10. Machine design¶

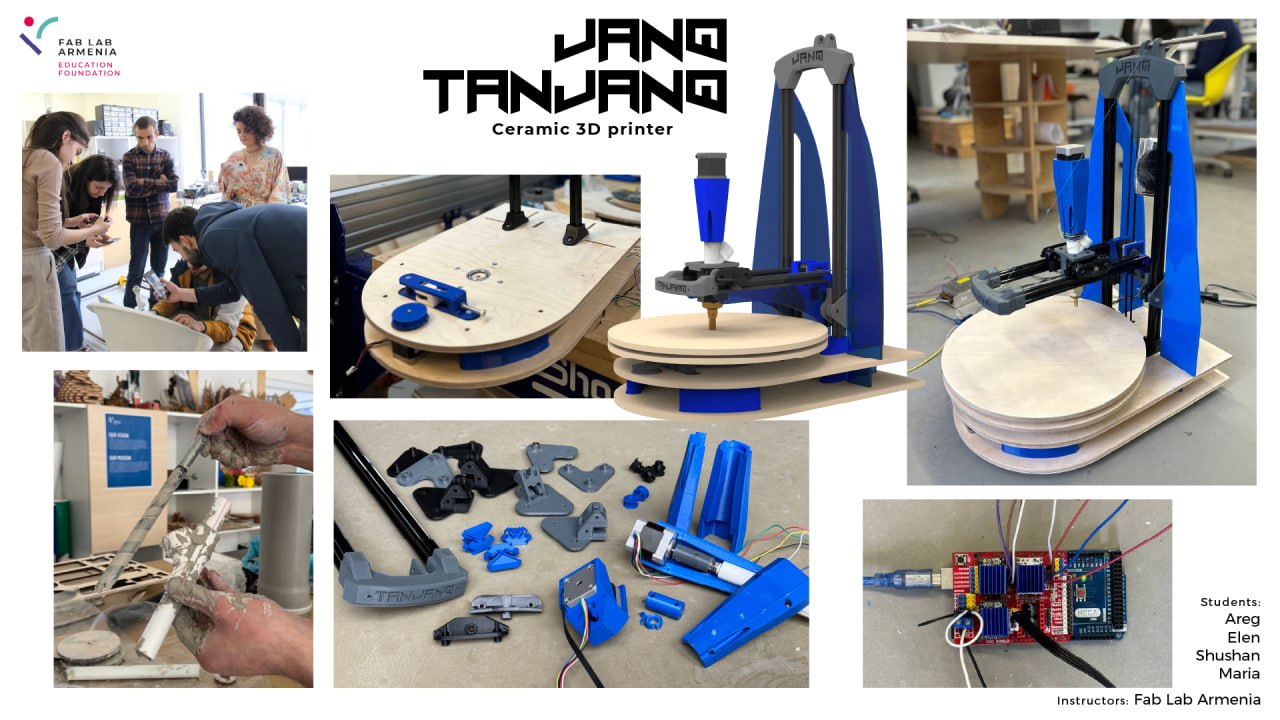

This week has passed actively working on our group project - Ceramic 3D Printer.

Research¶

We did a great research to find out what problems do we need to solve, how clay extruder works and what axes need for this type of 3D printer. we searched for parts (what type of parts we will need), extruder (what type of extruder we can make), printing surfaces for it also, with circular bed.

More about this week you can see in our Group Page.

Then we discussed all work, that should be done and we divided the work into 4 parts.

I decided to design the printing surface and the mechanisms and parts associated with it.

Ceramic 3D Printer’s bed¶

As we all decided together after discussion, we were making a circular bed for printing on it.

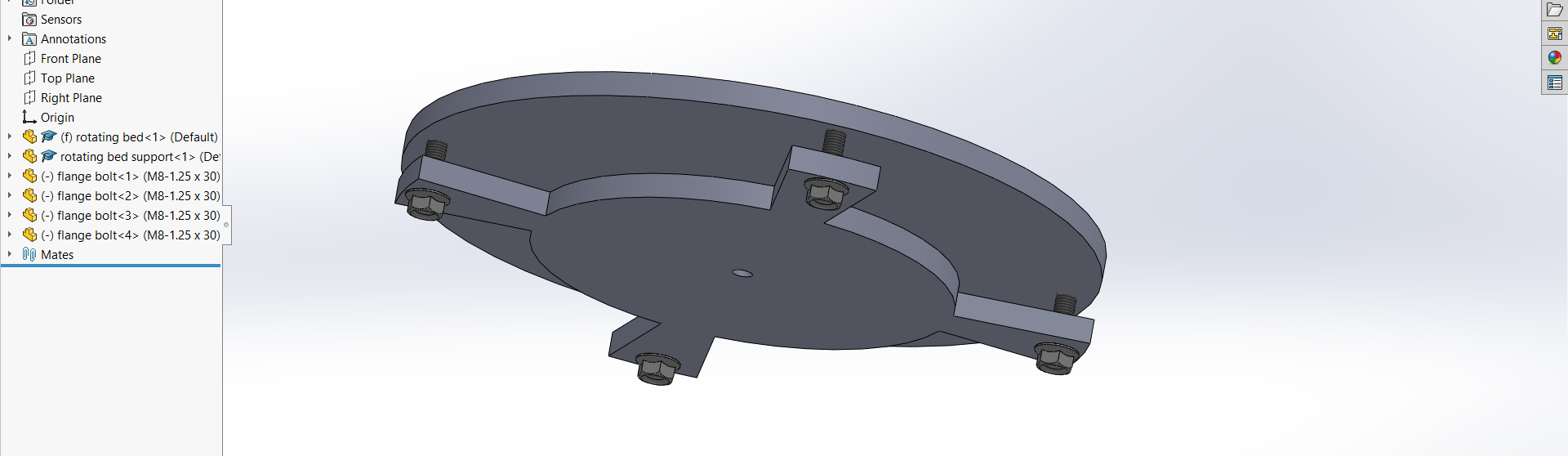

My part of work was designing 3D printer’s rotating bed. And as Babken suggested to us, we designed it circular․

Starting to work, I sketched bed types and forms.

