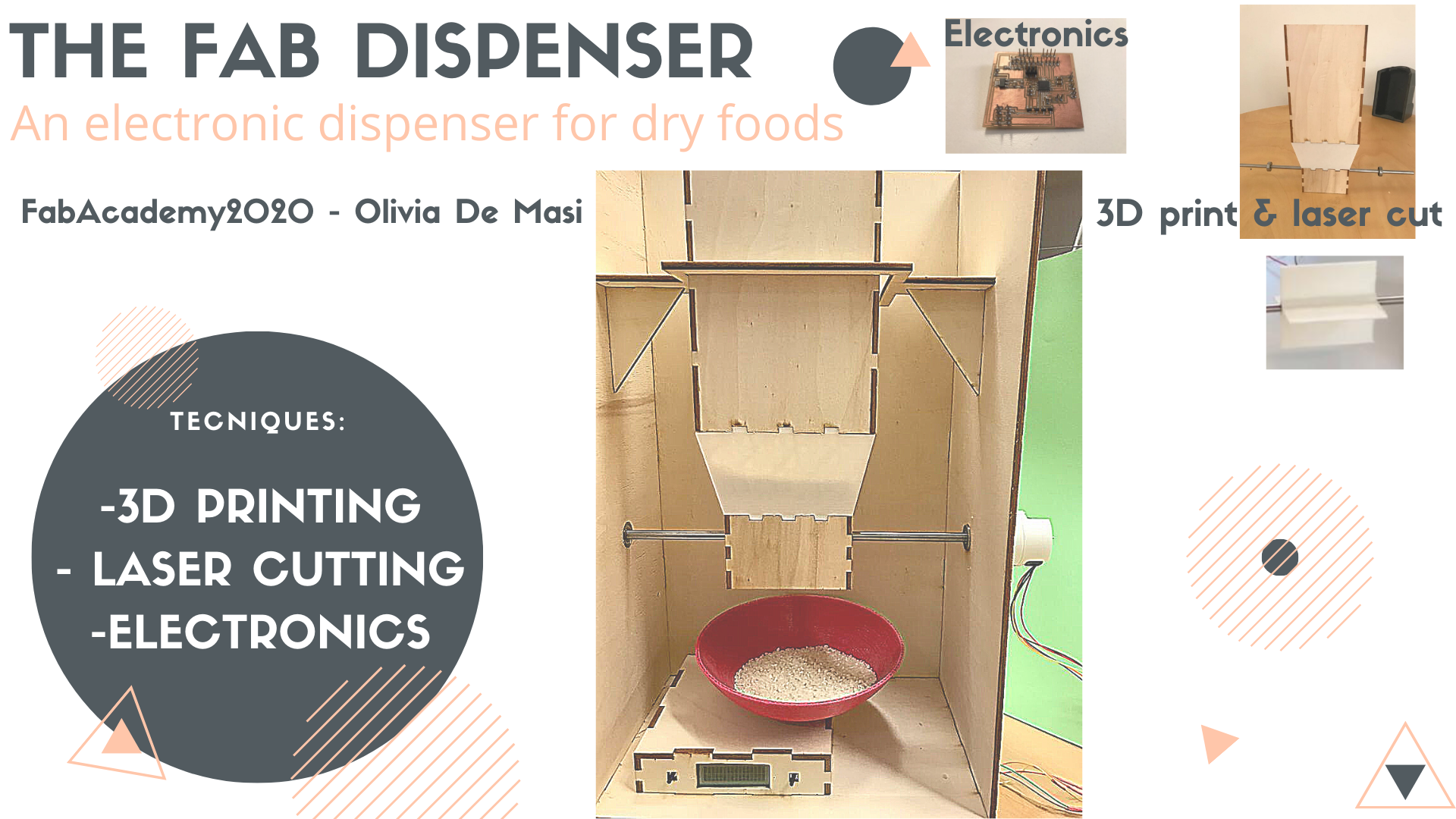

Concept: the idea of this project about smart packaging and creating a circular system of reusable capsules and distributors for dry foods.

Cad modelling and assembling: I'll have to 3D model the distributors and the reusable cups and find the right material to print/mold/cut them.

