WEEK 15. Wildcard week¶

Cassignment

Design and produce something with a digital fabrication process (incorporating computer-aided design and manufacturing) not covered in another assignment, documenting the requirements that your assignment meets, and including everything necessary to reproduce it. Possibilities include (but are not limited to):

Objetive¶

this week we're free to do things we haven't seen during the course.

i think it's a great adventure to learn the principle of plasma cutting.

My goal is to make a flat wrench using this plasma cutter.

## Machine

what I’ve learned about plasma cutting.¶

### plasma ?

-

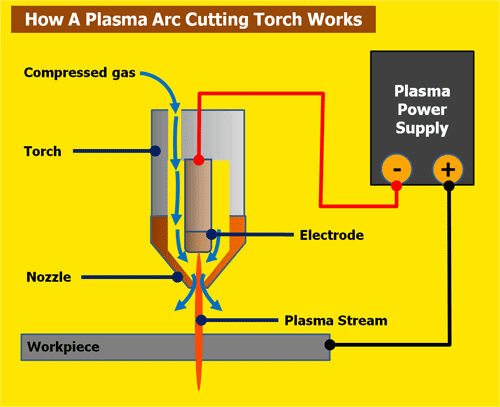

Plasma is simply a column of superheated gas that can be used to cut through metals.

-

Plasma torches work by using compressed air or compressed gases, such as nitrogen, to ionize and create plasma.

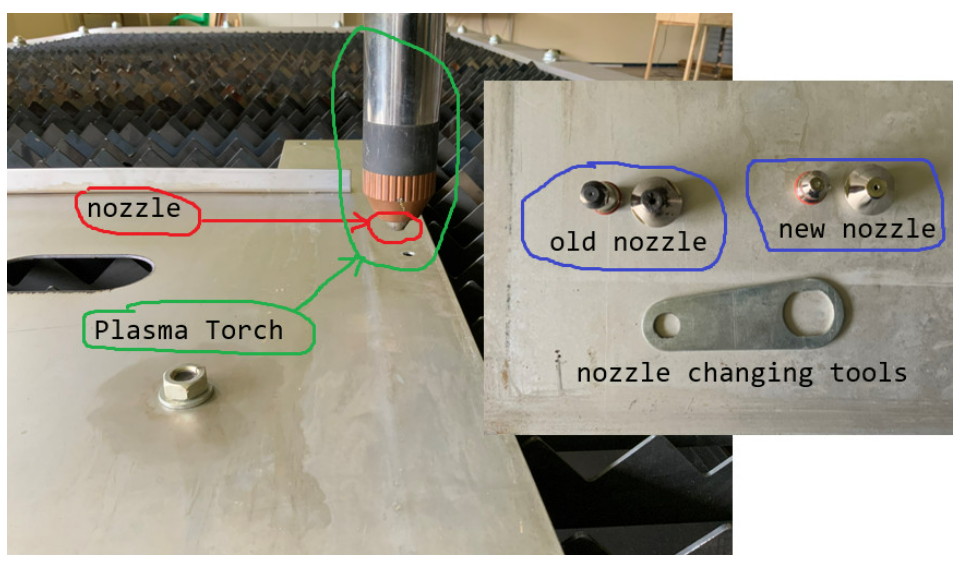

For plasma cutting, a copper nozzle is generally used to concentrate the gas flow on the pilot arc passing through it.

The pilot arc passes from an electrode in the torch to the material to be cut. This is known as the “transferred arc”. Although there are also “non-transferred” arcs, these are not generally used for cutting.

In addition to the nozzle, the electrode is generally also made of copper, but has a metal insert at the point where the arc is attached. Without this insert, the copper would melt too quickly.

Advantages of plasma cutting¶

Plasma cutting offers a number of advantages. You can cut all conductive materials,

including sheet metal and non-ferrous metals, and achieve excellent cut quality for thicknesses of up to 50 mm.

Maximum cut thickness is 150 mm.