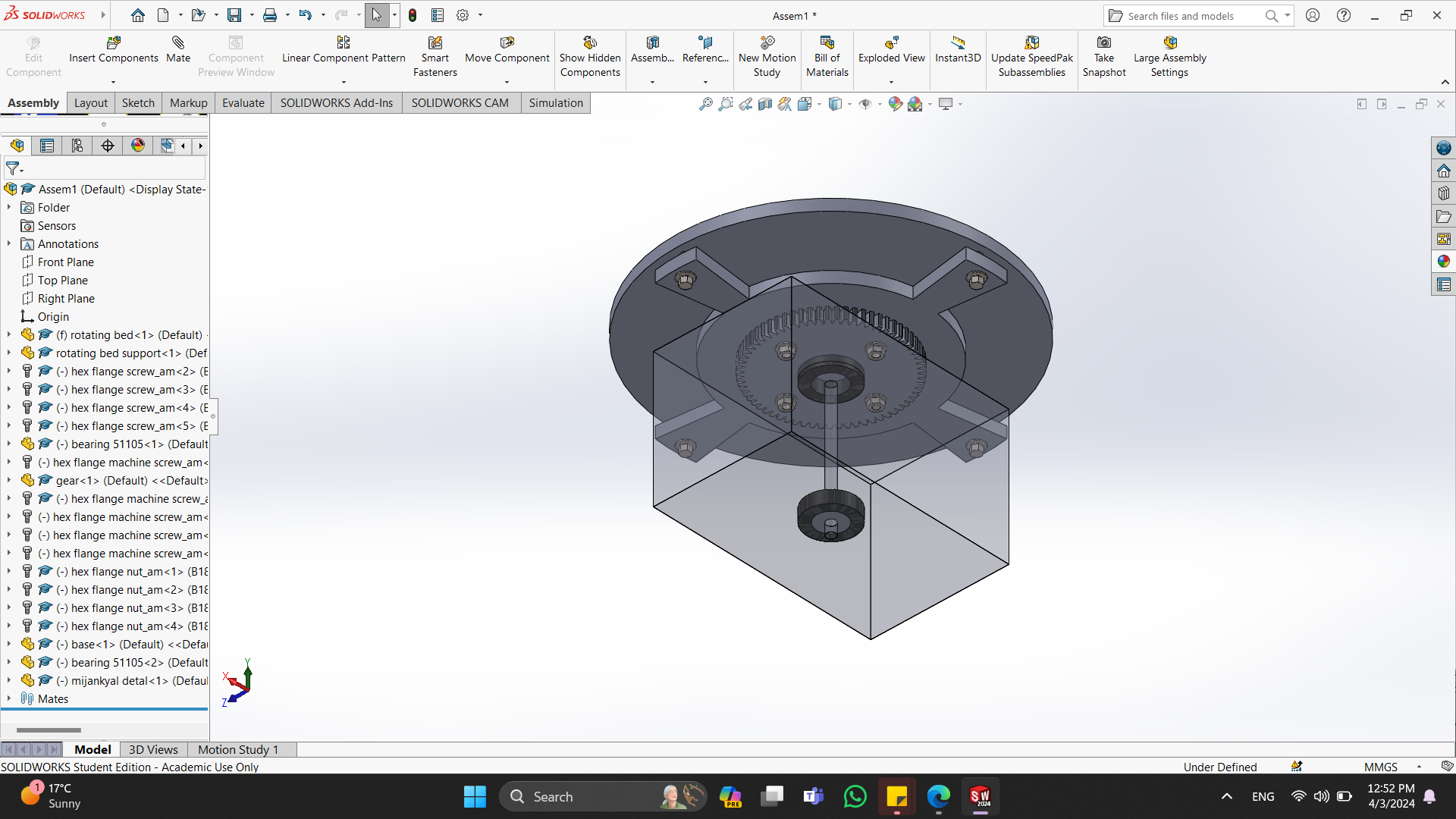

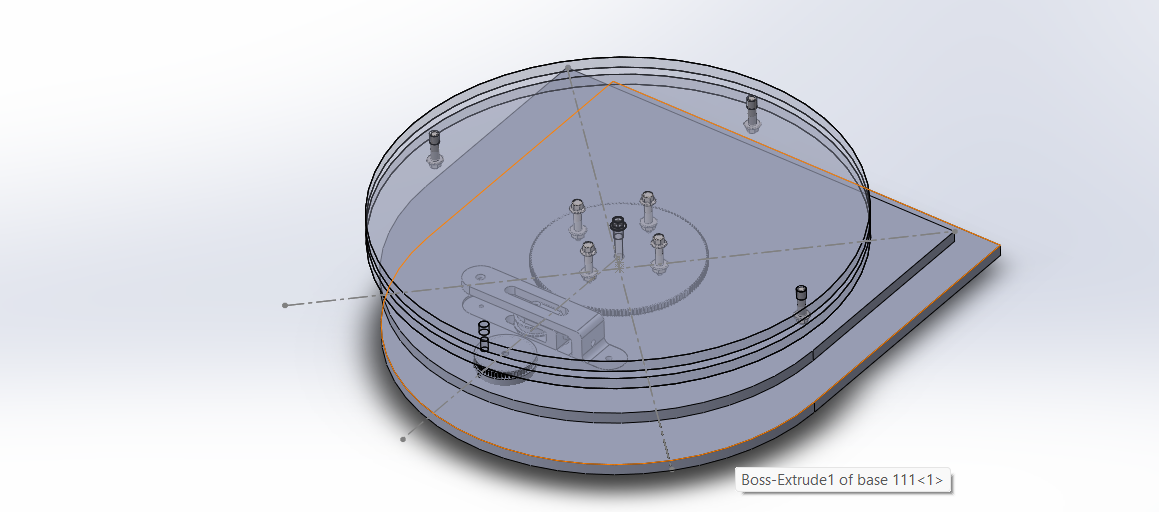

Started to make 3D models. I was modeling in SolidWorks.

