WEEK 12. Molding and casting¶

group assignment:¶

review the safety data sheets for each of your molding and casting materials,

then make and compare test casts with each of them

extra credit: try other molding and casting processes

## individual assignment: design a mold around the stock and tooling that you’ll be using, mill it (rough cut + three-axis finish cut), and use it to cast parts extra credit: use more then two mold parts

Objectives¶

my objtive this week is to make a node

1. the realsaion of the mold¶

a The design¶

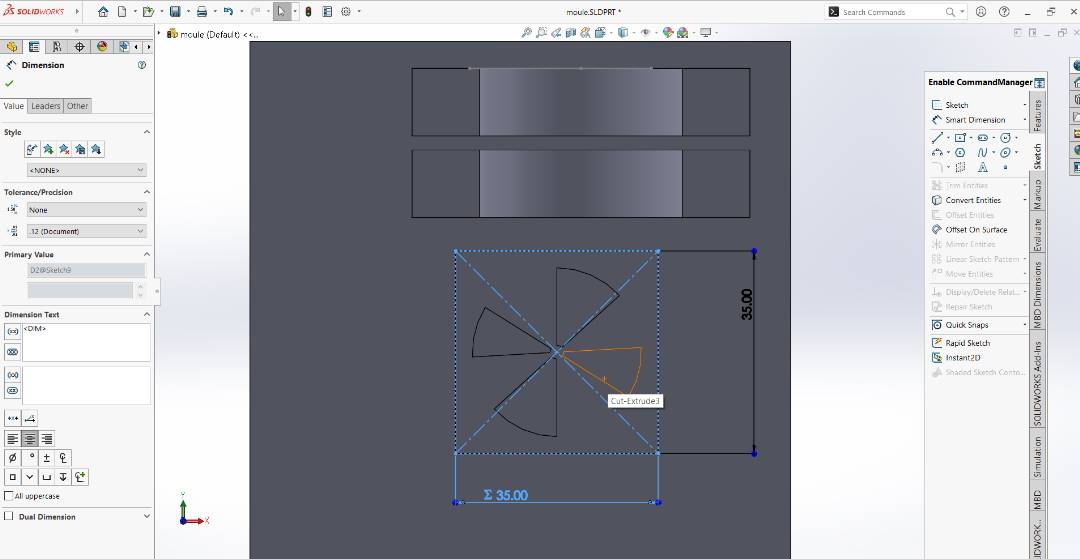

For the realization of my mold I used the solidWorks to model it and generate an STL file

