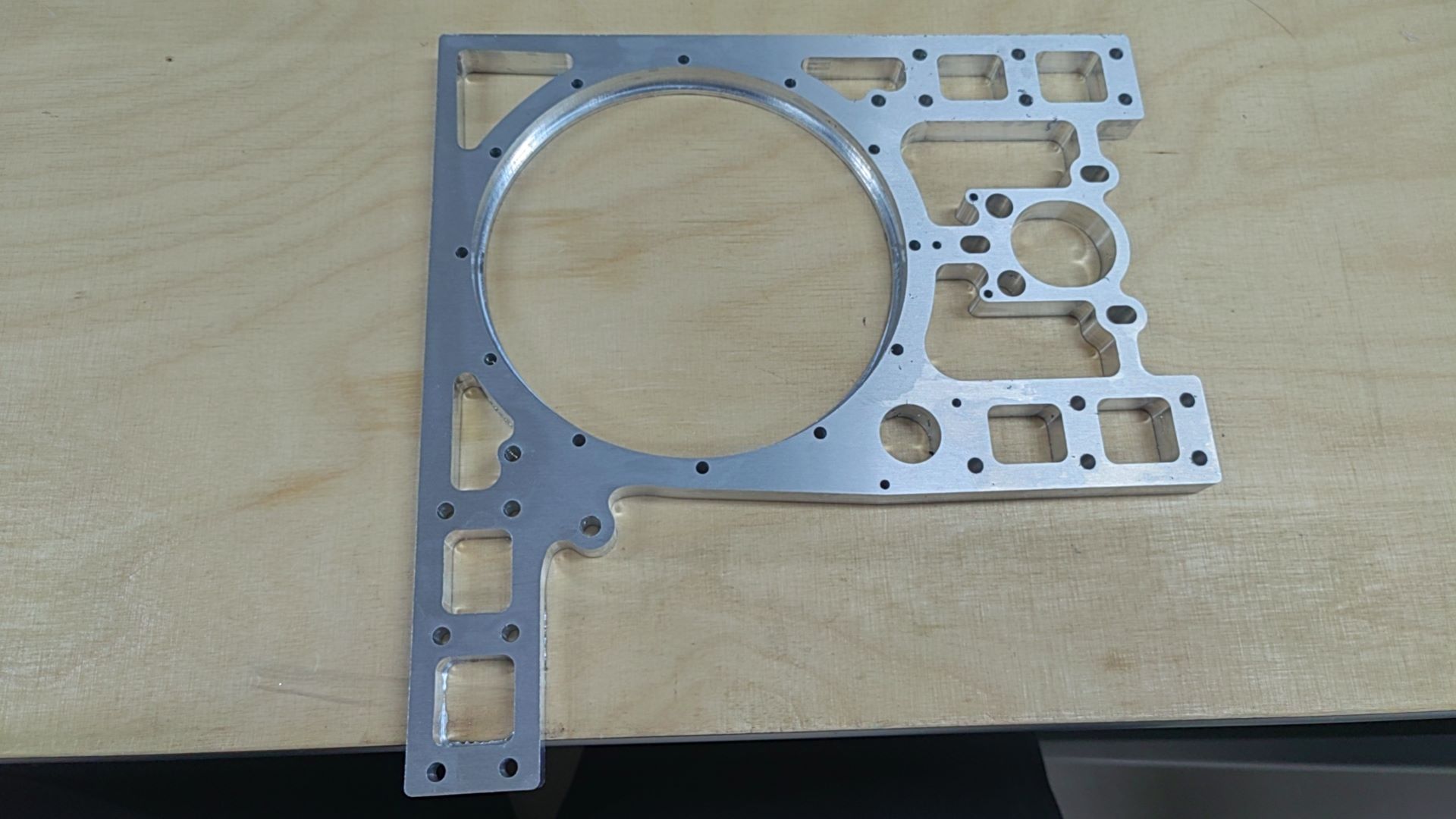

This is a wheel mounting bracket from the FRC competition. This time, I will cut it using 6061 aluminum alloy.