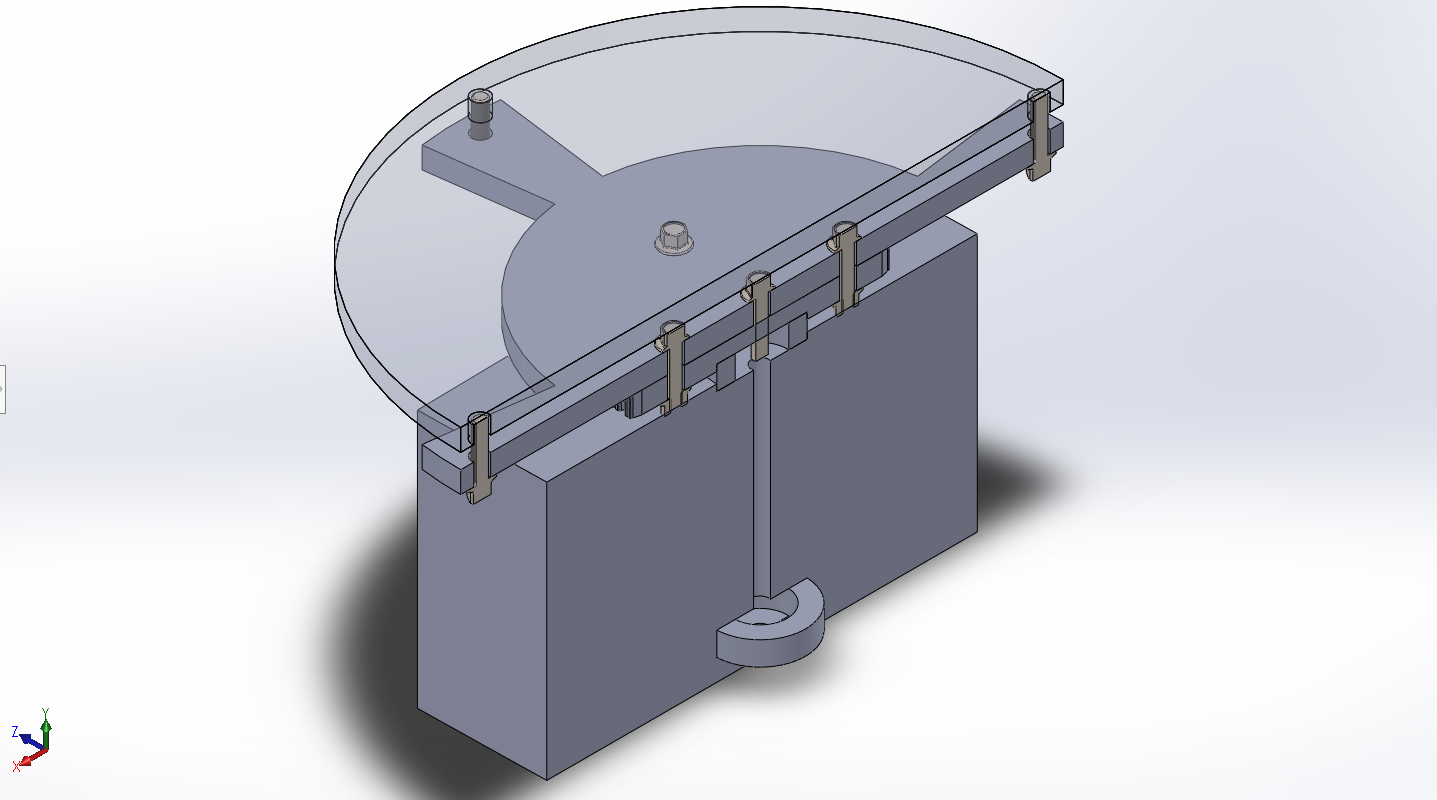

With this part I also started to design mechanism and box where will be built-in wires, stepper motor and etc.

I was modeling and changing things on it.