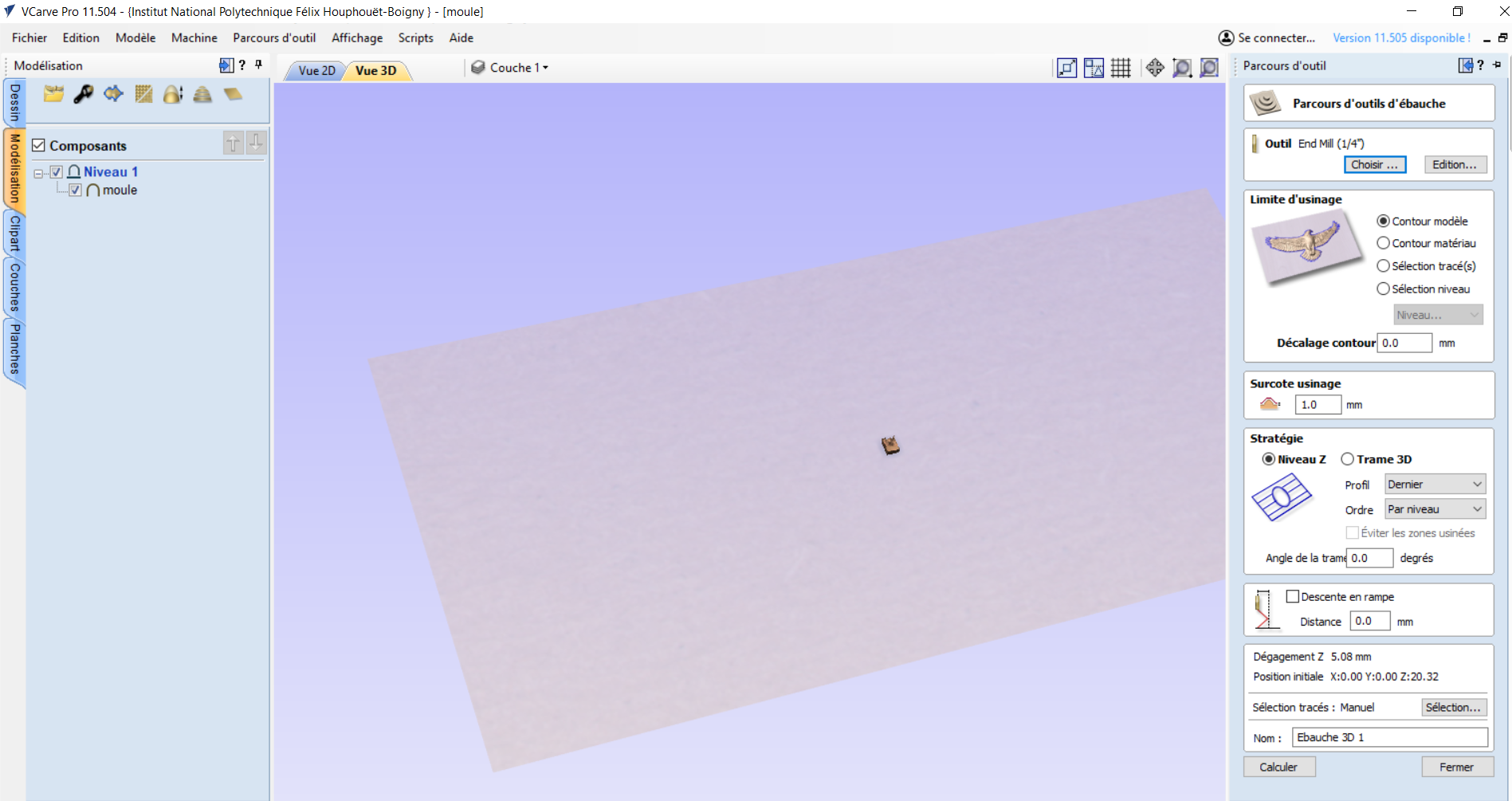

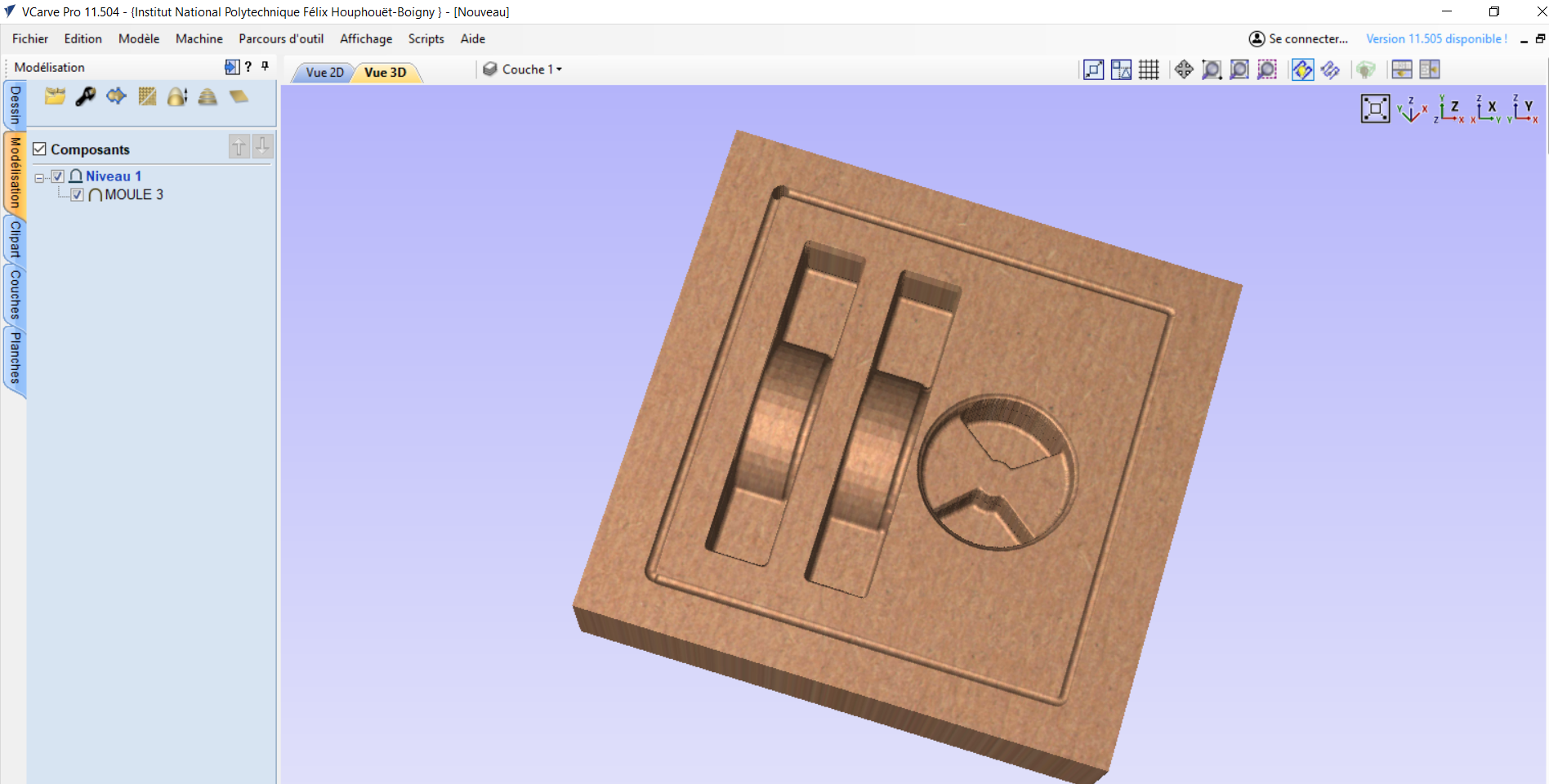

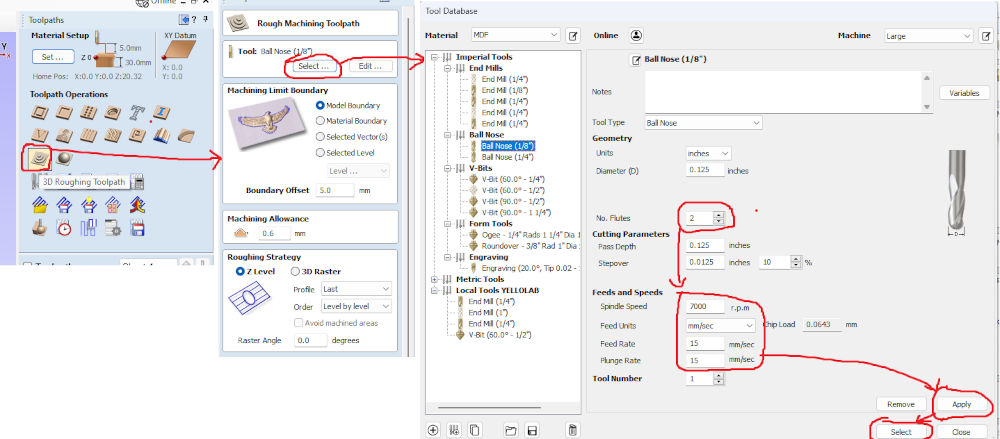

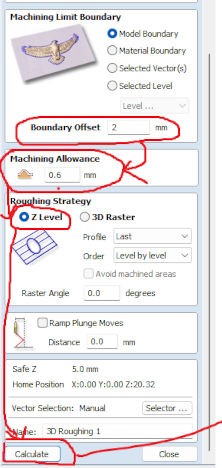

b preparation on vcarve¶

explaining steps :

