15. Wildcard week¶

Hello! this time, I’ll tell you a story.

Without ideas I got problems¶

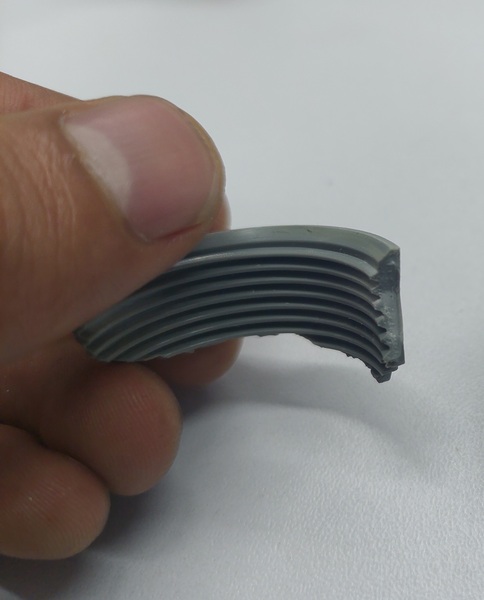

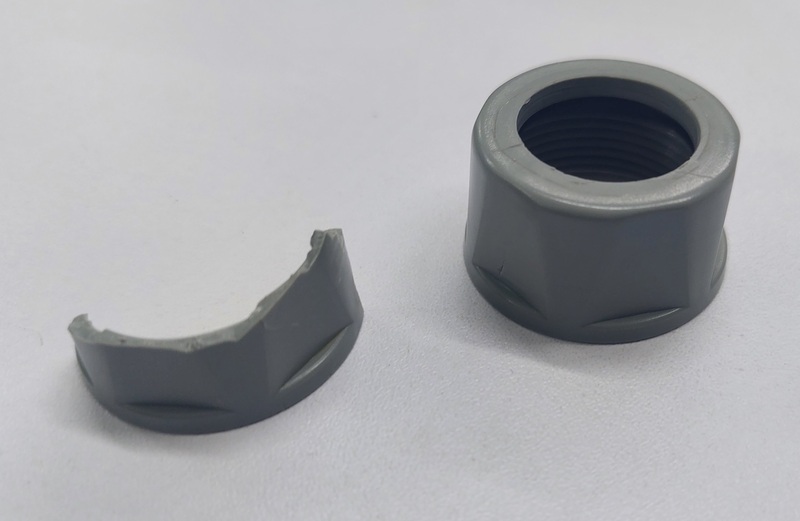

One day, thinking about what activity to do, a lab partner approached asking for help, because an instrument (pH meter) had a broken piece (they probably made it fall and lost the pieces),

She showed me the broken piece and I said let’s design a replica and print it in 3D but there was a problem, the PLA was not going to resist contact with the test substances they use, and it had to maintain the color relationship, seconds before denying the help, I saw salvation for both, both for my colleague and myself.

Solution x2¶

Yes yes, I know I said that 3D printing was not the solution, but how about 3D printing with another technology that is not FDM… for example SLA…

Design¶

Before starting, I had to take measurements and design the piece, so let’s get to work!

The design you will find it at the end of this assignment.

Just like FDM 3D printing, we must export the design in STL format.

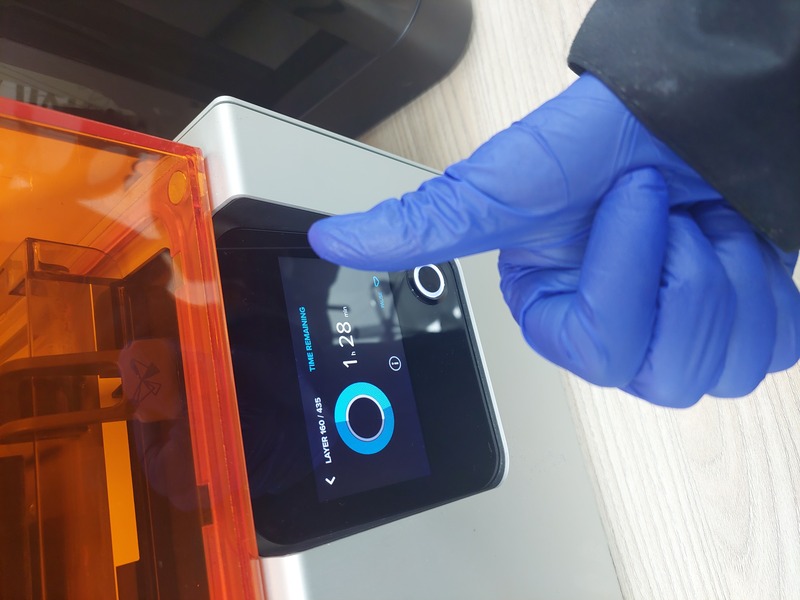

Impresion 3D SLA¶

To begin with, we see a different team structure than usual, we work with resin and the printing base is on top (don’t be scared with this printer, it prints upside down). and we don’t see filaments, we see resin, so the first thing is safety,

Now if you go to work, put on your personal protection equipment before touching the equipment, the resin can irritate the skin, and if it happens, you should wash the area with plenty of soap and water, avoid spreading it and exposing it to the sun.

the process is very peculiar, I leave you a small video.

When the 3D printing process is finished, you may see the piece with a strange shape, but it is the liquid resin that impregnates the piece, the first thing we must do is wash the piece, it is done with isopropyl alcohol, they can do it in a simple way. manual in a container, in my case I have access to a washing machine, and well I use it.

We leave it washing for a few minutes, and when it is finished, we must cure the piece, so that it takes on the definitive form, we do this with equipment that emits UV radiation.

The work process is sequential, first remove and wash the piece, then cure, the processes cannot be done in reverse

The result was satisfactory, very useful, of double utility, we helped a colleague and I was able to use a new 3D printing technology that I had not seen before.

Finally, I leave all the designs.

- Download the files here

This is all for this time.