4. Electronic Production

Group assignment

This week we made an electronic board. I learned the whole process to make it. From making the design, etching the design and soldering the components. The group assignment is at the following link.

Electronic board design

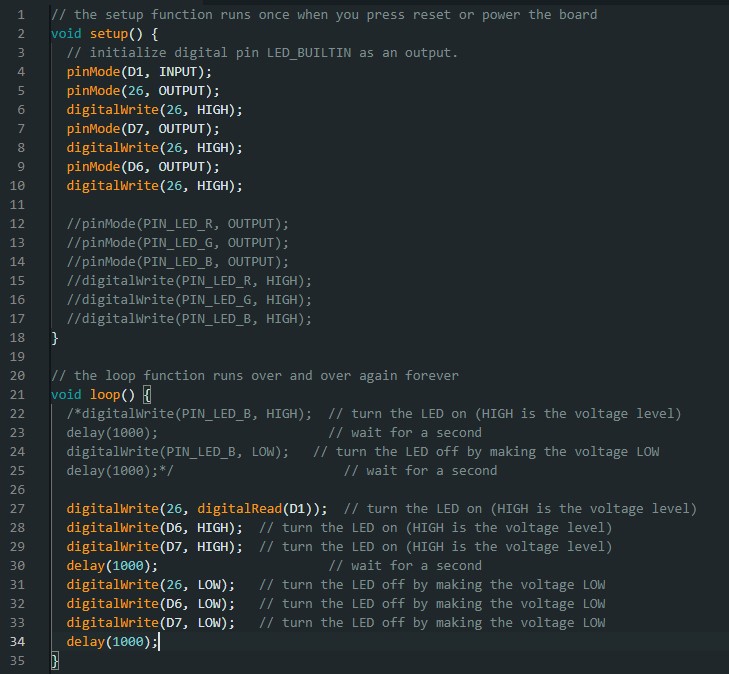

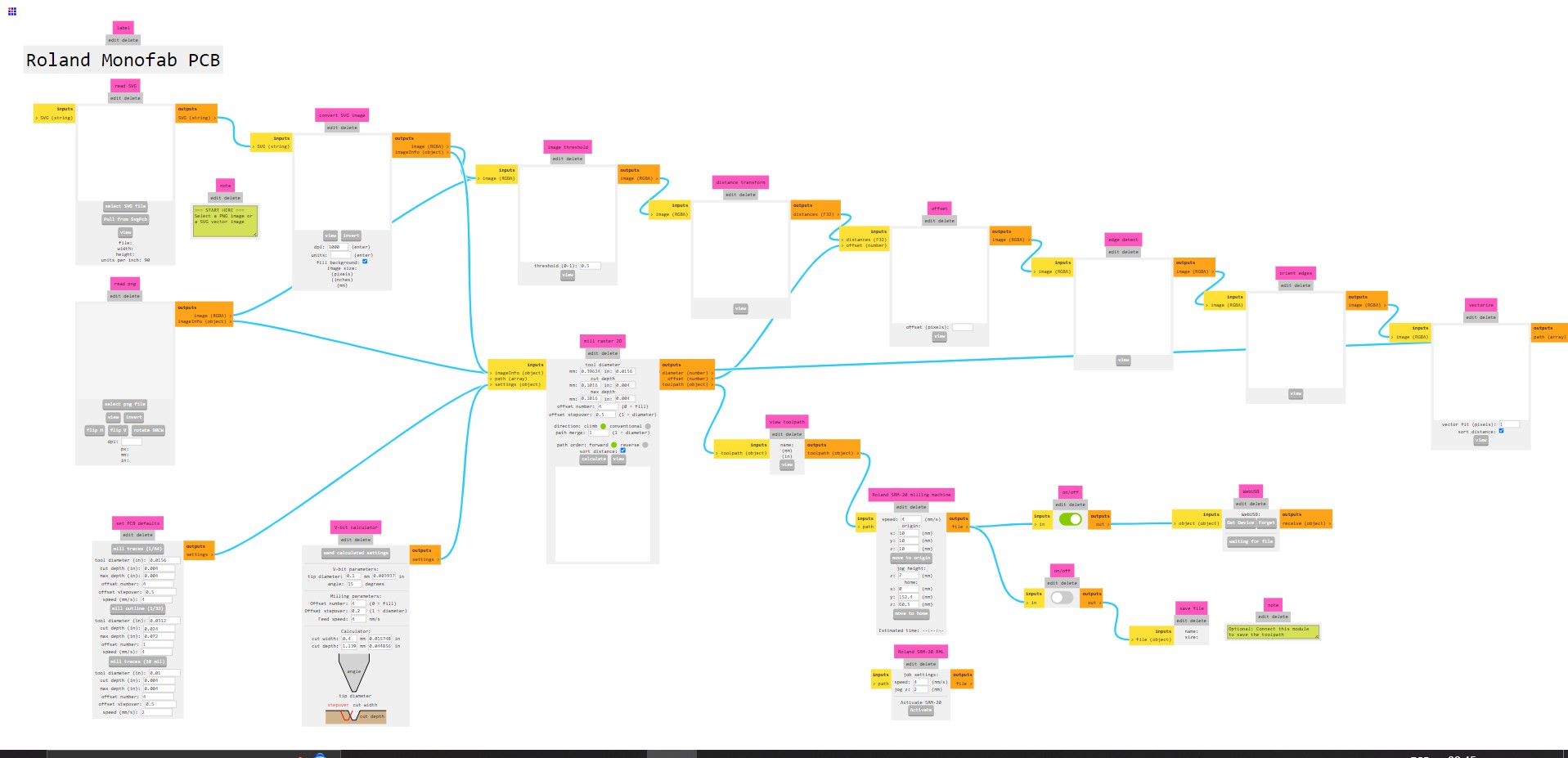

For the design of the electronic board, we used a ready-made design. On the group assignment page are some links. The one I used is the MODS link to prepare the designs.

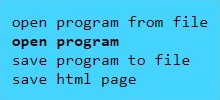

When we open "MODS" it shows us a menu where we select programns.

Then we select the option open program.

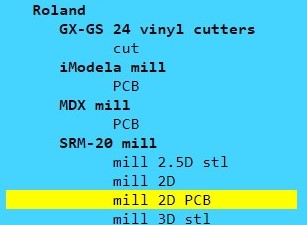

Then we select the option of the image.

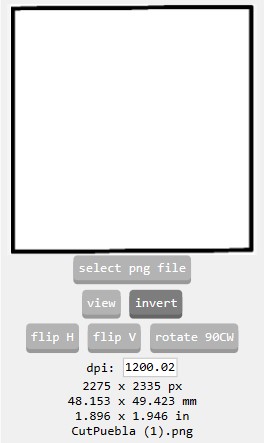

It will send us to another page where we will see the following:

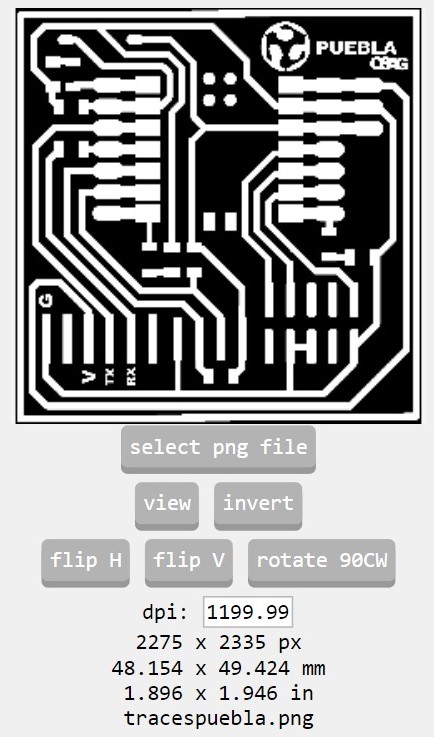

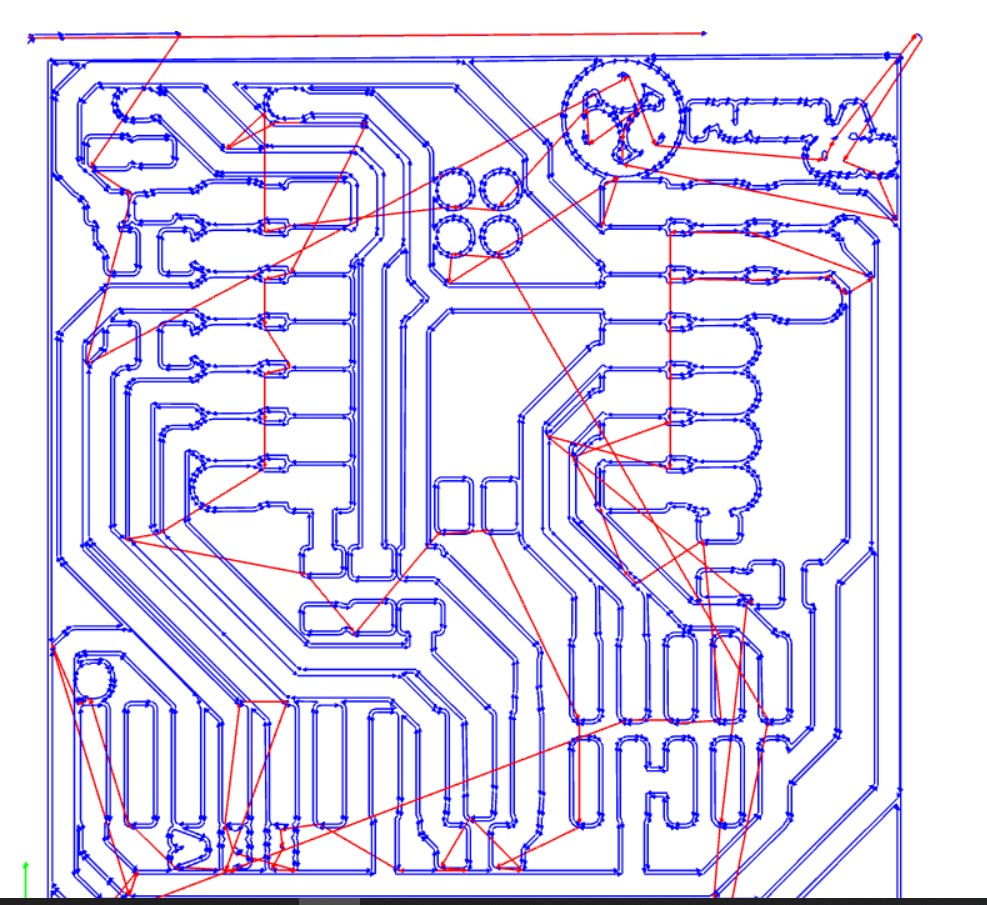

Select the first file we downloaded called traces.