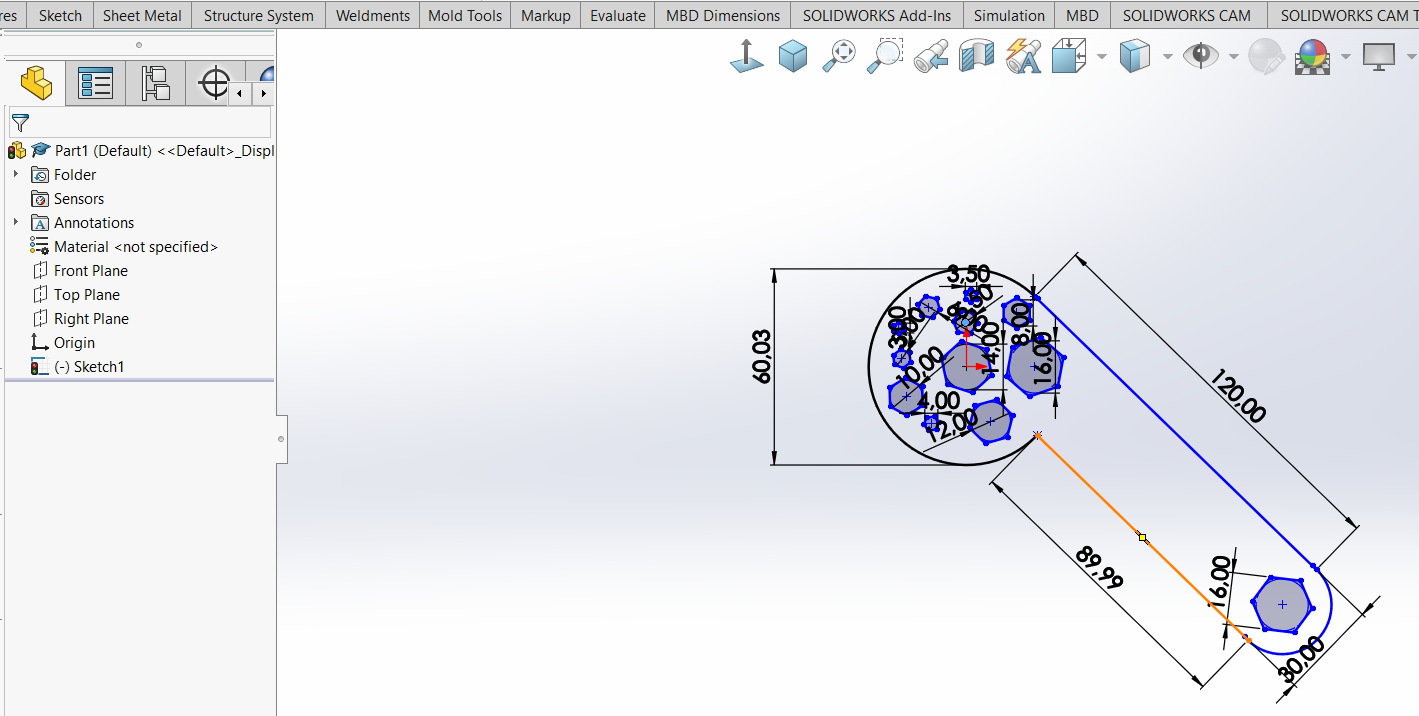

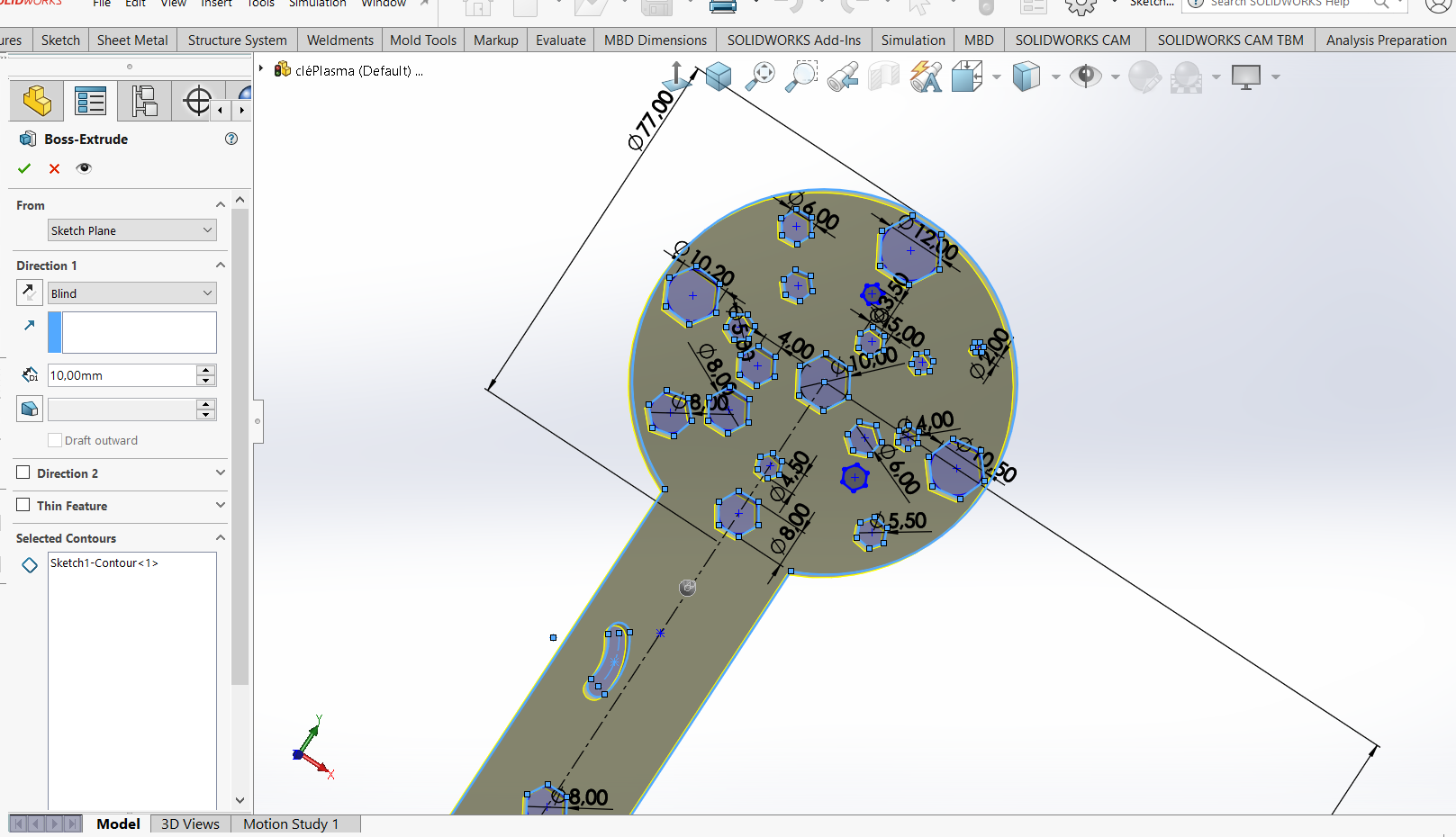

I- MODELING¶

I first modeled my part on solidWorks.

II- LASMA MACHINE¶

III- EQUIPMENT REQUIRED¶

III.1- COMPRESSOR.¶

III.2- POWER SUPLY.¶

Three-phase power supply: 380 v .

