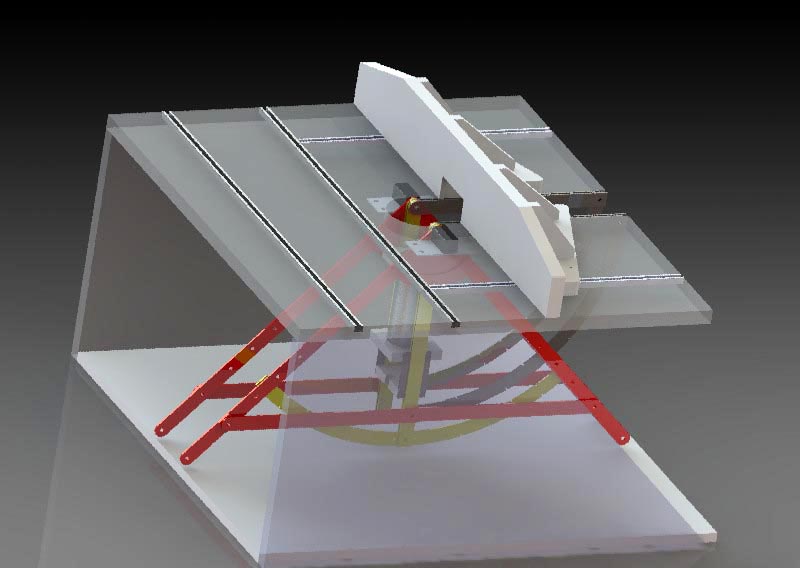

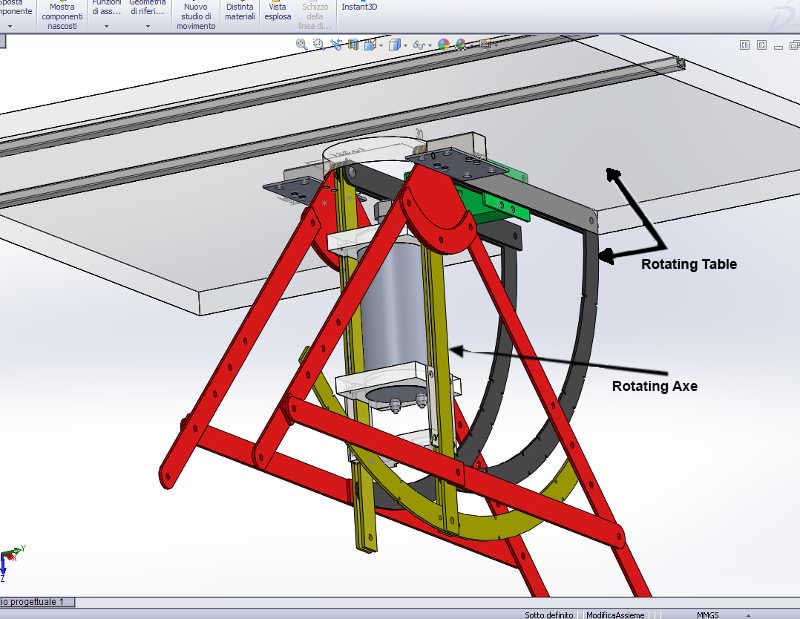

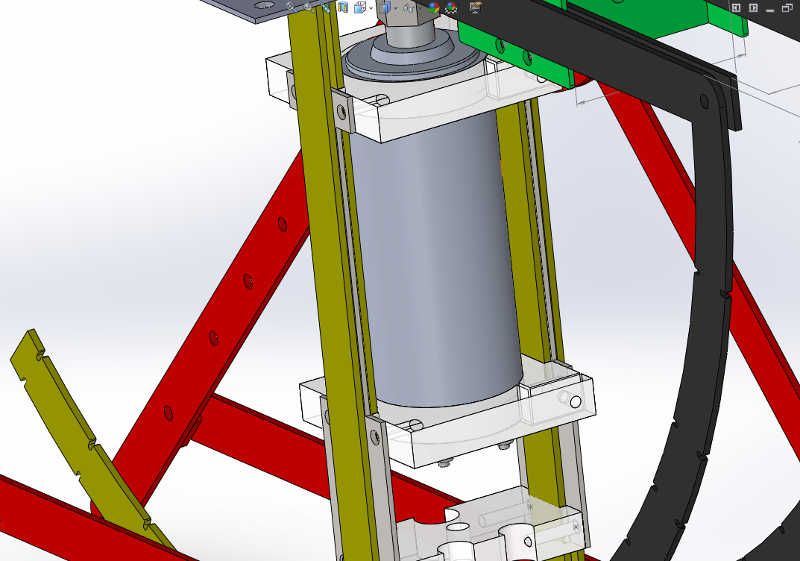

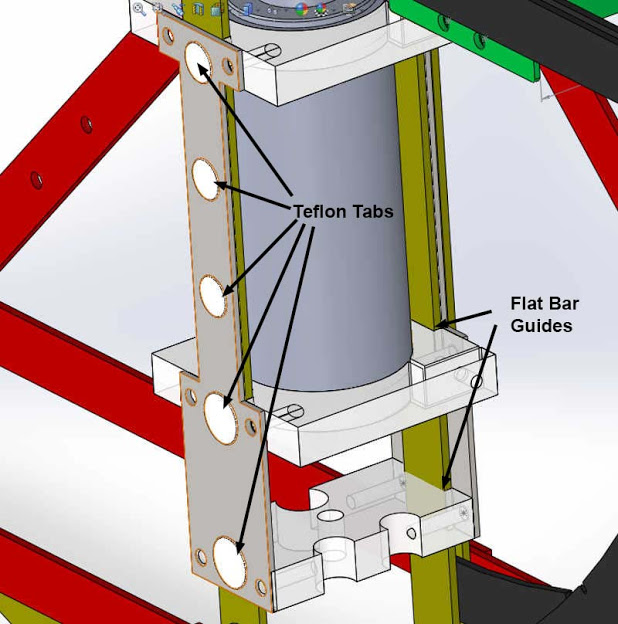

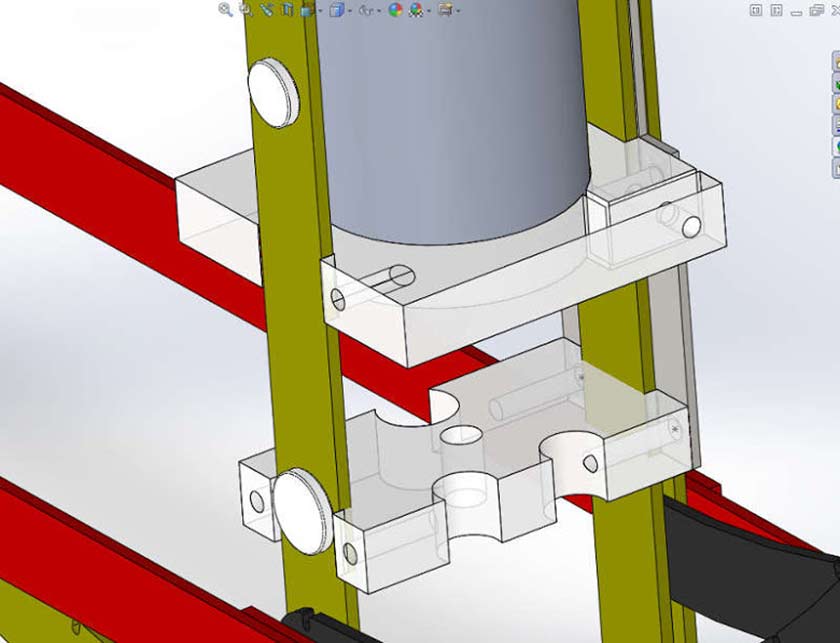

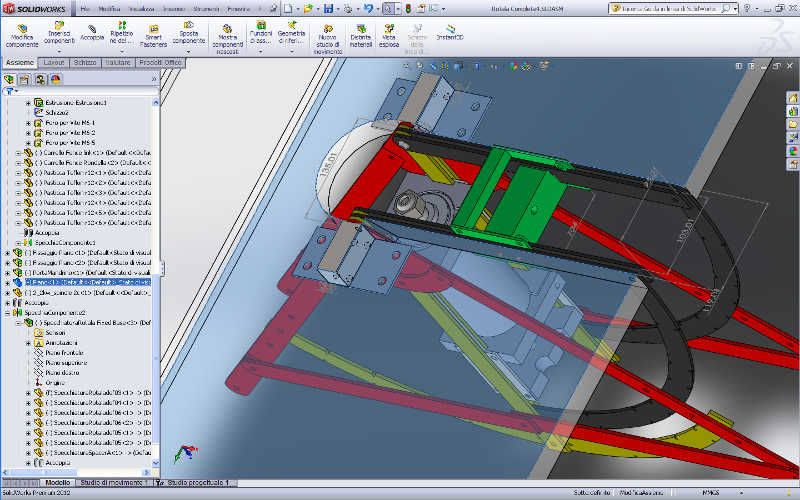

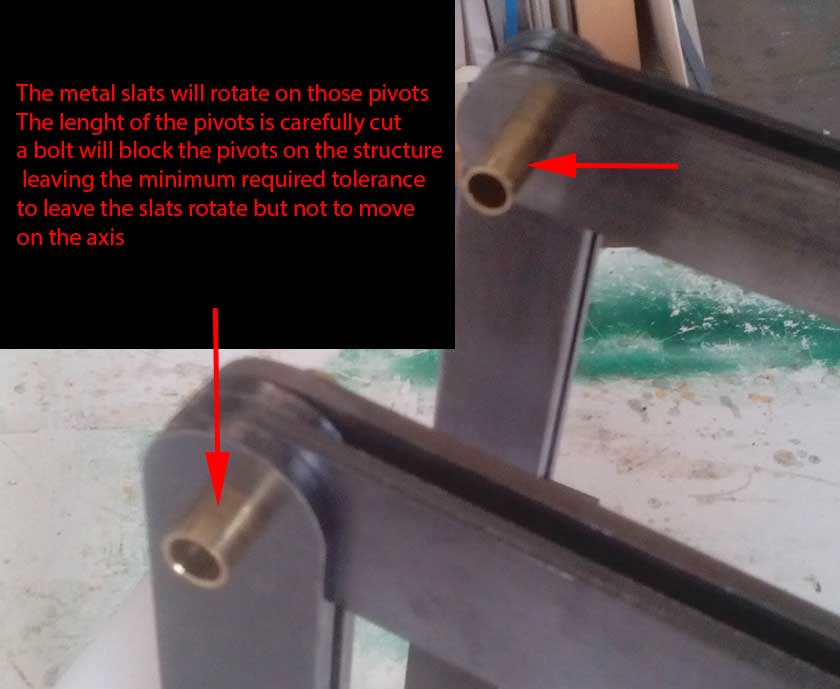

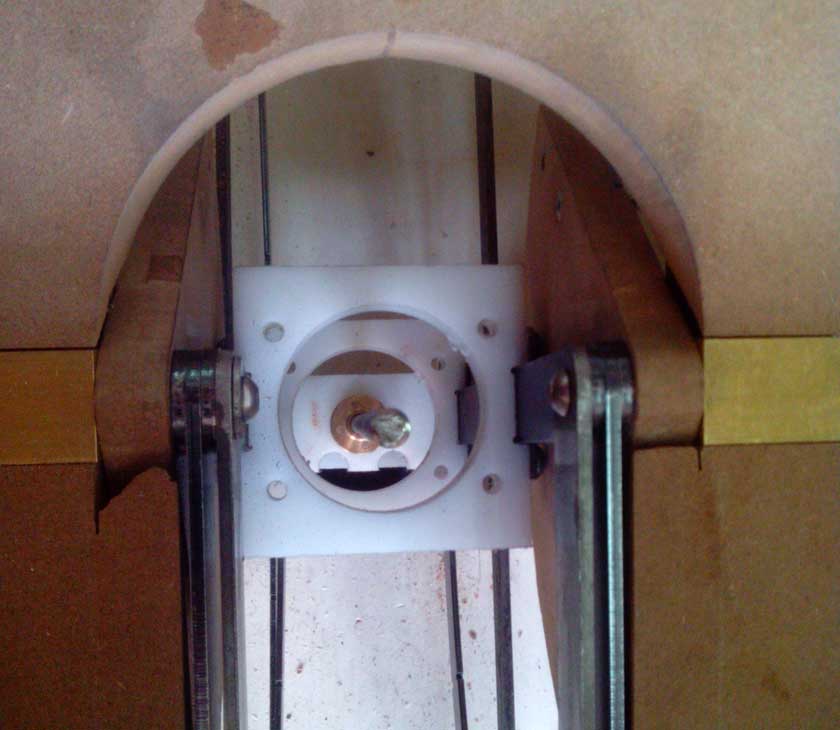