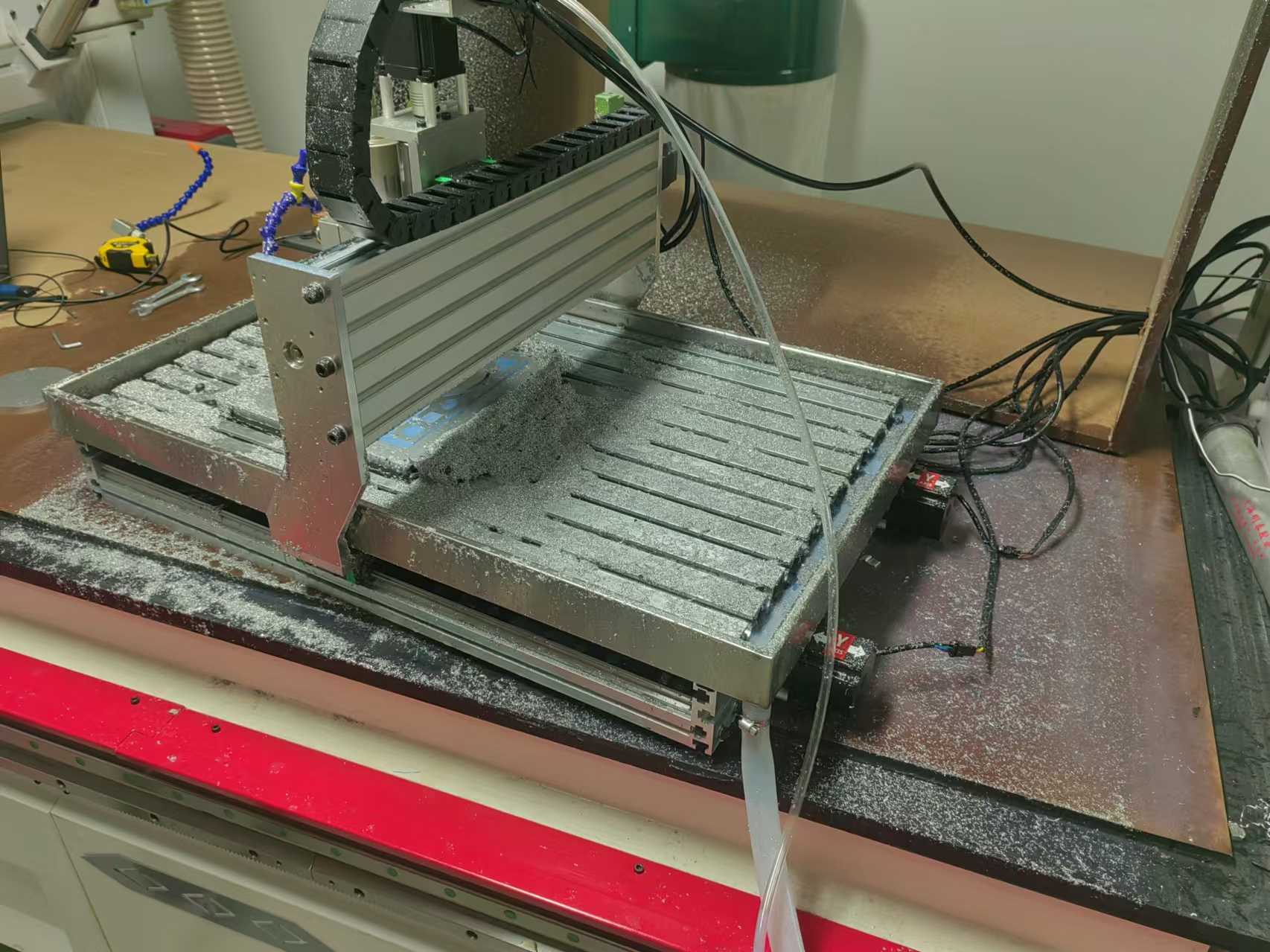

Machine parameters:

- Working area: 400*700

- Spindle power: 1.2kW water-cooled spindle

- Spindle speed: 24,000 rpm

- Operating system: GRBL

- Additional features: Water cooling (cutting fluid), cutting fluid filtration and circulating water tank

I used Fusion 360 as the CAM software and divided it into six steps (I know sequential cutting can be kept, but I think this allows for clearer organization). A total of three tool changes are required. Here is my machining list.