III.3- PLASMA NOSE.¶

IV- SECURITY¶

V- SOFTWARE FOR CAO¶

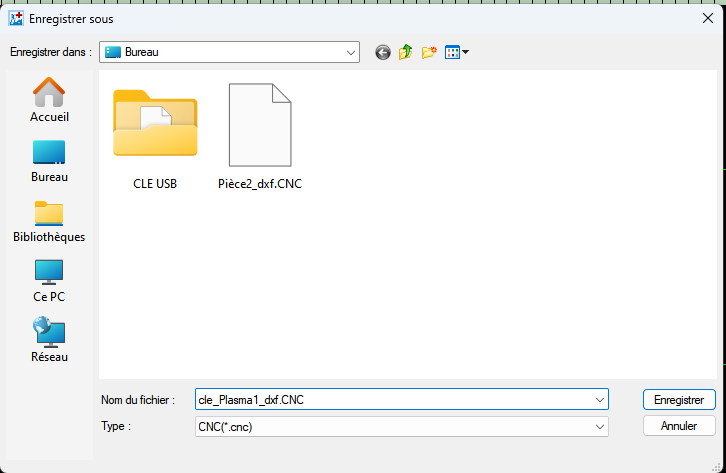

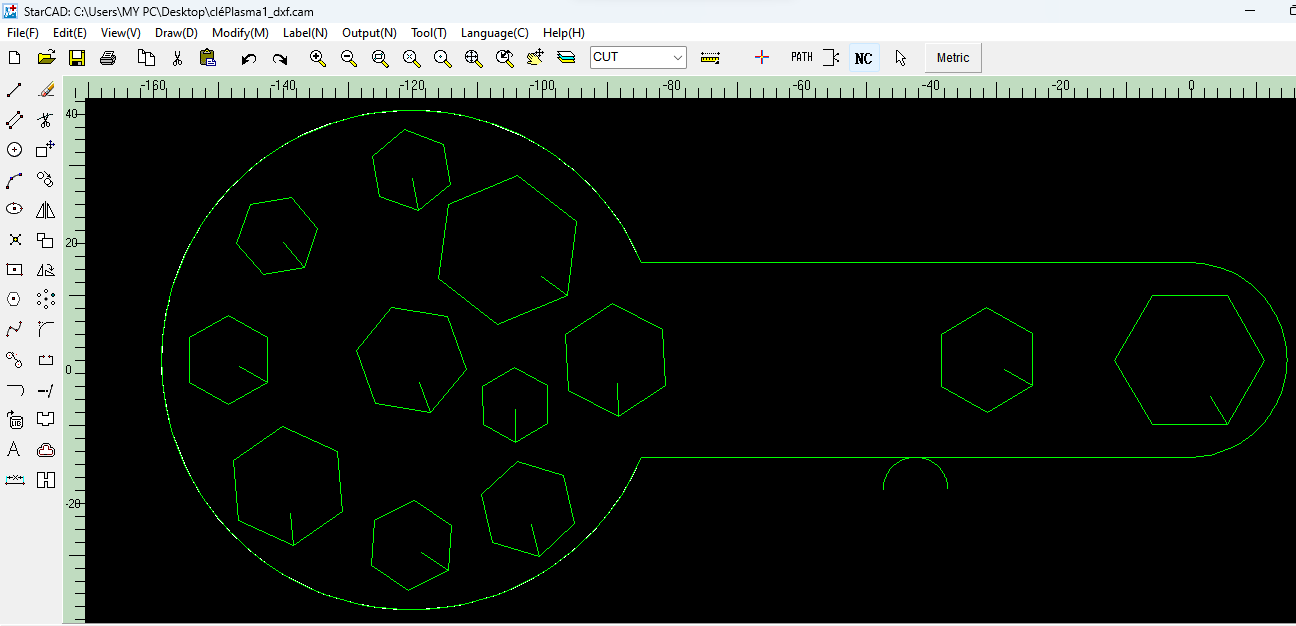

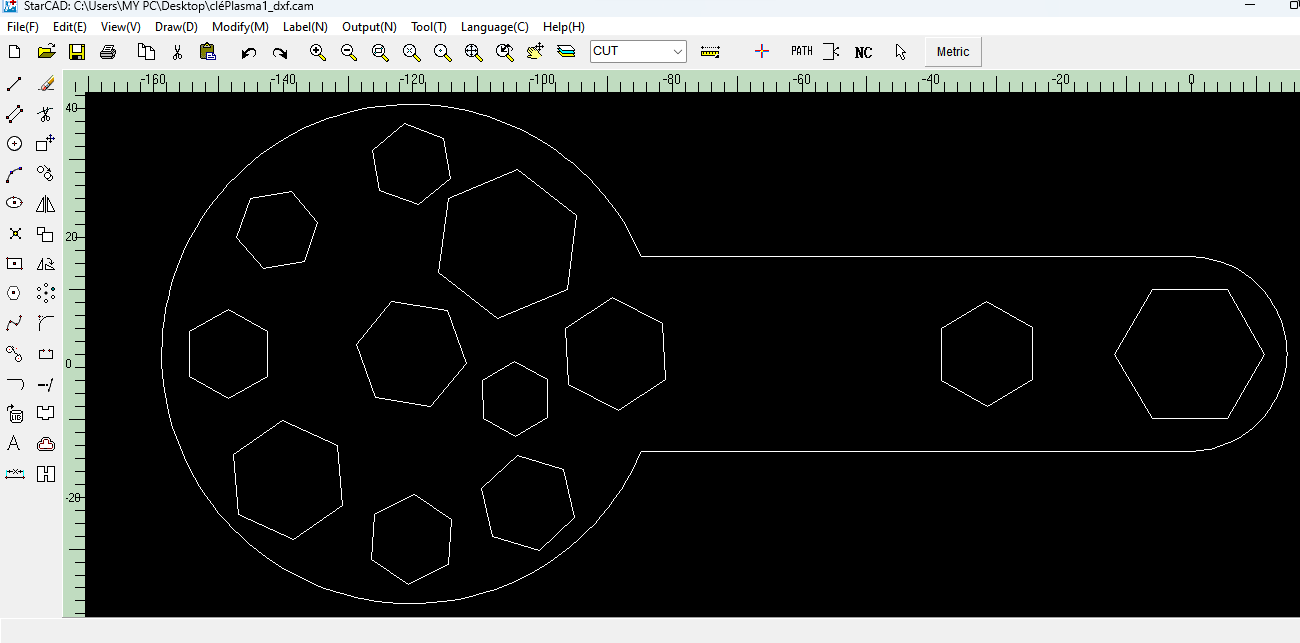

The plasma cutter is a CNC, so it works with CAM software. in this case you