Electronics Design | Week 07

Group Assignment

Objectives of the Group Assignment:

Equipment need to be Tested:

Multimeter:-

Continuity test at LED on the board

Intro

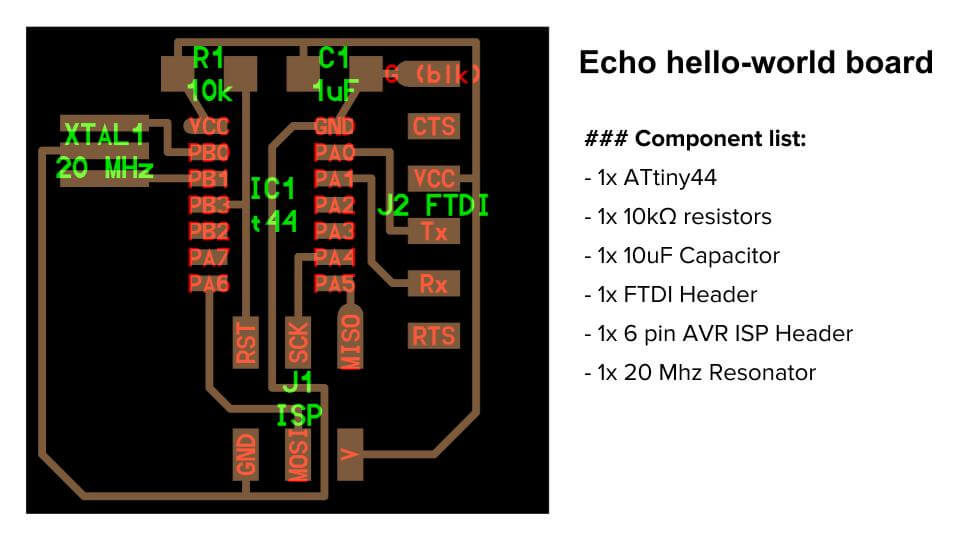

This is the list of materials I'll need to make my Hello echo board.

Component list:-

Additional components:-

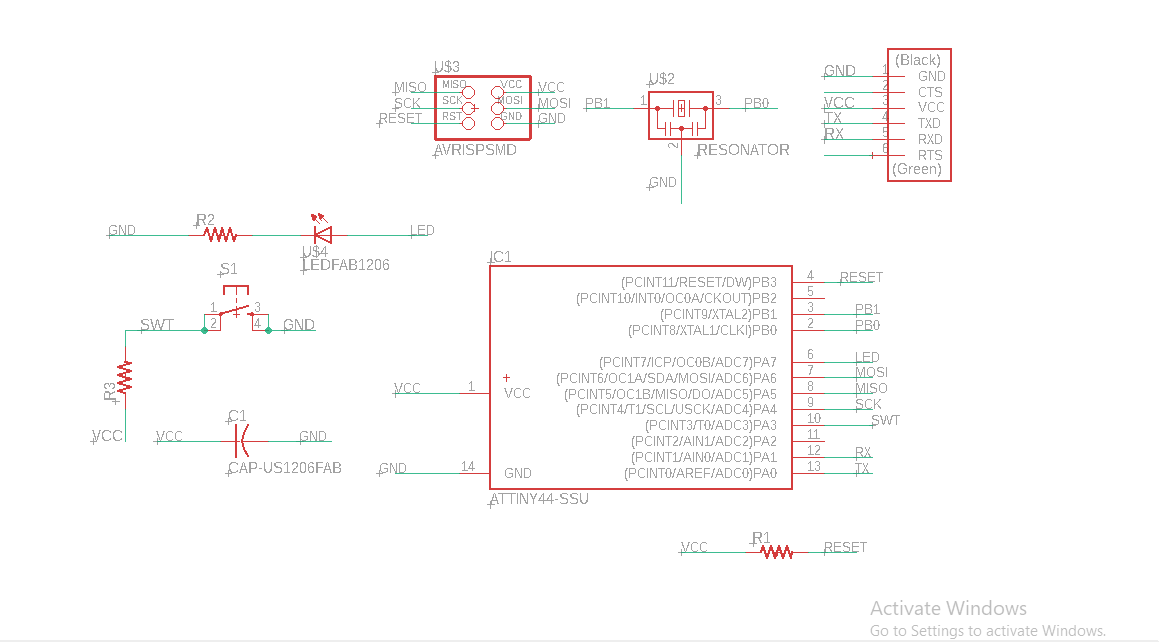

Design

Eagle was used to create the board.

Workflow

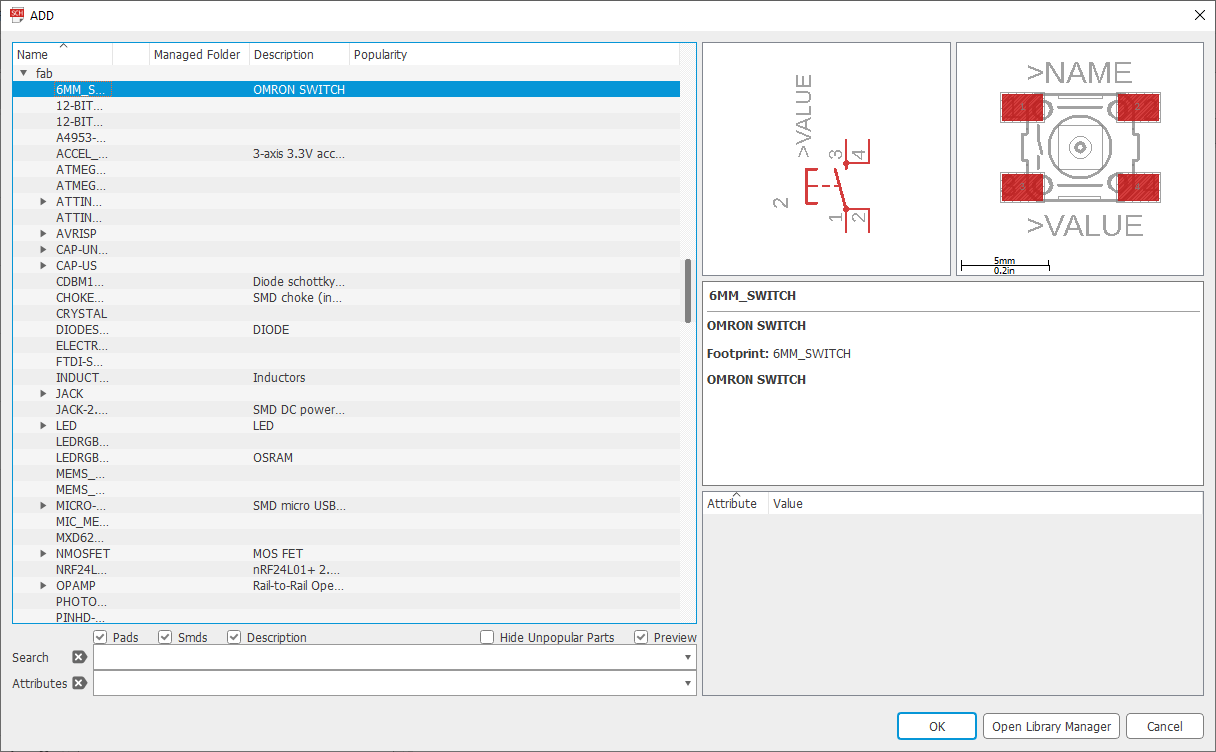

why would you want to use fab library when other libraries are available?

