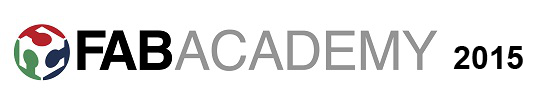

My weakest point, is programming and controlling a system via terminal/command line .... so for this assignment I choose to develop and make work the software control of the project :-) hopefully my mate Alessandro Papaleo is much more capable.The first step was to install the pygestalt and relative utilities:

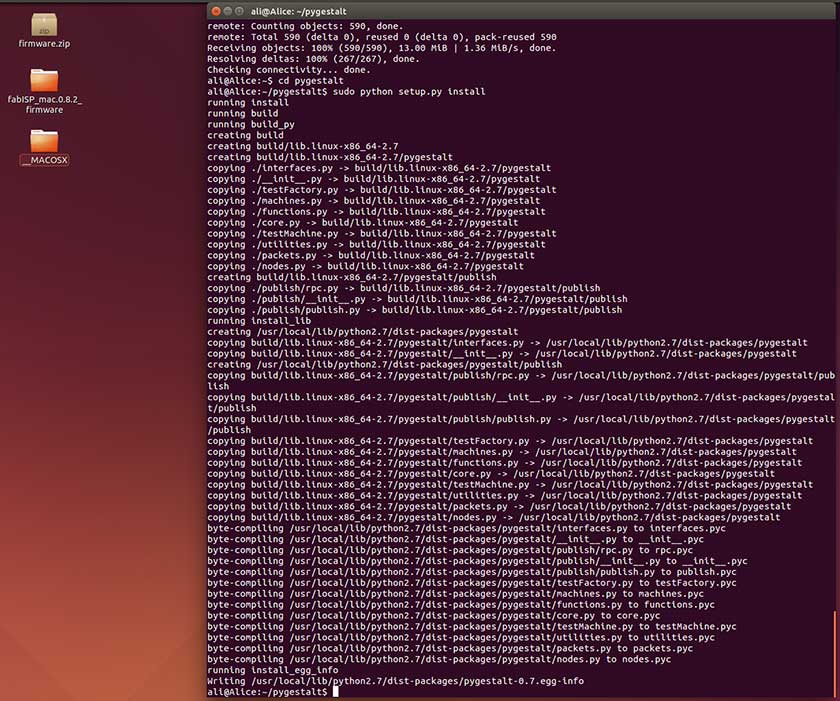

Following the Shawn's instructions. The procedure is so well documented tha even a linux newbie like me was able to succeed. The secon step was to make the Gestalt Nodes comunicate with my pc. This part was not easy and it took several hours and many try. The USB port did not comunicate with the rs485 FTDI cable so we could not reach the gestalt boards

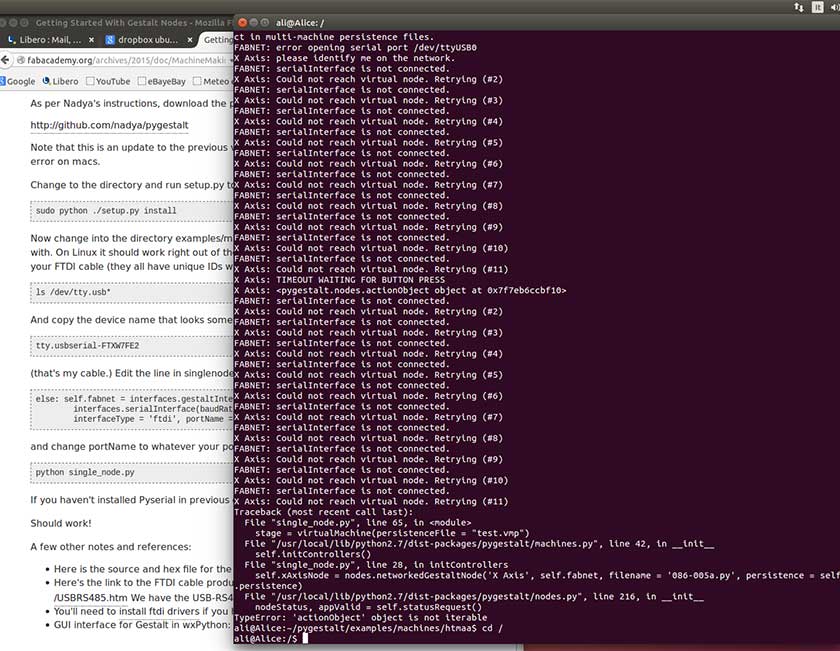

.... But then Alessandro found the solution ! ... to activate the USB serial comunication you need SUDO permissions ... et voilà :-) connection established !!

We replicated everything on Alessandro's MAC, but again no comunication ... the problem was solved changing in the pyton program the USB recognition line from: /dev/ttyUSB0 to: /dev/tty.usbserial-FTXW4FZ4 From there the path was flawlessly, just a matter of study and understanding. We tested with the single_node.py then the two nodes xy_plotter.py and then we learned how to add two more axis in the python code and how to change the code parameters. The further step was to understand how to move with our coordinates manually inserted and how to automatically read a file whit G-code coordinates.