can use it by importing the DXF file wich is 2D file

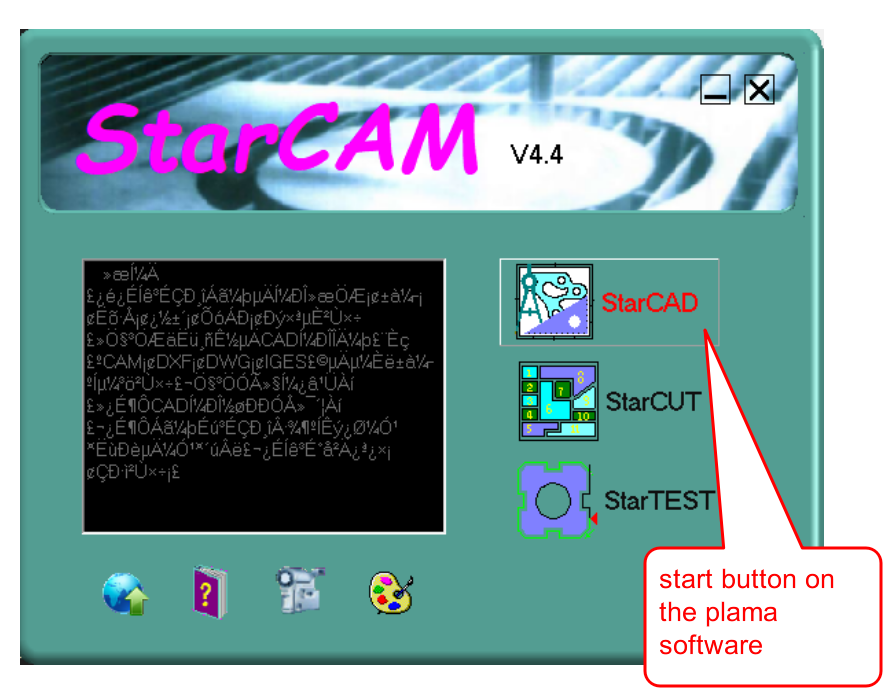

VI- Starcam¶

it came from machine builders.CLIC

1- first of all i exported the file

the green color is justified by the fact that we have now exported . Normal!

