Week 15: Wildcard Week

Assignments

The assigments for this week is:Design and produce something with a digital fabrication process not covered in another assignment

Casting with Vaccum Formed Mold

For this wildcard week, I decided to revisit molding and casting assignment, this time using vacuum forming to create the mold.Milling the model

Similar to the previous assignment, I first need to fabricate the model. I was unable to use the model made in the previous assignment as it was milled into a block making it unsuitable For vacuum forming. This time round, I needed the model to be stand-alone. Using the milling process described previously, I created the new model.

Vacuum Forming

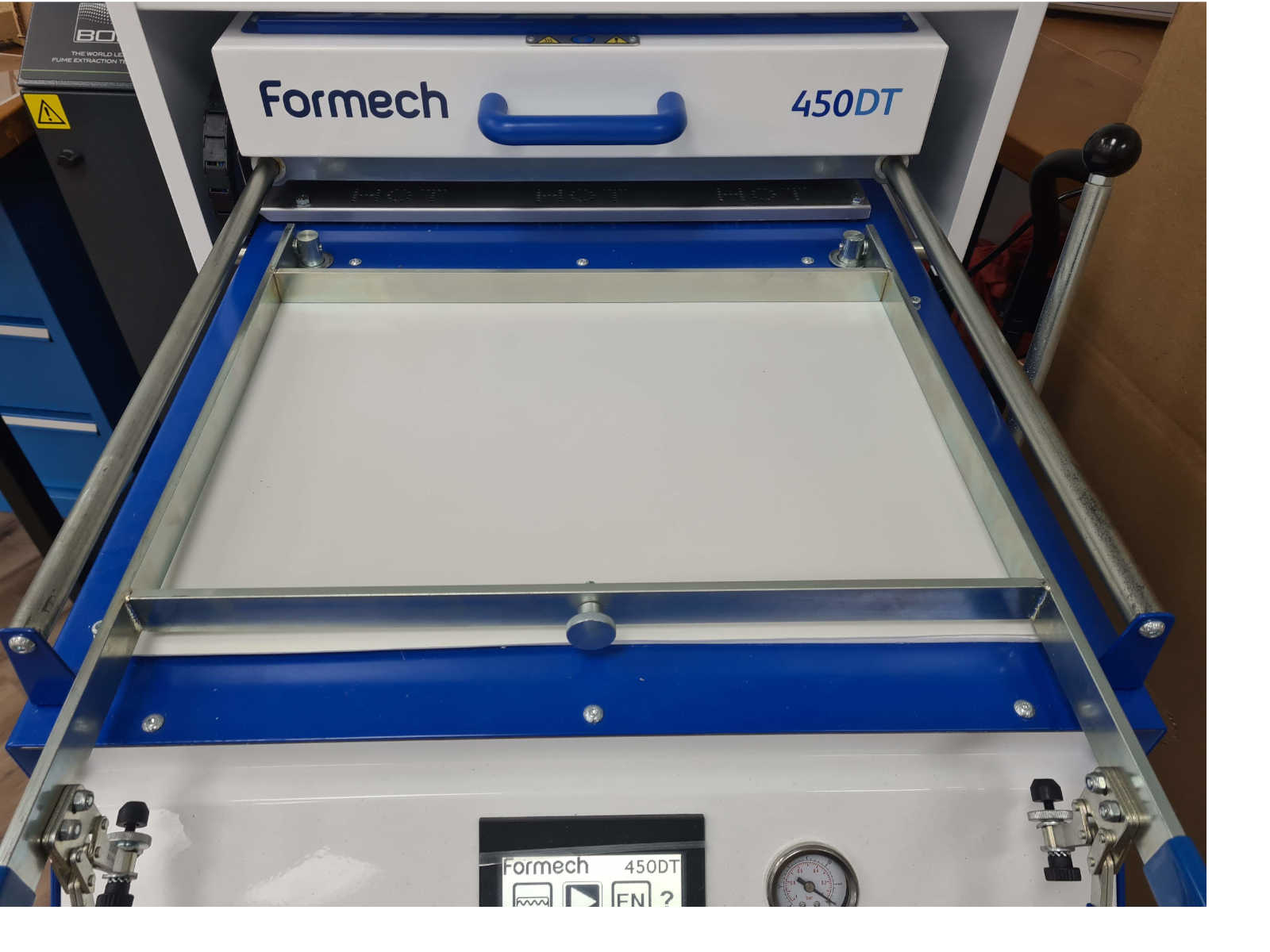

For the vacuum forming, I used the Formech 450DT. To use the machine, I first switched it on and placed the model on the table.

To use the machine, I first switched it on and placed the model on the table.

Then, I placed the forming material on top of the forming area and clamped the material down.

The material I used is a HIPS sheet with 1.5mm thickness.

Then, I placed the forming material on top of the forming area and clamped the material down.

The material I used is a HIPS sheet with 1.5mm thickness.

Next, on the LED control panel, I pressed the left most option to start the heater and left it to heat for 15 min

to reach its operating temperature.

Next, on the LED control panel, I pressed the left most option to start the heater and left it to heat for 15 min

to reach its operating temperature.