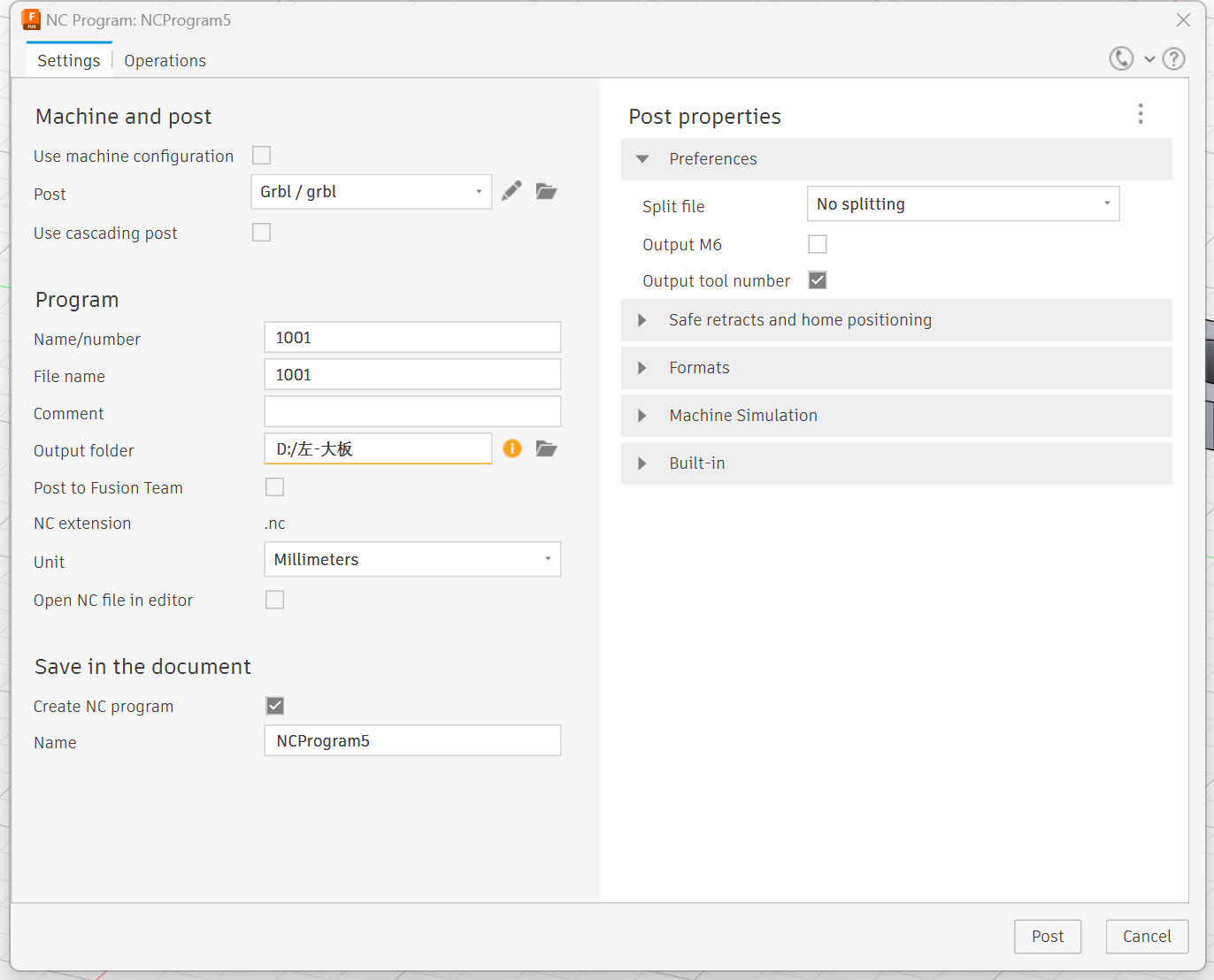

I divided it into three toolpaths because three tool changes are needed. Initially, I planned to manually add pause commands in the NC code, but then I realized that I’d have to re-zero the Z-axis each time, so I’m glad I didn’t do that. Another key point in this step is that options must be modified step-by-step from top to bottom. At first, I selected “winpc-nc” instead of “grbl” in the post-processor. When I changed the output path and then modified the post-processor, the output path was reset—this operation logic is really inconvenient.

