9. Mechanical and Machine Design¶

Individual Assigment¶

Hello! this time, let’s learn about the Maslow CNC.

The Maslow CNC, it’s a vertical cutting equipment, noted for its low cost and its open-source feature.

The whole team participated in the development and construction of this machine,

My work for the team¶

I carried out the analysis of the equipment to integrate all the elements, the mechanical, electronic and control part, as well as all the mechanical design.

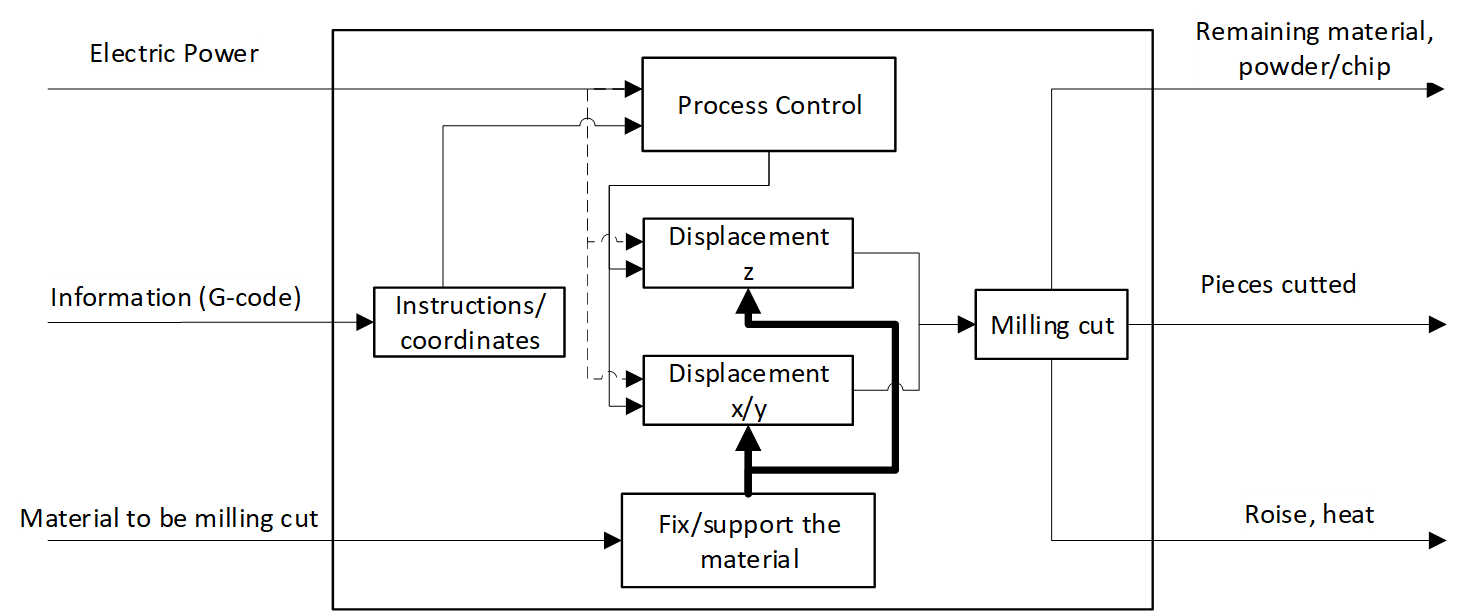

I started with a diagram of what our machine should have,

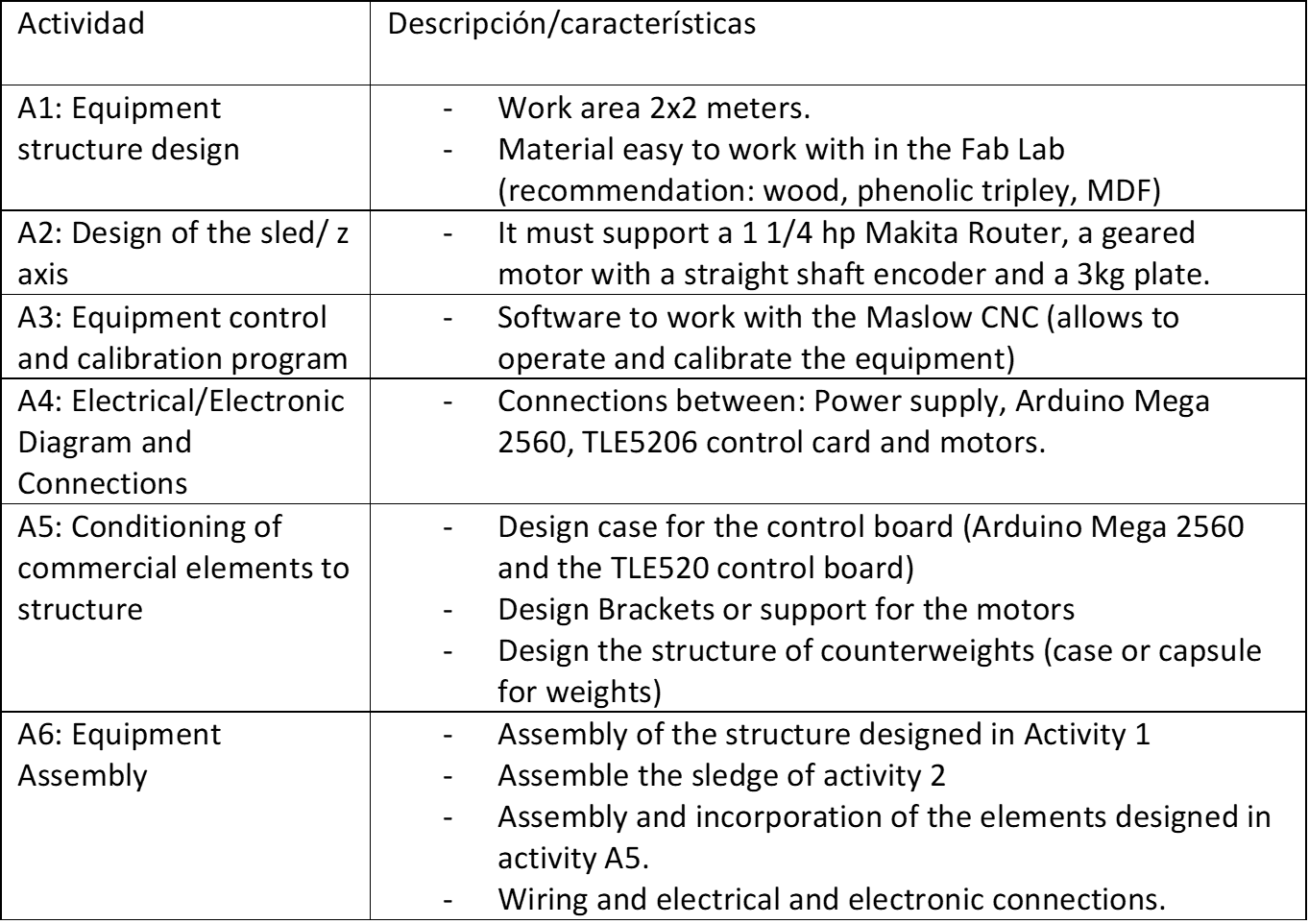

then move on to breaking down the activities for the whole team, break all the work into six activities,