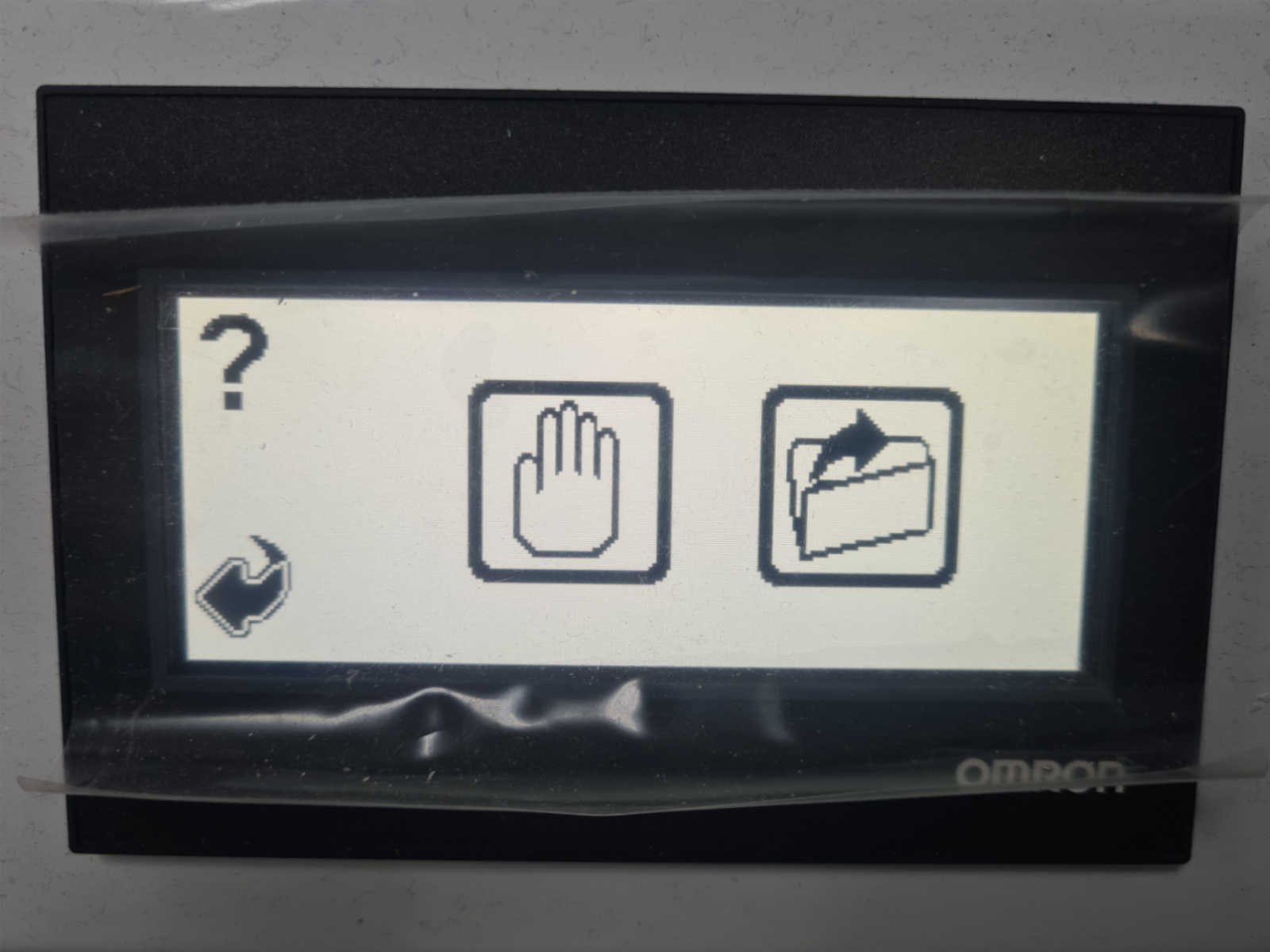

After 15min, I pressed the middle "play" button as shown in the photo above to enter the load options.

After 15min, I pressed the middle "play" button as shown in the photo above to enter the load options.

Here, I press the option on the left, with the hand symbol, to enter manual mode.

