THE FAB DISPENSER

Concept:

The idea of this project about smart packaging and creating a circular system of reusable capsules and distributors for dry foods.

Tecniques:

3D PRINTING

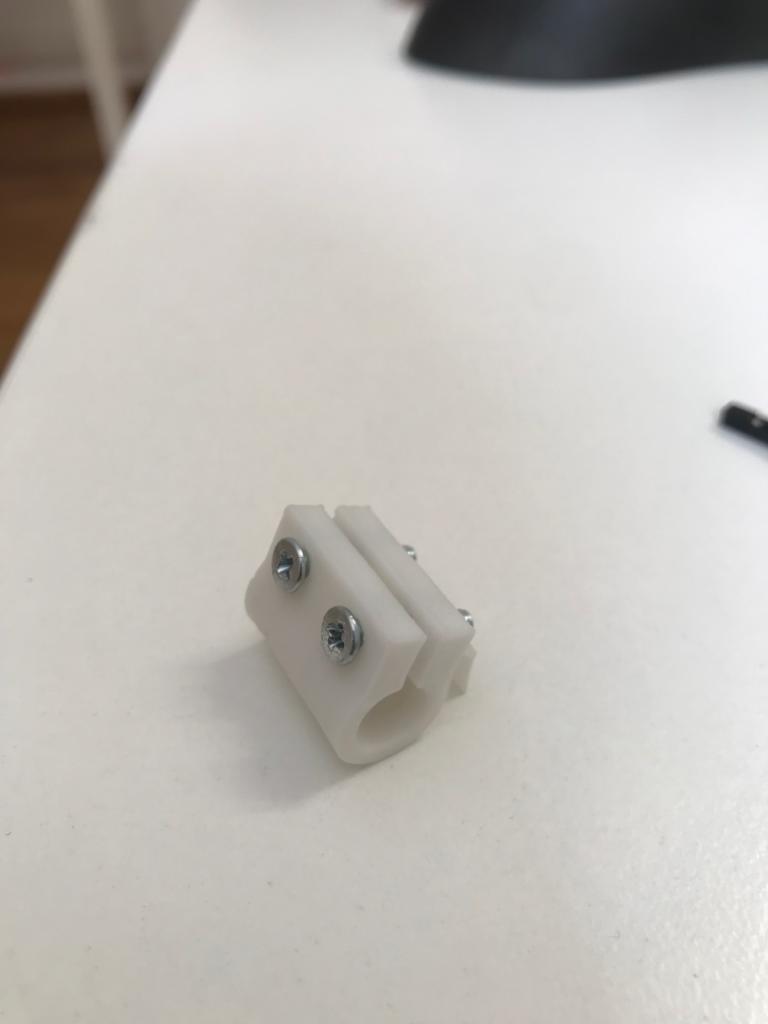

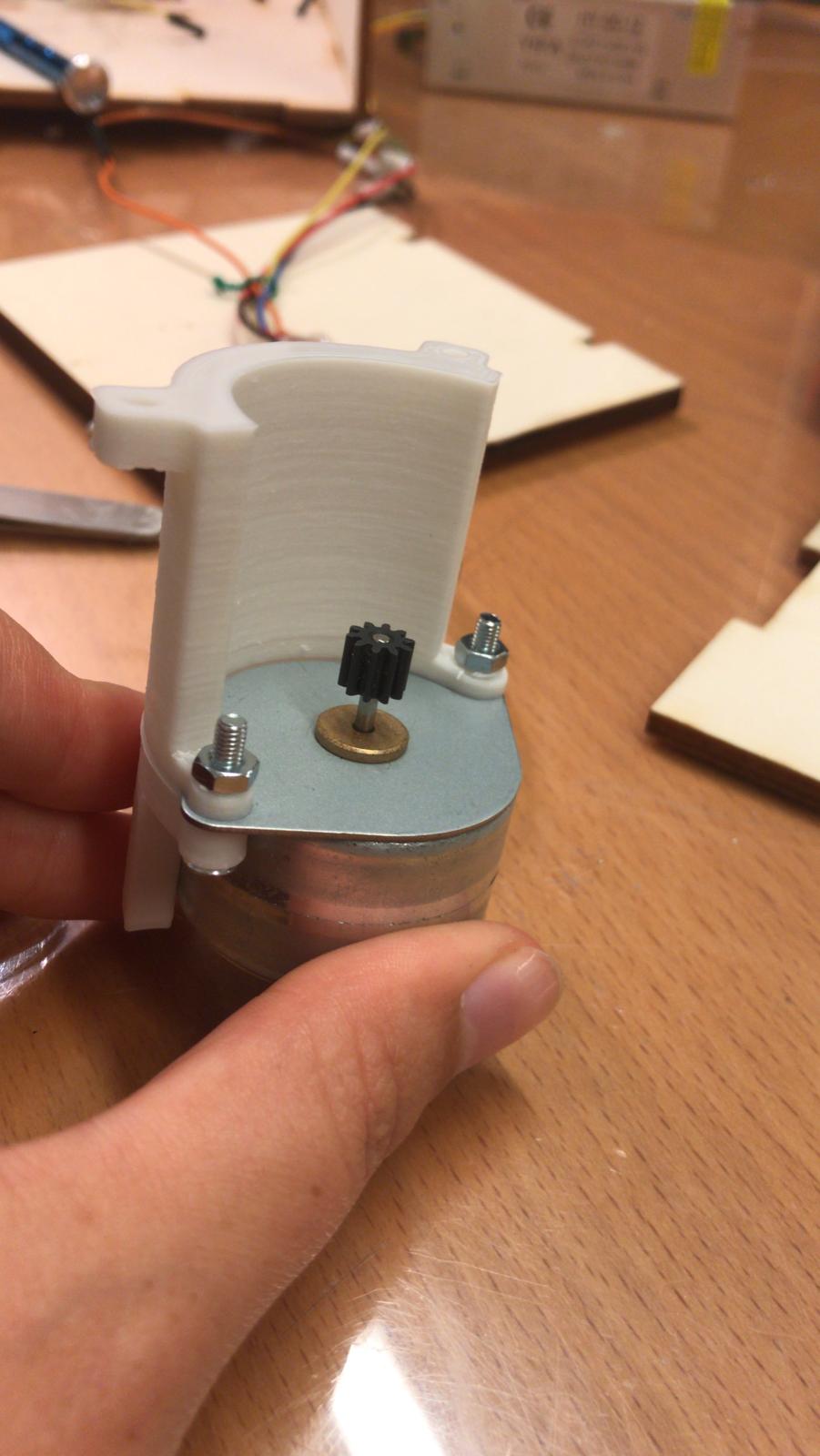

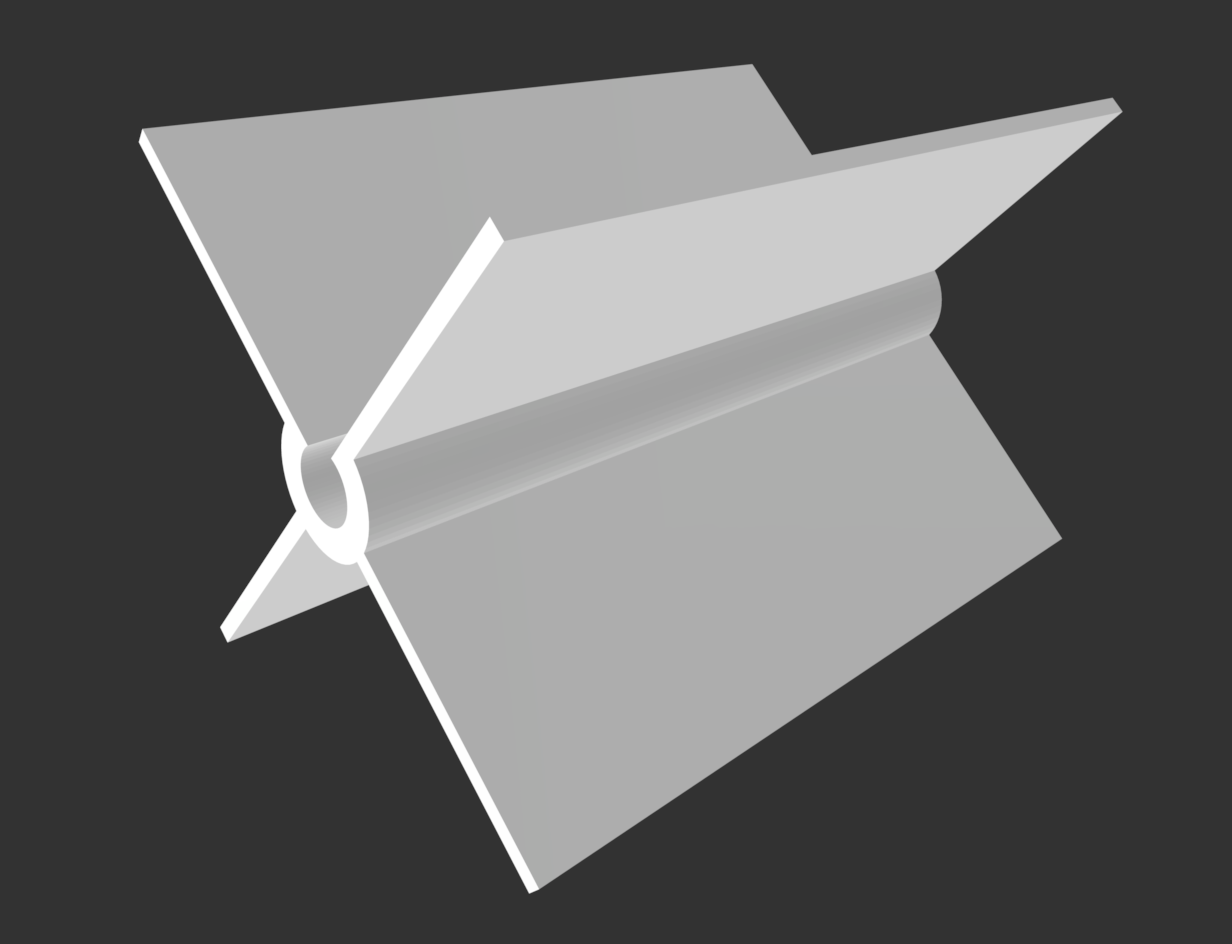

I printed the helix, the motor support system, the tightening part of the dispenser