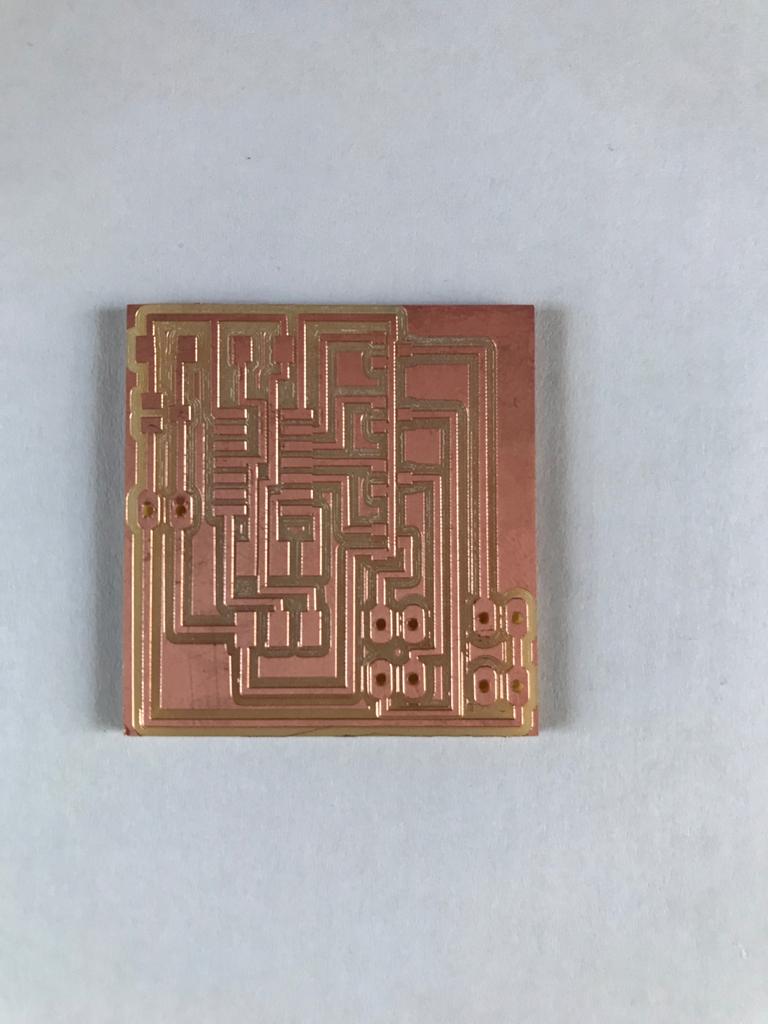

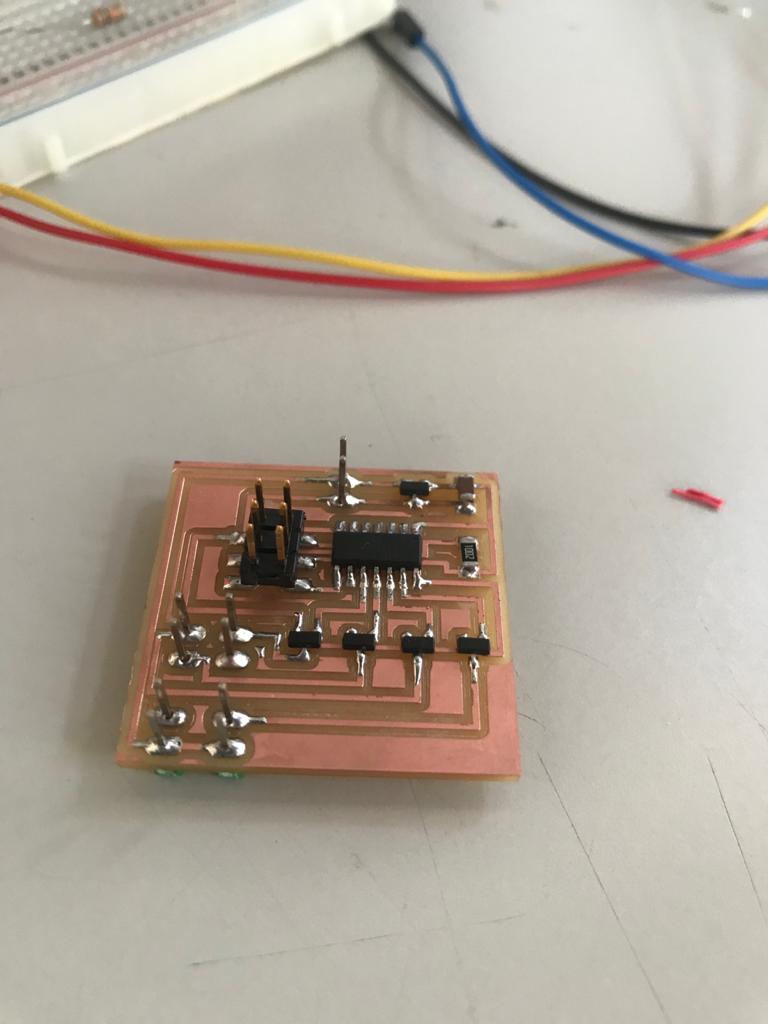

Electronics: I'm going to mill and program boards for the tracking of the cups and for the mechanical part of the distributors (opening and closing when the cup is underneath it).

Benchmark: The inspiration for this project came from a brilliant Chech company called MIWA (MInimum WAste):

