Internet of things ? Well for me it's internet of people !

I will be 52 this year, so I think I made some experience in my small world ... My greatest Master is a person I never met, he lives in country I have never visited: South Africa, which is very far from mine (Italy), his name is Gerald Dorrington and he is a mechanical engineer, his company Mechlift is the largest manufacturer of bin lifters in Africa. He have run a 8'x4' ShopBot since 2000, when his son Sean started a CNC cutting service "Camcraft" in Cape Town. After 4-5 years the growing business of "Camcraft" needed some machine upgrades, and Gerald who already had modified his shopbot decided to start with his own project The Mechmate and built a forum with the plan and all the info to help building the "beast" (well now in SPqWork FabLab we call it "the Gentle Giant" :-). The Mechmate was a totally Open Source until Gerald quit the forum after 5 years of generous daily activity teaching with immense patience to many some of his huge knowledge. One of them it's me.

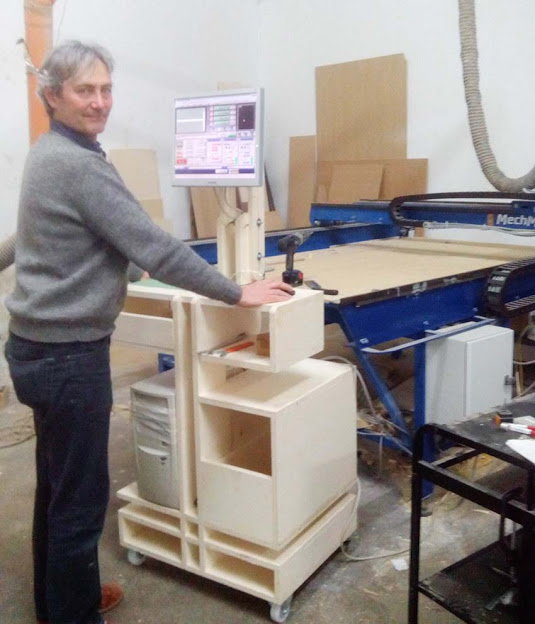

For this assignment I decided to build a PC stand for the CNC machine, the height is the primary factor, I need to have a correct standing position while I use the CNC machine, and the monitor should be easily positioned to a confort distance. It will be nice to have the possibility to move the whole thing in a rest position the closest to the machine. To design the desk I started a preliminary design in sketchup, wich I think it's very fast and easy if you still don't have an idea of what to do. When my idea was a bit more clear I choose to do the project in Solidworks. I am still a beginner but I like the way you can change things without starting again. Giacomo Falaschi anothe Fabacademy student from Fablab Cascina made his assignment with us he is more advanced than me in solidworks and his assignment work is totally parametric, he used the "functions" and changing one parameter ( for example the material width) all his project automatically adapt to the new dimension. WOW !!!. I need to learn this !!!.