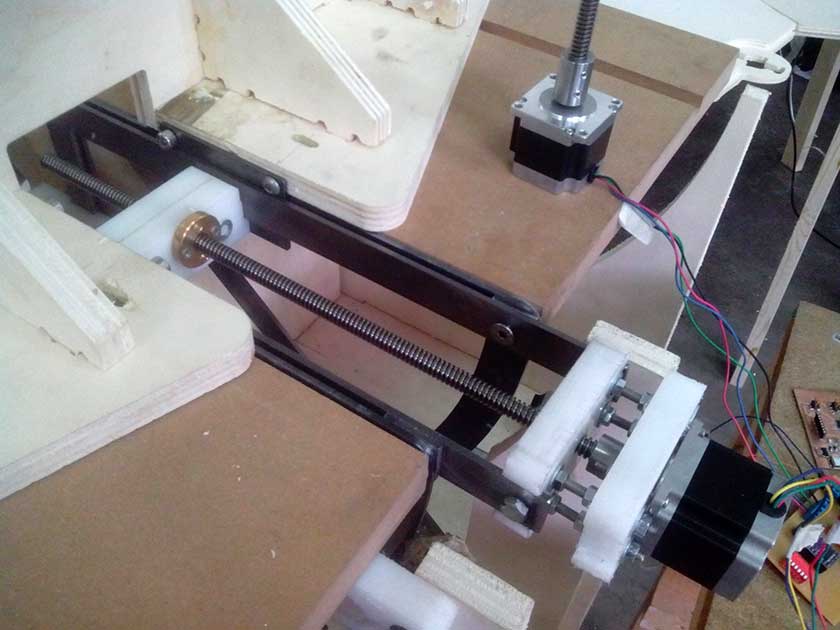

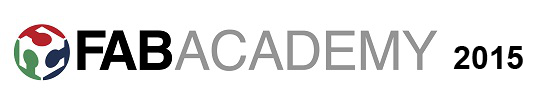

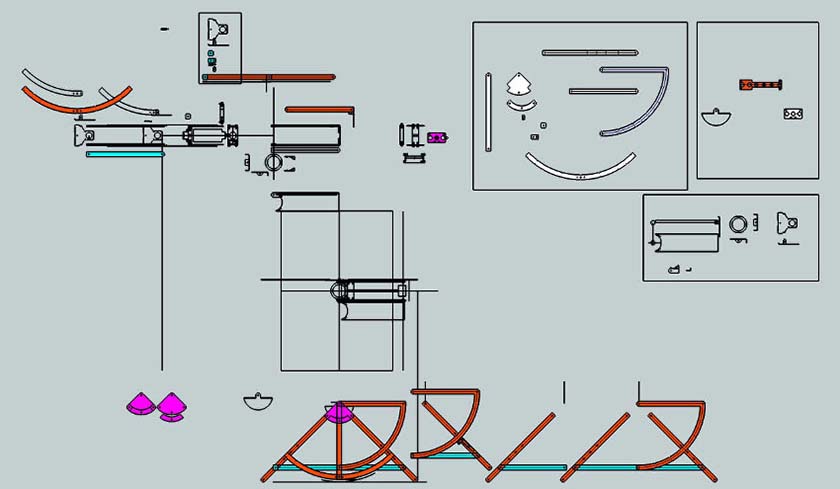

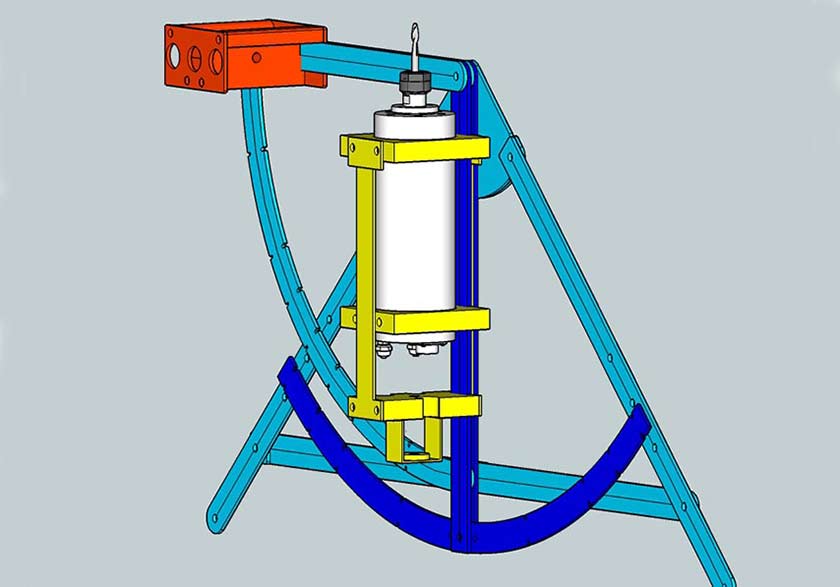

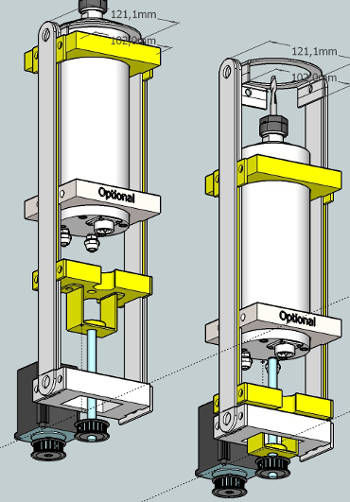

I started with some idea one of them was this first-photo: but my friend Marco Tonci inventor and designer had a better solutions, he drew with 2D CAD an innovative full metal structure for my router table, to better understand it I need a 3D sketch so I imported the 2D CAD in Sketchup. The pieces need to be cut by a metal laser cut sevice ... but I am thinking to mill them with my CNC in aluminium instead (or carbon fiber if not too expensive).This is the idea of the height movement: The idea is to have a "sandwitch" of a 4mm metal blade (yellow) sliding inside other 2 4mm metal blades, HDPE or Teflon "skates" will be used. In this picture I colored the part with four colors (third photo), the parts that rotete are in blue, yellow is for parts that move in Z axis and orange for the Fence support (X axis), Turquoise is structure parts that don't move.