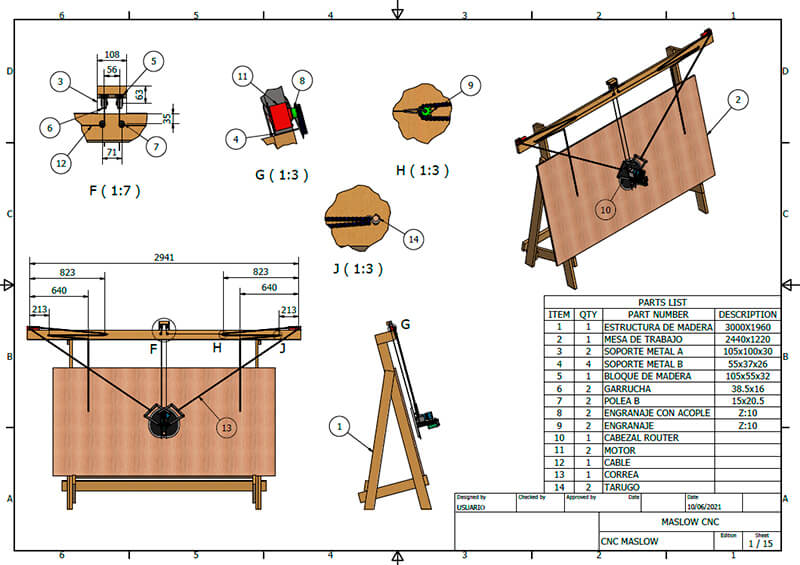

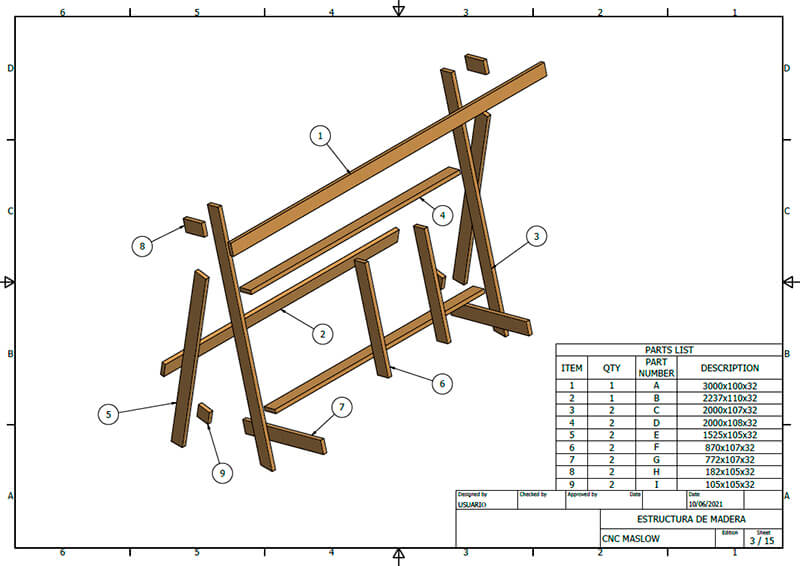

And I began with the design of the machine, analyzing each of the components that were needed.

The first activity was my main job… the design of the structure was where I started, and why I did only this activity, and how everything came to fruition… well, here comes my story with this assignment.

My story (One for all)¶

Well, I work at Fab Lab U. Continental - Huancayo (Center of Peru), I do my assignments alone, yes… I’m alone in the city of Huancayo… and I take care of and attend to this Fab Lab, my Fab Lab :D