and the support between the motor and the iron bar and:

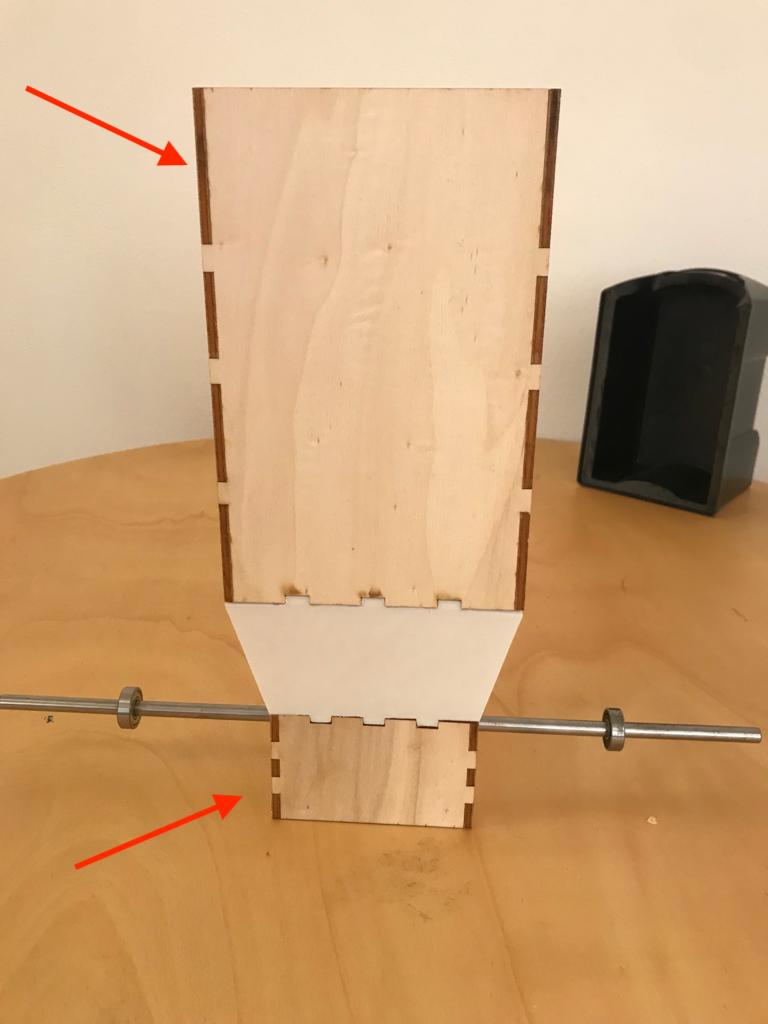

LASER CUT

I laser cut the external cabinet, part of the dispenser and the weight scale box:

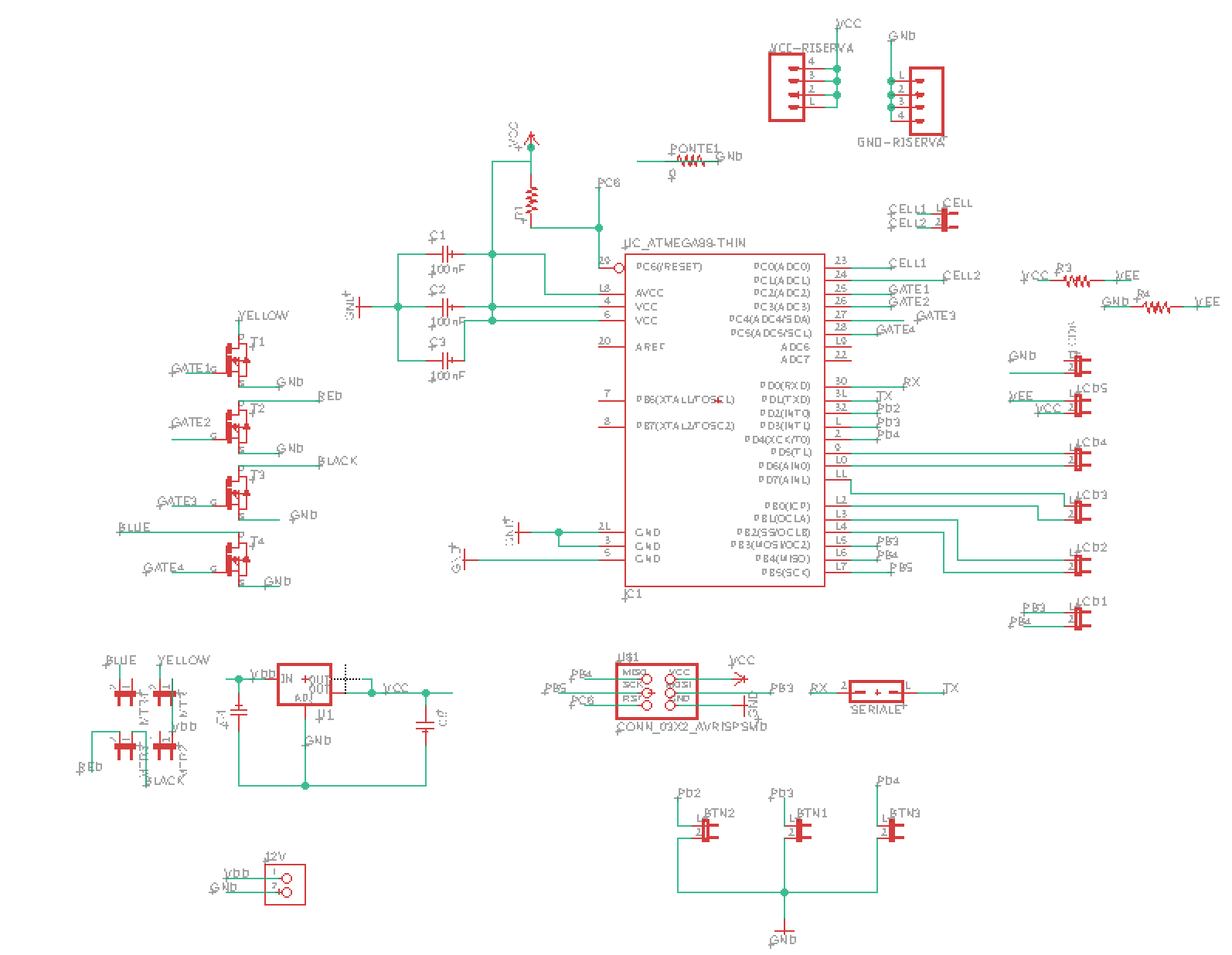

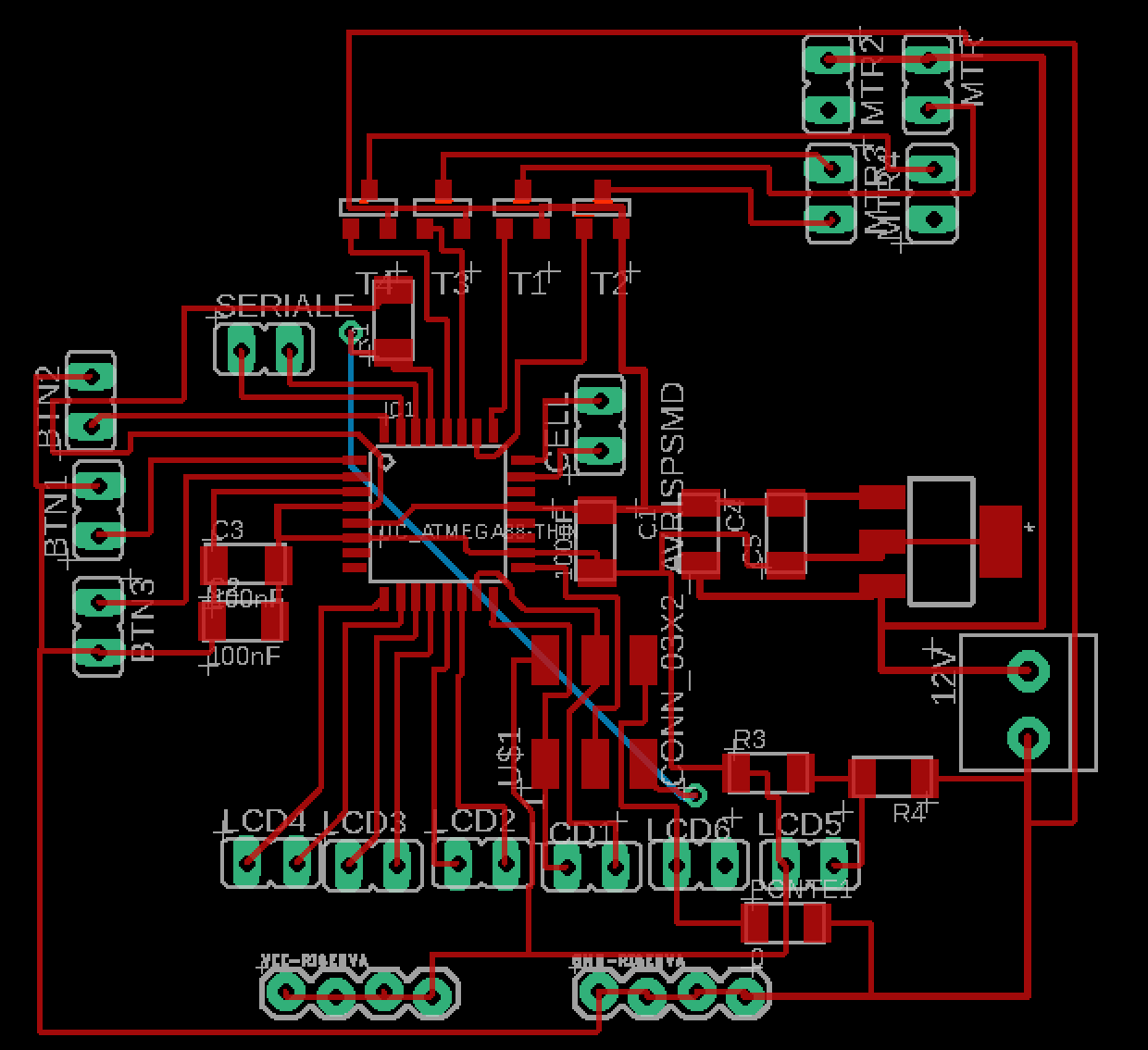

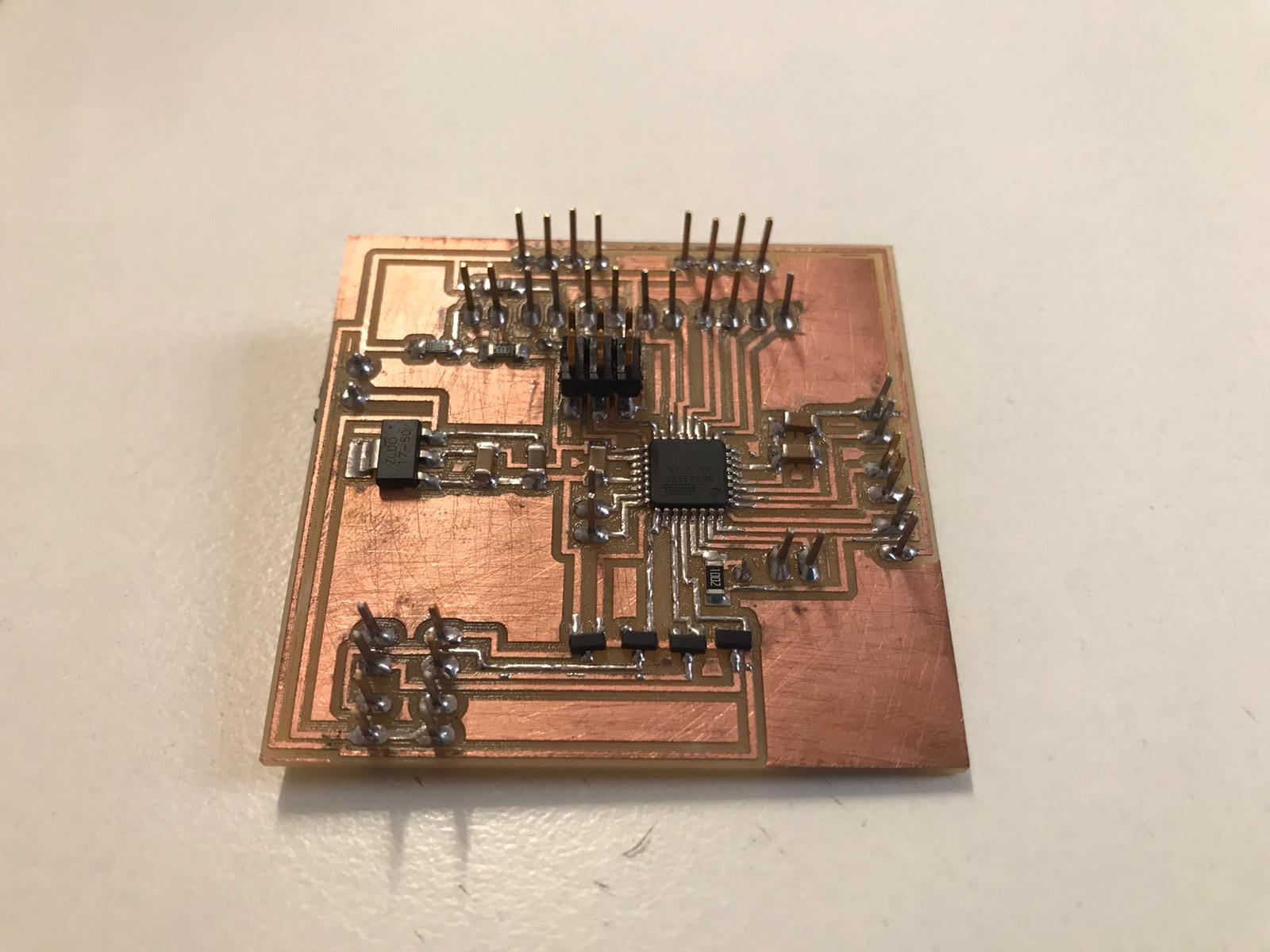

ELECTRONICS PRODUCTION

These are the files: schematic, board.

The code I used:

And this is THE FAB DISPENSER!

THE FAB DISPENSER REVIEW

These are my considerations in hindsight about the Fab Dispenser:

1) the stepper was perhaps not the best choice because as as soon as something got stuck between the helix's blades and the structure the motor

didn't have enough torque to proceed. Therefore, maybe the use of the DC motor with reductions that we have in the lab and that I used for the machine week would have been more suitable;

2) the placing of the load cell and the LCD and all their connections should perhaps be rethought, because putting everything on the bottom of the structure (precisely in the small box) turned out to be a nightmare.

3) for the redesign process I would definetely cut the structure out of an OSB board with the shopbot so that it is

more solid and stable and easier to assemble.