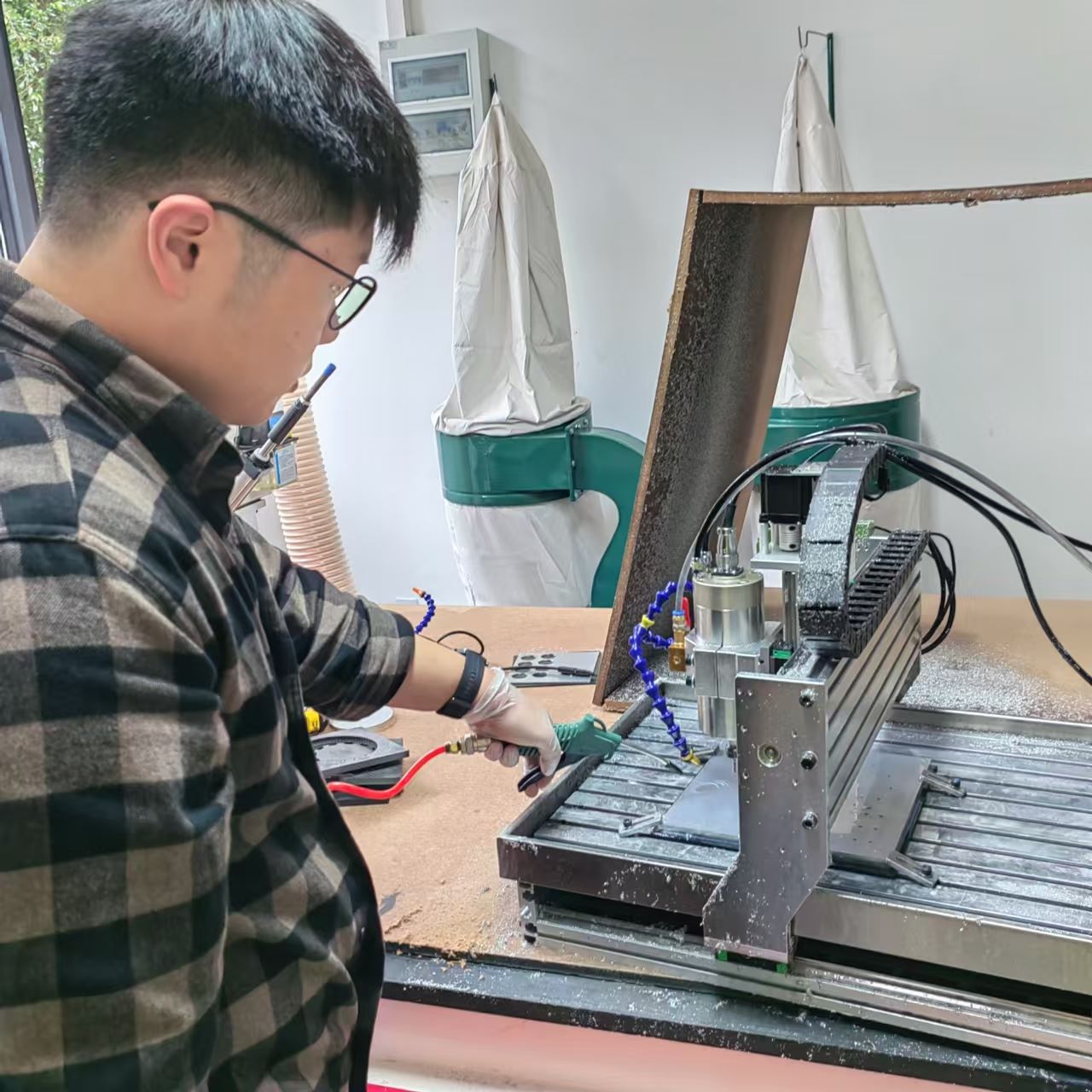

Before officially starting the cutting process, be sure to wear a P100-level mask, as aerosols from the cutting fluid can be released during operation, which is harmful to health.