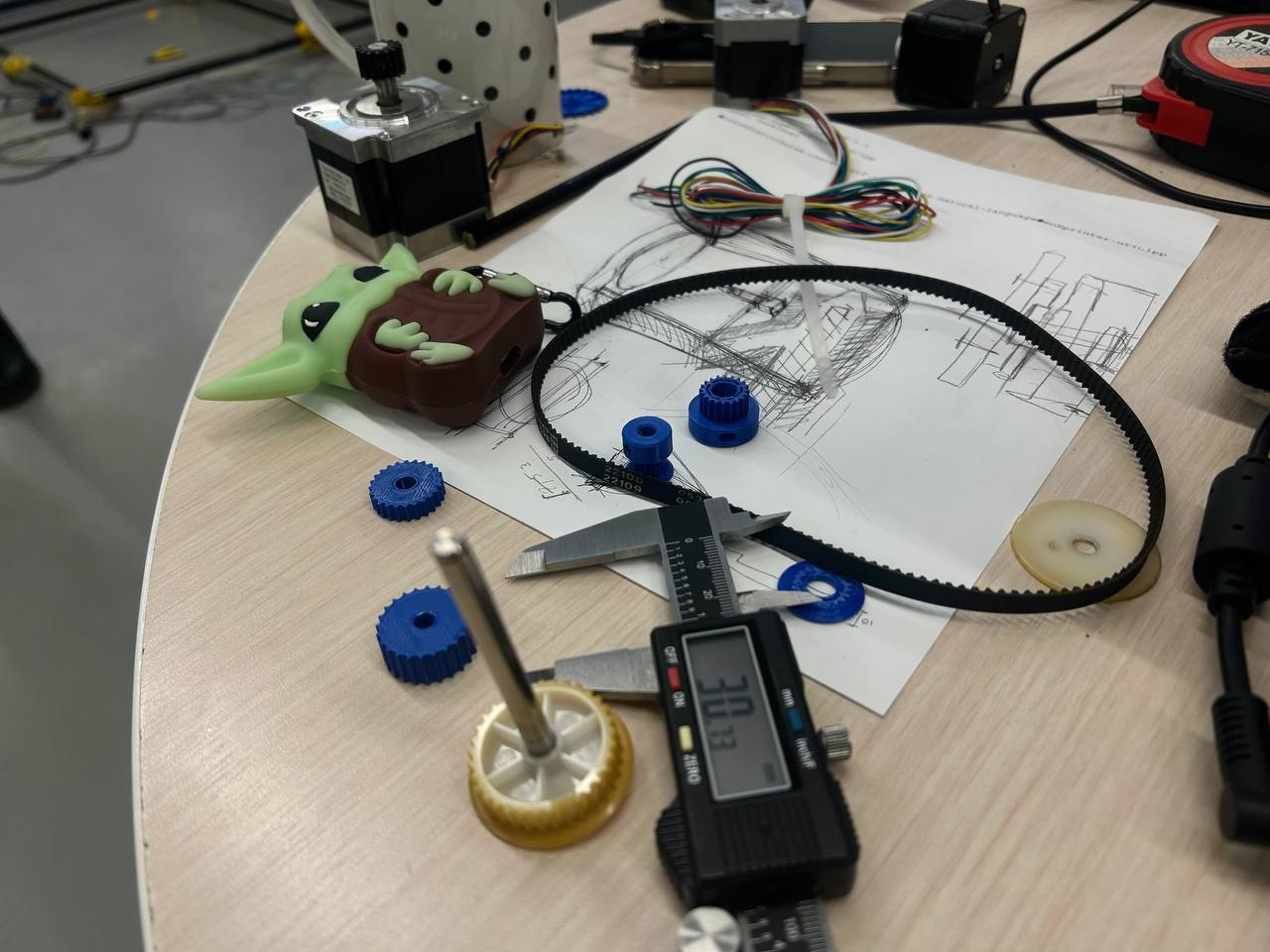

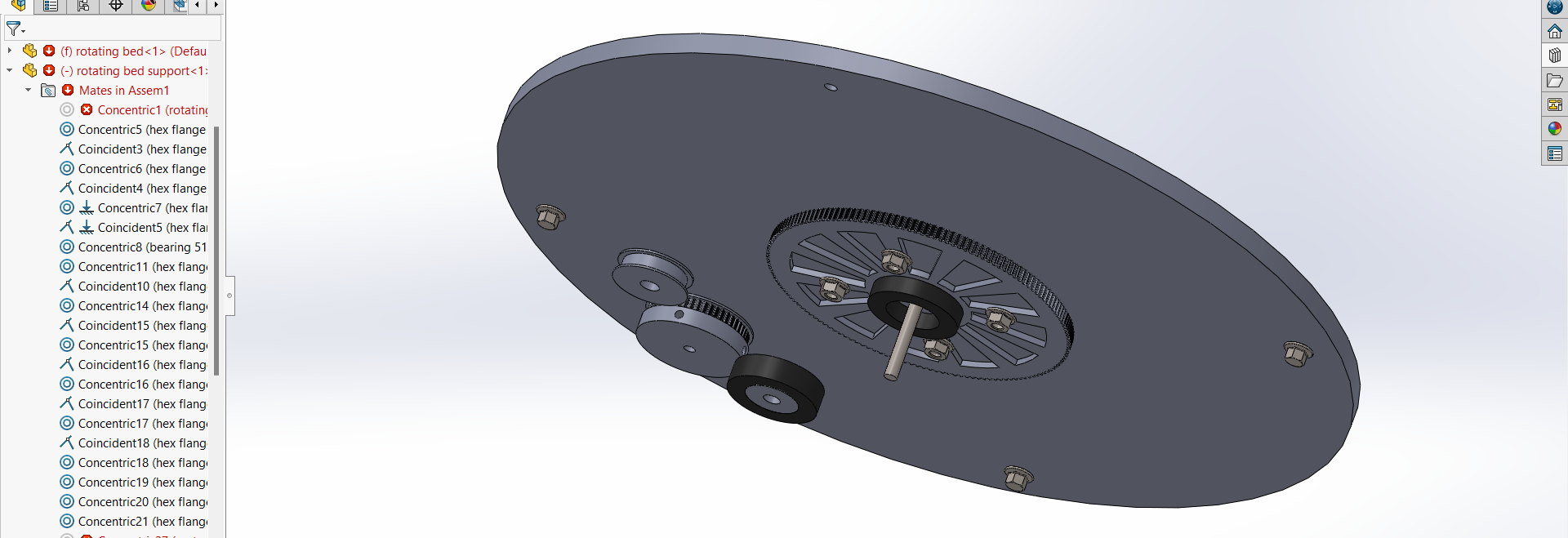

Along with the design of the rotary table, I also thought about the design of the rotating mechanism. Here I was lining up the gears.