the color should become white

2- i move to fabrication

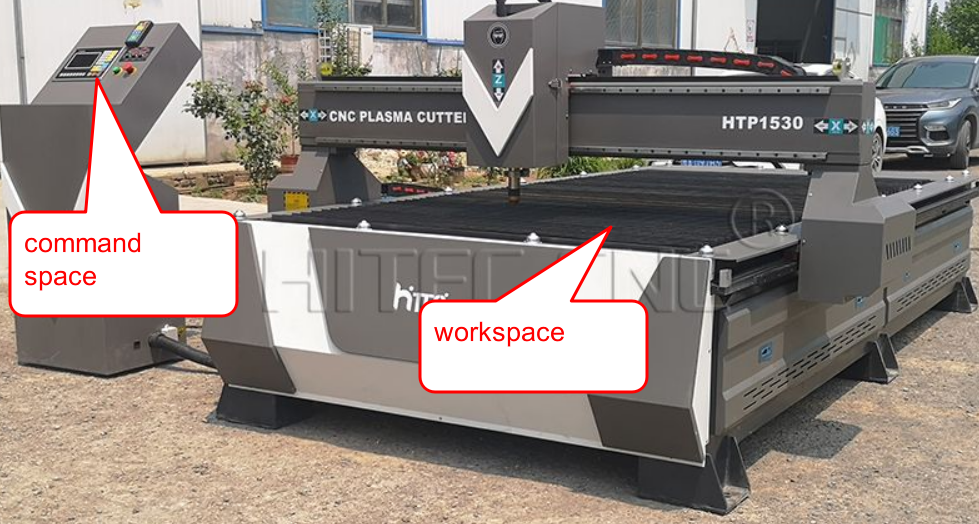

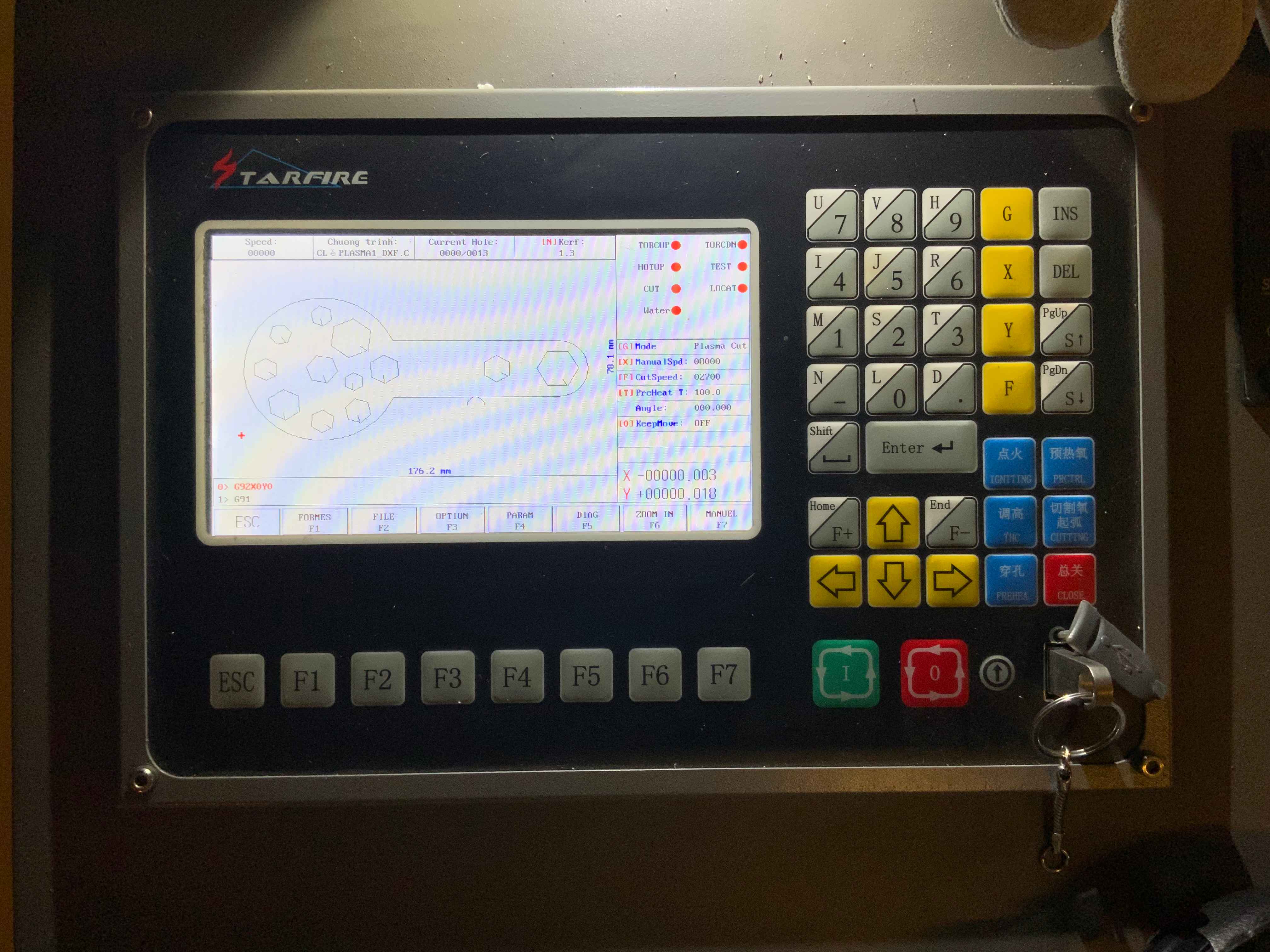

VII- MACHINE INTERFACE.¶

Specification¶

| Brand | Hiteccnc HTP-1530 |

|---|---|

| Working area | 1500x3000mm |

| Power supply | Huayuan 160A |

| **Control system ** | CNC Starfire Control system with HYD Independent THC |

| Software | StarCAM |

| Resolution | ± 0.03mm |