http://www.miwa.eu/

3D MODELLING

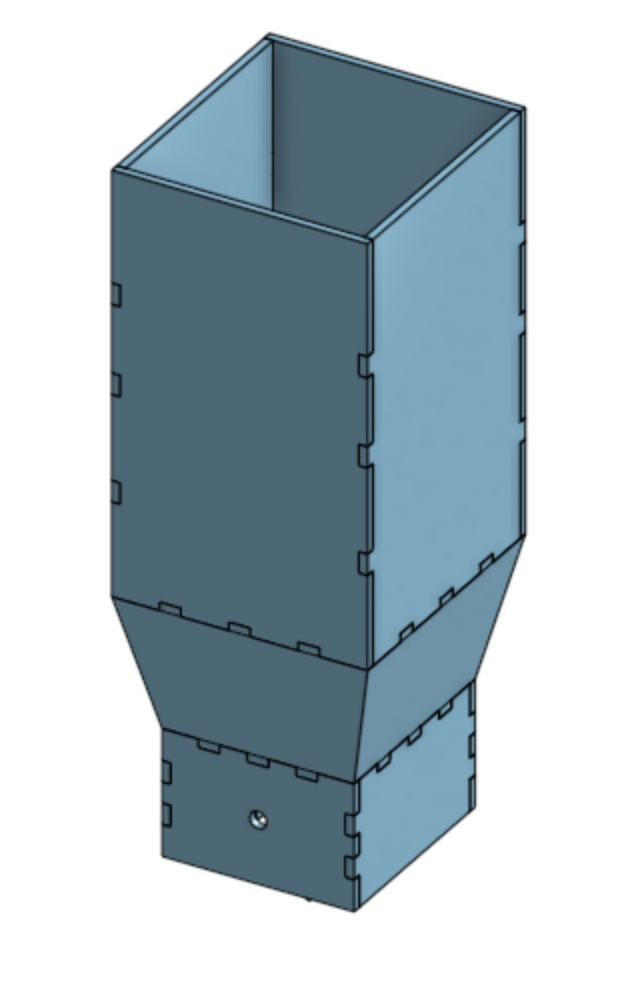

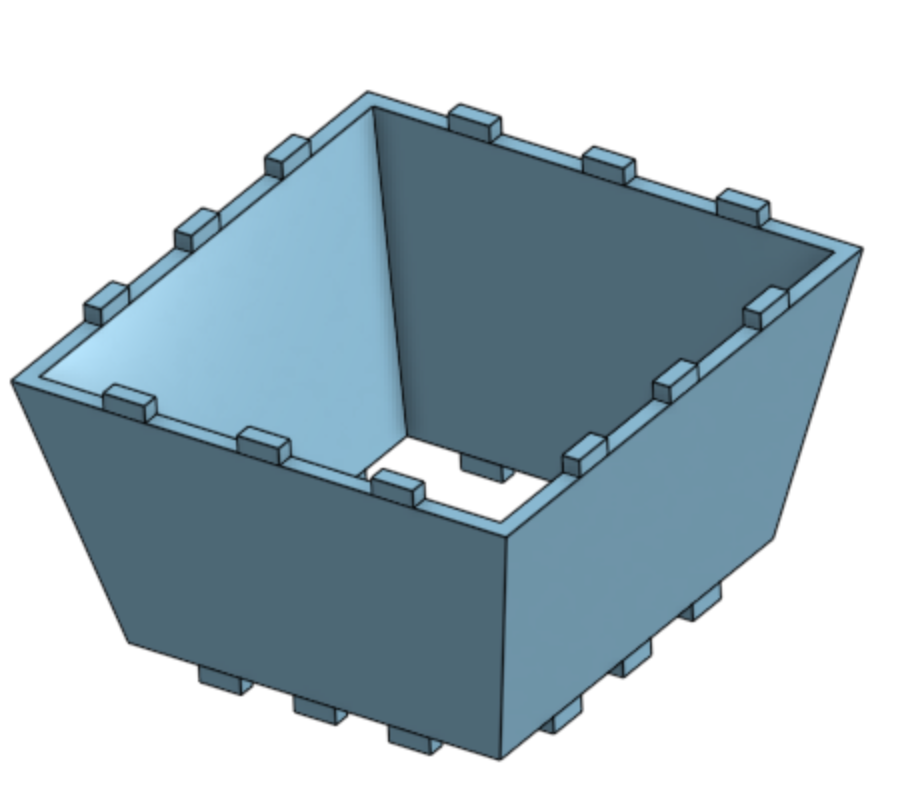

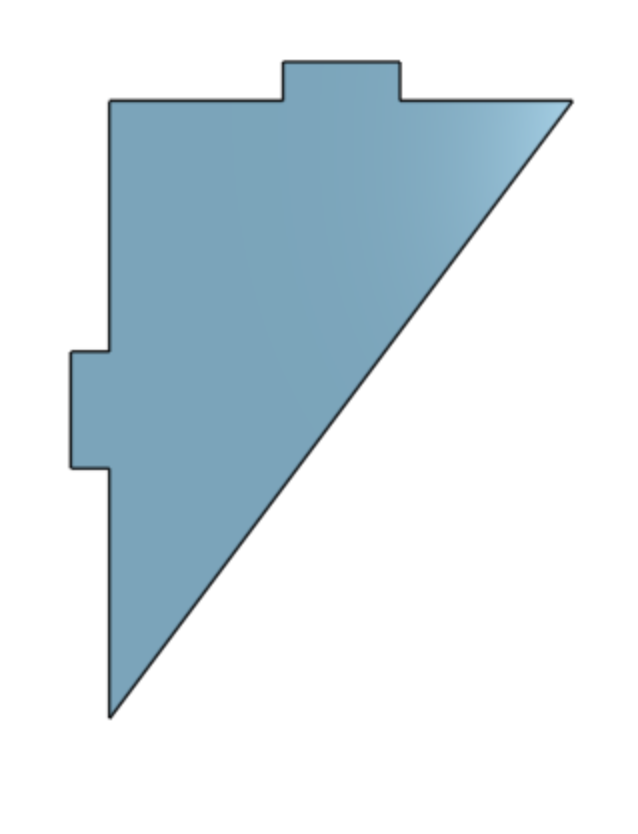

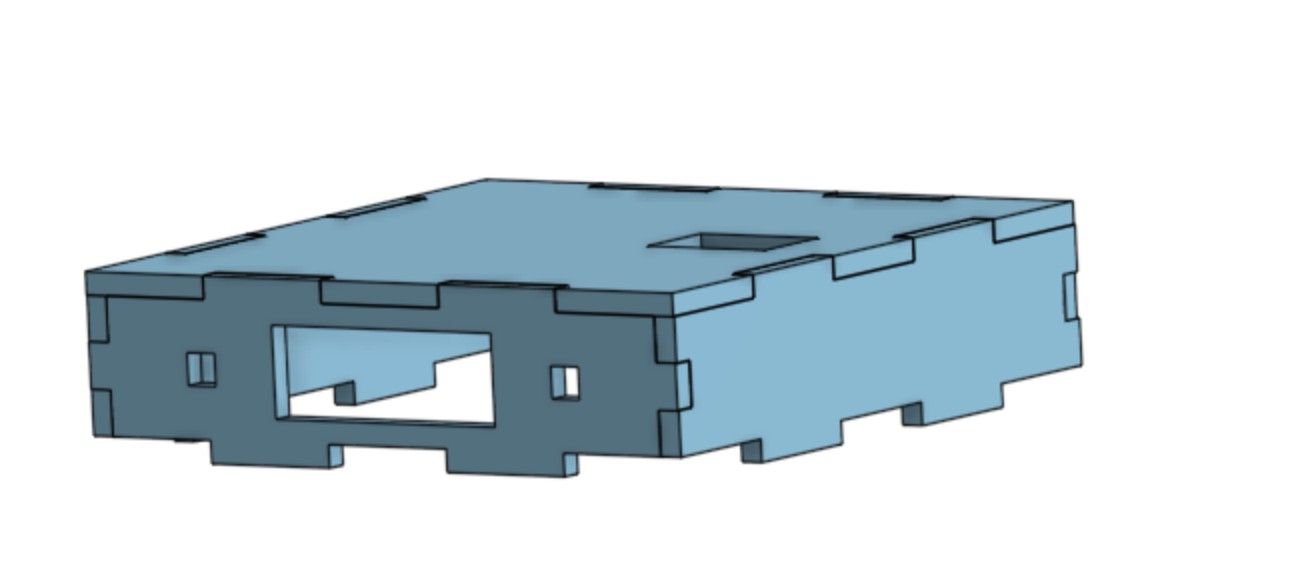

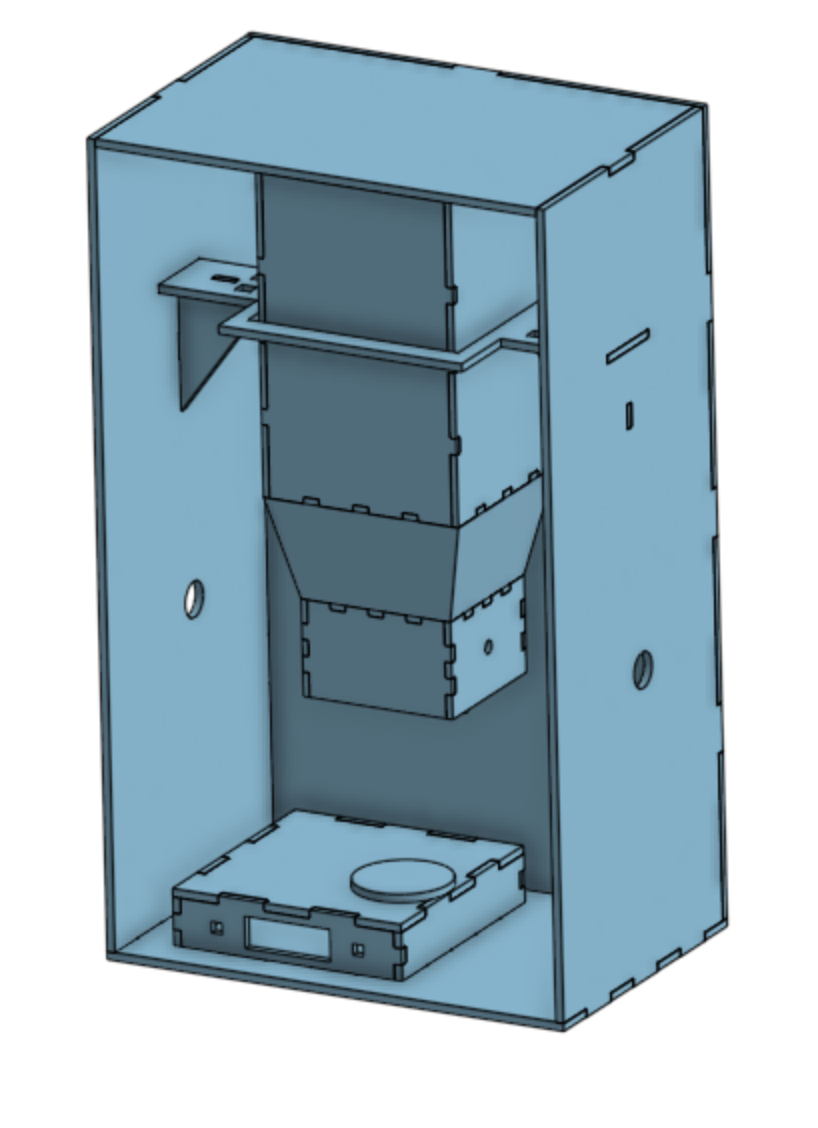

I started modelling the dispenser of food as I new I had to have an idea of the dimesion I wanted to give the whole cabinet, so the project it self. I had to figure

out how to create the funnel to narrow the dispenser. I decided that the best way was to laser cut wood for the top and the bottom parts and to 3D print the funnel.