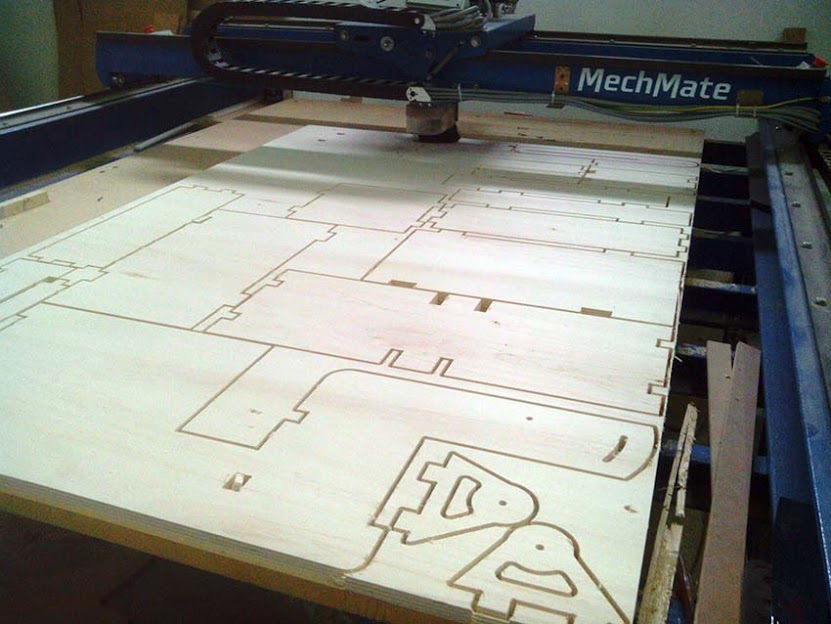

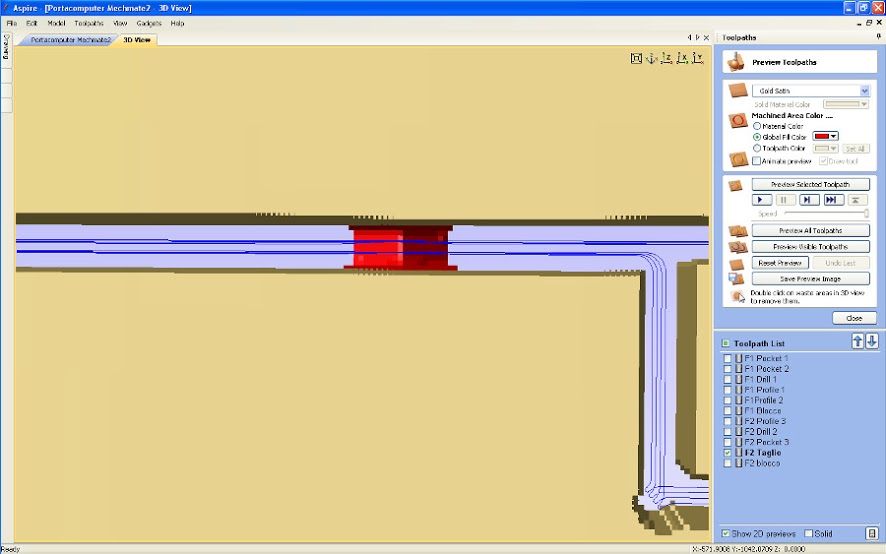

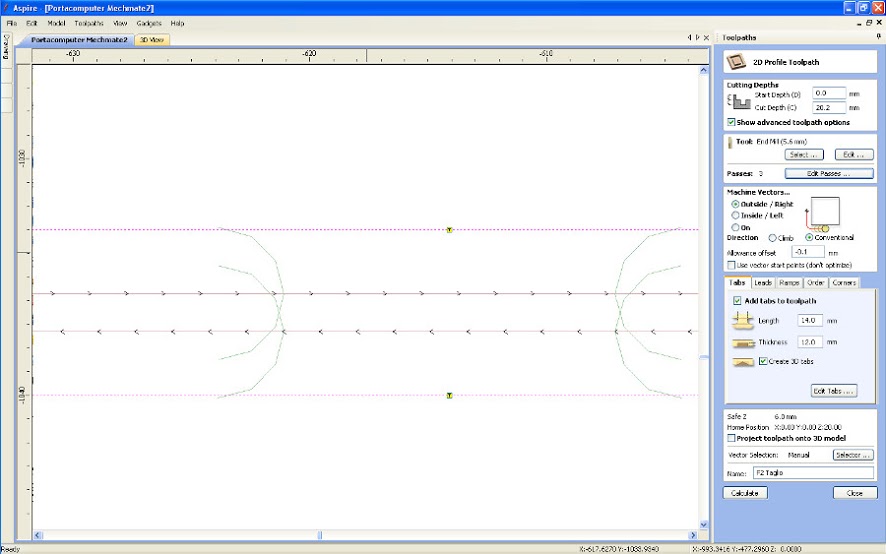

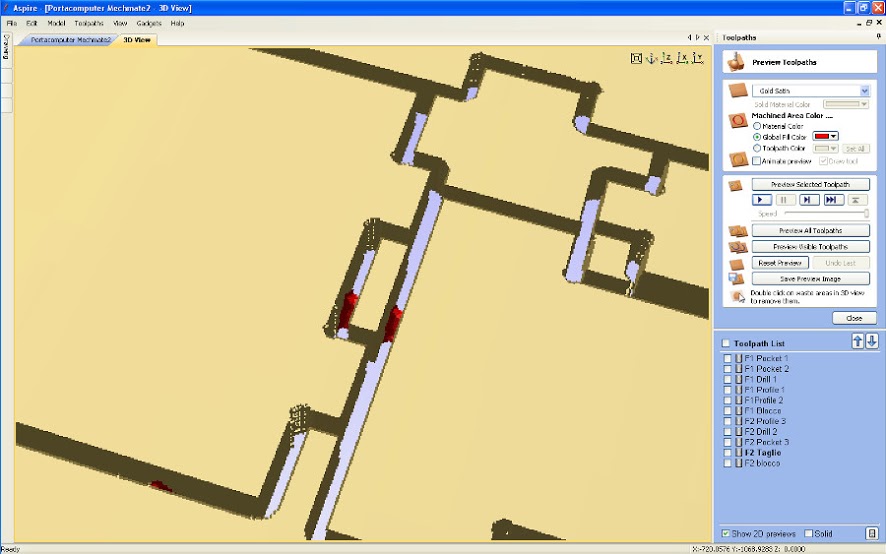

It took me 2 days to complete the design and then I exported all the parts in dxf format which is very well acepted by my Cam program: Vectric Vcarve Pro. Vcarve Pro (used also as Shopbor official CAM) is maybe the simples Cad-Cam I tested and is also versatile and powerfull, his cost is around 500€ and in four years of experience I did not find any better cost/feature performer. One of the greatest fetures is the possibility to exatly place tabs where you needs in a very easy way. As material I choosed an economic 20mm poplar plywood, cutted with a 6mm upcut 1 flute end mill tool with a speed of 3600mm/min and 7mm depht of cut ( generally depht of cut should be equal to mill diameter, softer materials allow deeper cuts ... spindle power is obviously a factor).

Here you can download the solidworks project's files:

Download Pc Desk

One flute upcut end mill are my favorites, the reasons why I prefer one flute over two or tree flutes are: they cost less, they have a better chipload, and generally are more strong. Understanding chipload is the key to better performance in terms of wear and speeds .... this is the Onsrud reference It is the best I ever found. Each mill as a feedrate and rotation speed range, if the feedrate is too slow and/or the rotation speed is too high the mill will rapidly deteriorate loosing his sharpness due to excessive heating ( good chip removal is essential because heat is transferred to chip); if feedrate is too high and/or rotation speed is too slow you won't remove enough chip and the mill will broke or the piece will be moved or the machine will loose steps depending who is the weakest. In my personal experience understanding my machine it's very important. I nedd to know which is the maximum load/speed combination until I start losing steps, and that is material dependant, I've worked flawlessly at 6000mm/min with depht of cut of 100mm !! with Extruded Polystyrene and at 3600mm/min ( 6-8mm end mill 1 flute) with European Beech and Oak but you have to test with your CNC machine (mine is a particulary strong).