1 open V carve and create a new file

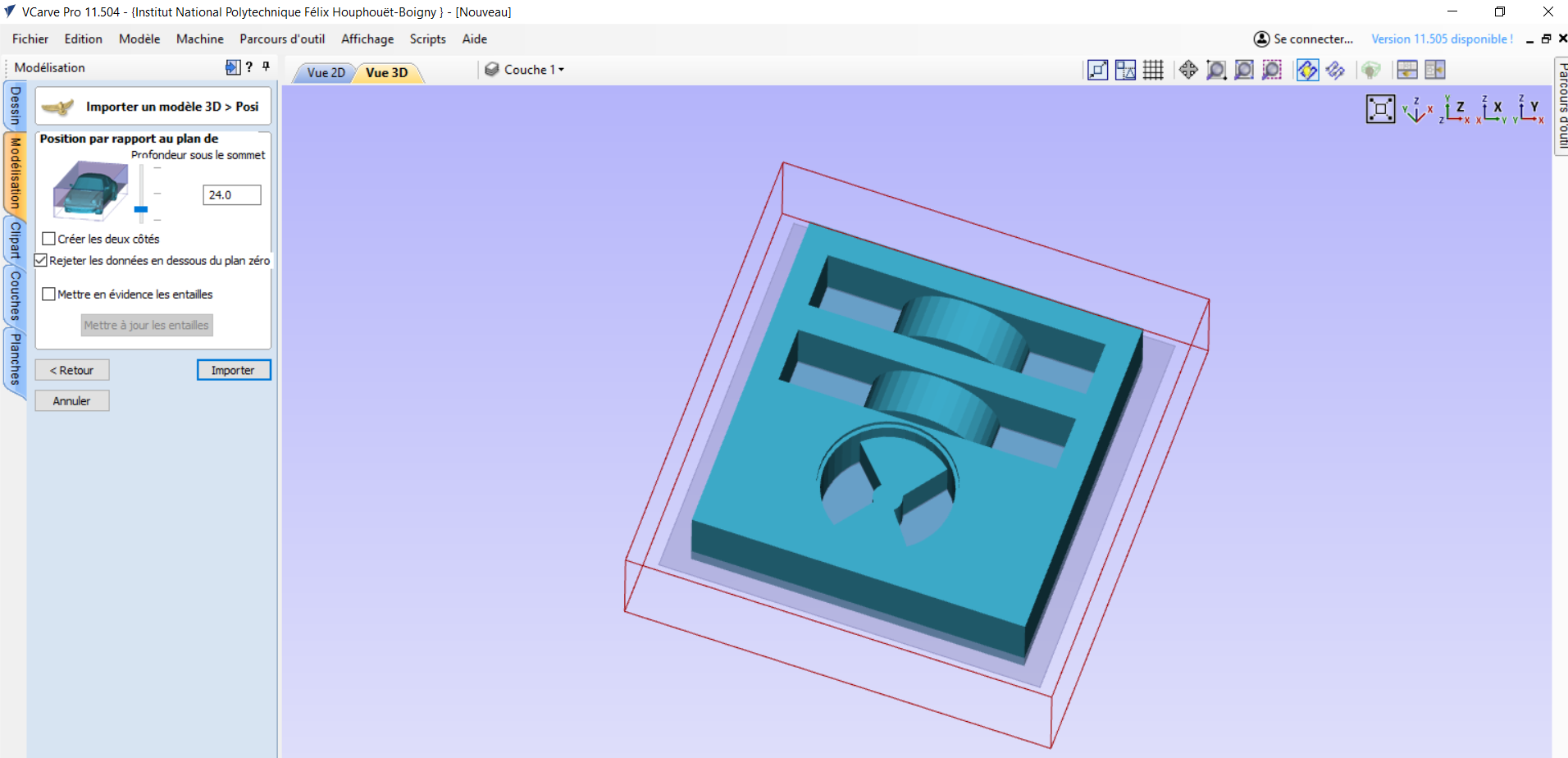

2 import the the STL file usi,g the modelind tool on vVcarve

3 put your piece in center of your space put your prt size

3 then import the model

4 choose your tool and calculate the toolpath

5 then choose the processor and generate the the machine file (rml...)

