FINAL PROJECT¶

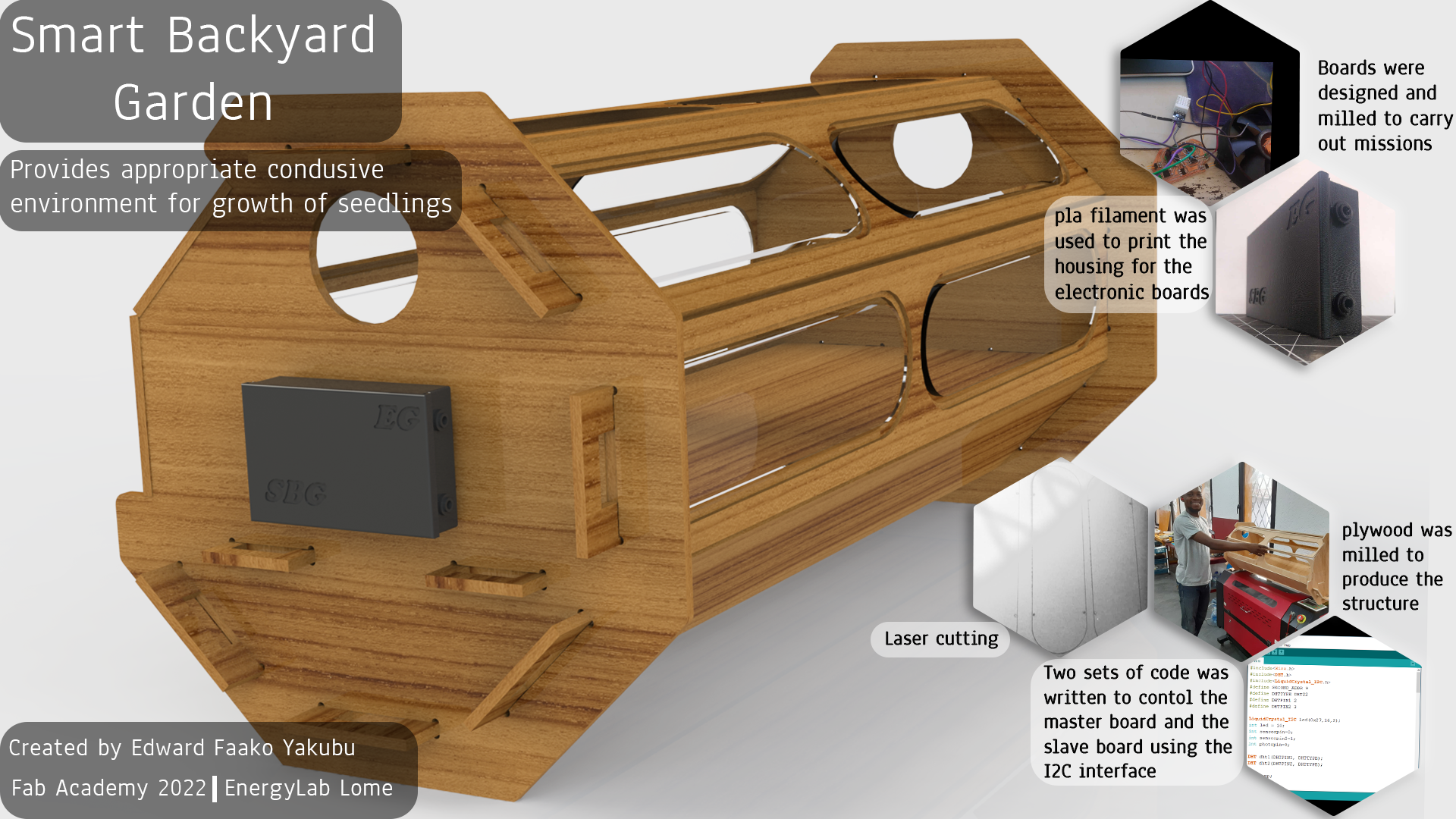

Presentation Slide¶

Presentation video¶

REFER TO : - FINAL PROJECT DEVELOPMENT FOR FULL DETAIL ABOUT THE PROCESS.** - Application and Implications for the answers to the questions posed.