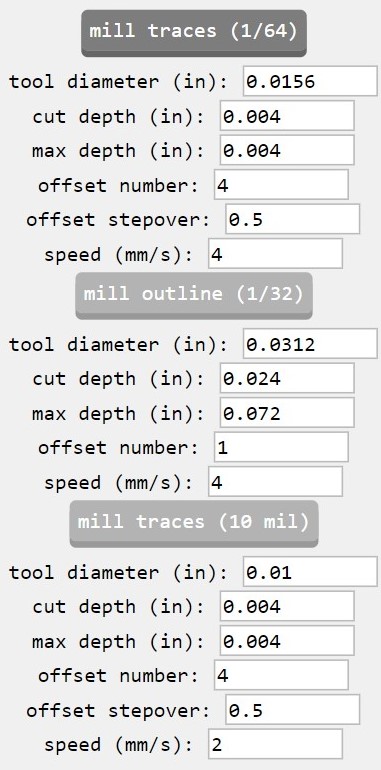

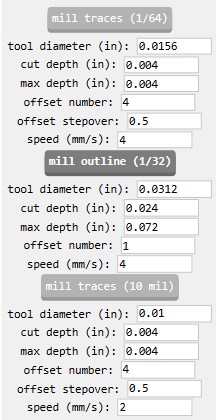

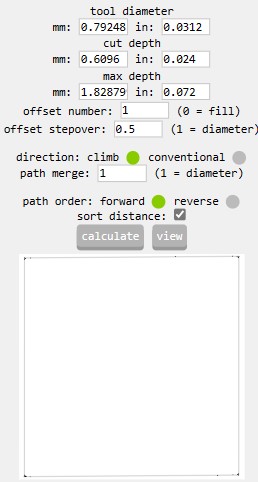

Then select the mill traces (1/64) option.

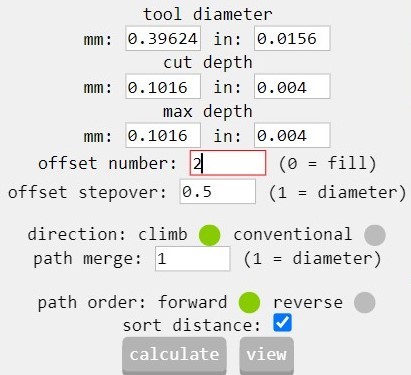

Next, we change the offset number to 2.

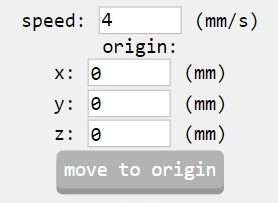

Change the x, y and z values to 0.

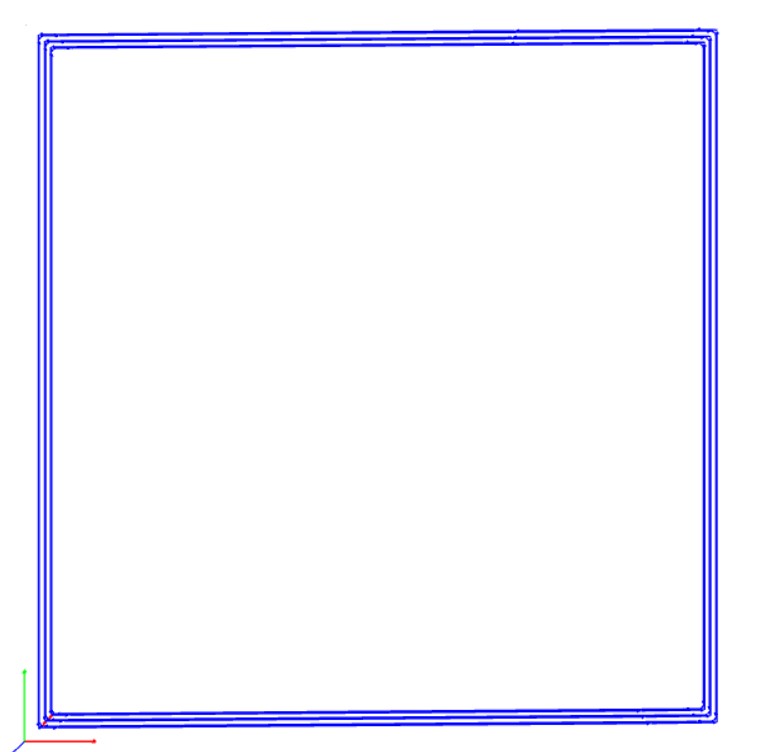

Finally, we get the following file in .rml format.