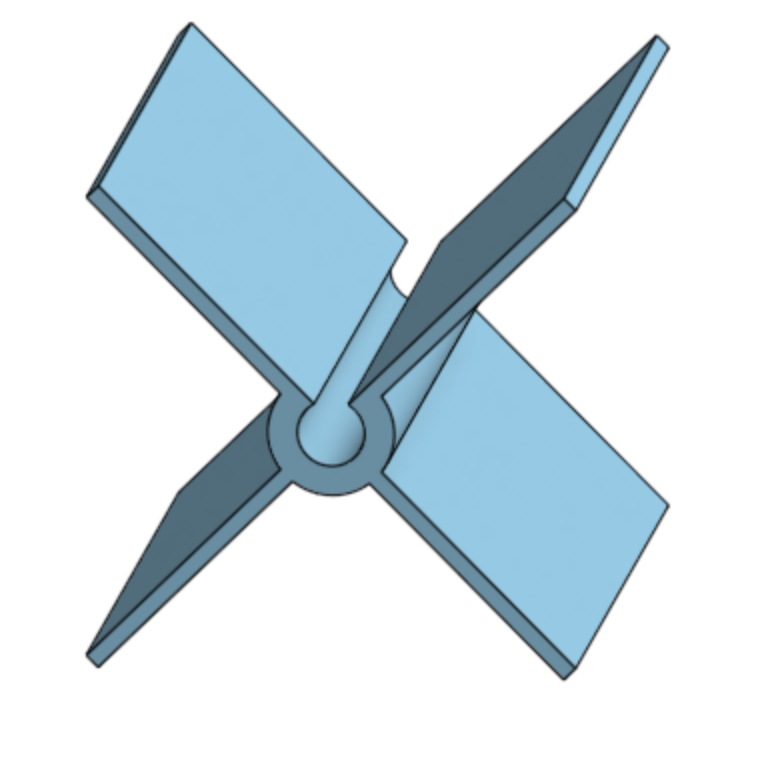

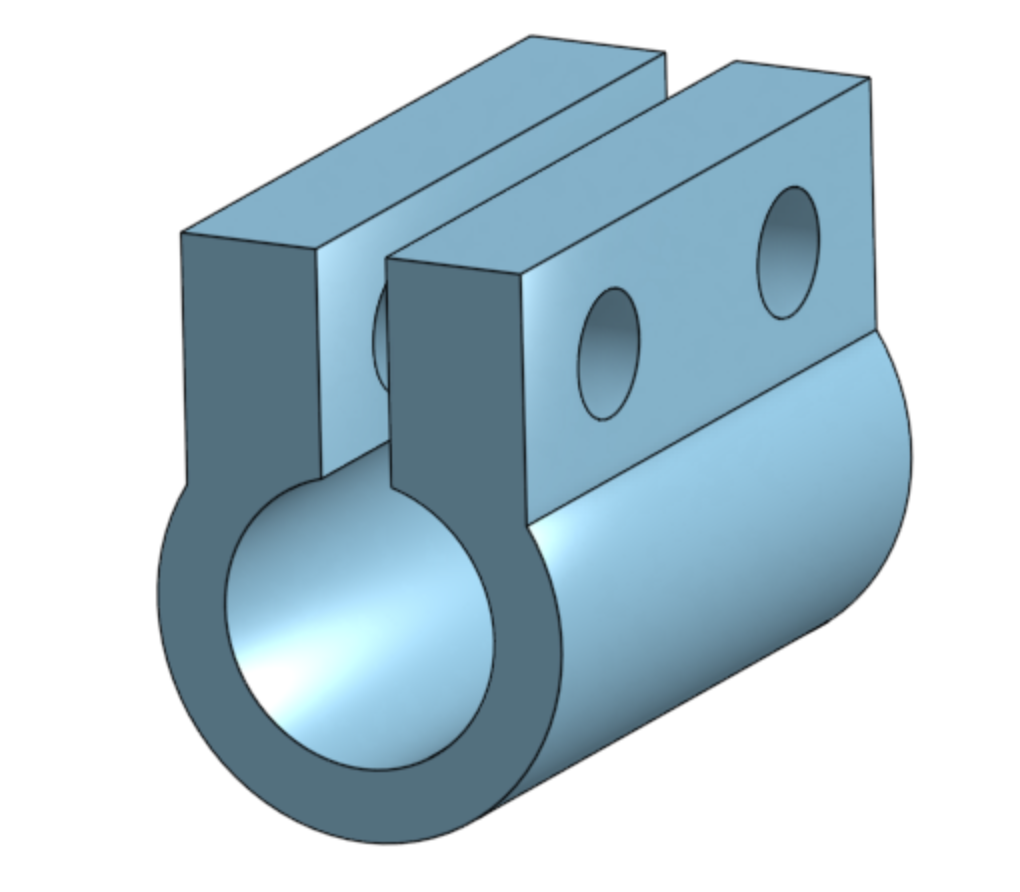

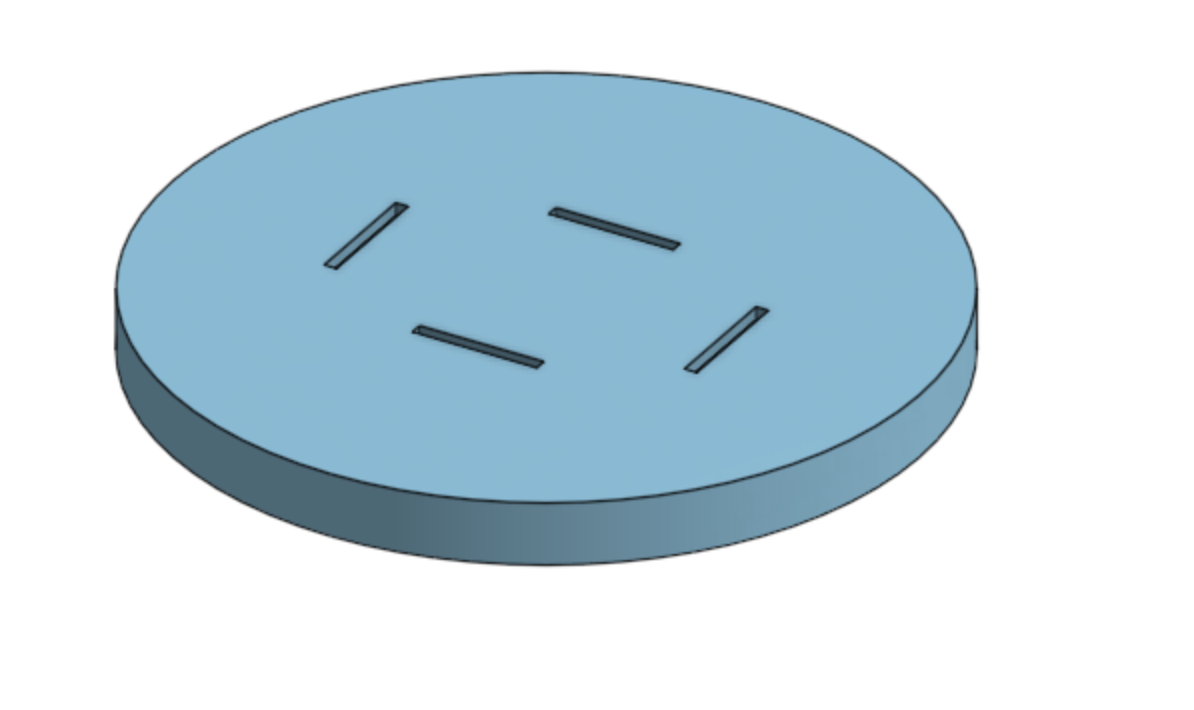

I then designed the helix that was going to make the food fall down, and I decide to leave the middle hole (in which the iron bar connected to the stepper motor had to be) open to gain more flexibility.