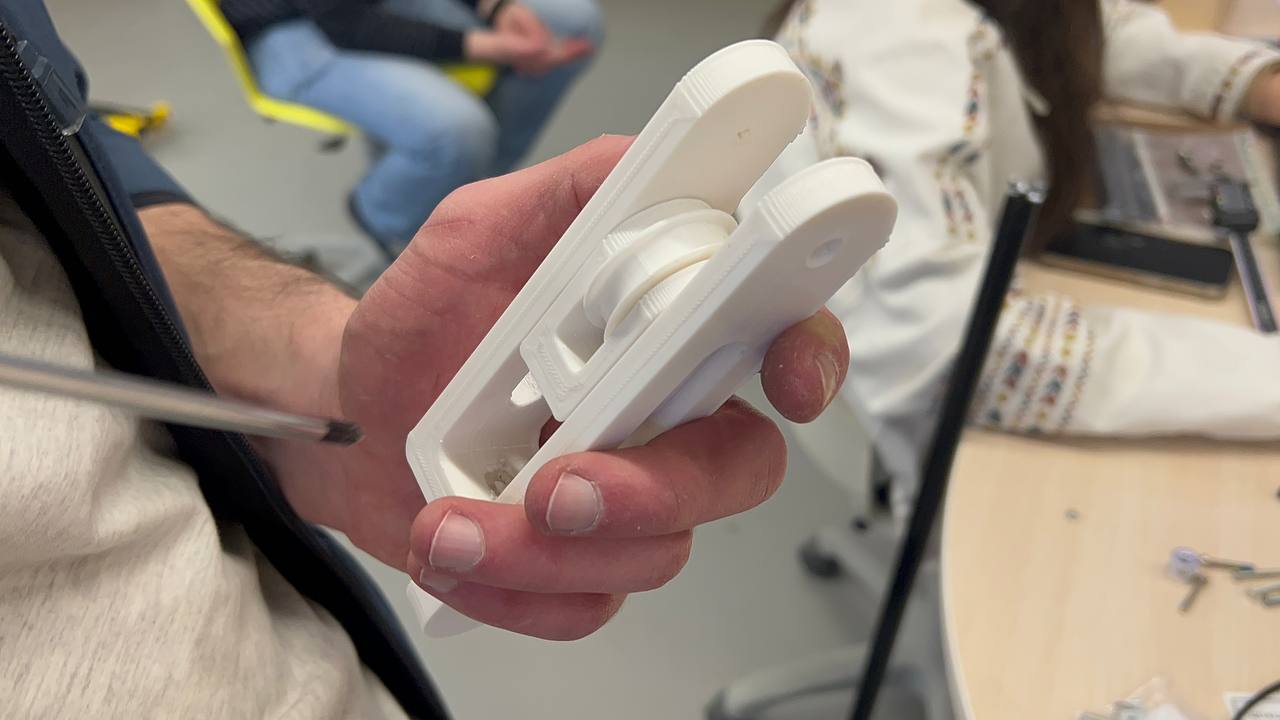

We were thinking about belt tensioner systems.

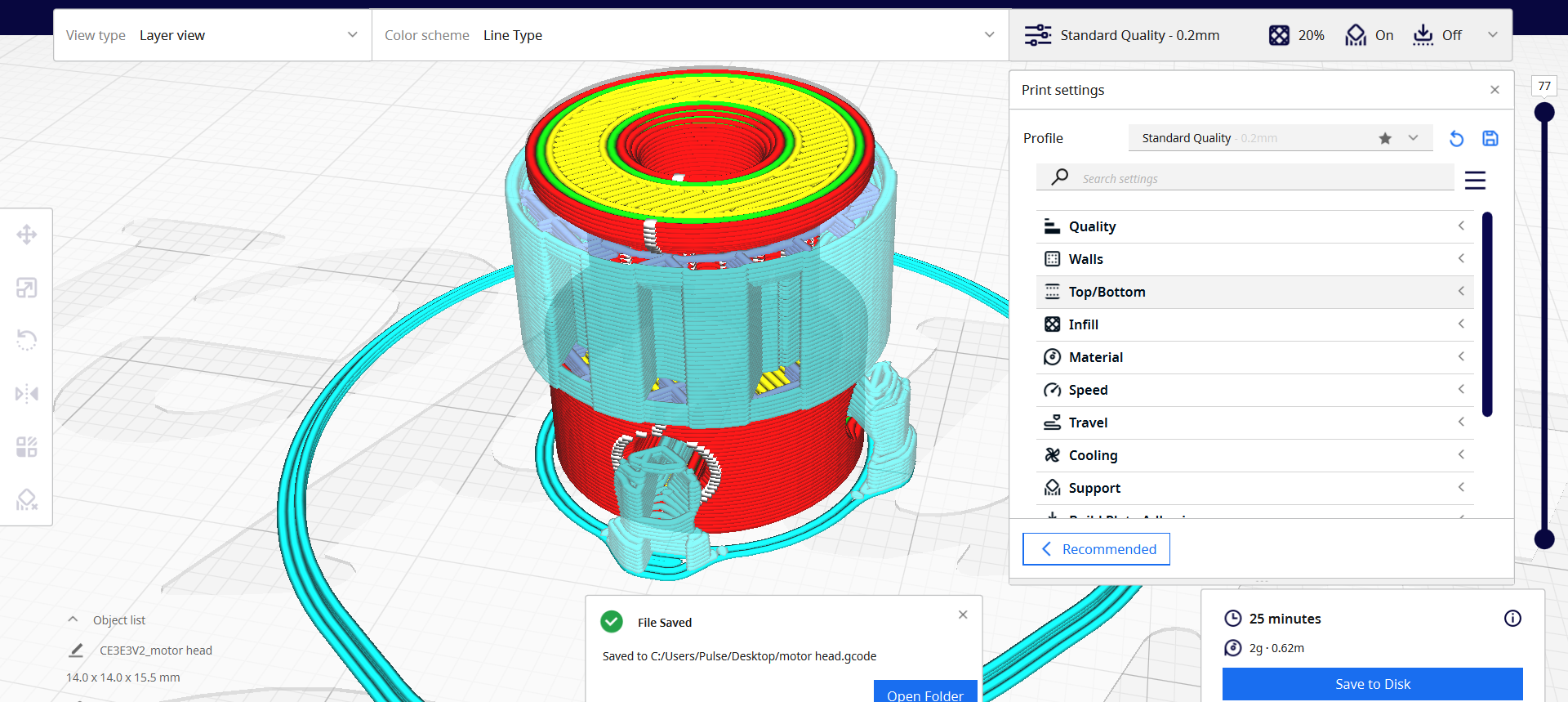

That’s why I designed these gears and 3D printed them. We wanted to test it.