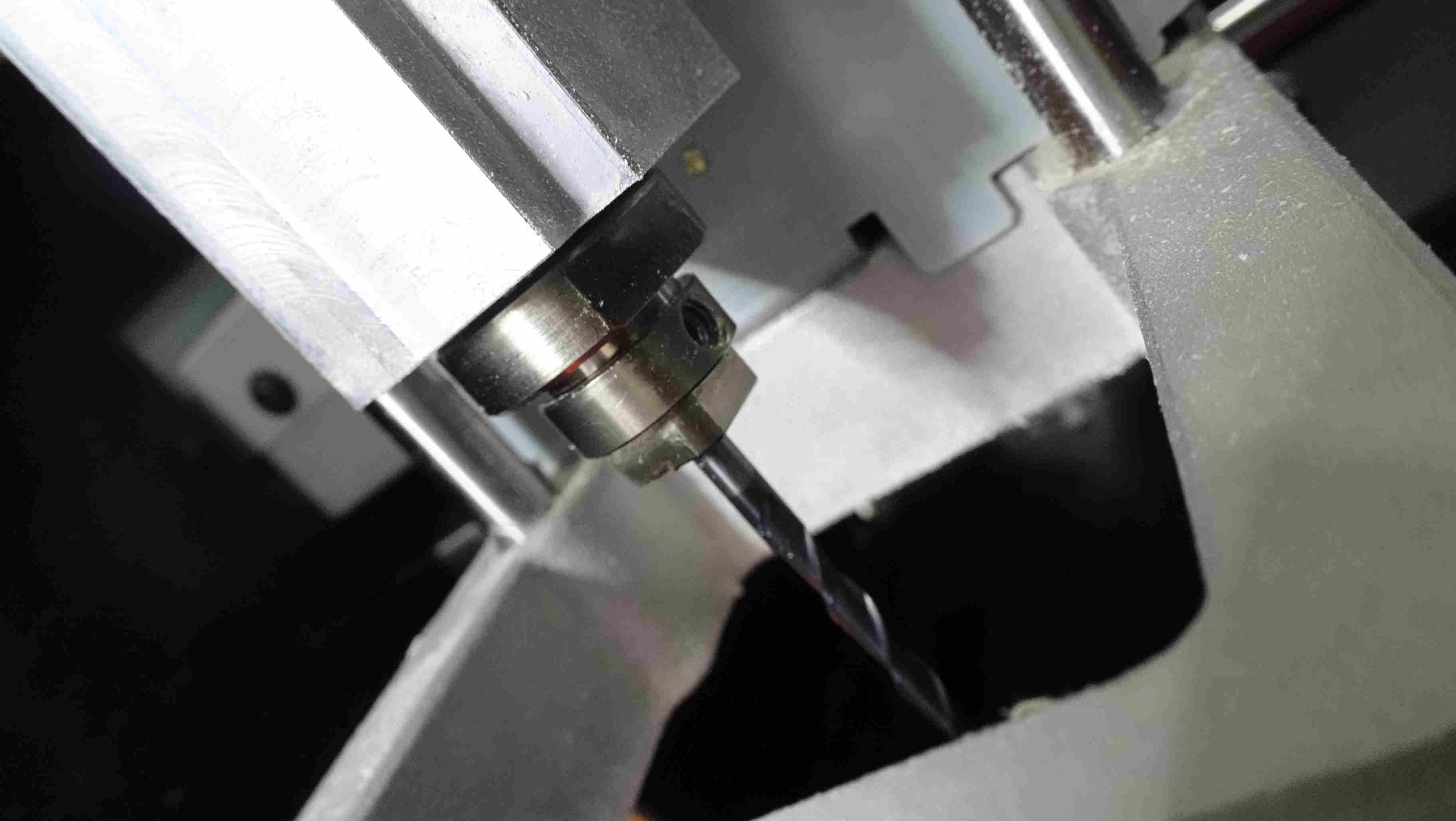

- Cutting parameters

- fabrication tool

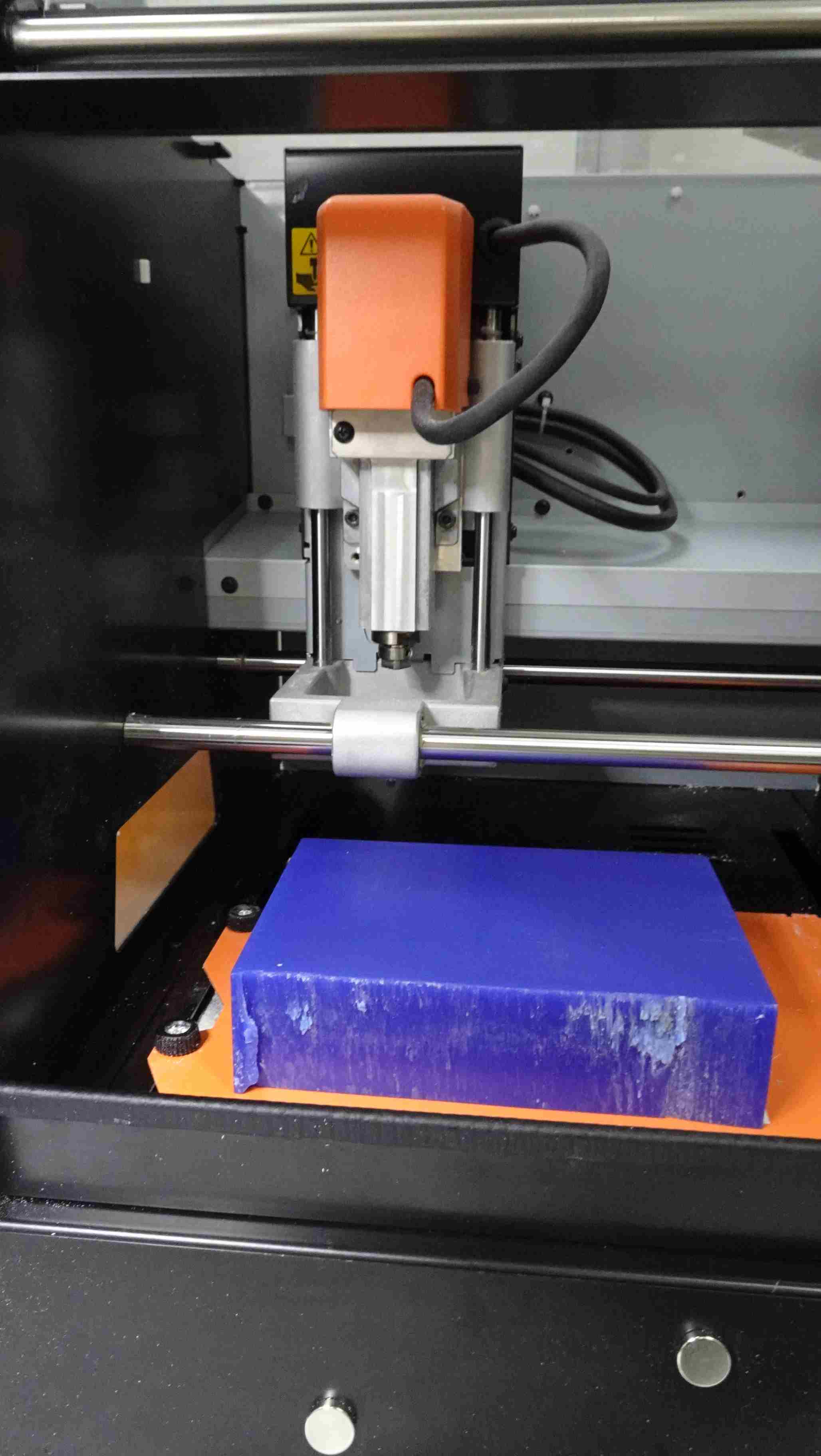

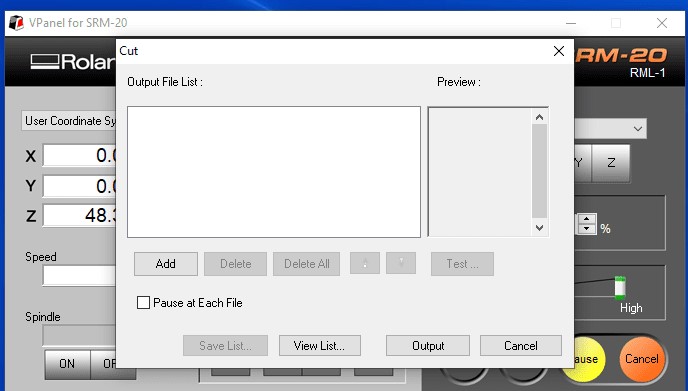