A very important thing with CNC routers is the "fix" of your work piece. I use to screw the material onto a 30mm MDF sacrifical layer, to be shure I do not hit the srews I place some guide holes onto my nested CAD where I am shure it's not on the path of my mill, then I export it as a separate Gcode and I run the CNC (tipically 3mm depht it's ok) will all the axis zeroed, the small holes don't move the pieces as the forces are only on vertical Z axis, when all the guide holes are done I use a cordless screw driver to secure the piece (on some hardwood a complete pre-drill could help to avoid wood break). I think this is a very economical sistem and it takes litle time to do.

Other common fixing systems are :

Large Vacuum are the fastest, but at a very high energy cost: an effective large system needs motors in a 7.5-10 Kw/h range ...

Vacuum Pads are very effective on production jobs, particulary when your work needs the complete surfacing of the top. The pad can be shaped to best work with 3D bottom shaped parts ( ex: Surf Boards, Electric Guitars ....)

There is not a perfect solution I think some are very effective on some works but not good for others ... holding down/fixture is an art :-). I had some realy hard times finding a good solution !!,

Tabs Are my CNC best friend, I devoloped some tricks to help my work: the first one is the way I place tabs when I nest many parts toghether, Vectric Cam programs (Shopbot uses Vectric programs with a different name) allows manually placement of the tabs which in IMHO is essential. I place the tabs in front of each other when the clearance of pieces is less than the diameter of the mill , this will avoid that one of the pieces toolpath remove the tab of the adiacent piece.

Dust collecting is essential. There are ways that can help and are more efficent: separators. Separators avoid the clogging of the filter using a cyclonic system that drop most of the dust before going to the filter. There are two concept that can be used by DiYers: one is much easier to build but slightly less efficent is called Thien Separator and a more sophisticated Cyclone designed by Bill Pentz :Cyclone Plans.

... work in progress ... Cutting Tools