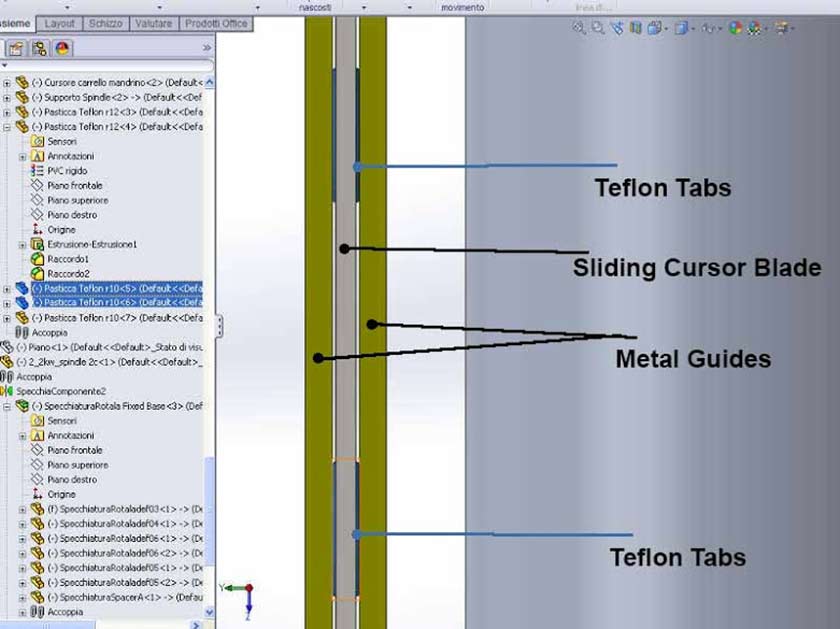

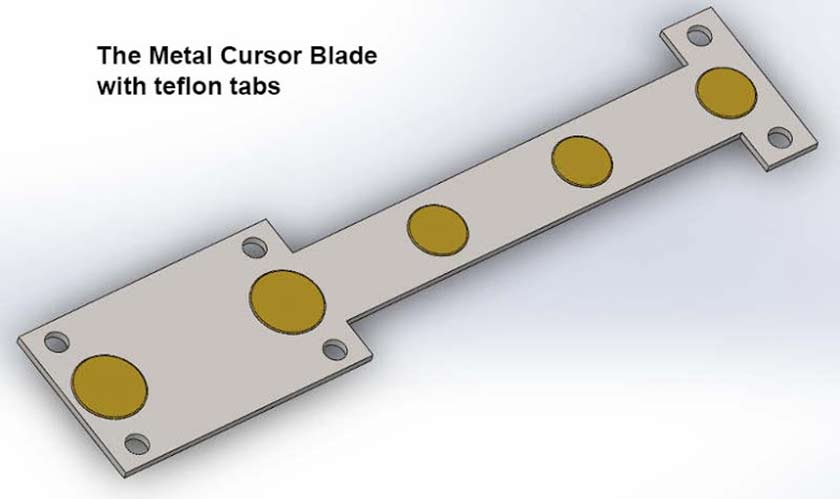

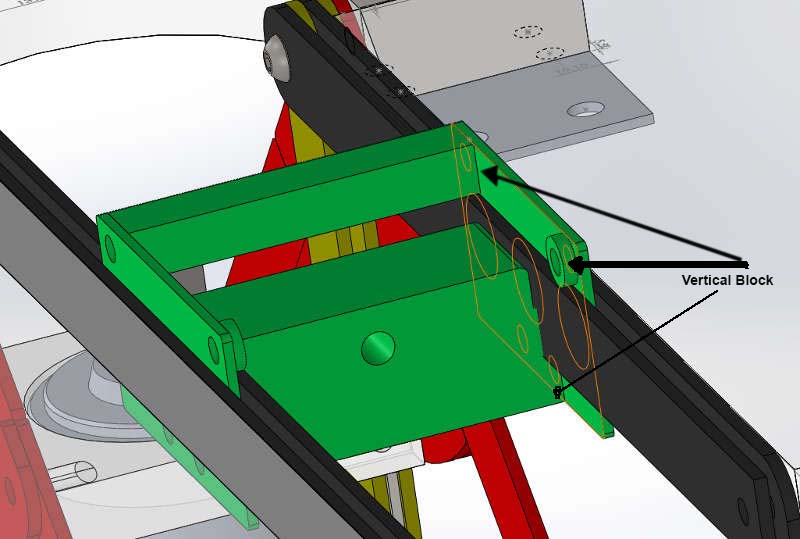

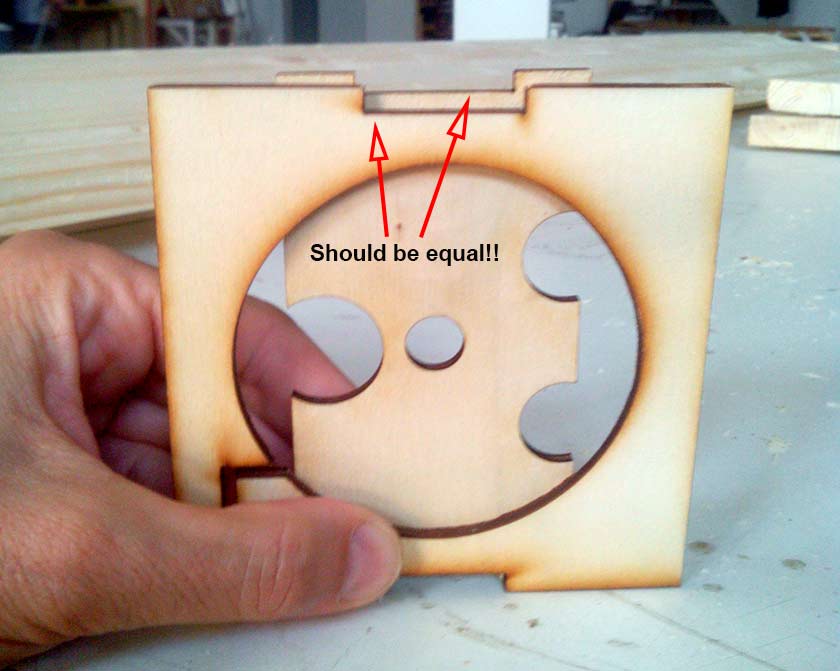

Designing in Solidworks it's becaming a pleasure. Here we see some features of the project. The basic idea is to use material frequently available. Some parts would benefits if laser cutted, metal laser cutting service is not difficult to find and generally economic. The idea of the sliding mechanism is to be economic without sacrificing precision. The system consist in two 4mm metal blades and a 3mm cursor wich slide in between, some 4mm teflon (or any other suitable material) tablets are inserted in the cursors to achieve a better sliding. Same for the Fence movement, the carriage slides between the metal blades, vertically is held in position by blocks, and laterraly by the blades with teflon tablets