- fabrication fist Open the roland software

- choose the gcode file from your folder by clic on “add” then out put

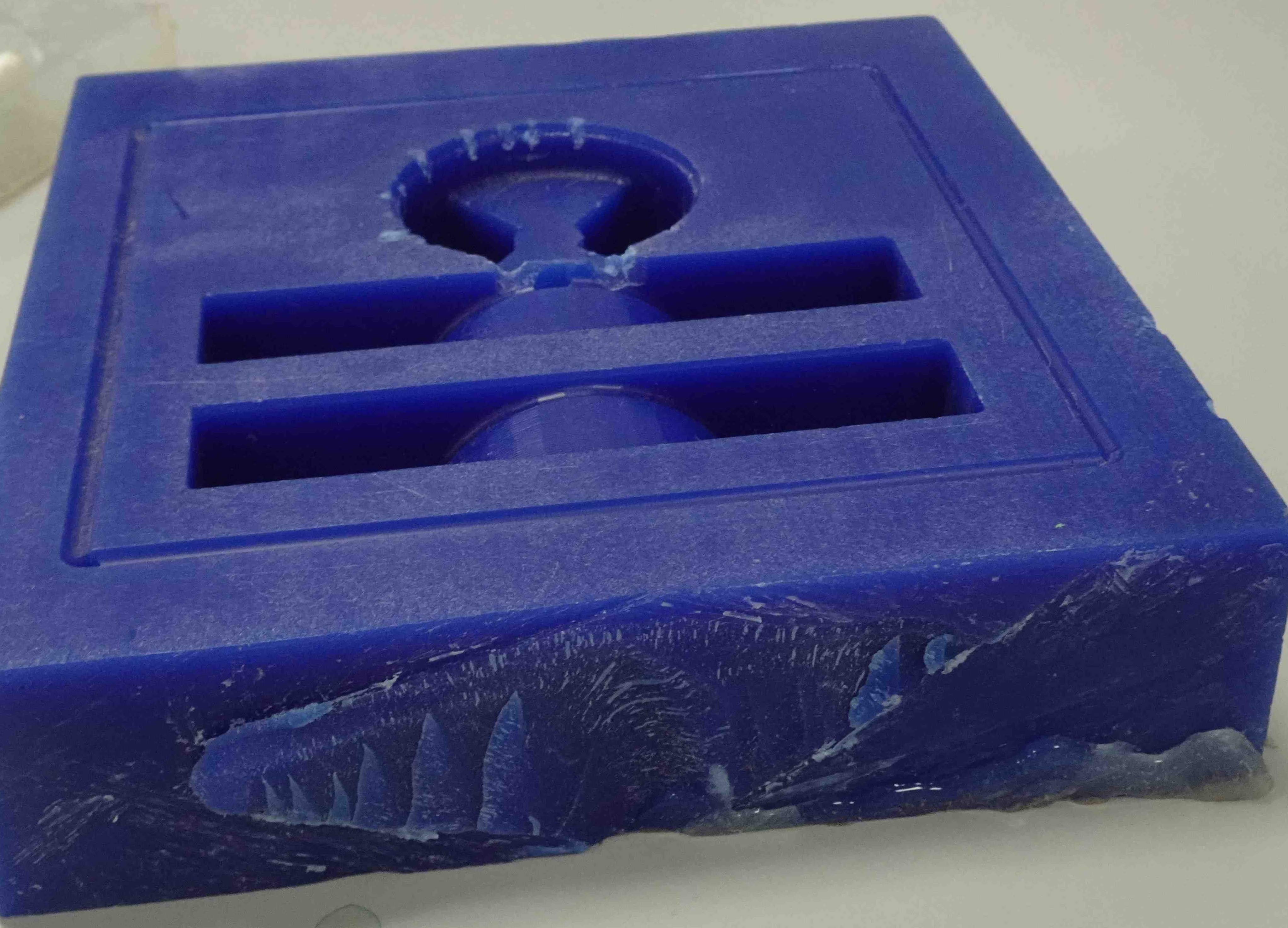

- After fabication