After I designed and changed many gears, so that teeth will fit perfectly. In right bottom photo is the best fitted gear.

We were measuring pitch and number of teeth.

As CoPilot explained clearly:

“The number of teeth is a critical factor in gear design. Each gear has a specific number of teeth, and this count affects the gear ratio, torque transmission, and overall performance of the gear system.”

“Pitch: The pitch is the distance between corresponding points on adjacent teeth.”

“Pitch Circle Diameter (PCD): The pitch circle diameter is a fundamental dimension in gear design. It’s the diameter of an imaginary circle that passes through the center of the gear and is tangent to the tooth profiles”

“Gear Ratio: The gear ratio determines how many times the output gear rotates relative to the input gear. It’s calculated as the ratio of the number of teeth on the output gear to the number of teeth on the input gear. For example, if the output gear has 20 teeth and the input gear has 10 teeth, the gear ratio is 2:1”

“Module: The module (m) is another important parameter. It represents the ratio of the pitch diameter to the number of teeth.

After we realized that 2-sided are not so necessary, so we made it with one side.

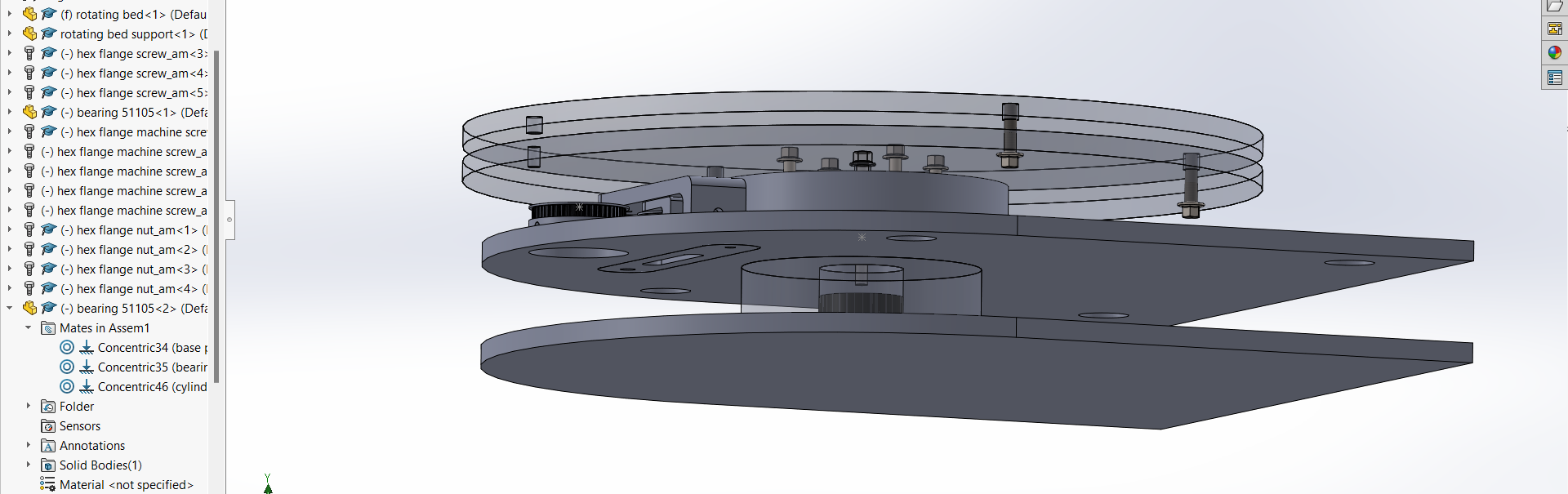

Added the horizontal bearing.

It helps the bed to rotate much more smoothly. We need it to ensure accuracy.

For the middle wheel Areg designed a part, that will hold the wheel into base construction. Thanks to this, we will be able to adjust, tighten or loosen the tension of the belt.

Me and Areg finished designing the bed part together.

Design and sizes of it were changed like this.