To configurate the second file I follow the next steps:

First, I open the file and I invert it.

Then, I chose the tool to make the cut, in this case I used the tool (1/32).

The difference between the first file and this is the offset number, when we change the tool we can see a new configuration.

To finish the file I used the same configuration.

Finally, we obtain the next result:

PCB milling

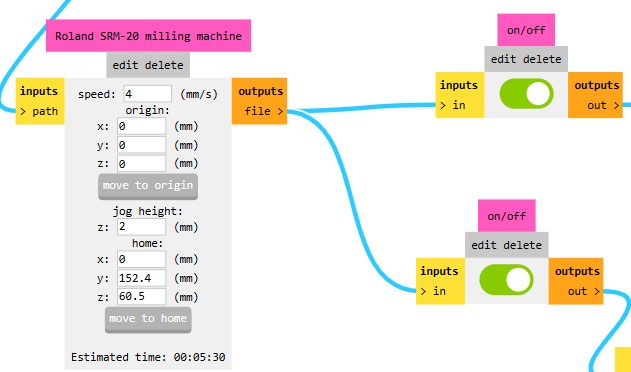

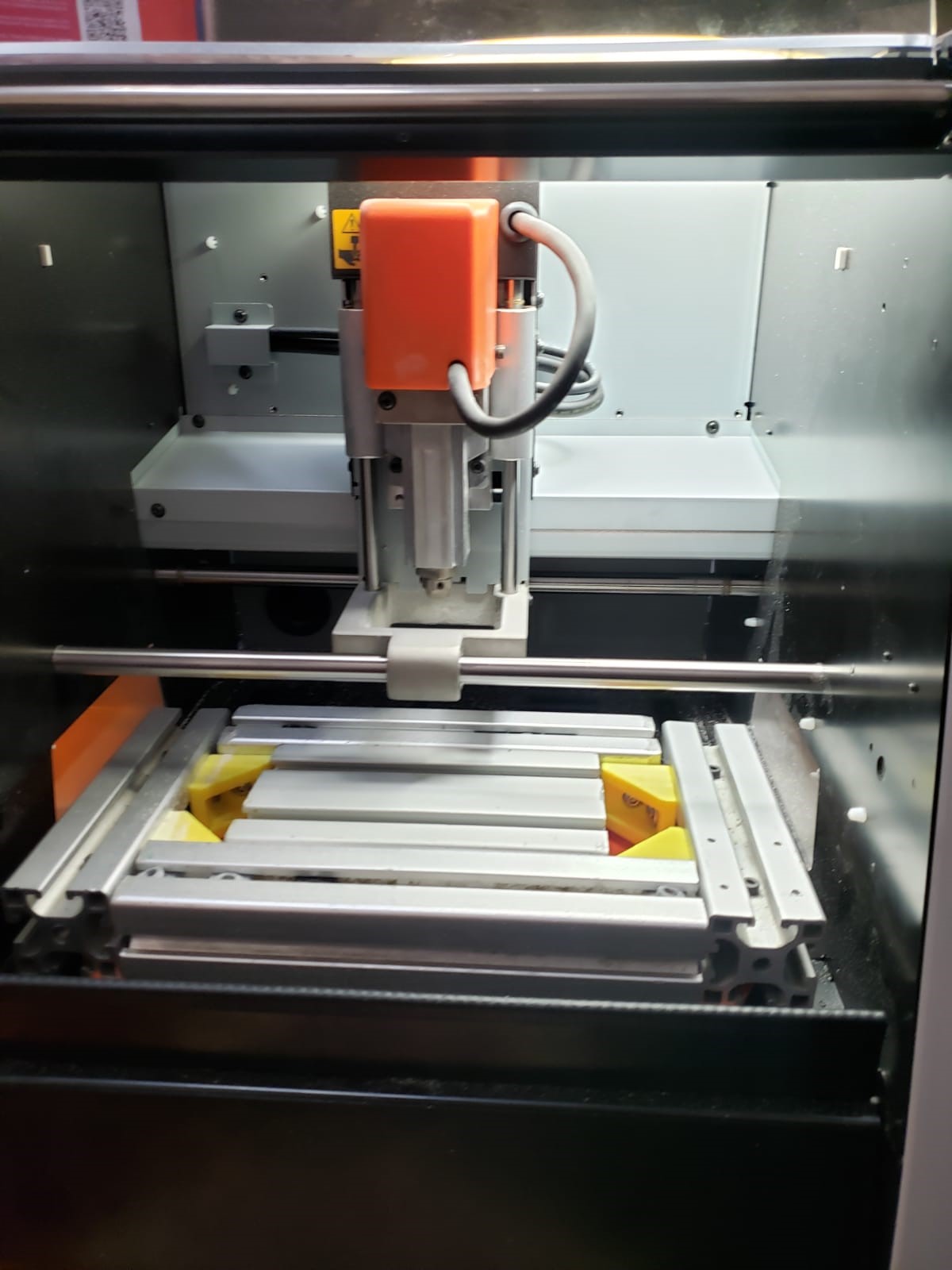

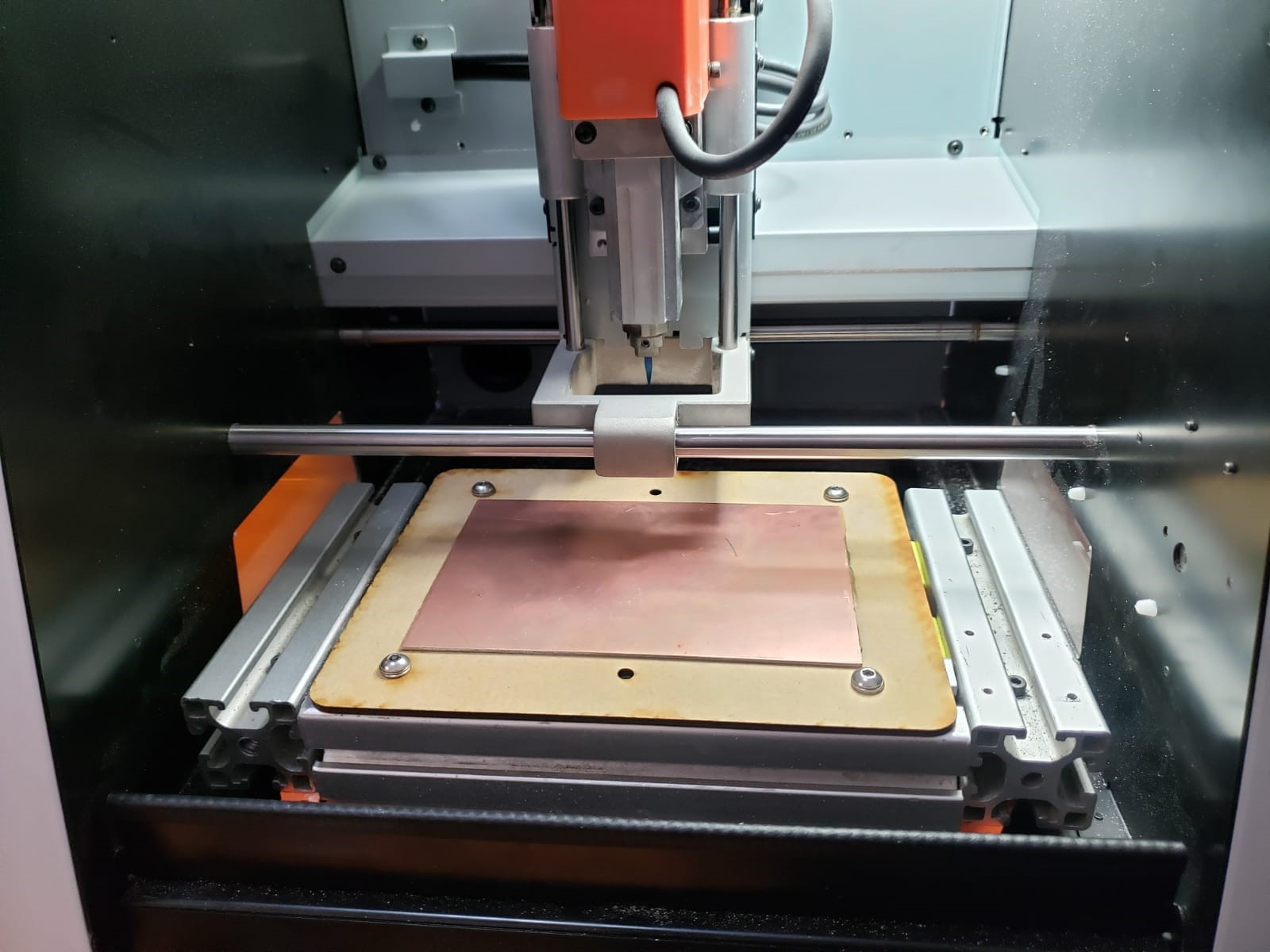