### 2 chemical preparation for the mole

2.1 choice of material¶

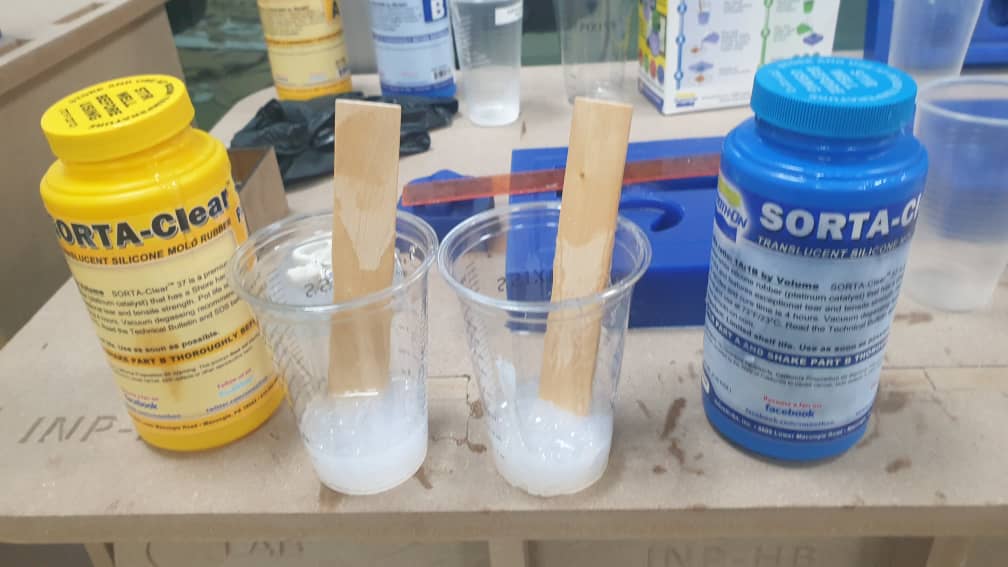

i choose tHE LIQUID SILICONE RUBBER before begin to us it i try to surch somme knowledges about.