| Command | G code (uoo,nc,mmg,plt) |

| Voltage | 380V, 3 phase,50/60HZ |

| **Consumble Parts ** | Cutting nozzle and electrode |

| Max working speed | 0-10000mm/min |

| Motor and driver | Leadshine stepper motor and driver |

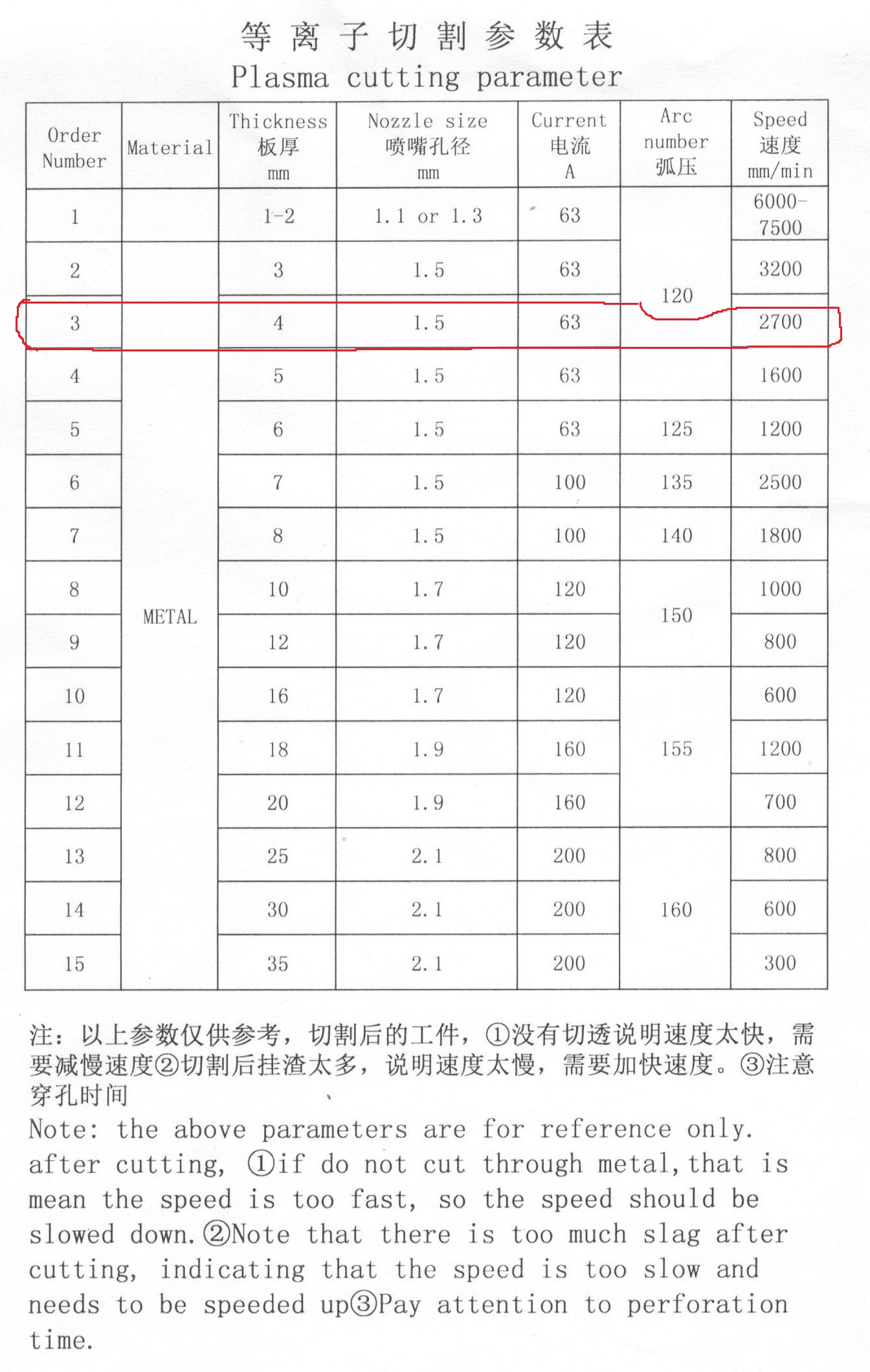

VIII- MACHINE PARAMETERS¶

Parameters others

VIV-FABRICATION¶

WE NOW MOVE ON TO THE MANUFACTURING PROCESS: - CONNECT USB KEY - SELCTION YOUR STARcam FILE - and start cutting