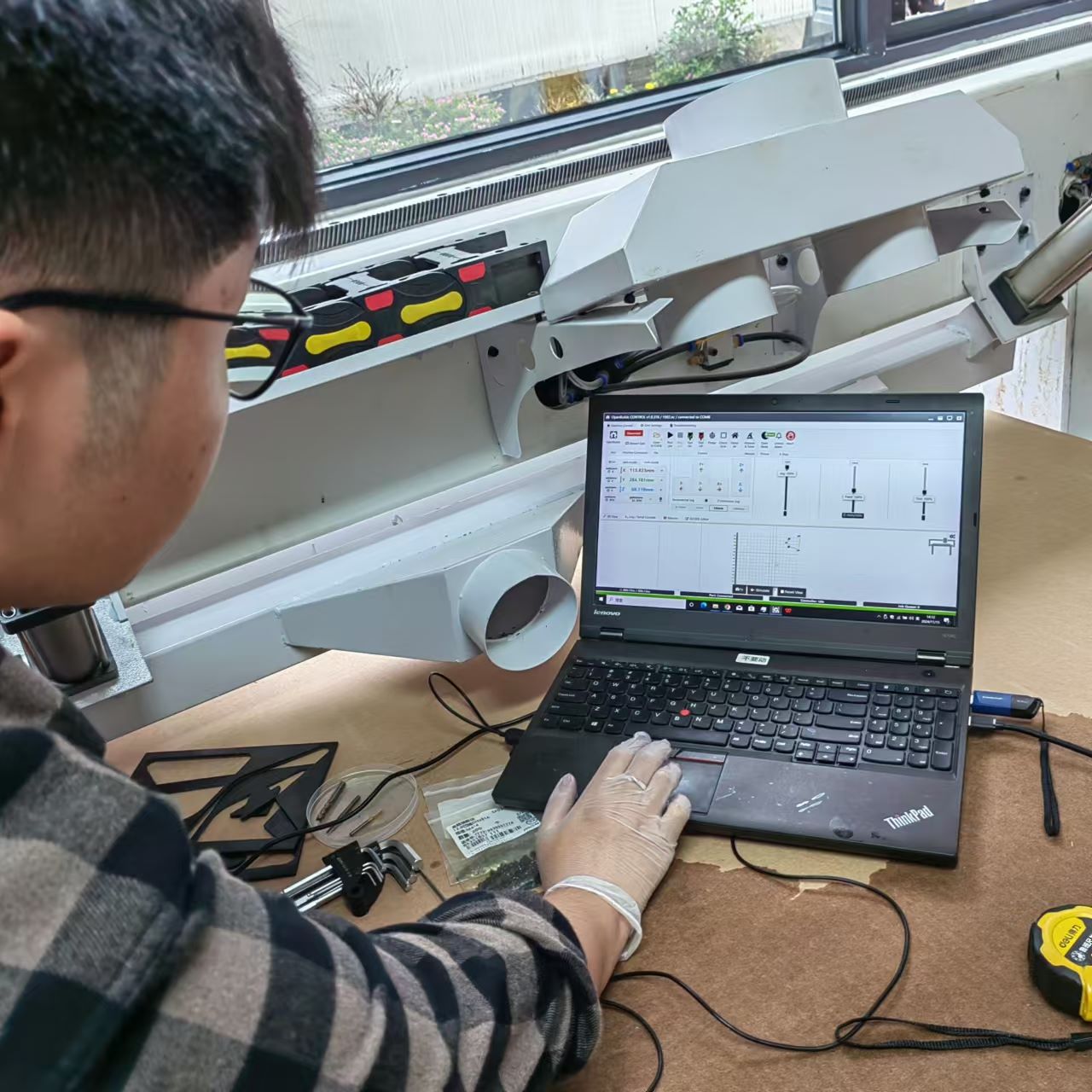

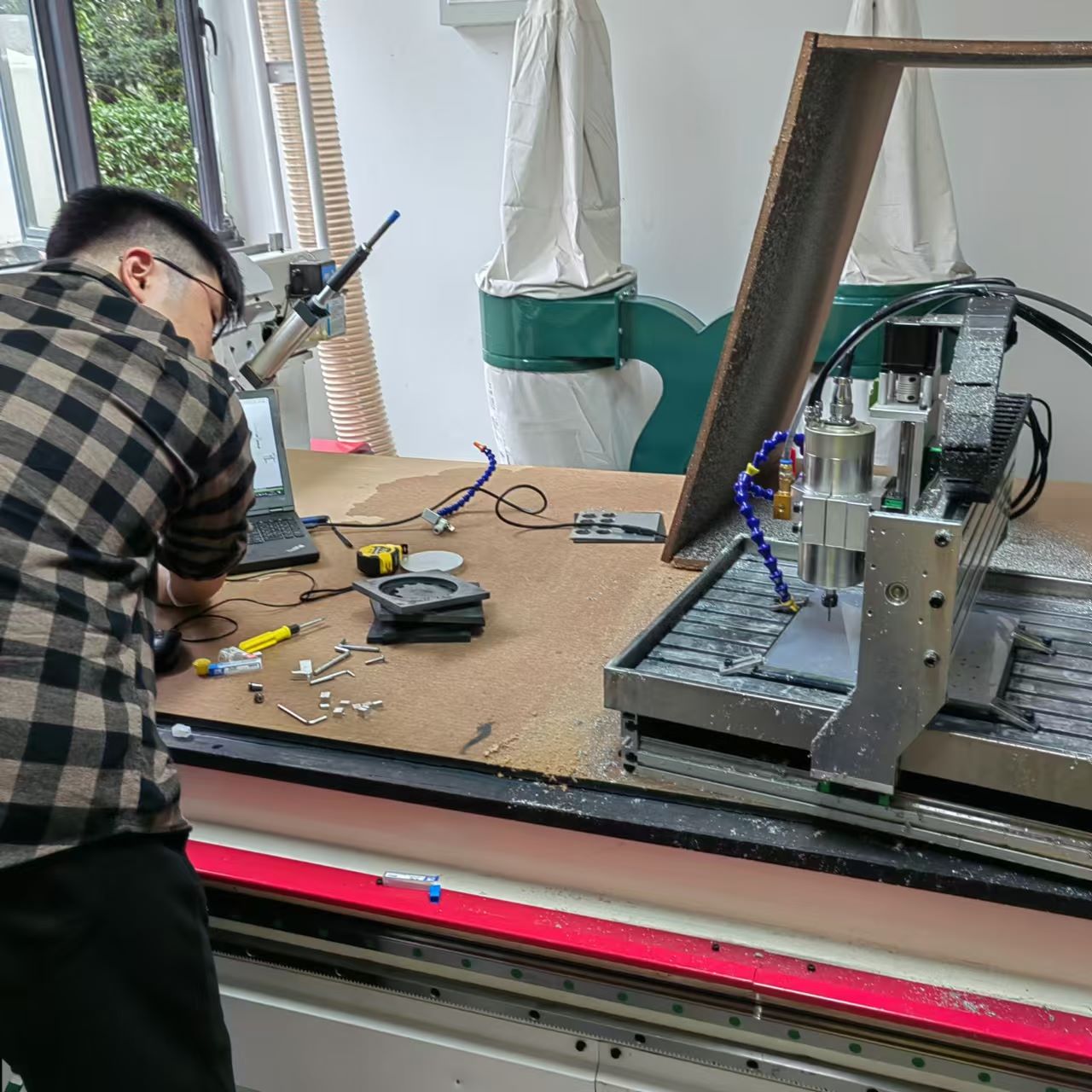

For the control software, I use OpenBuildsCONTROL. After importing the first file, I changed to a 2mm end mill. The steps are as follows:

- Confirm the XY position, then use the size function to check if the frame is within the aluminum plate.

