17. Project Development¶

Hello! this time, let’s learn about Embedded Programming.

Mi final Project¶

My project is a PID control module, with which students can study and understand the parts of this type of controller.

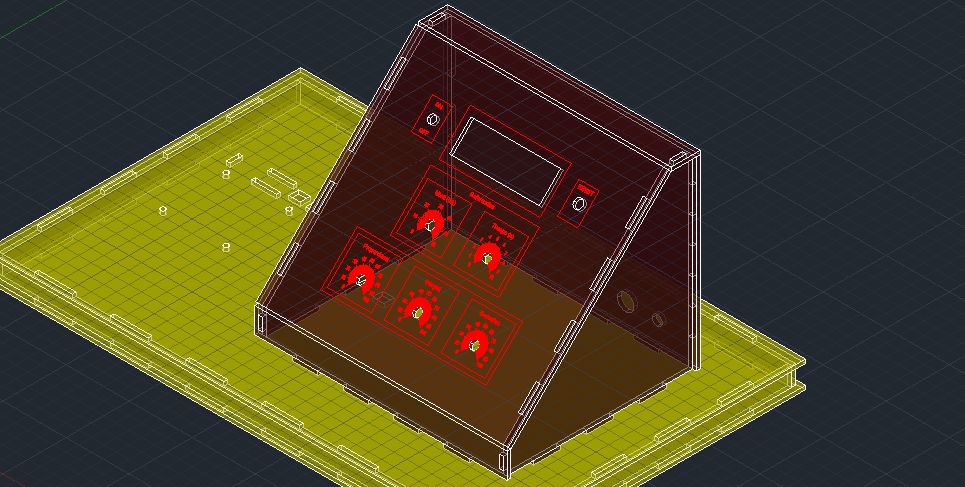

In the assignments, I was devising some parts of my project, such as the panel or HMI.

Also the programmer with which you program the electronic card.

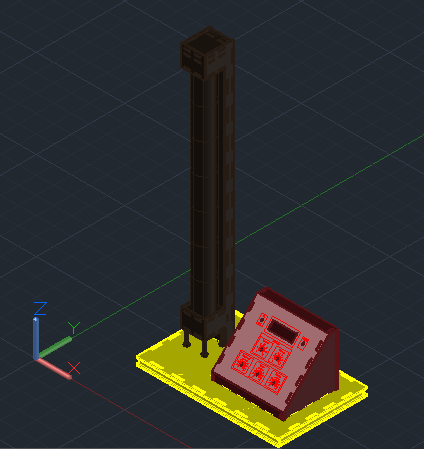

but there were also some elements that had to be designed later, such as the base, the tube support.

I thought about the project very well so that all the elements that it requires, the Fab Lab has, this to avoid logistical problems.

Manufacturing my project¶

At first glance it may be thought that only the laser cutter was used, but in itself it did not have much work other than design, I decided to use this technology, because the project was relatively large for a 3D printer and very small for a CNC, my project has 30 in. tall, all support extrusion was done on laser cutter.

Accessories were also wanted, and that’s where the 3D printer comes in, which allowed me to give that touch of elegance to the module for the potentiometers.

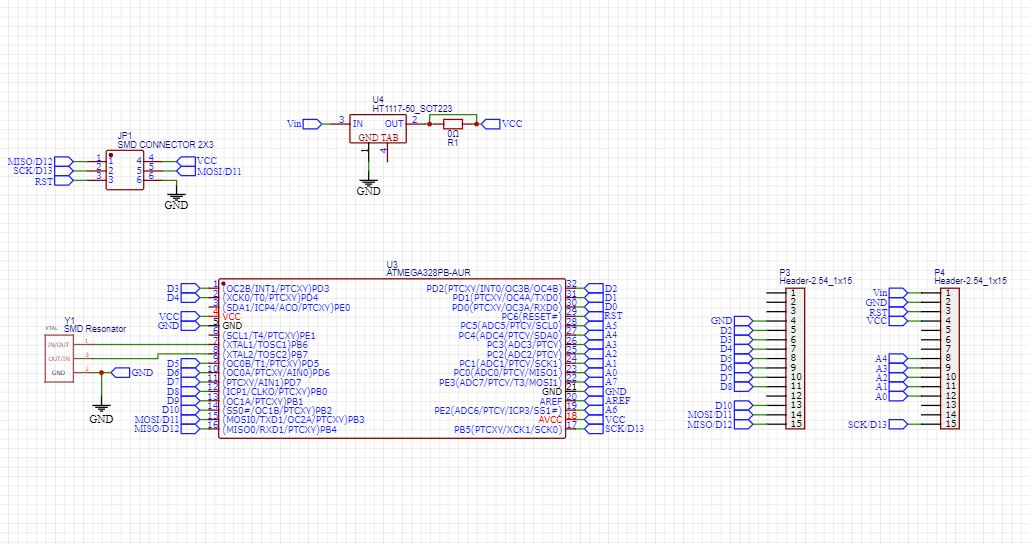

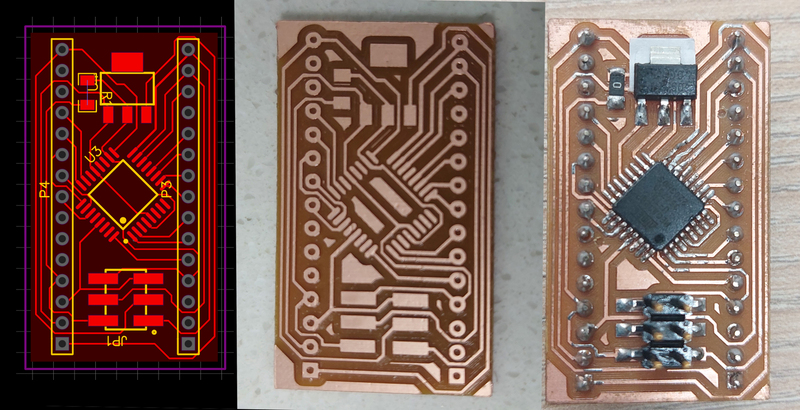

And the heart of all the PCB, here I used the Roland CNC, which in itself was the one that gave me the most complications for the design, an idea I had was that if someone wanted to replicate this project, it was very possible that they would not have access nor the expertise to use a CNC, so I thought, I can design my PCB inspired by a commercial electronic board, an Arduino UNO was very common, and I took an Arduino Nano as a reference, and there came the challenge, of several days trying to find the minimum step tolerances between PINs, the routes were an ordeal, but in the end it was achieved!!!,

so anyone who works in a fab lab can replicate my project, but also any student who does not have direct access to a CNC to PCBs, my effort will be worth it so there are no excuses!!!.

And he commercial components then use the following: - LCD-display. - Potentiometers. - Push button. - tToggle switch. - Ultrasonic sensor. - Fan. - Wires, lots of wires.

Evaluation¶

Say if my project is good or not, it was decided by students, in the end that was the goal,

Invite some university students who didn’t know about PID control yet and after a 5 minutes explanation about PID, let them experiment and draw their conclusions about the control actions. and all were largely correct conclusions about the Proportional, the Integral and the Derivative

In that sense, I consider it to be a success.

The most satisfying question was… if I want one. Can you manufacture here in the Fab LAB? and obviously my answer was YES!