MOVIE

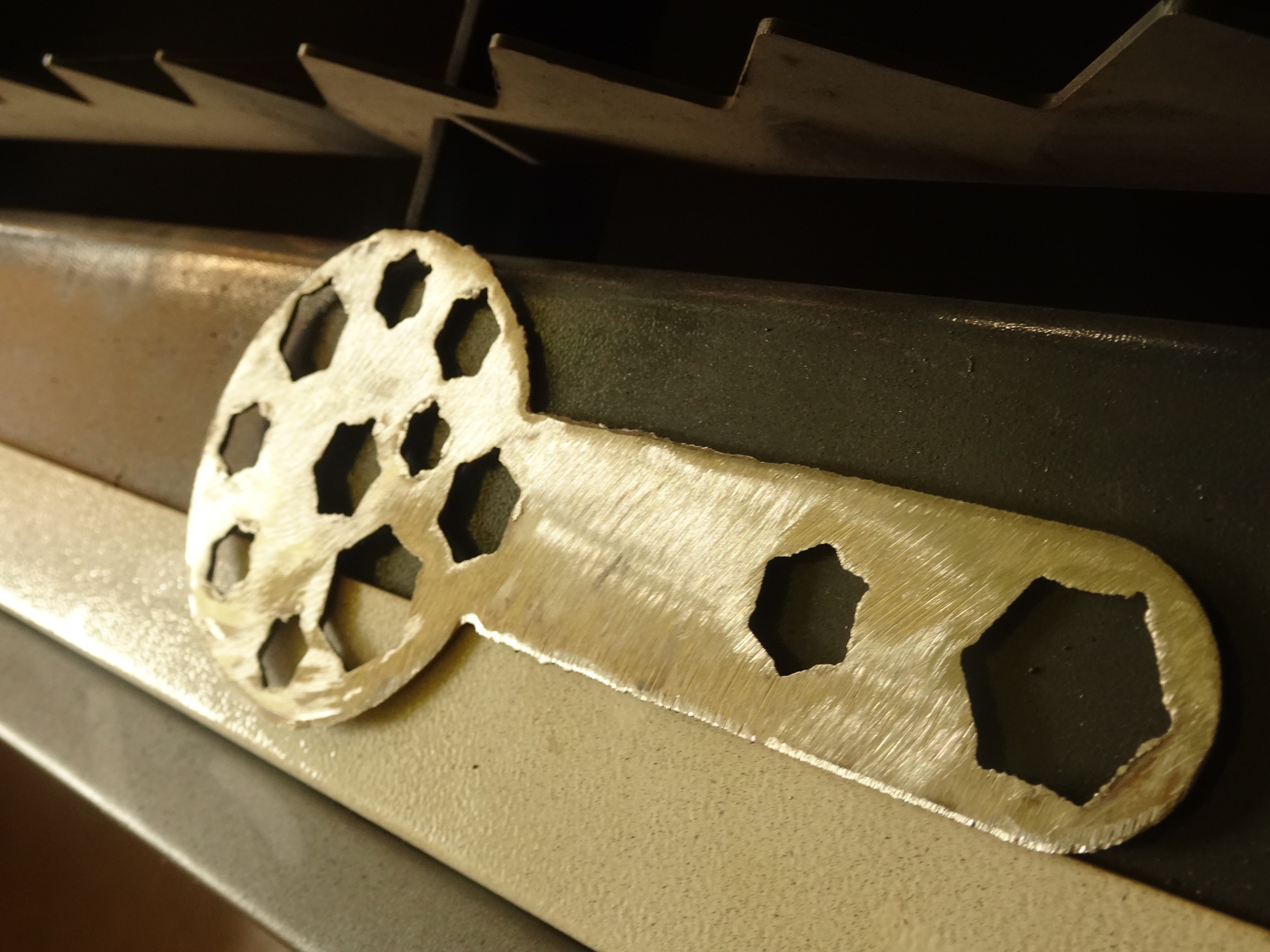

Grinding and Test¶

part manufactured

.

.

the difficulty

For small openings compared to laser cutting, this machine has its limits for these small applications, moreover because of the burrs left after cutting we pencil for assemblies with precision clearance.