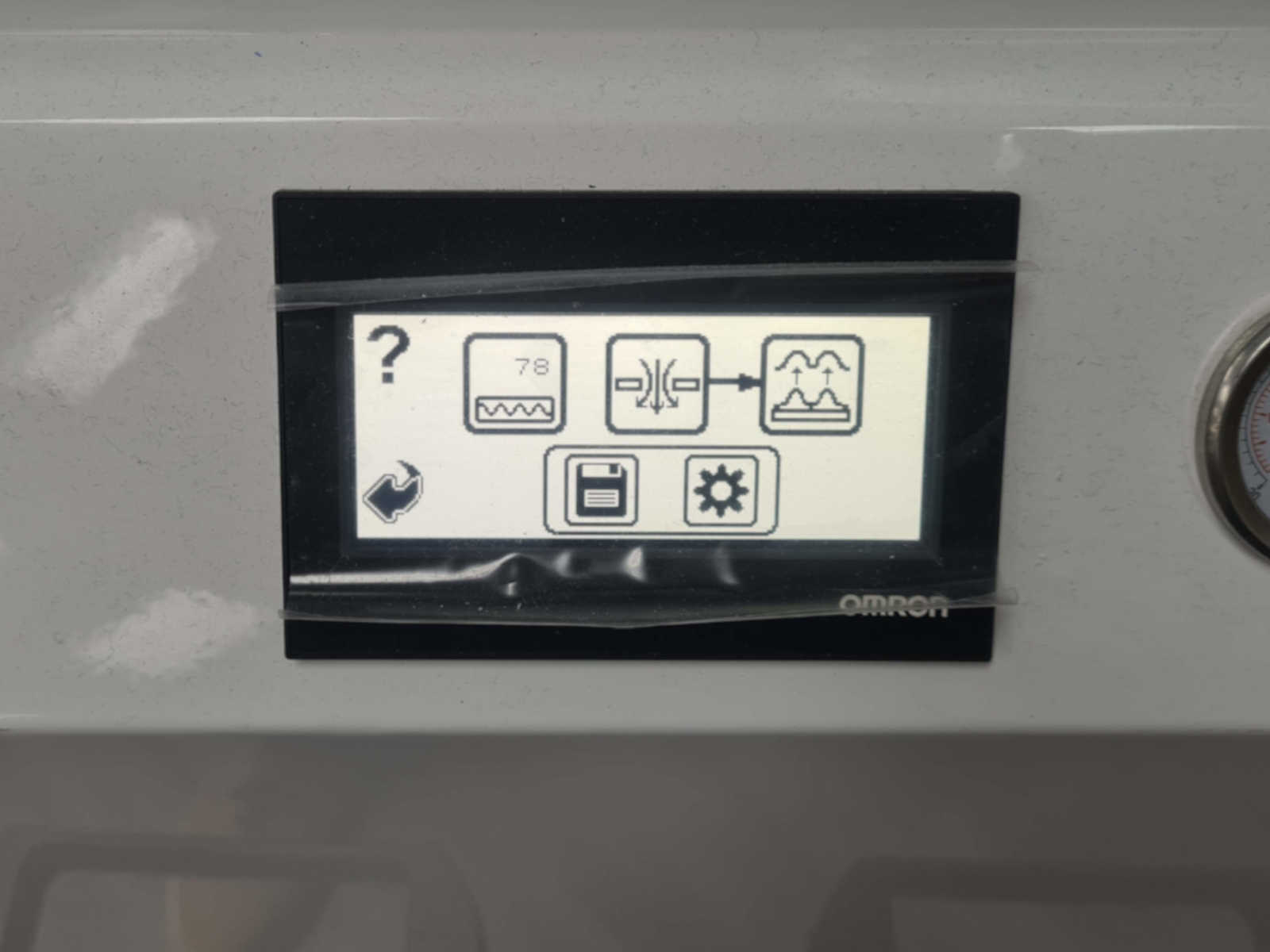

The manual operation screen appeared. The screen has 3 options: heat timer, vacuum and release (from left to right, top row).

Here, I press the option on the left, with the hand symbol, to enter manual mode.

The manual operation screen appeared. The screen has 3 options: heat timer, vacuum and release (from left to right, top row). Now I'm ready to heat the HIPS sheet. I pulled the heater over the sheet.

Now I'm ready to heat the HIPS sheet. I pulled the heater over the sheet.

The heater timer on the manual opration screen started timing once the heater was pulled over the material. I allowed the material to heat for ~120 sec

and then tested the softness by gently touching it.