I then designed a gasket to link the stepper motor to the iron bar and the helix. As I did for the helix I left the hole in the middle open and I added two holes for two screws to tighten

the gasket around the motor and the bar.

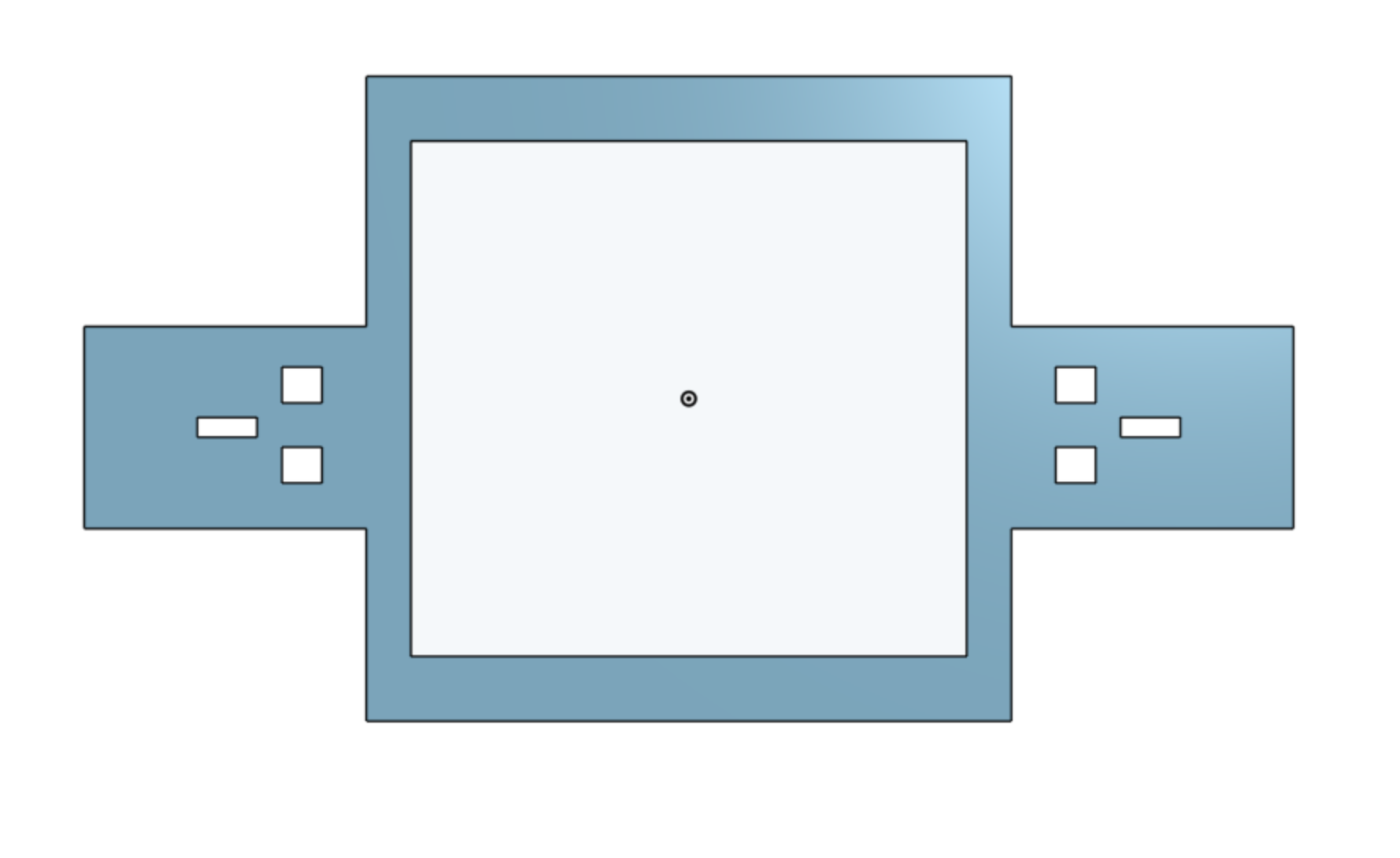

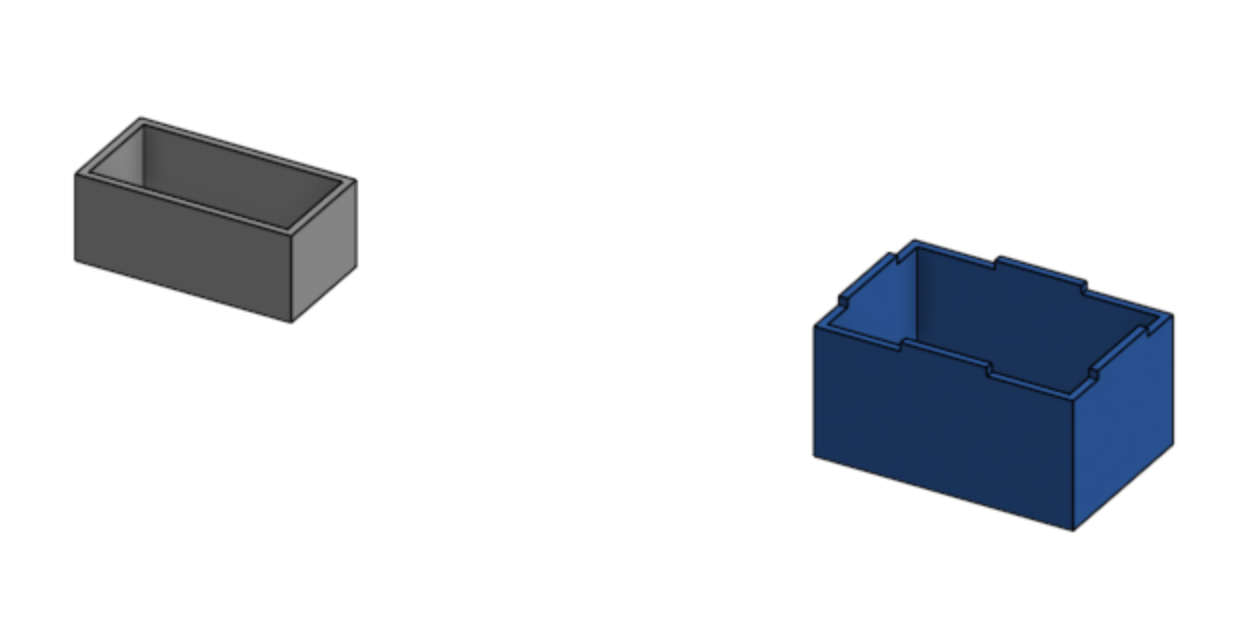

I designed the external cabinet as a rectangular box, but I had to figure out how to make the dispenser hang from it. So this is the support I designed, and next to it are the wooden brackets that I used to

hold it firmly to the carbinet's side:

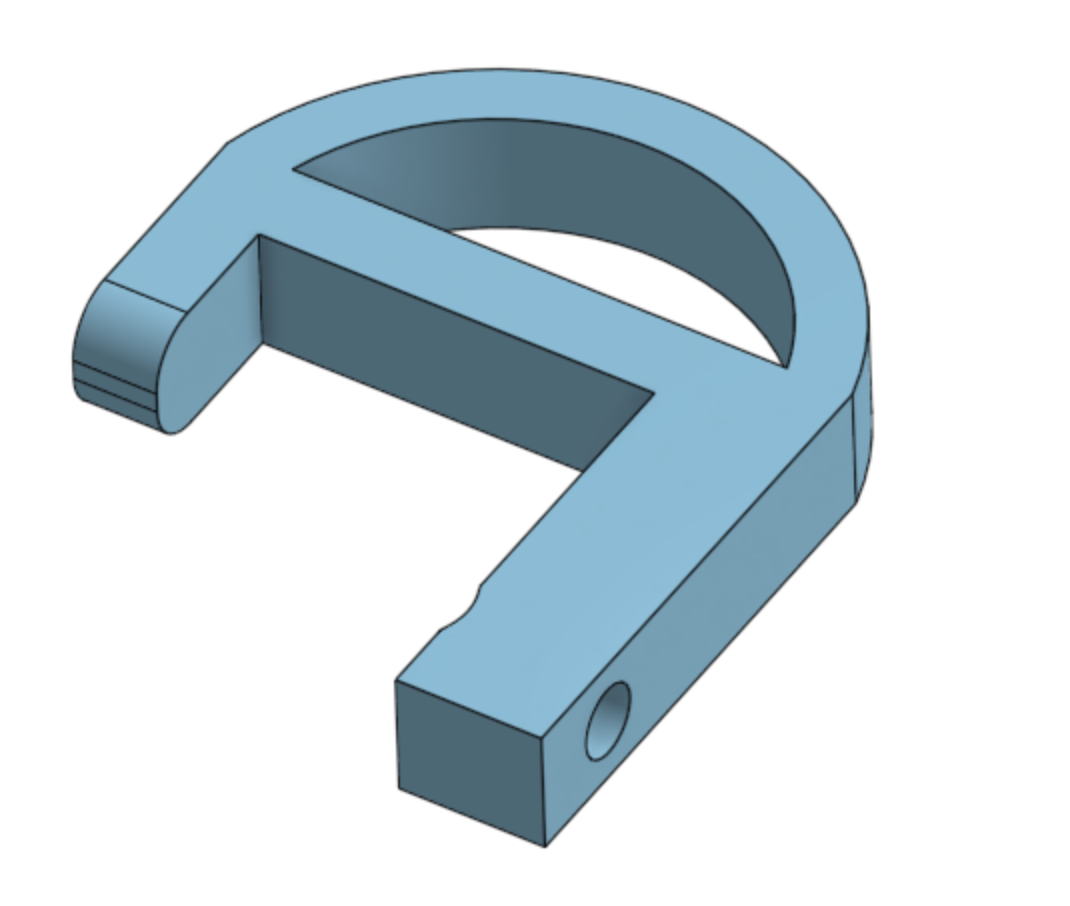

And the of course I put 4 3D printed hooks that uses gravity to make the hole thing more solid:

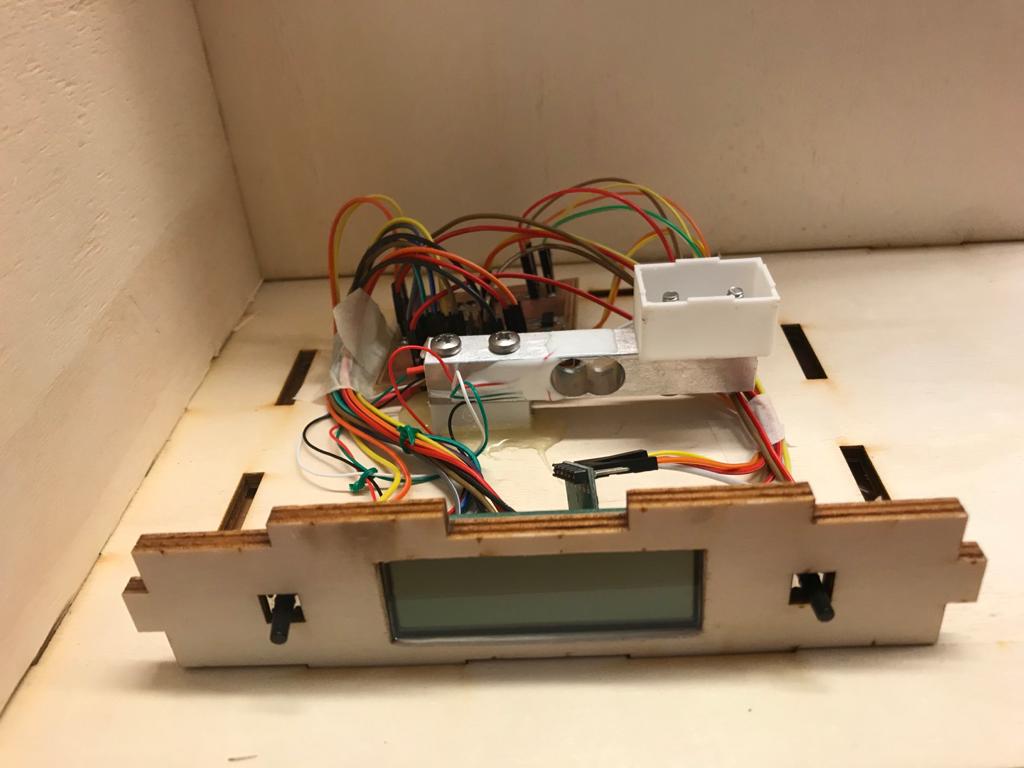

I then made a smaller box which was made to contain the loading cell, the LCD and the buttons.