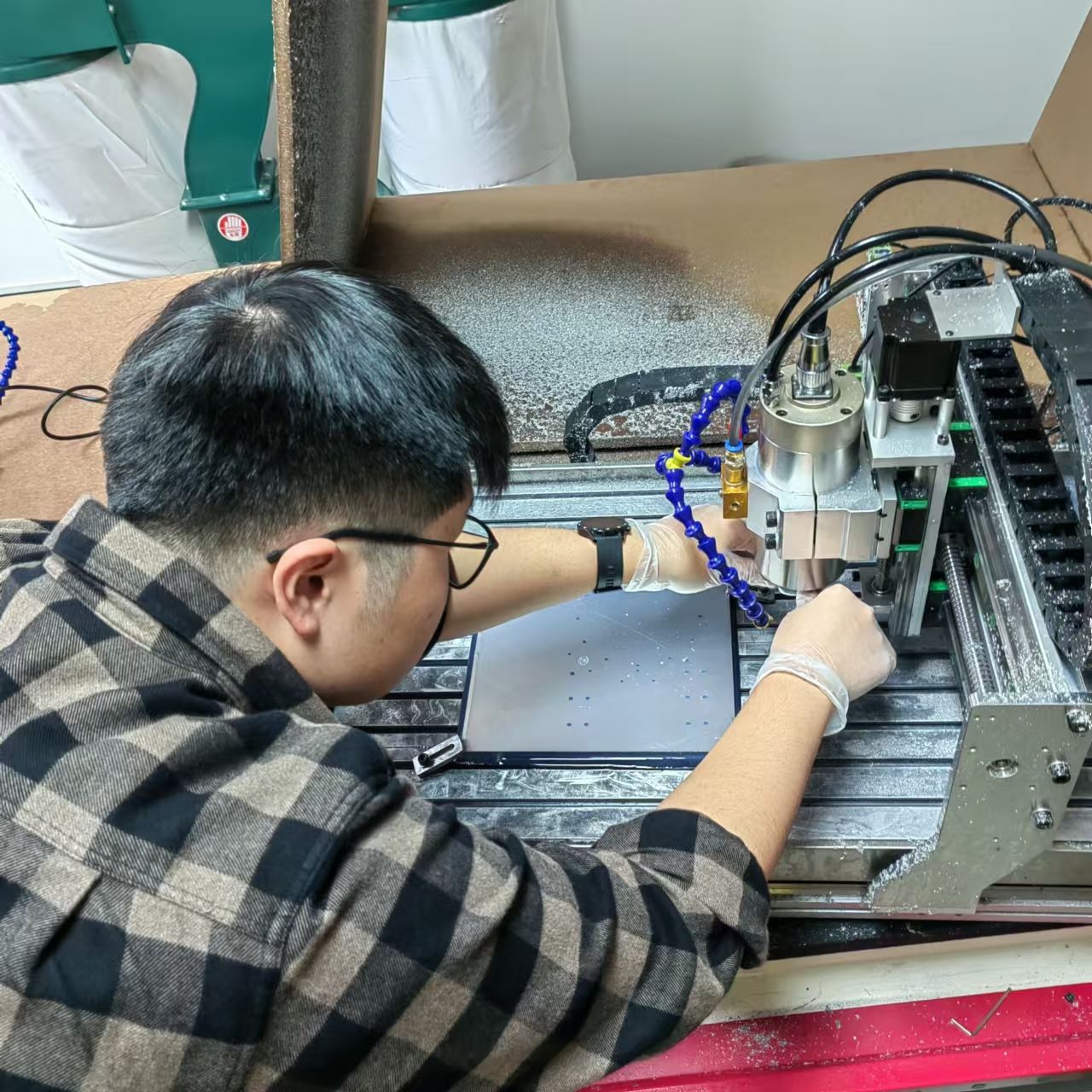

- Manually set the Z-axis height.

- Close the cover to prevent aerosols and water from splashing out.

- Turn on the spindle and confirm that the inverter setting is 400 (24,000 rpm).

- Turn on the spindle water cooling.

- Turn on the cutting fluid cooling.

- Start cutting.

Cutting complete!

sorce file