Downloaded Eagle:-

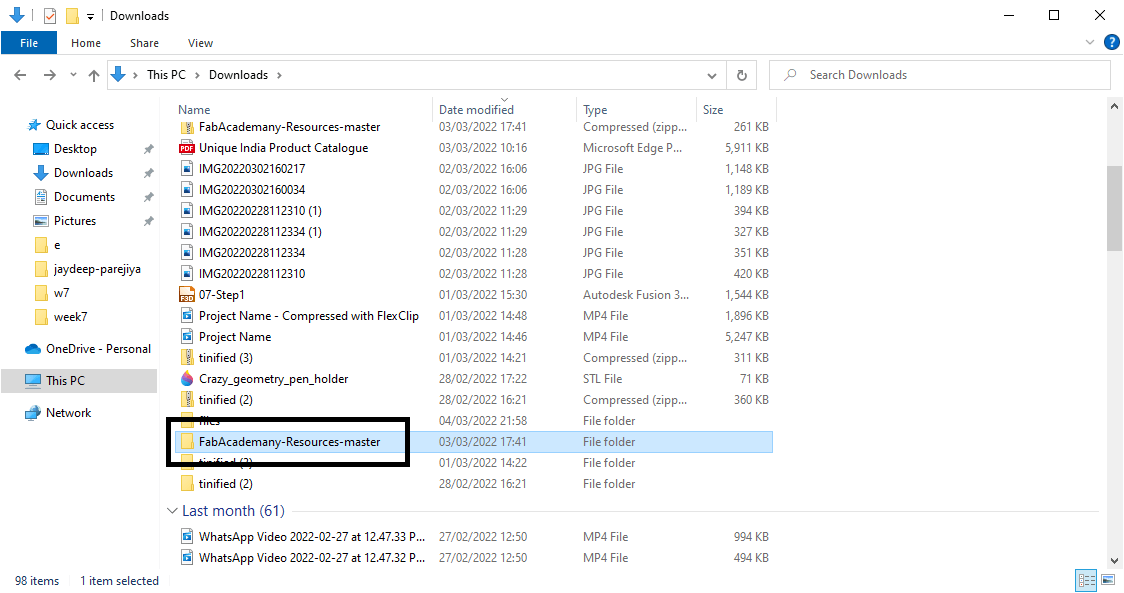

Installed Fab.lbr Library

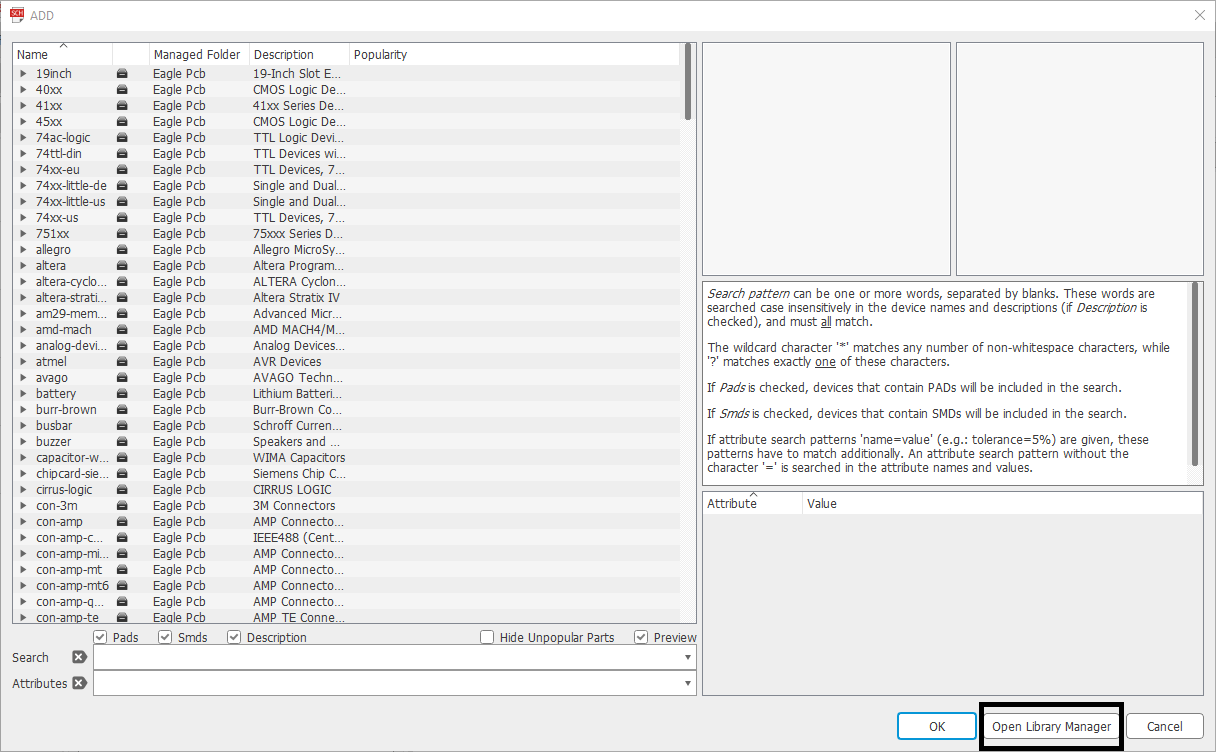

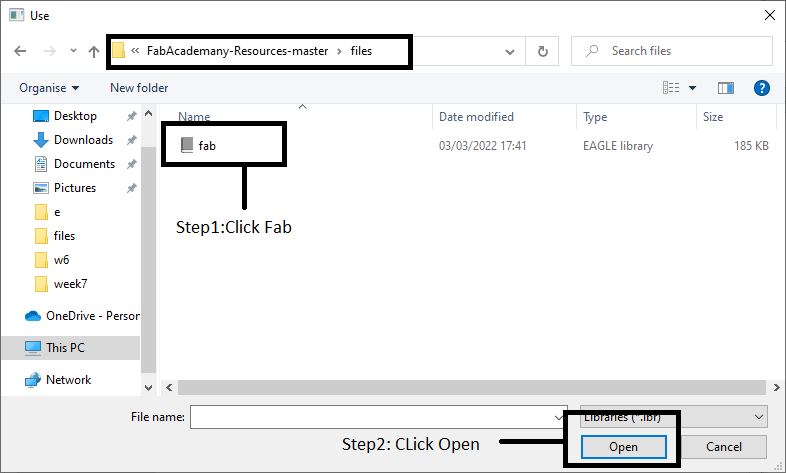

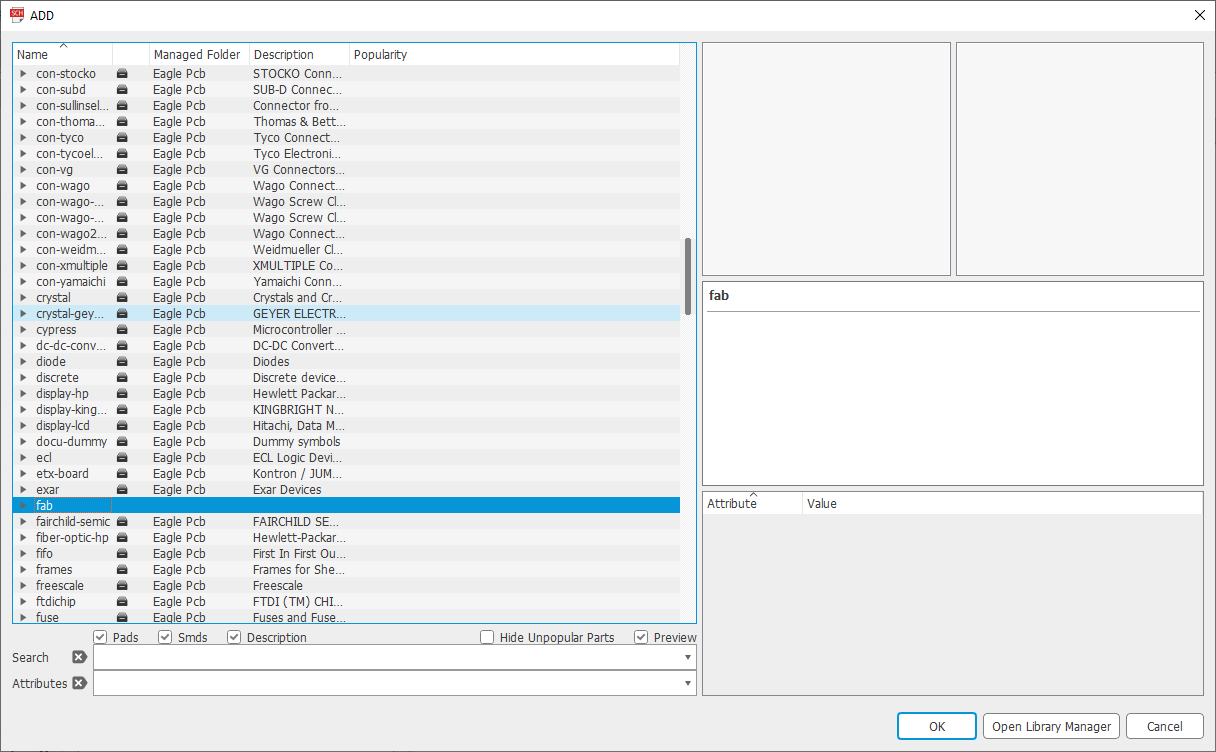

Add Library

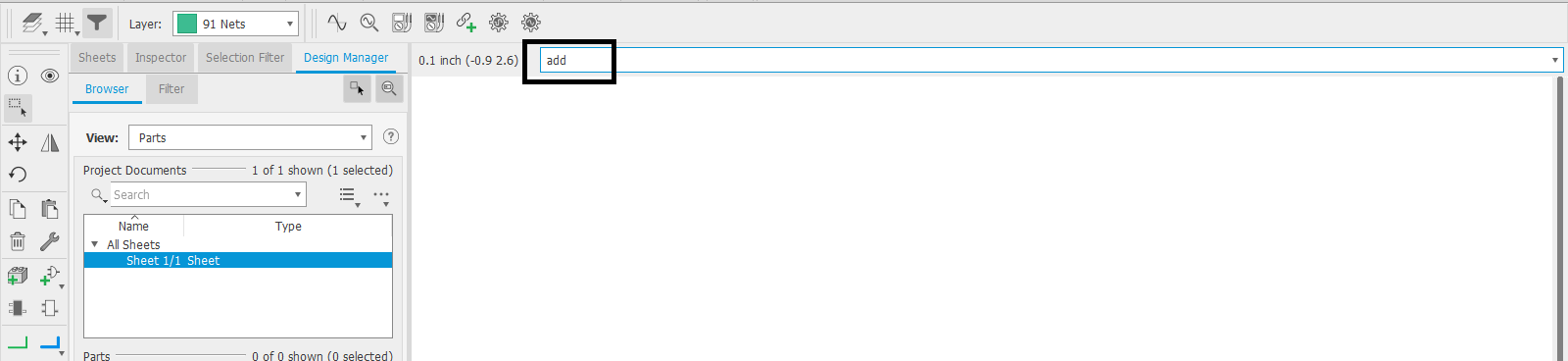

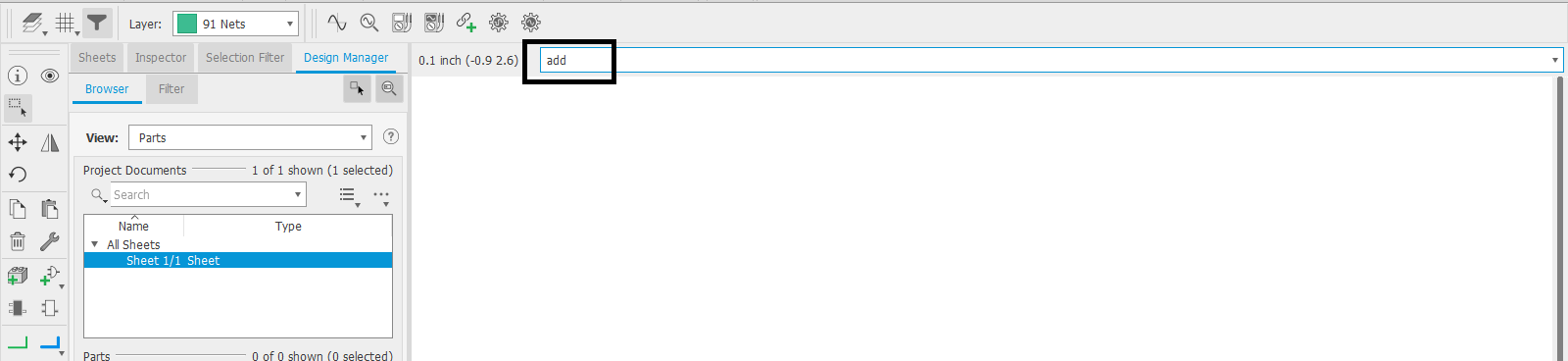

Command Line

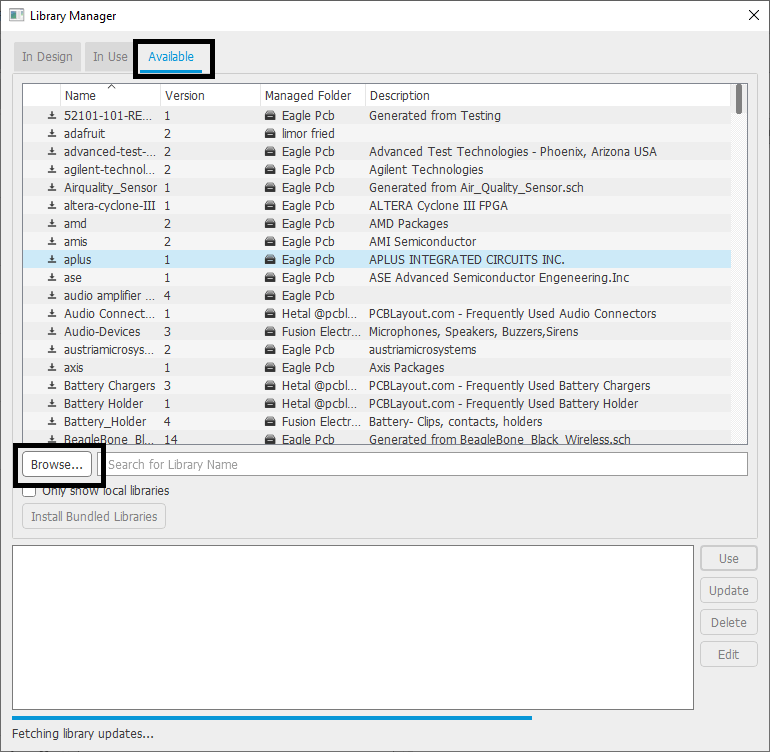

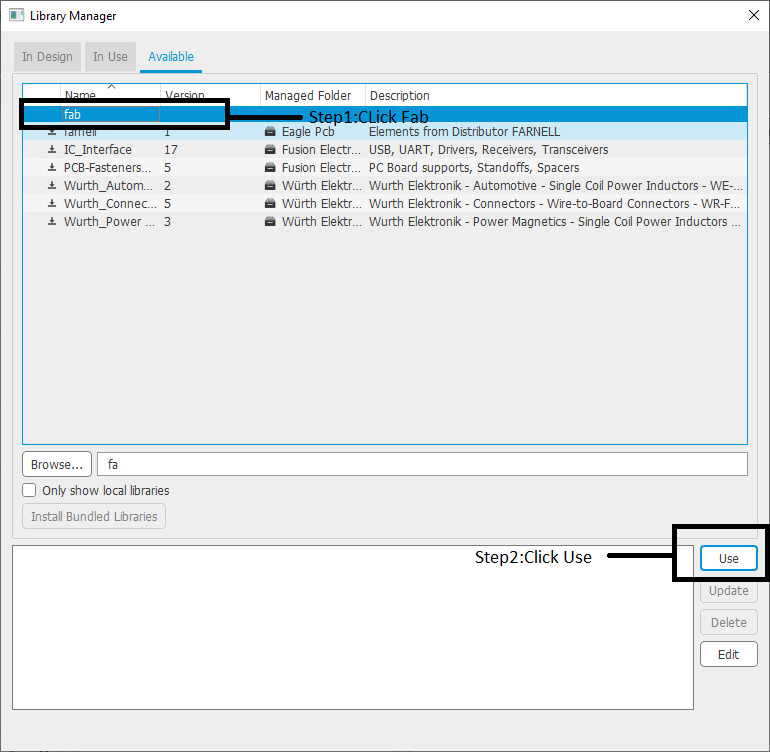

Library Manager:

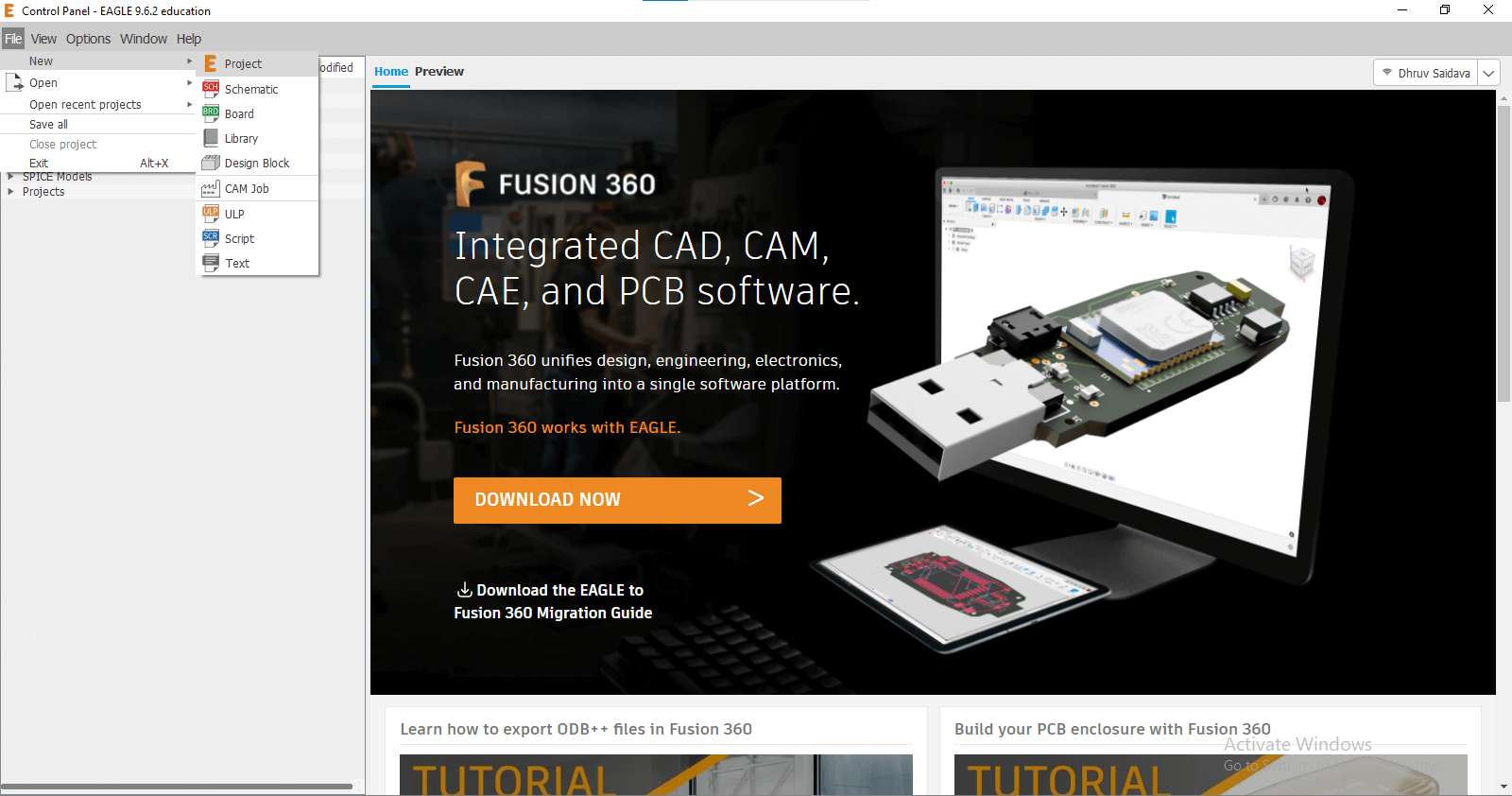

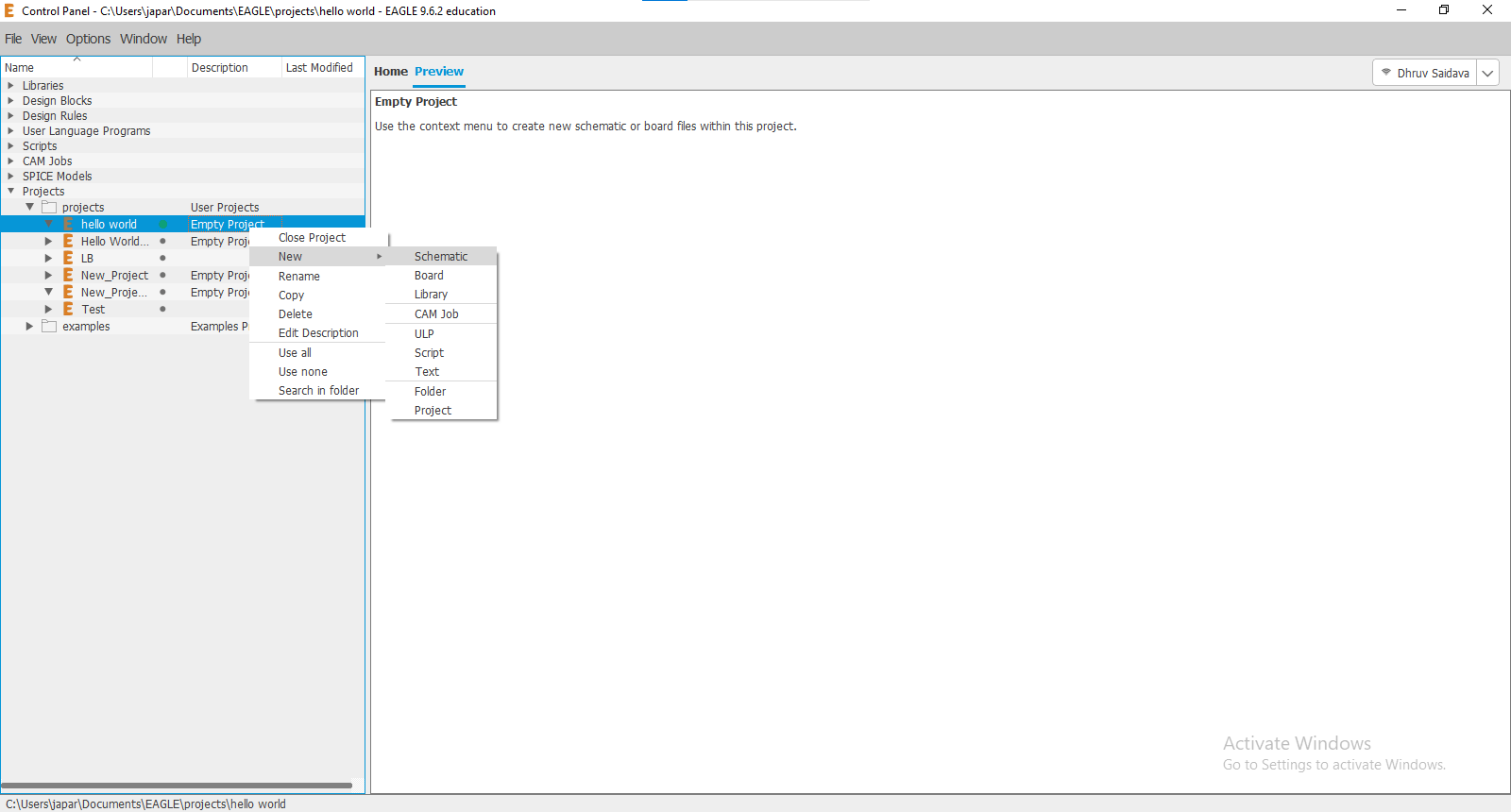

Created Project:-

What Is Schematic Design ?

Selected Components

Library Components:

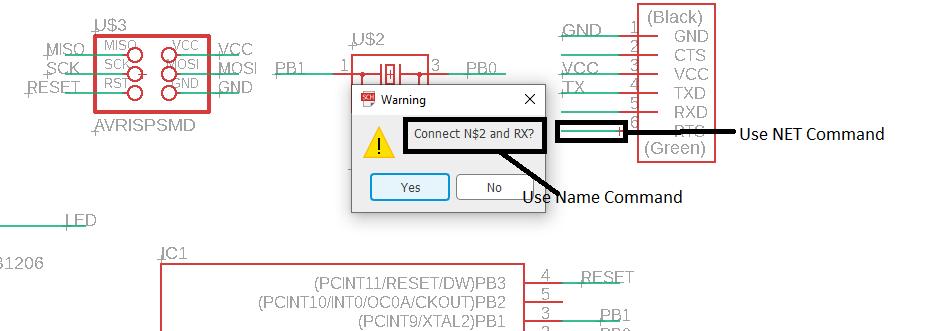

Made Connections:

NET:

Name:

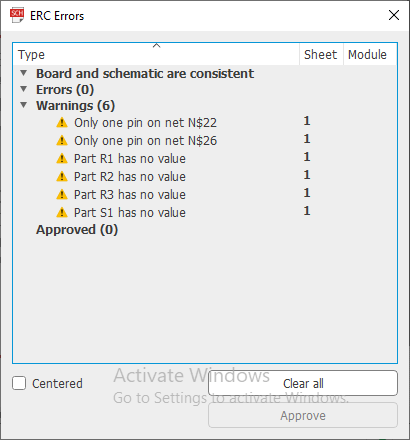

ERC Check:

What is the ERC?

What is the autorouter?