Bill of Materials¶

Electronic components¶

| PART | TYPE | QTY | cost/unit($) |

|---|---|---|---|

| AT-tiny | 1614 | 2 | $1 |

| Capacitor | 10uf SMD | 2 | $2.05 |

| Linear voltage regulator | 5V 1A | 1 | $1.56 |

| Resistor | 0 ohm SMD | 2 | $0.07 |

| Resistor | 5k ohm SMD | 2 | $10.71 |

| Resistor | 10k ohm SMD | 4 | $14.69 |

| LED | 3.3v SMD | 1 | $0.15 |

| Photo resistor | 1 | $0.185 | |

| Mosfet | N-CH 50V 16A | 3 | $2.4 |

| Pin header | single row, 40pins | 2 | $4.47 |

| subtotal | $46.625 | ||

| all the electronic components can be bought here |

Electric parts¶

| PART | TYPE | QTY | cost/unit |

|---|---|---|---|

| dc fan | 12V dc 90mm | 1 | $7 |

| water pump | 12V submersible | 1 | $8.99 |

| LED | 12V strip | 2 meters | $3 per meter |

| LCD screen | I2C 16x2 | 1 | $9.99 |

| Humidity&temperature sensor | DHT22 | 2 | $6.345 |

| soil moisture sensor | 2 | $7.50 | |

| Wires | 2mm | 3 rolls(different colorss) | $12 |

| subtotal | $71.68 | ||

| these parts can be bought here |

Non Electrical parts¶

| PART | TYPE | QTY | cost/unit |

|---|---|---|---|

| Ply-wood | 1.5m x 2.5m | 1 | $19.88 |

| Plexi-glass | 0.5m x 2m | 1 | $19.09 |

| Screws | 4x8mm(30/pack) | 1 pack | $2.23 |

| 3D printing filament | PLA | 1 | $25 |

| Garden hose | 20mm diameter | 1meter | |

| Glue | hot glue sticks | 15 | $2 |

| subtotal | $68.2 |

PROJECT FILES¶

3D printing - Component housing

Laser model - Laser_files

Enclosure CNC Files - side_panels

Electronic boards files - Output_copper_traces

Closing Words¶

It has been a great honor to be part of this year’s Fab Academy. My heart is filled with gratitude to the organizers and to the teaching staff. The last 20 weeks have been fun, intriguing, full of learning new things, errors, mixed emotions and a whole lot. So before I started this training my expectations where through the roof regarding the new thing I would learn and add to my skill set. Personally I love learning new skills to better my life and people around me. But I did not expect the weekly pressure to pull of assignments to be of this great magnitude. This pressure has helped shaped me to work and cope in pressure situations, I know the profeesional world has more pressure in store us but this has helped in training me to work under pressure.

I have learnt new skills like: - operating a vinyl cutter to produce vinyl stickers - A large and small CNC machines to mill and route shapes I want - How to solder like a professional - how to design my own custom electrical circuit - how to mill out a circuit board design - Types of joints and fixtures - How to calibrate and use a laser cutting machine - The tricks of getting a good and quality 3D printout - The art of casting and making molds for casting - A deep understanding of microchips and microcontrollers - How to programe microchips - A new programming language -Processing

Aside the technical skills I was equiped with how to plan a project and work in spirals and then make adjustment when the need arises. As you know in this life every thing can not be always smooth. I had some moments where plans, assignments and decisions went so bad that I wanted to quit. but thanks to word of encouragement from my instructor, I was able to restructure my mentality and was able to pull through the difficult times.

The feeling of having the very first electronic circuit board you designed, built and programmed working is out of this world and it is intoxicating. It can be addictive. How proud and accomplished you feel is just something to strive for.

In conclusion I have been a very fortunate young man to be accepted to this noble Academy, my life has never been the same. I promise to use this knowledged acquired to better my life and the people around me. THANK YOU !!!! Fab Academy. Best of luck to anyone following this blog, just believe in yourself and and never give up.