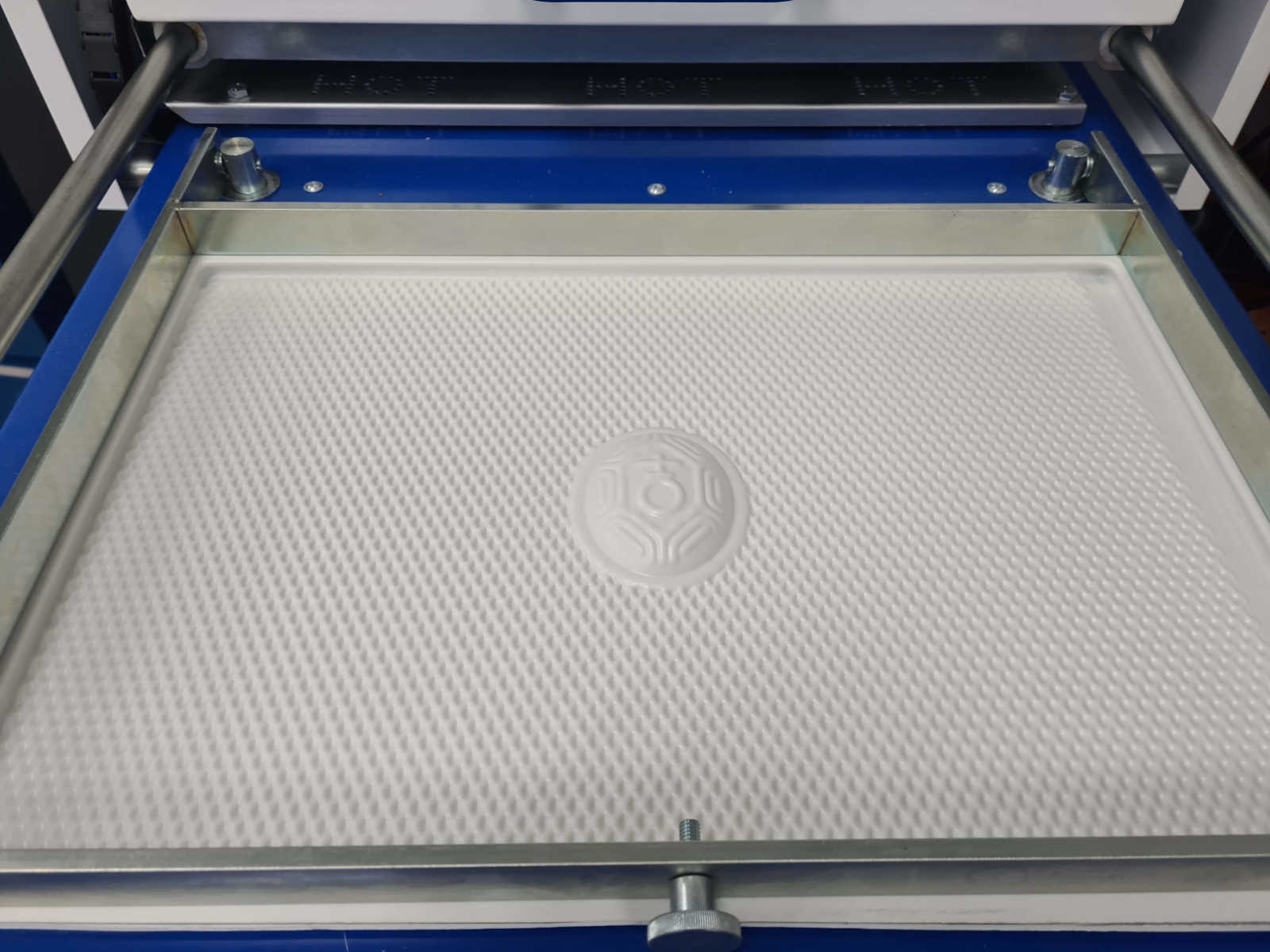

Once I'm satisfied with the softness, I quickly raised the table by pulling the lever at the right side and

pressed the vacuum button in the middle of the control panel. The material immediately formed around the model to form the mold.

The heater timer on the manual opration screen started timing once the heater was pulled over the material. I allowed the material to heat for ~120 sec

and then tested the softness by gently touching it.

Once I'm satisfied with the softness, I quickly raised the table by pulling the lever at the right side and

pressed the vacuum button in the middle of the control panel. The material immediately formed around the model to form the mold.

Then I pressed the release button at the right of the control panel to get the model out of the mold. The mold formed has all the details of the model.

Then I pressed the release button at the right of the control panel to get the model out of the mold. The mold formed has all the details of the model.

Casting

After I cut out the mold, I proceed to do casting with Jesmonite using the procedure described in the molding and casting assignment. It was a dit difficult to take the cast out of the mold after the cast was formed. Along the way, the edges of the cast were chipped off at

two places. Fortunately, the main body of the cast came off the cast intact.

It was a dit difficult to take the cast out of the mold after the cast was formed. Along the way, the edges of the cast were chipped off at

two places. Fortunately, the main body of the cast came off the cast intact.

The details of this new cast is comparable to the previous cast that was made using silicon mold.

The details of this new cast is comparable to the previous cast that was made using silicon mold.

I find vacuum forming a faster and more convienent way to create mold for casting, particular if a number of molds were needed. However. as the

mold created from vacuum forming are quire rigid, it is probably more suitable for softer material (e.g. silicone).

I find vacuum forming a faster and more convienent way to create mold for casting, particular if a number of molds were needed. However. as the

mold created from vacuum forming are quire rigid, it is probably more suitable for softer material (e.g. silicone).