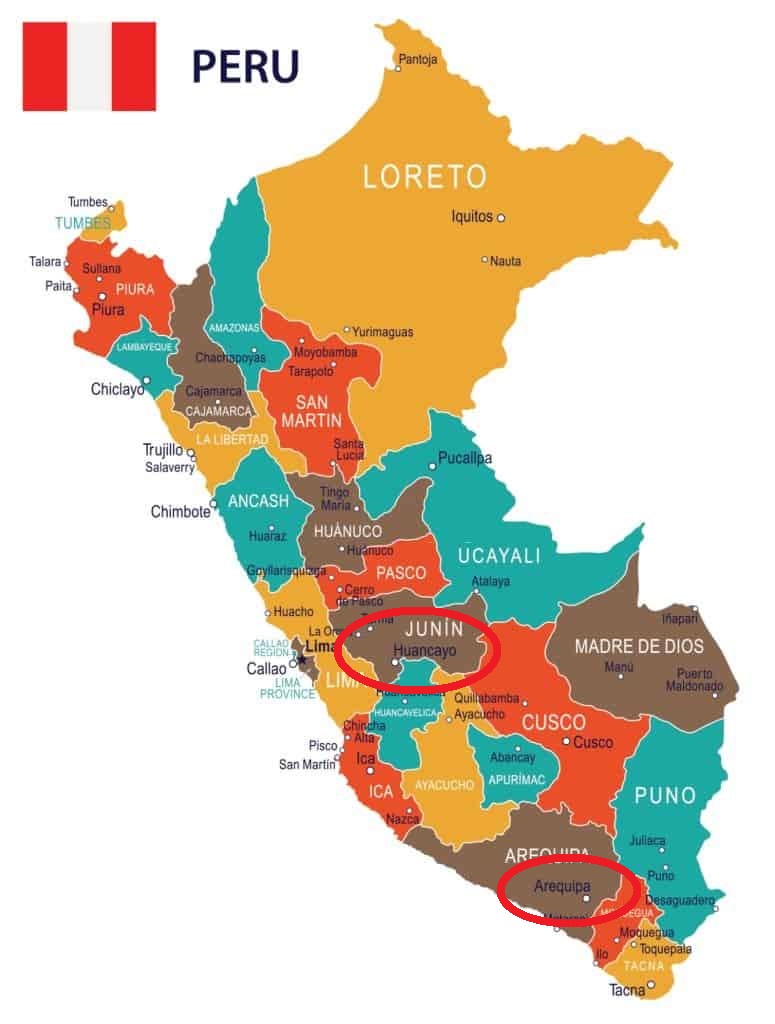

In this assignment the idea was to design and build a machine, I already had an idea of work, but my instructor told me that this was an opportunity to work as a team… so I joined the Fab Lab U. Continental - Arequipa (South of Peru)

So that you get an idea… well… I leave you the map of Peru with our two cities.

The problem was time, I could not afford to be 2 weeks out of my city, without attending my FabLab, so my instructor gave me the role of being the head of ideation and design, so I began to organize the work, analyze the machine and prepare the design.

With the designs ready, I shared them with my team and they began their part, while I was traveling from Huancayo to Arequipa, my new team that I had just met began to organize the materials, to manufacture the pieces of my design, etc.

Our story (All for one)¶

When I arrived, my instructor received me, and I met the whole team!!! That’s where I was surprised that the team was well advanced, and well the details of the development with my teammates from Arequipa are on the group page. To have more detailed information, I invite you to review the project documentation, clic Here.

It was a very good experience… what did I learn? well…

-

The team advances in relation to the slowest, this time it was my turn to be who they expected, why did I have to start with the process of analysis and study of the team in addition to the design, what would I change? I think I would ask my instructor for one more colleague from Arequipa to support me so that the information flows faster between both parties, it is not the same to receive information from someone you do not know than to have someone who is in the same space as you explain it to you.

-

Something that I missed was the final tests of the machine, the day the test was carried out I was traveling, when I arrived in Huancayo I could see the machine working through the video on the page, the internet is a wonderful thing, in the projects You have to know how to overcome difficulties and know how to keep going.

-

It was not a problem, but if something could happen, and that is that in my design we might find pieces that could not be found in the market, perhaps what I can apply for the next opportunities, is to be able to coordinate with the members of the team that parts and spare parts are in your care, and thus adjust my design, and avoid possible inconveniences.

And most importantly… I was able to work as a team… a team from another city… a team… that received my ideas and work well… a team that learned from me and I from them… teamwork… excellent experience.

I also leave you all the designs and documents that I made for this project, clic Here