ELECTRONICS

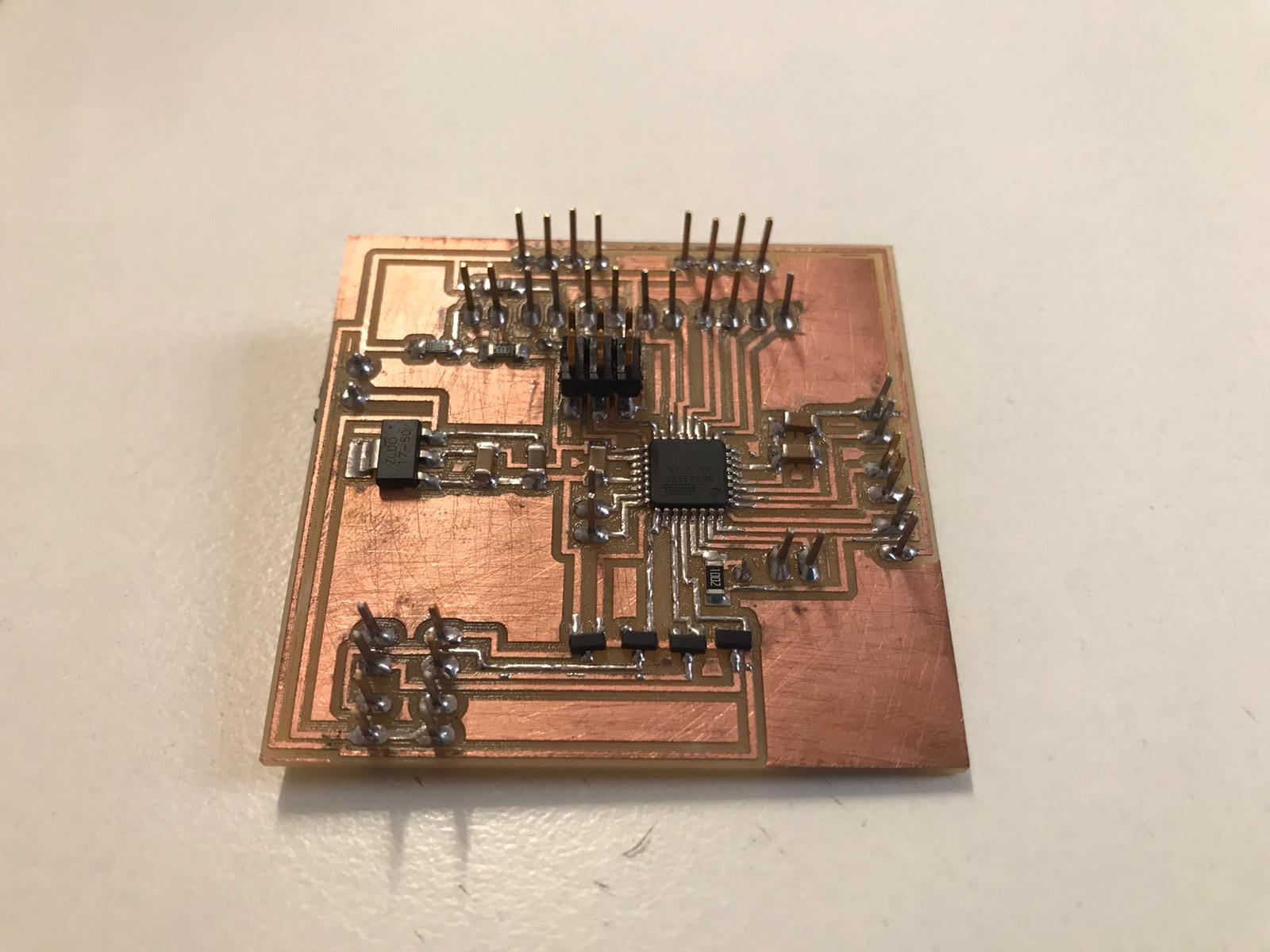

For the elctronic part I started from the stepper motor as I didn't use it before. I made a PCB looking at the fab schedule.

I then wrote a code to make the stepper start and it worked:

IMG_3355 from Olivia De Masi on Vimeo.