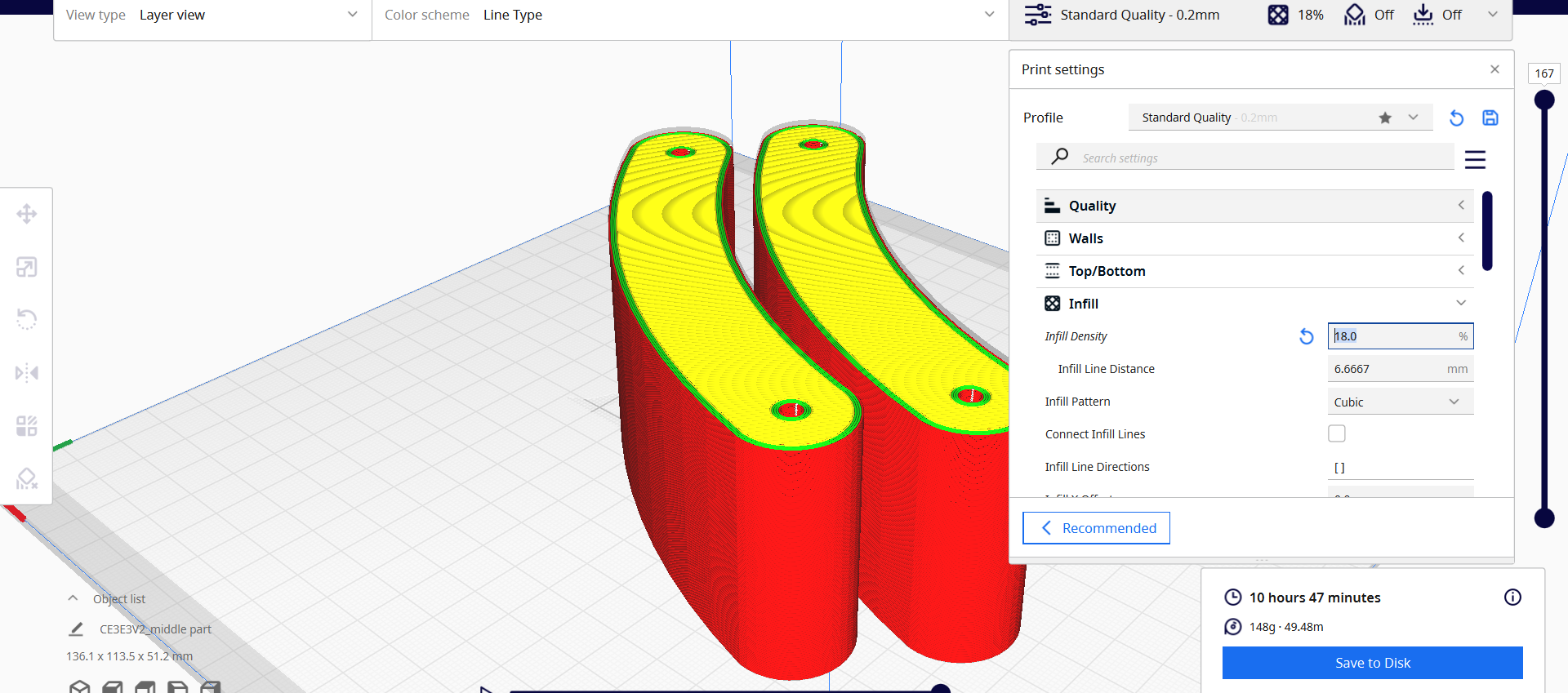

Besides that there were small parts that I need to print by 3D printer. Like the legs of the bed, holding joints, etc.

Those were the parts that had to be screwed to the actual table after assembly.

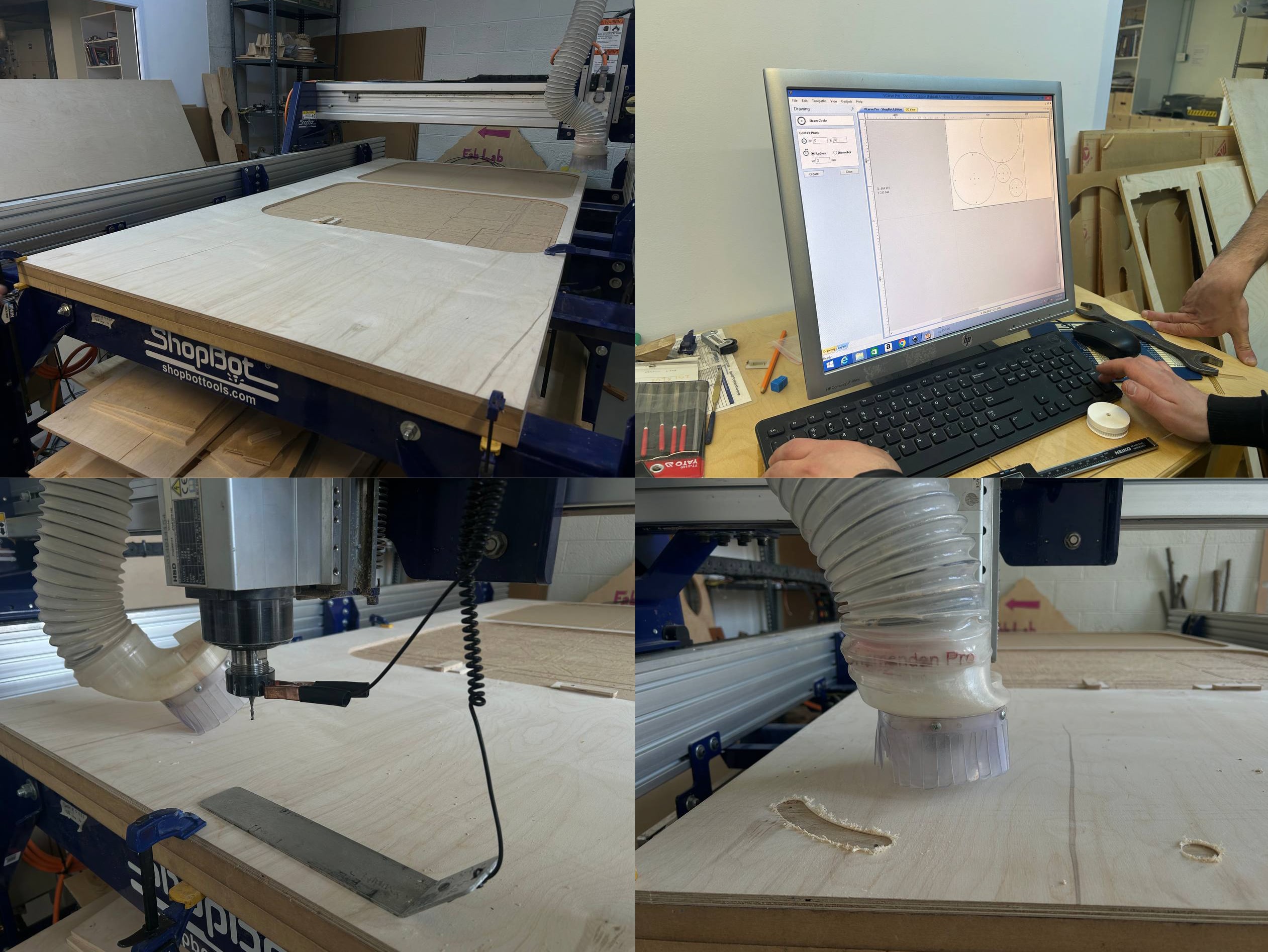

Bed cutting by CNC Machine¶

After I started cutting these parts by CNC Machine.

