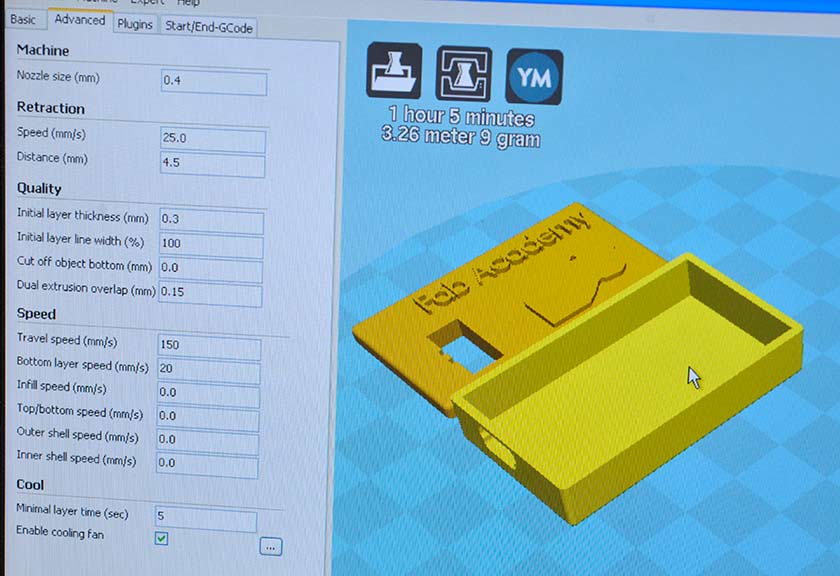

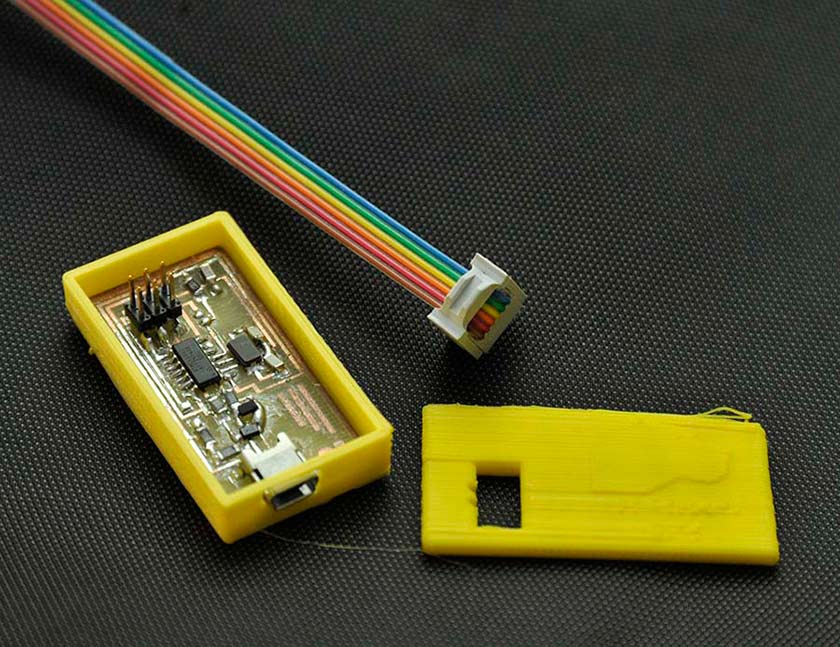

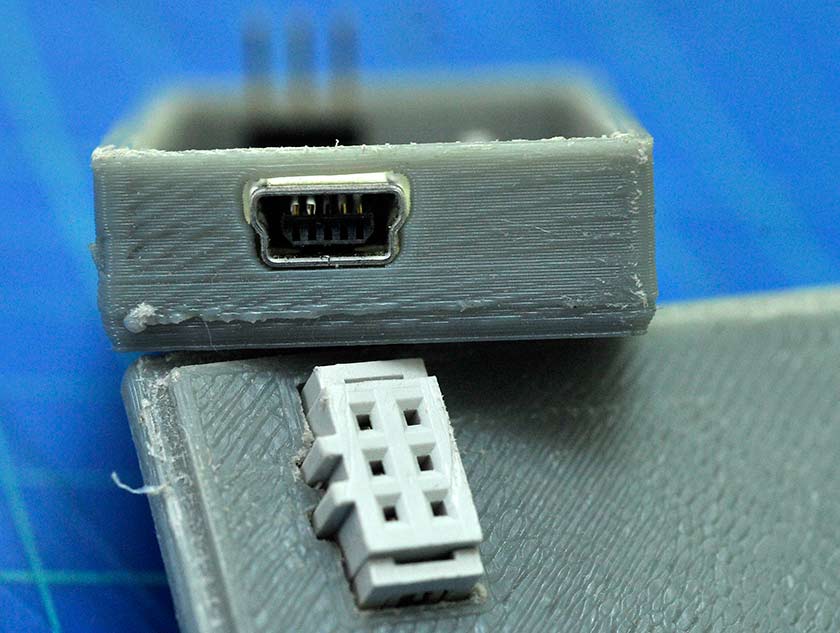

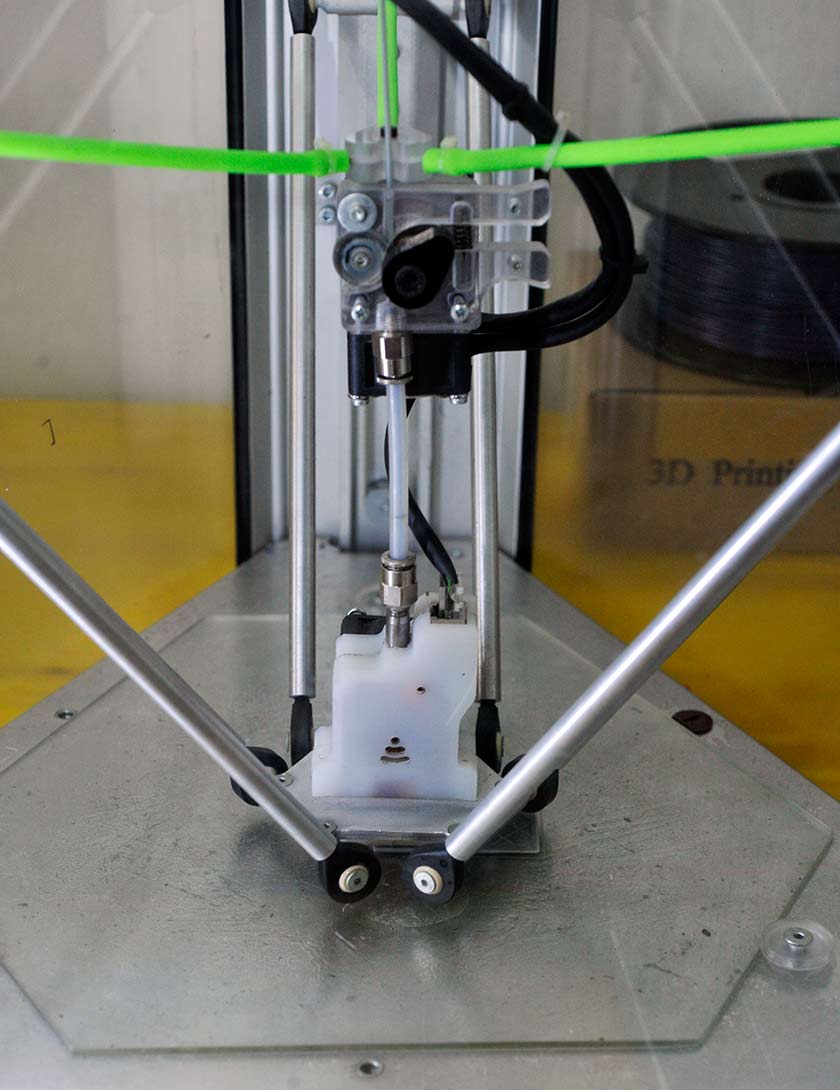

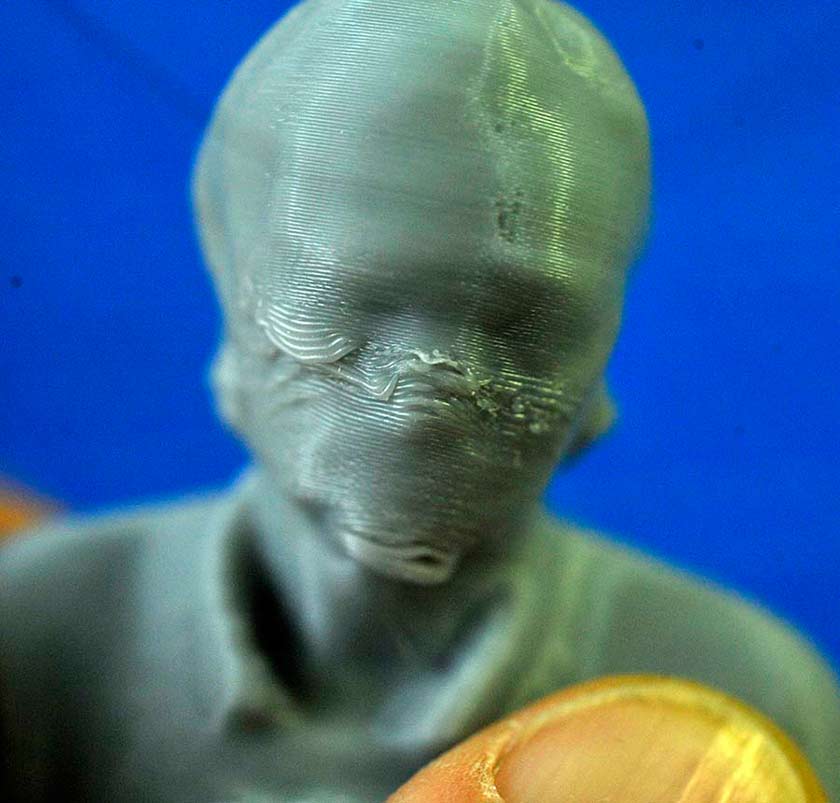

The Little Box During those days I made some progress with Solidworks, I love this program ! I wanted to test how precice is the 3D printing so I designed the box tight to my board, I also used the dxf of the board to see the placement of the mini USB conector and the Mole conector, I downloaded from the supplier site the 3D models of those conectors, and used them to have a precise idea of the dimensions. The parametric nature of Solidworks once you have a minimum of familiarity is fantastic, I was able to change some wrong dimensions in a flash. I exported the box in .stl and opened in Cura. The first try with a prusa i3 was an insuccess, I did not heat the base and the box detached from the base. The second try was not perfect but succeed (yellow box in pictures), the box was a bit larger so was the USB hole, the logo on the top quite cancelled ( I decided to scale it up a bit then ). The third try was made on a Wasp Delta printer. The result was nearly perfet ( just a little smaller that designed ) the final box ( gray ), the conector and mini usb perfecly fit ! 3D Scanning The first test was with Kinect and Scanekt