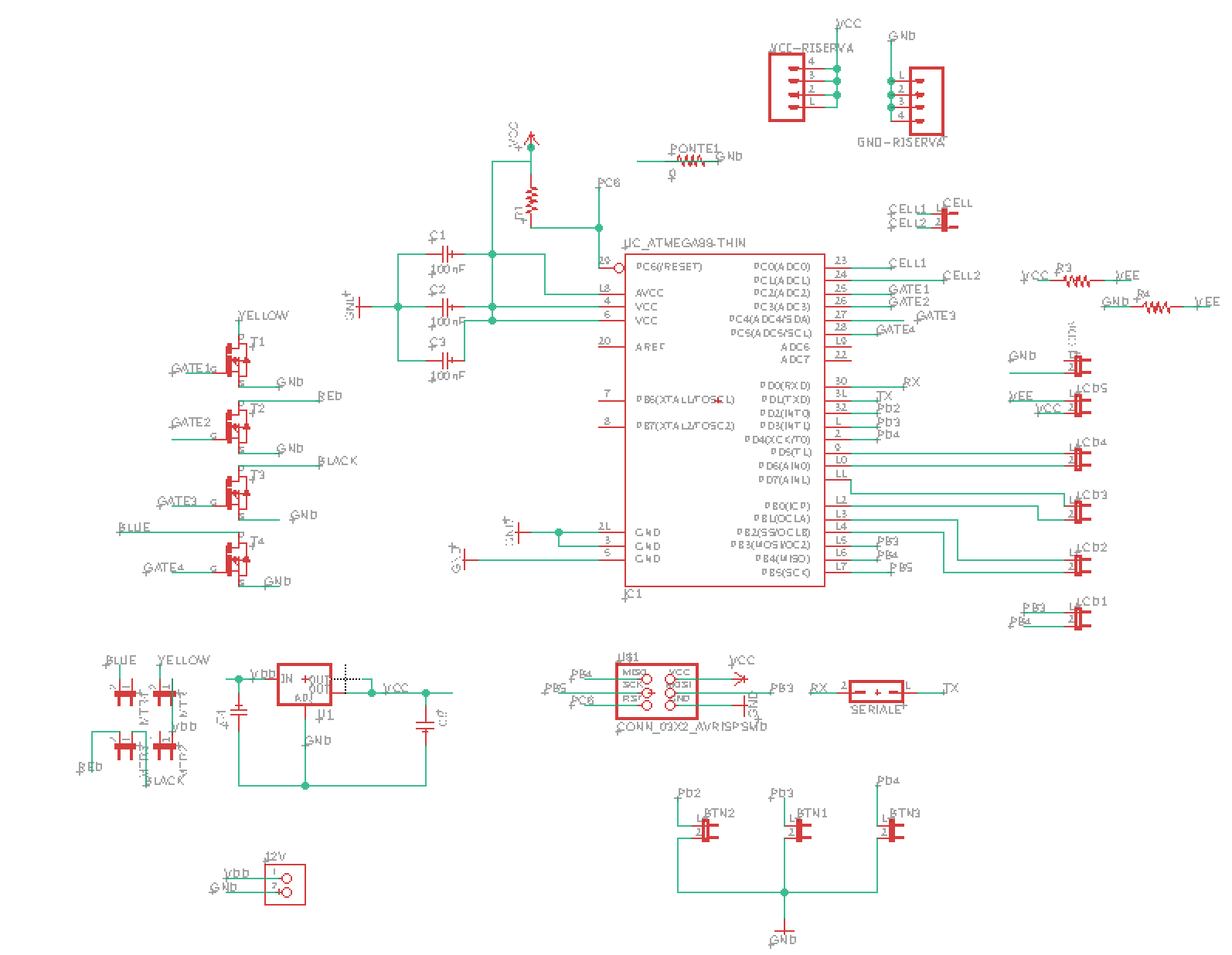

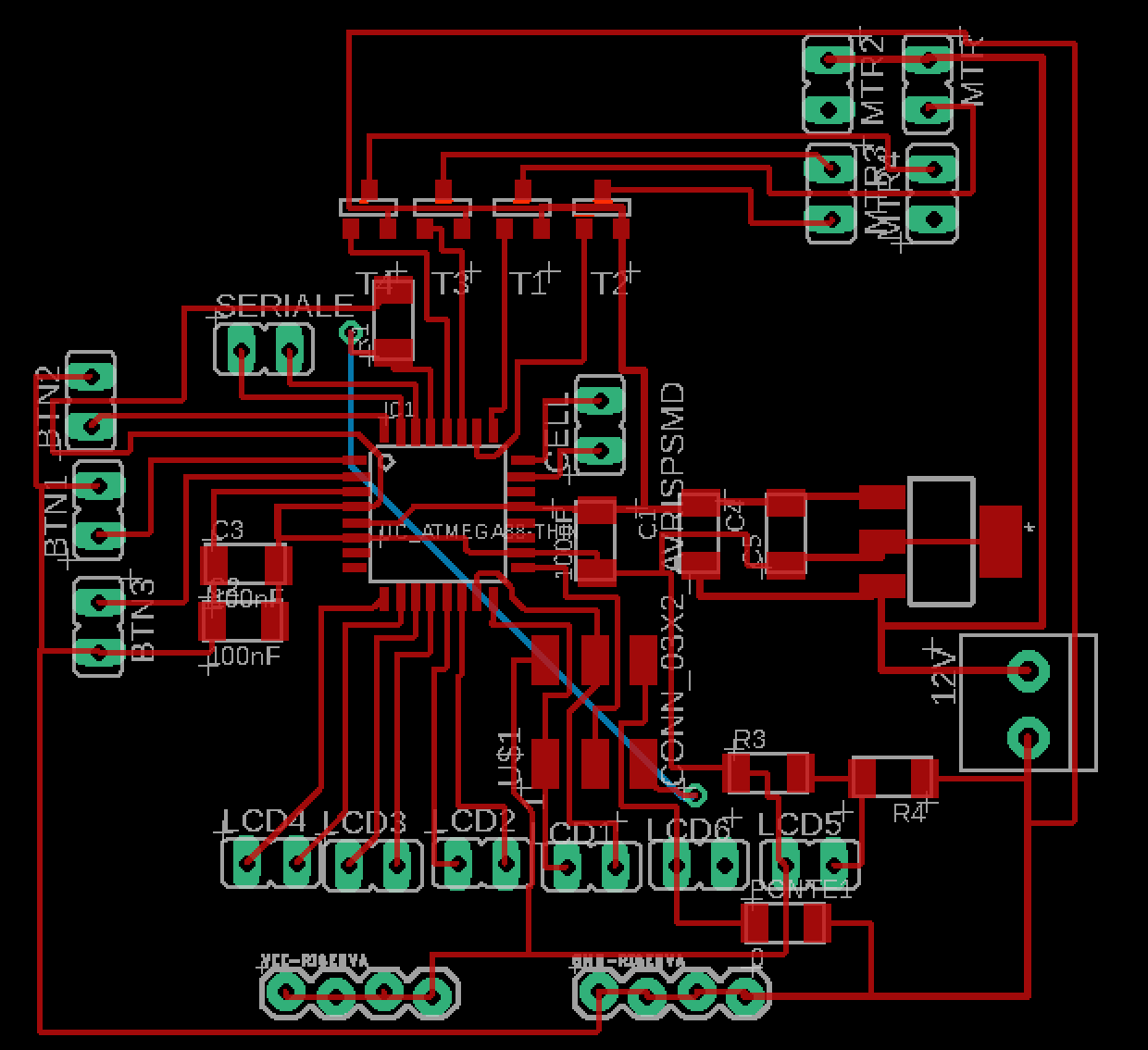

Then I thought about what the pcb had to do drawing some diagrams and I resulted with the following components:

- 1 stepper motor

- 2 buttons

- 1 LCD display

- 1 load cell

I started the design of my pcb using Eagle. This is the schematic and the board:

Here you can download the files: schematic, board.

And here is the soldered board (looks great!):

As a first thing I tested the stepper motor to see if it's traction was enough to turn the helix.

FIRST TEST

elica from Olivia De Masi on Vimeo.

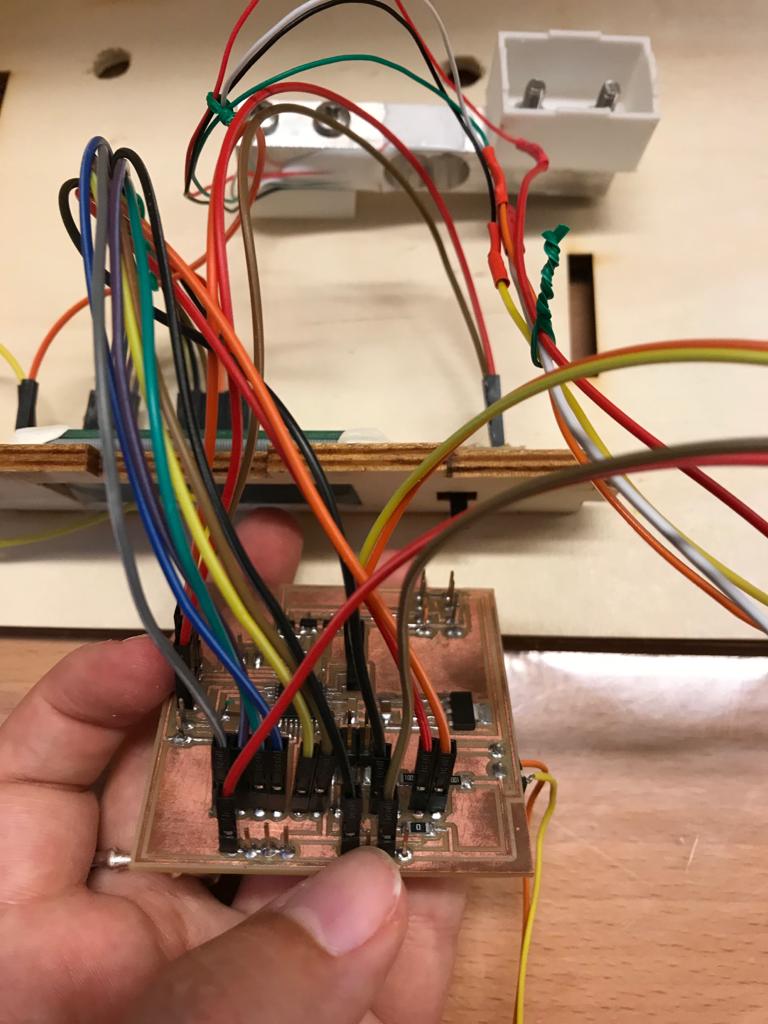

I carefully connected all the wires of my components to the pcb after testing each one individually.

And the one below is the code for the final project:

Embedding and Assembling

Electronics components:

Cabinet components:

video_ok from Olivia De Masi on Vimeo.