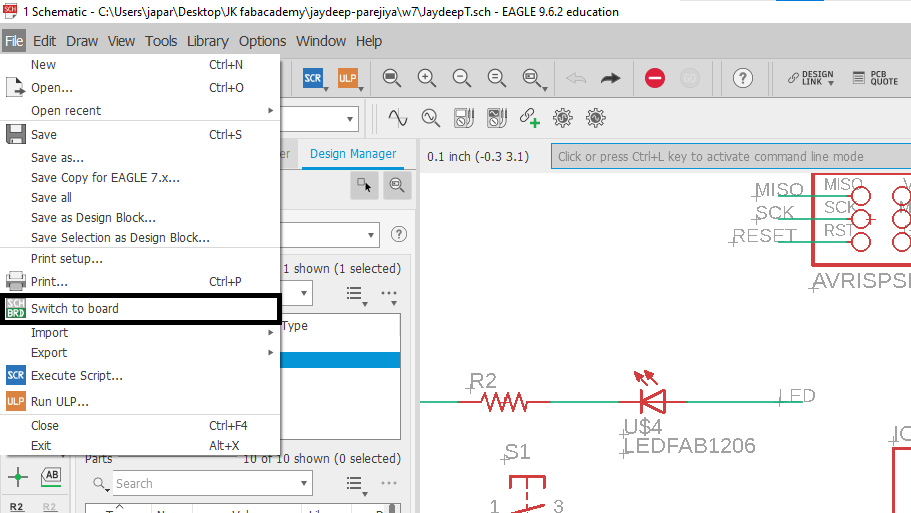

Switch to Board

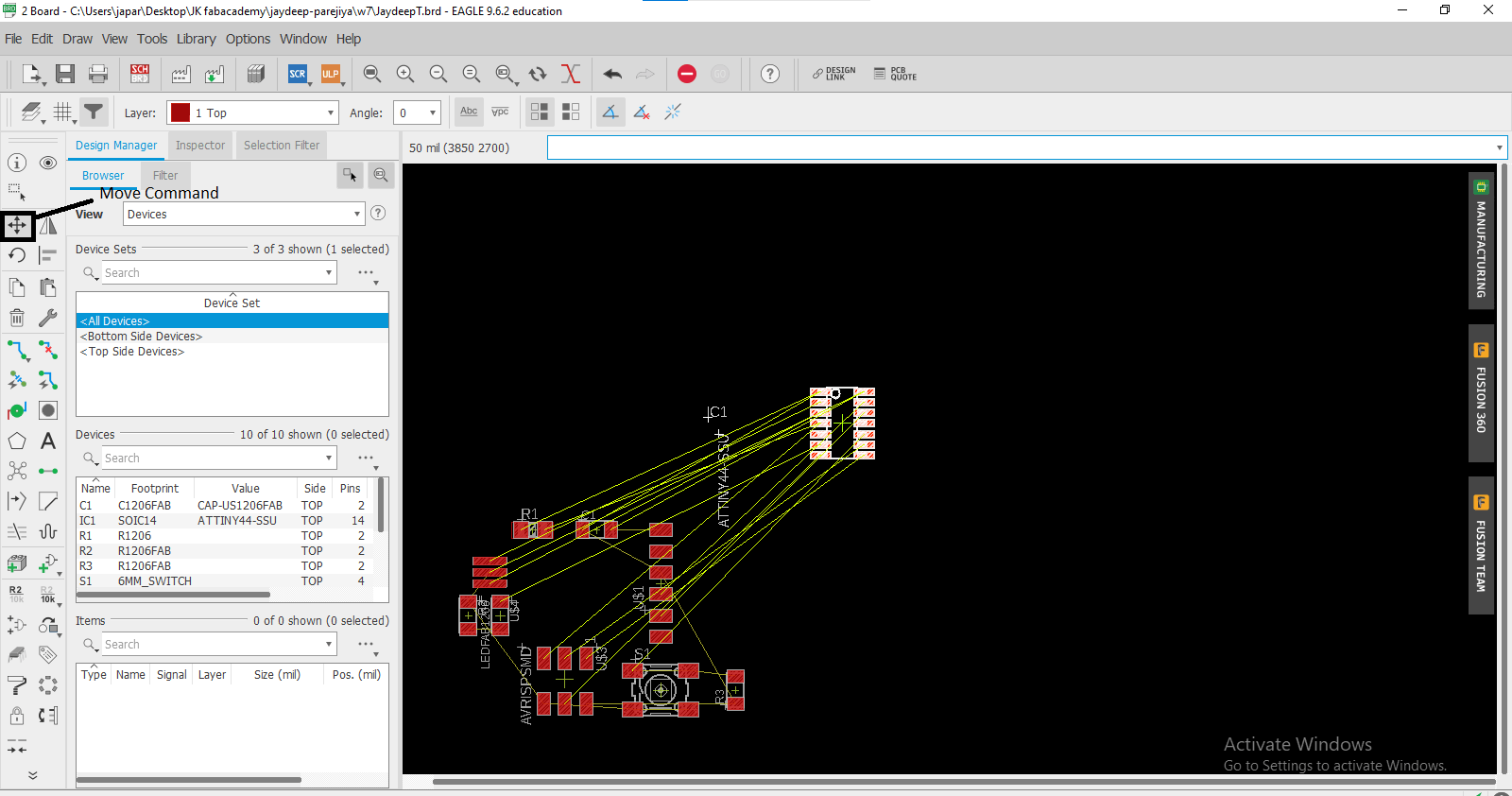

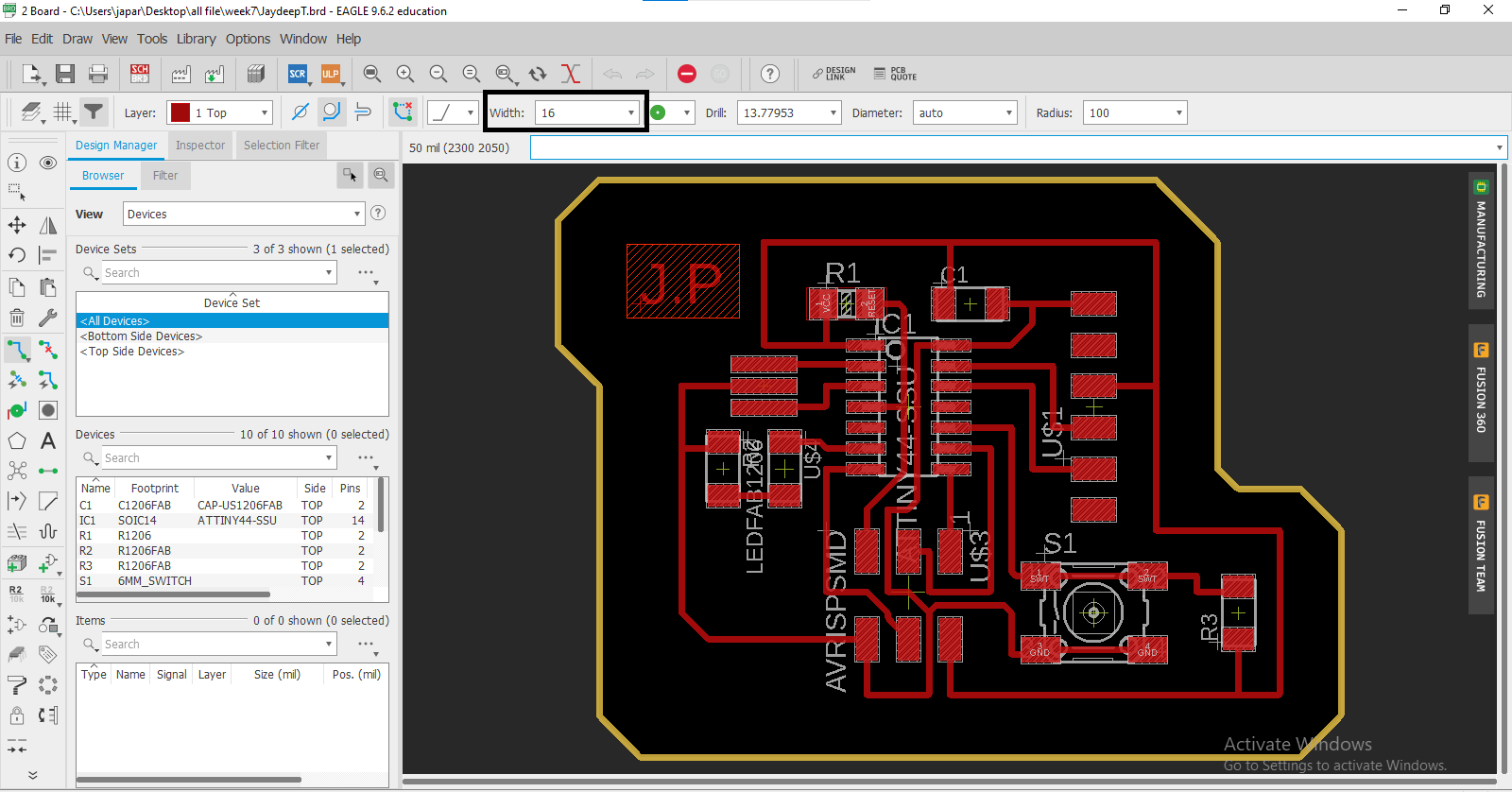

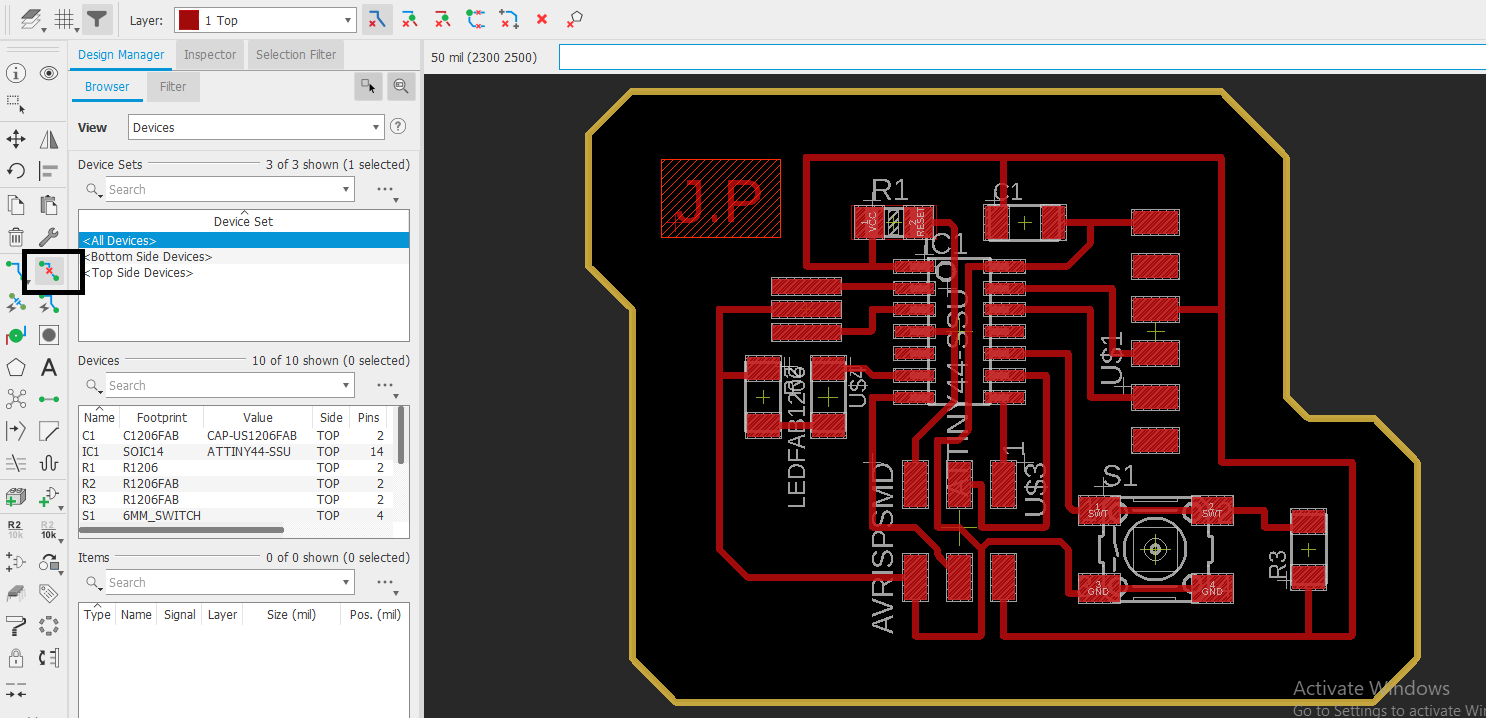

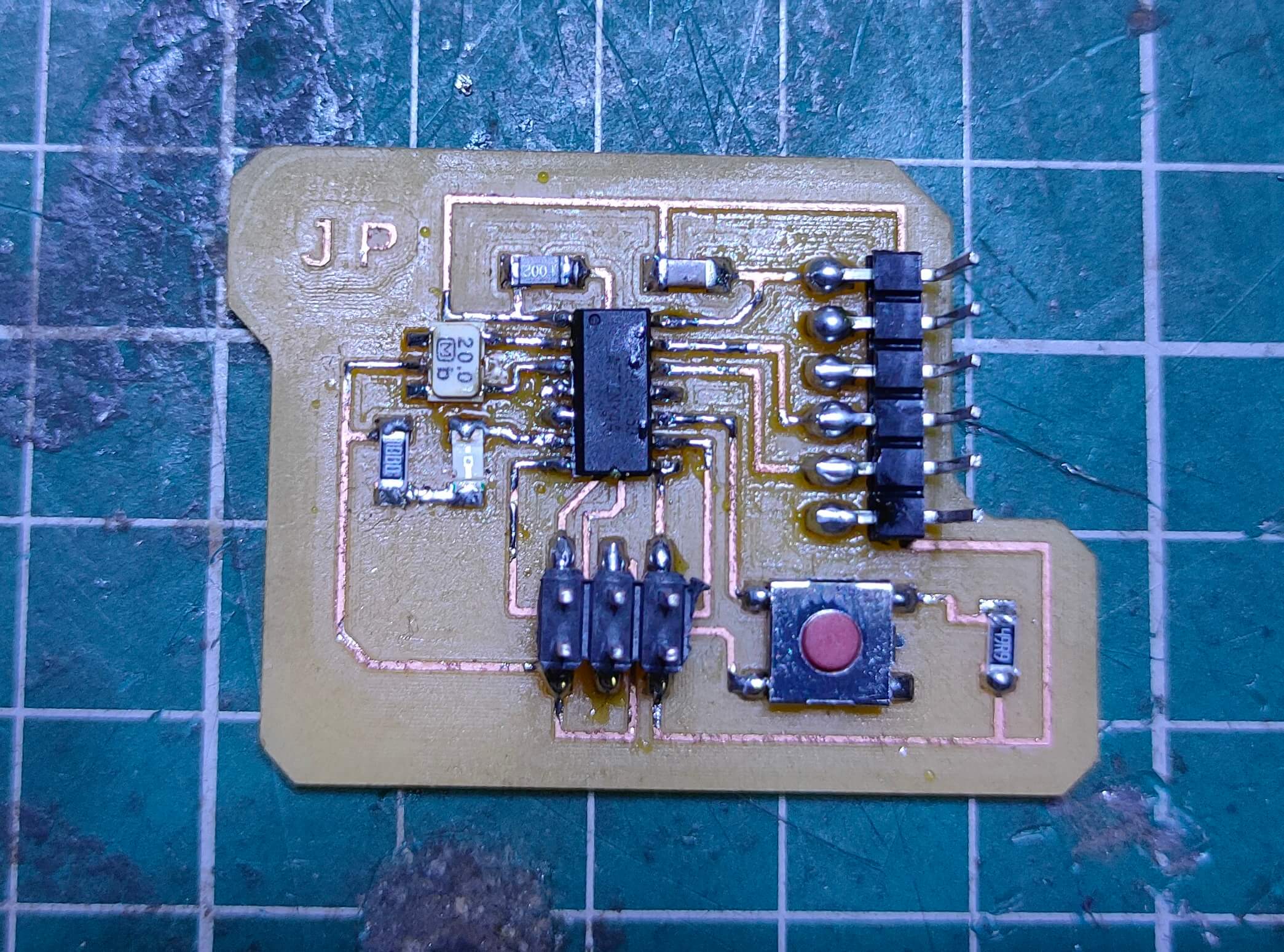

Board Design:

Moved Components:

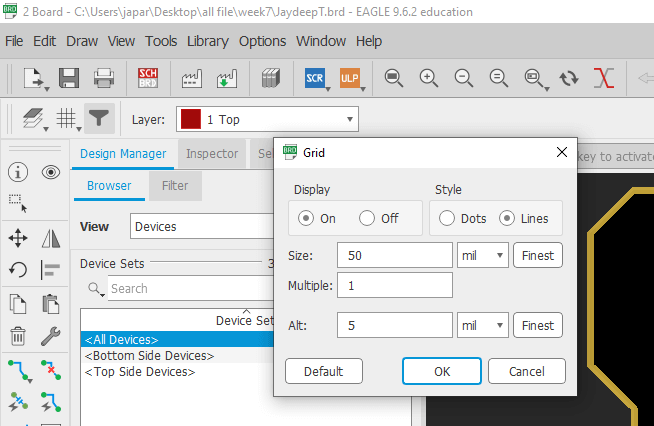

Grid:

Route Traces:

Ripup:

DRC Check:

What is the DRC?

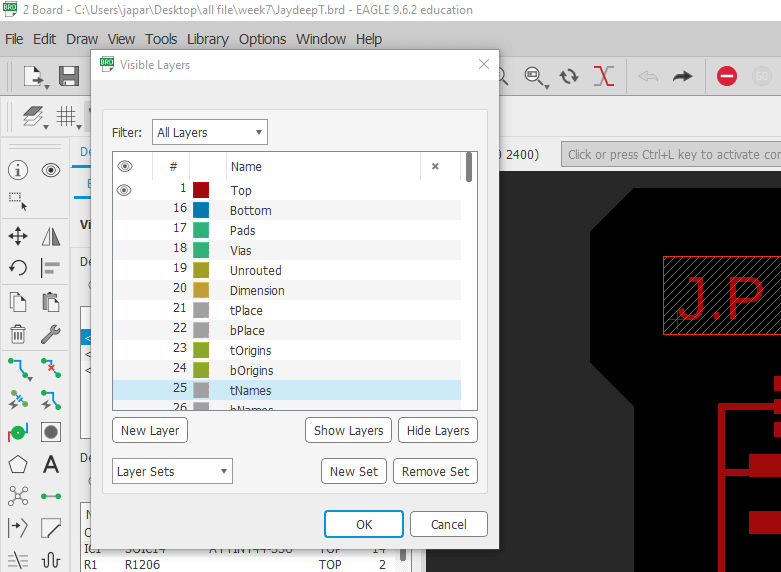

Layers:

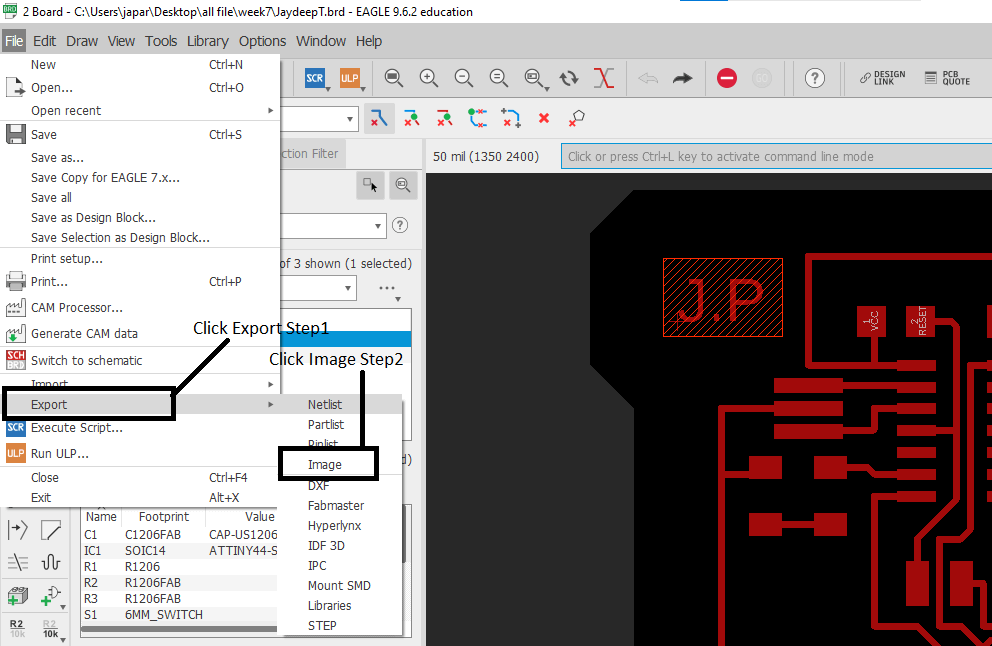

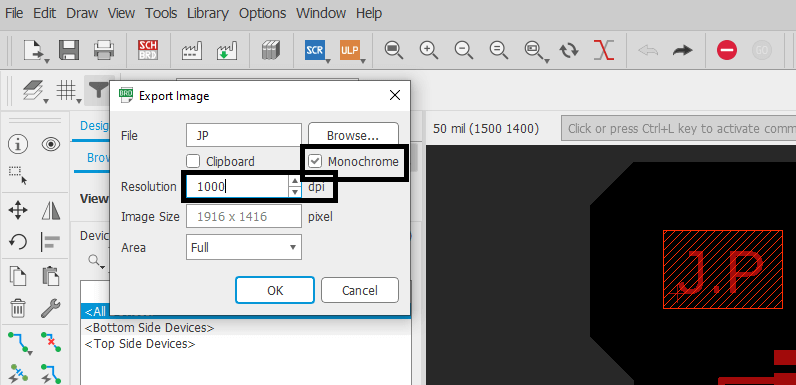

Export File:

Monochrome:

dpi:

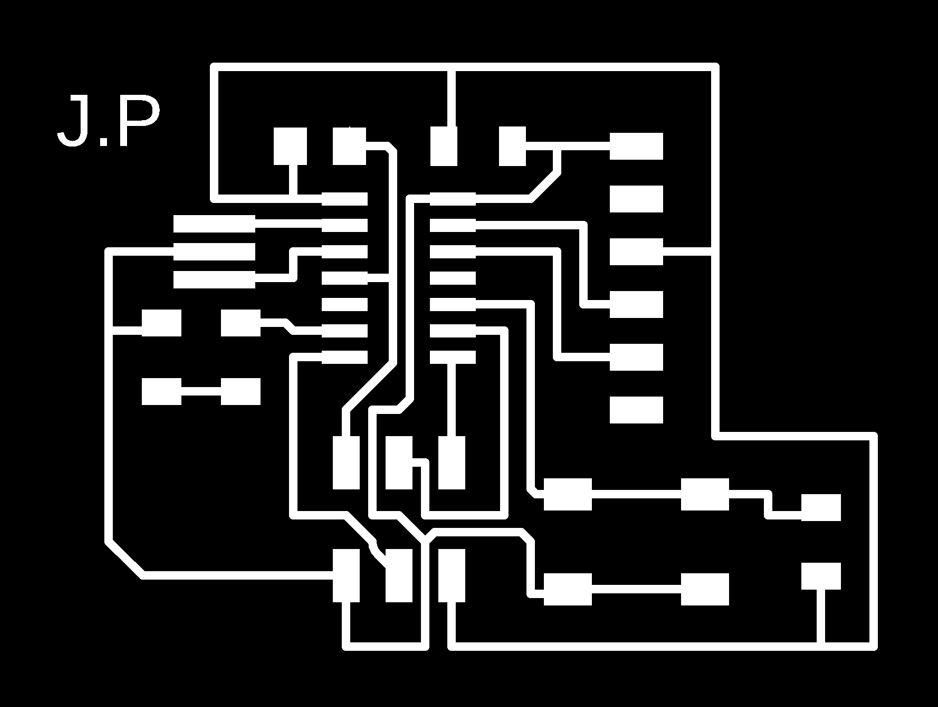

Final Board:

Soldering:-

Components:-The components I soldered to the PCB are listed below:

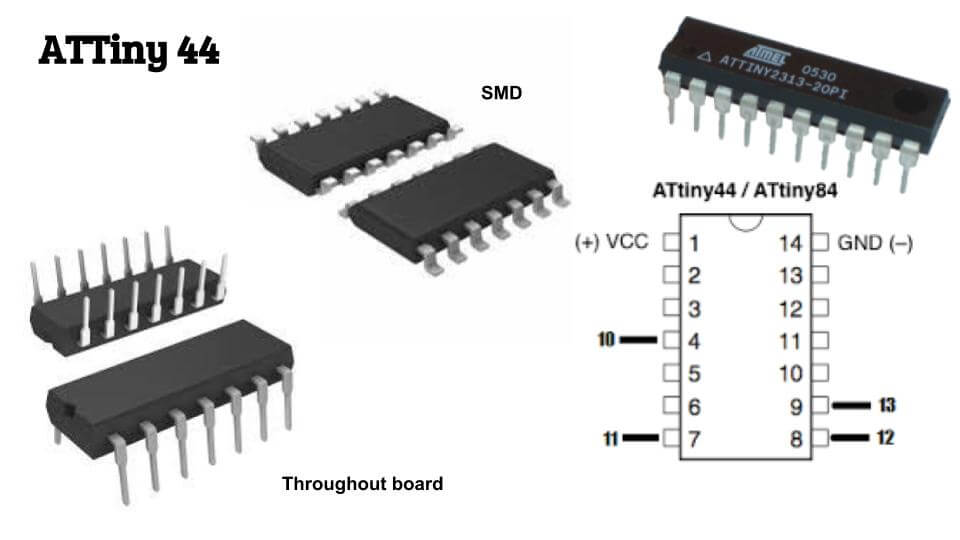

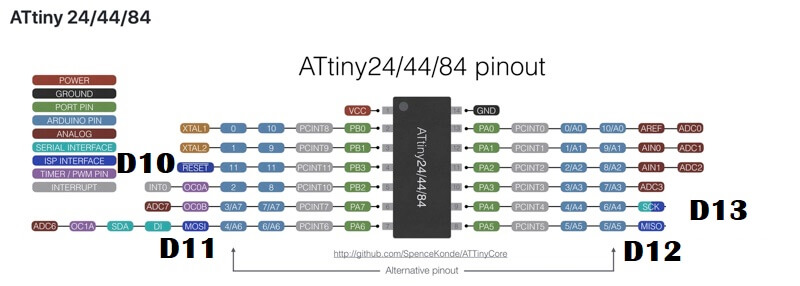

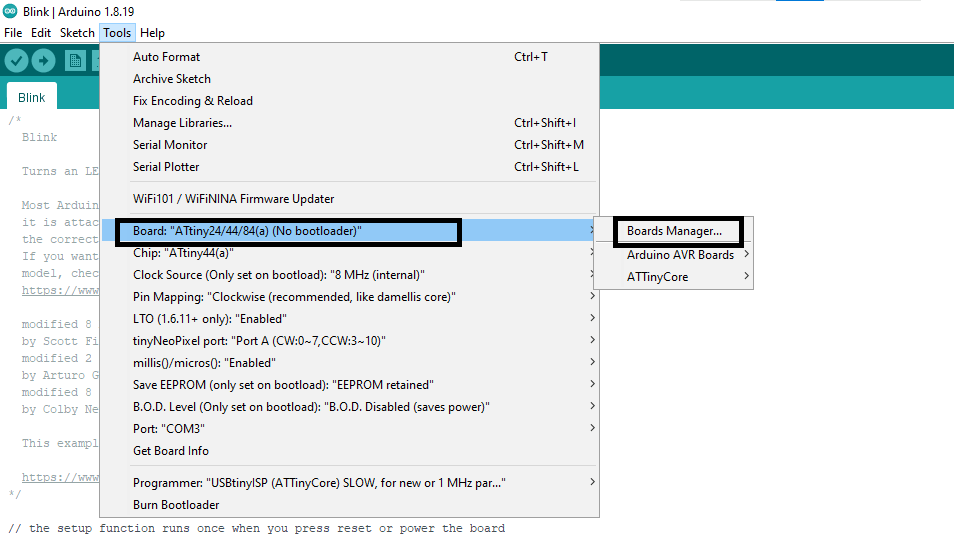

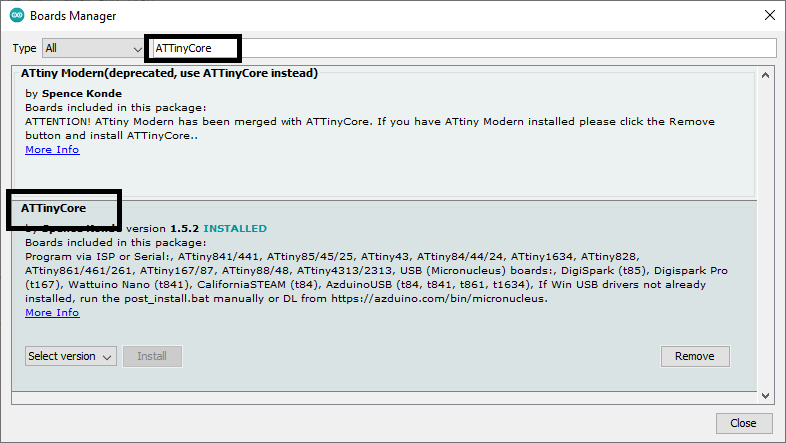

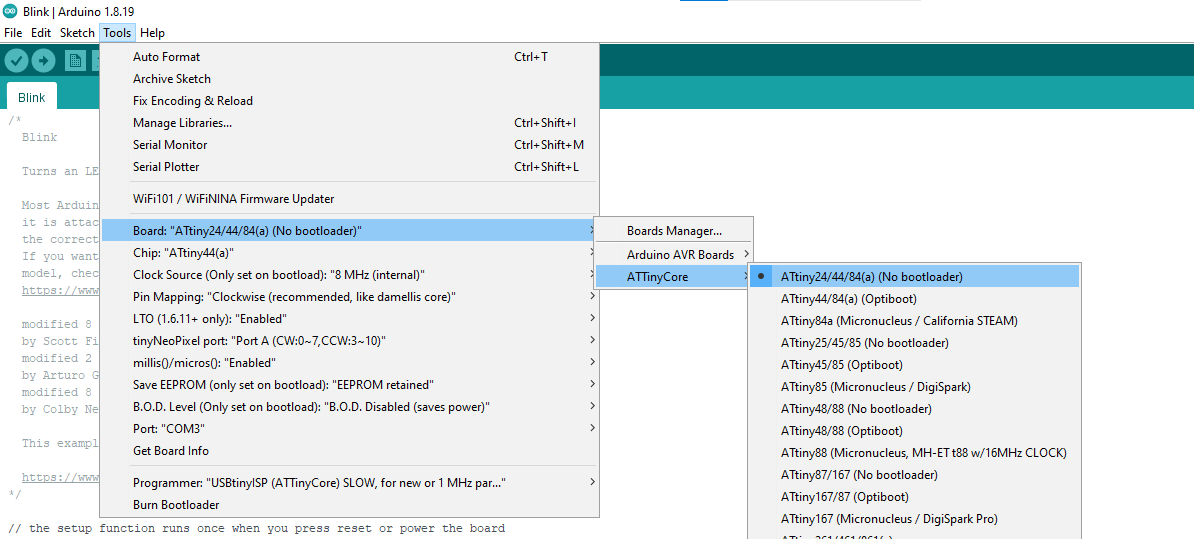

I.C.- Atiny 44

Resistor 1(R1)- 10k ohm

Capacitor- 1 micro Farade

AVRISP

FTDI

Resonator-20 MHz

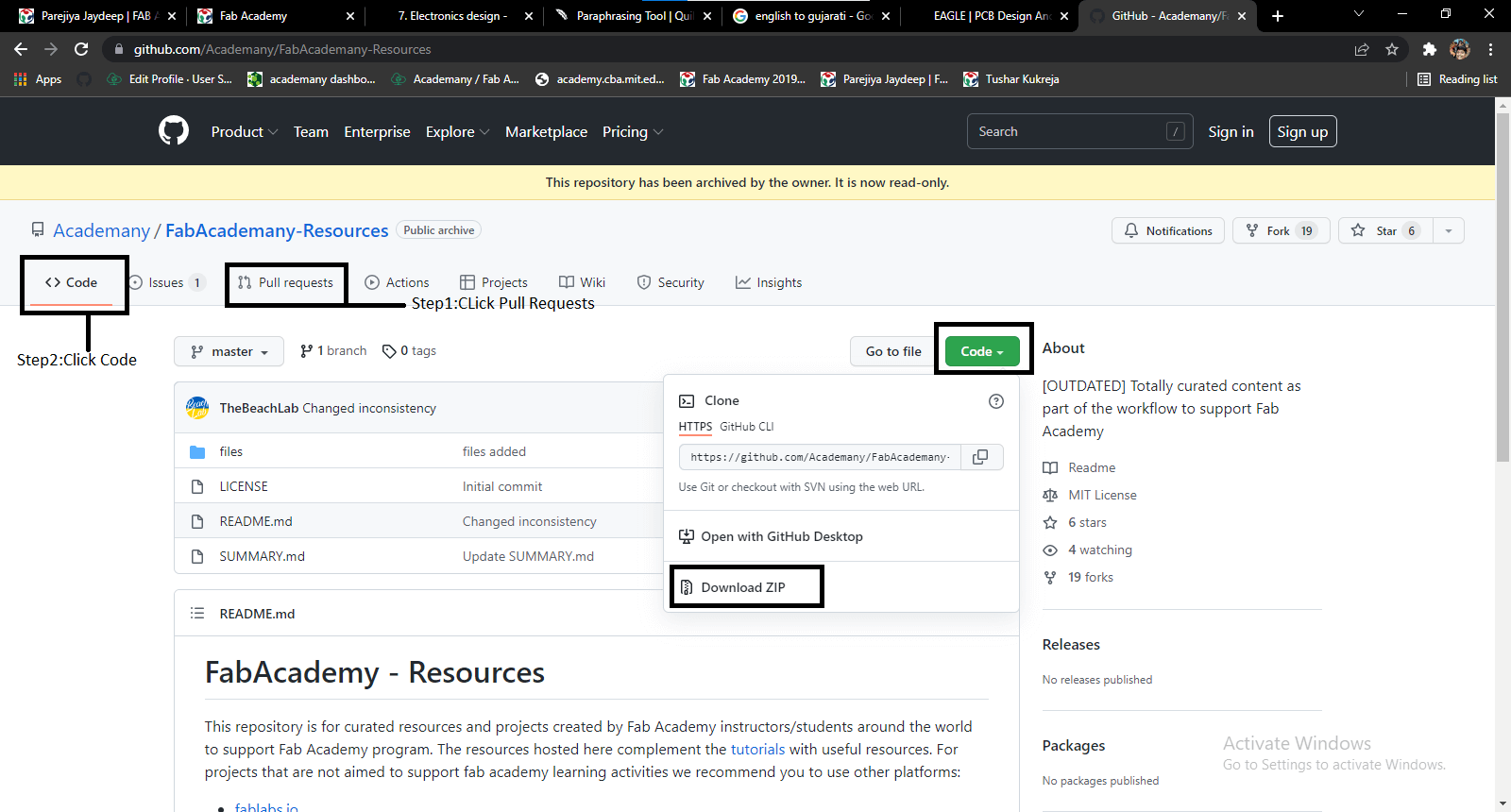

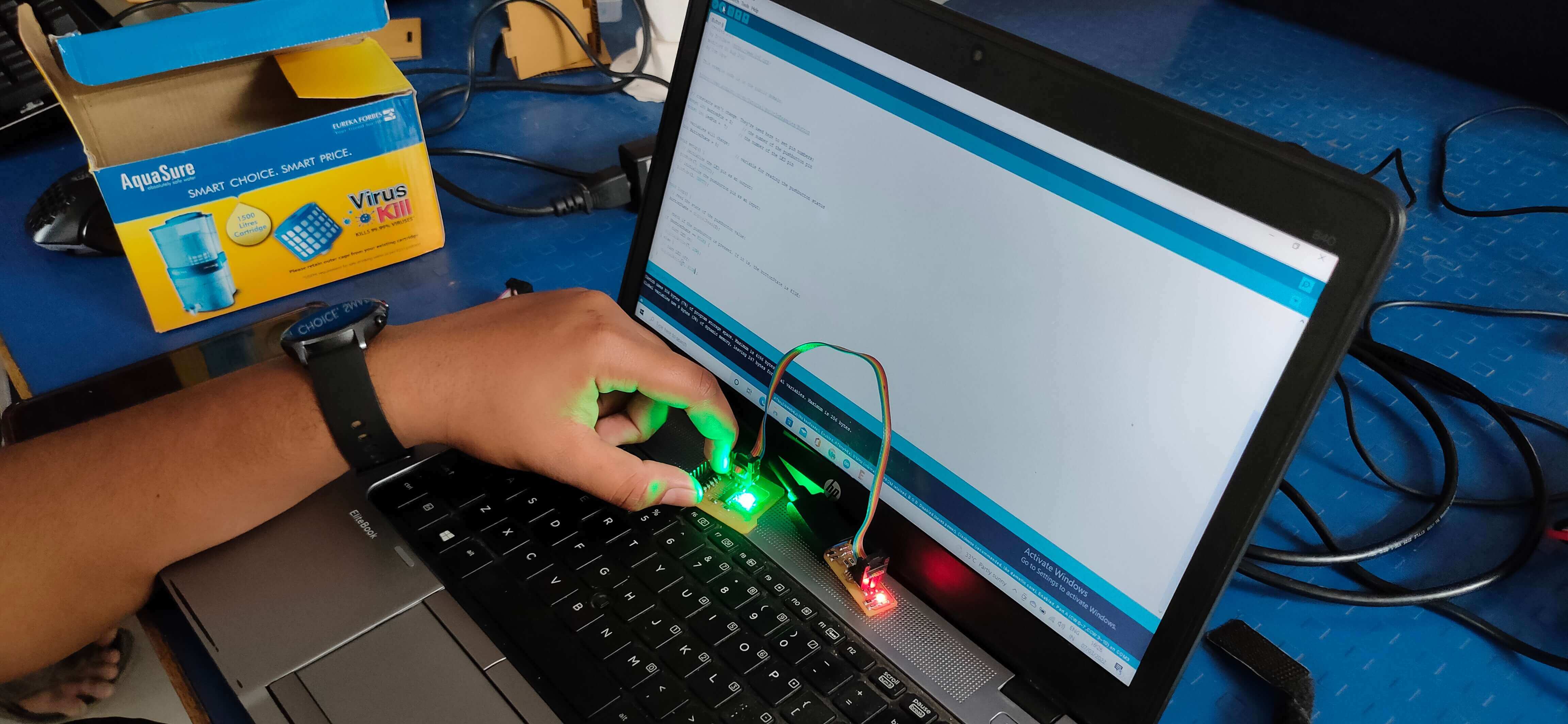