It took half of a day to cut all these parts.

Ceramic 3D Printer’s bed test assembling¶

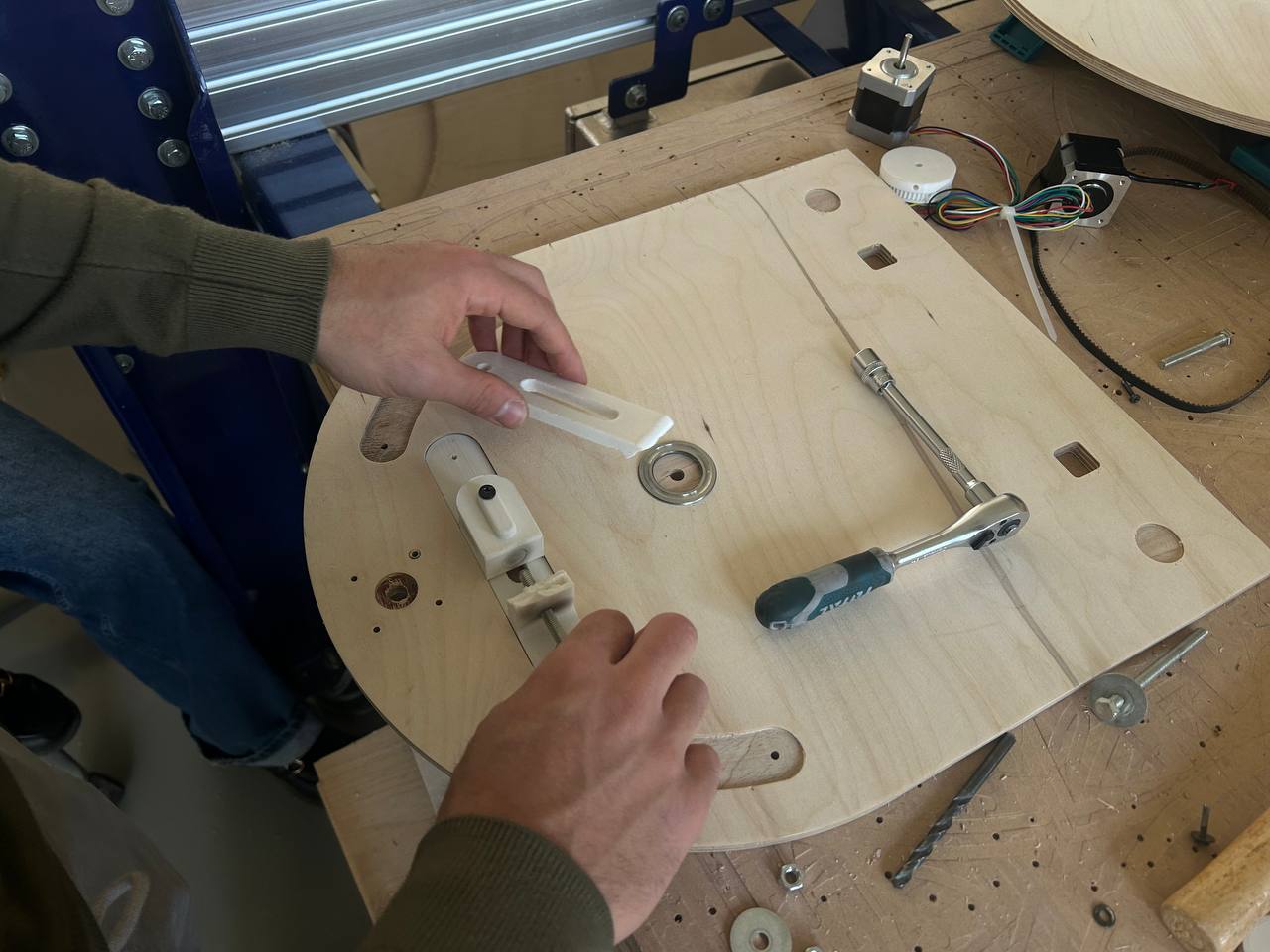

I started to assemble parts that I already have, to understand what issues I have.

Maybe there are some mistakes in my design or in cutting process.

So after we were testing rotation, parts and belt tensioner system.

After testing Mkhitar (our technical support specialist) and Shushan tested the electronics part too.

There were a strange sound in the end of the video, cause speed was much more fast that it needed to be.

While I was assembling I noticed defect in one of bed’s plywood. We cut the part where we had to put a pocket. So one of them were cut twice. And after started final assembling.

Here is the main part.

After we put on it other parts, that were made by Elen and Areg

Final Result¶

And here is the final result.

Recognize opportunities for improvements in the design¶

Conclusion¶

One of the most interesting parts of this week assigned to me. Designing gears seemed like an easy thing, but when you immerse yourself in the process, you realize that there are many places to make calculations. In addition, it was necessary to print self-supporting parts with the gear. By researching, I gathered a lot of information and found quite a few tools that can be used to assemble gear.

It took about 5 days to build the mechanism for the turntable part, and during those days the designs of the same parts were changed several times. The important thing is that the deadlines were enough to finish what we started. Also more days were needed for assembling all parts together.

I have collected quite a lot of information during these 2 weeks. In addition to mental work, in terms of physical work, there were a lot of screws and bolts to fasten. It is not so easy to understand the order of all of them, which one to fasten first. It was necessary to assemble and disassemble several times in order to assemble the base in the correct order.

Everything was challenging, very interesting and active.