2.2 what i learned and use such as instructions¶

i link this instruction to use the product and the mold building with Liquid Silicone rubber

- prduct datasheet

here is how the model was made

## Creation of the piece

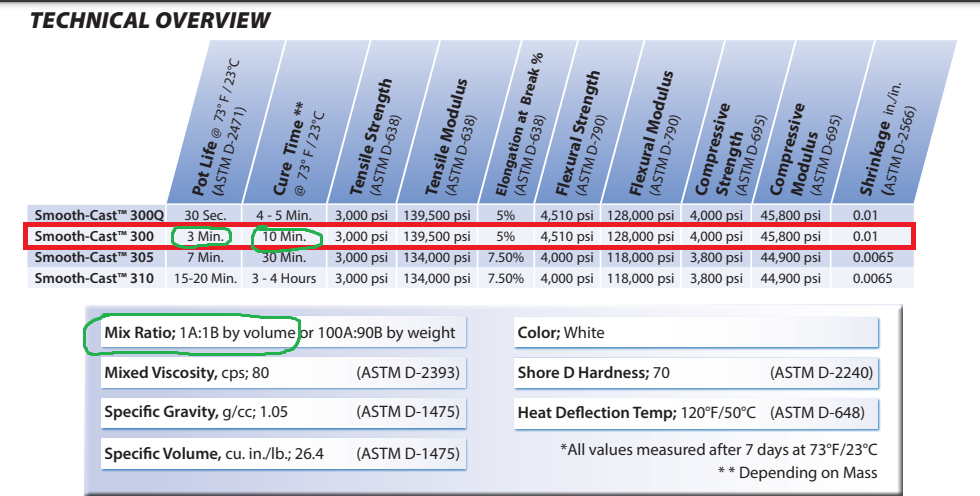

I followed the instructions from the SMOOTH-CAST 300 product website

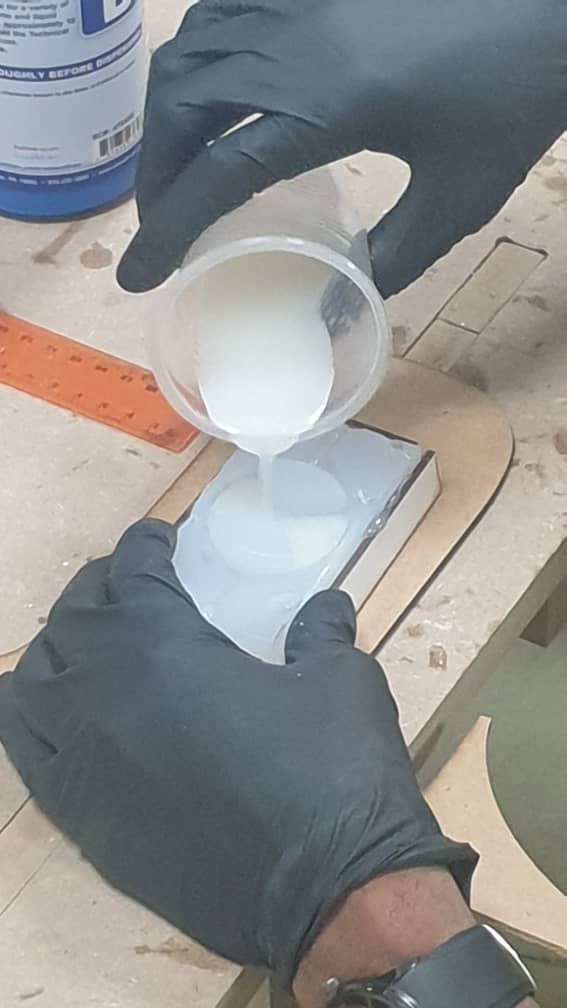

### mixed and cast

summary

what learned:

i didn’t put the guide to fixe the mold part toget easely so it was verry difficult to build the mold before casting.

i recommand to to make it for all mold.