Programming:

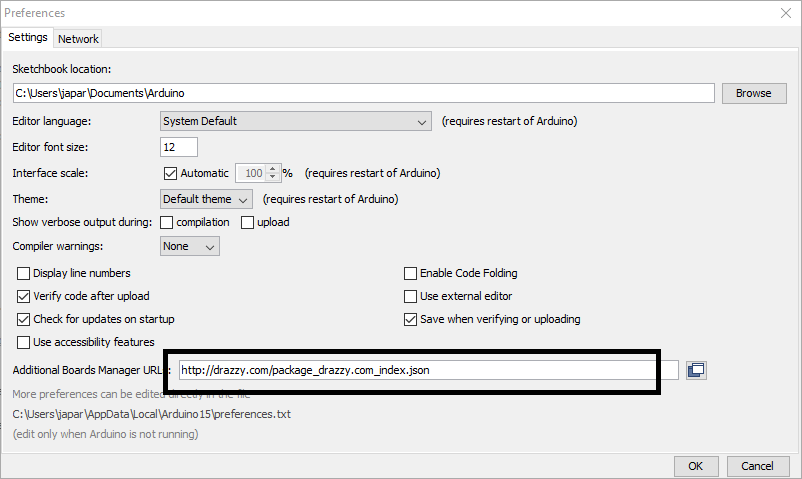

http://drazzy.com/package_drazzy.com_index.json

Upload Button Code

Step5: Button And LED Blik Code.

Upload LED Blink Code:-

LED Blik Code:-

Original File All

« 3D Scanning and Printing | Week 06 Computer Controlled Machining | Week 08 »

Safety

Switch by Parejiya

Jaydeep is licensed under CC BY-ND 4.0