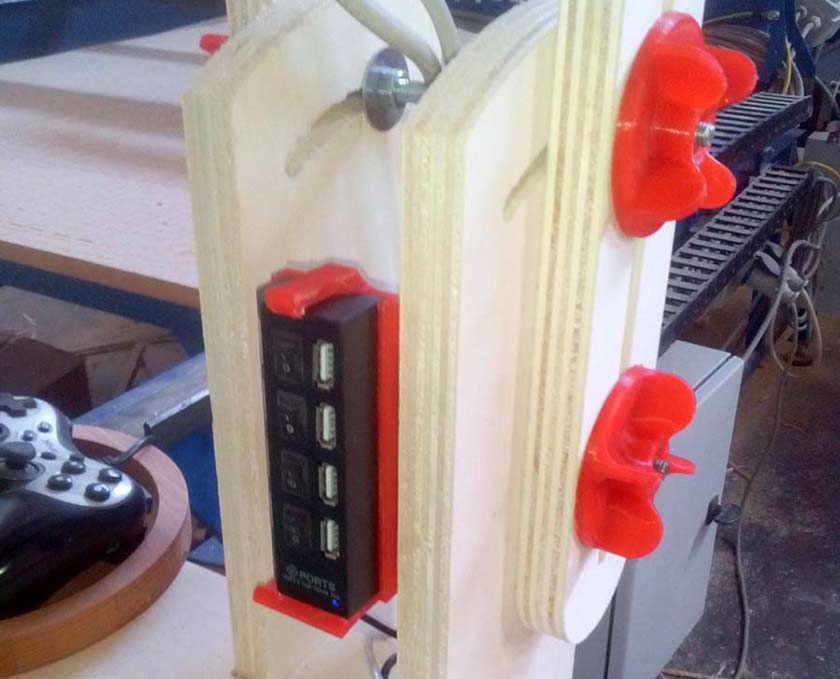

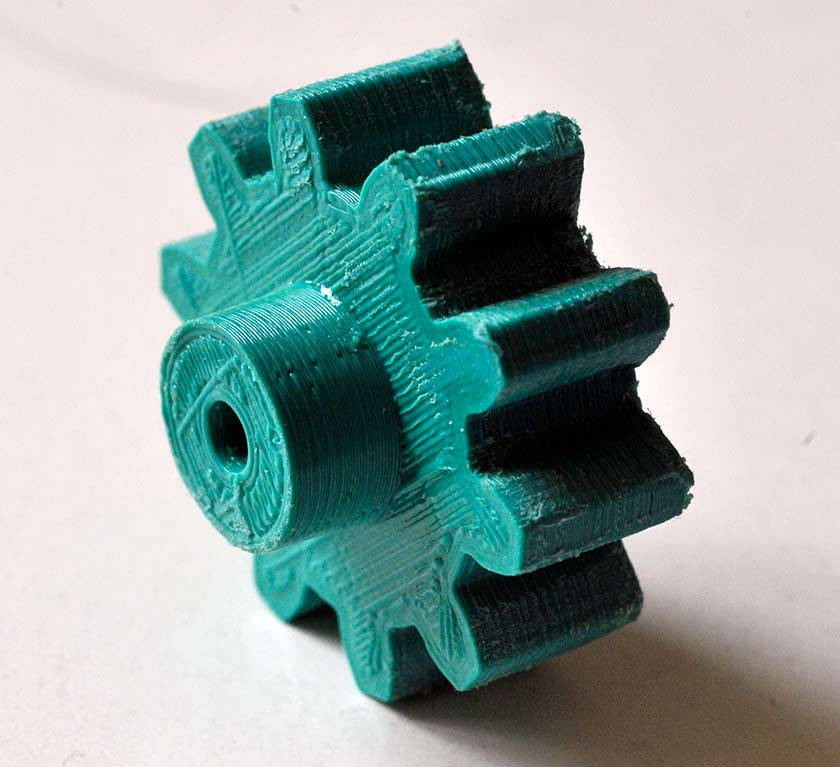

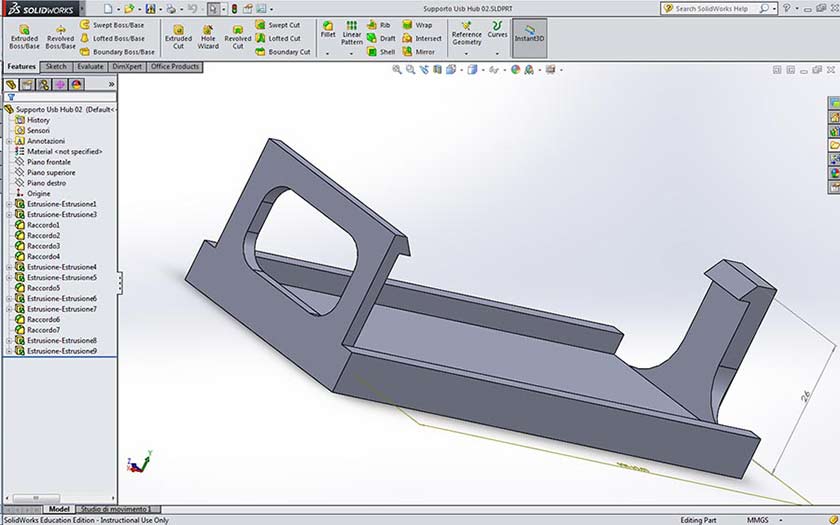

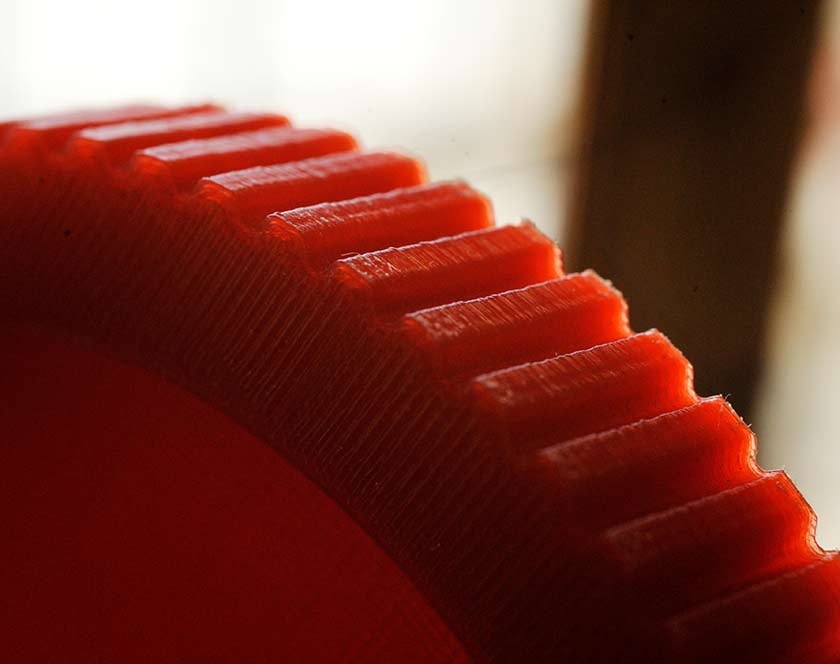

18 March Updates The "make something big" assignment needed some parts that are perfecly suited for 3D printing like the threaded knob to block the position of the monitor, I used the knobs also as a model for Moldig. I also needed a support for the USB hub that should be located in a comfortable position, I designed with Solidwork a support that as some spring tensioner that allow an easy remove of the hub.