The machine I used to make my board is the ROLAND SRM-20 model.

This machine has the following features:

Cutable Material

Modeling Wax, Chemical Wood, Foam, Acrylic, Polyacetal, Acrylonitrile Butadiene Styrene (ABS), Printed Circuit Boards

Operational Travels in X, Y, and Z

203.2 mm (X) × 152.4 mm (Y) × 60.5 mm (Z)

Loadable Workpiece Weight

2 kg

Operation Speed

From 6 mm/min to 1,800 mm/min

Software Resolution

0.01 mm/step (RML-1), 0.001 mm/step (NC Code)

Mechanical Resolution

0.000998594 mm/step

Spindle Rotation Speed

Adjustable from 3,000 RPM to 7,000 RPM

Interface

USB

Operational Noise

During operation: 65 dB(A)

External Dimensions

451 mm (width) × 426.6 mm (depth) × 426.2 mm (height) (17.76 in [width] × 16.80 in [depth] × 16.78 in [height])

Weight

19.6 kg

PCB development on PCB Milling

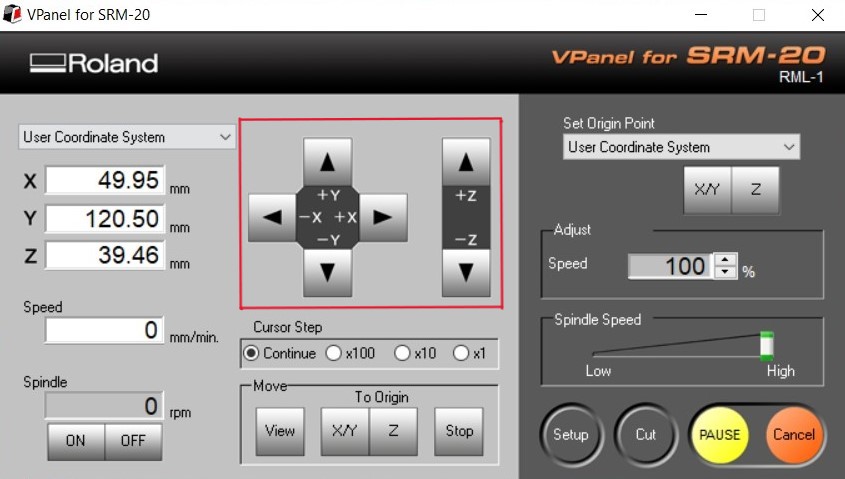

To start with the etching of the board, we open the PCB Milling software called VPanel for SRM-20.

To start we turn on the machine and connect the machine to my computer.

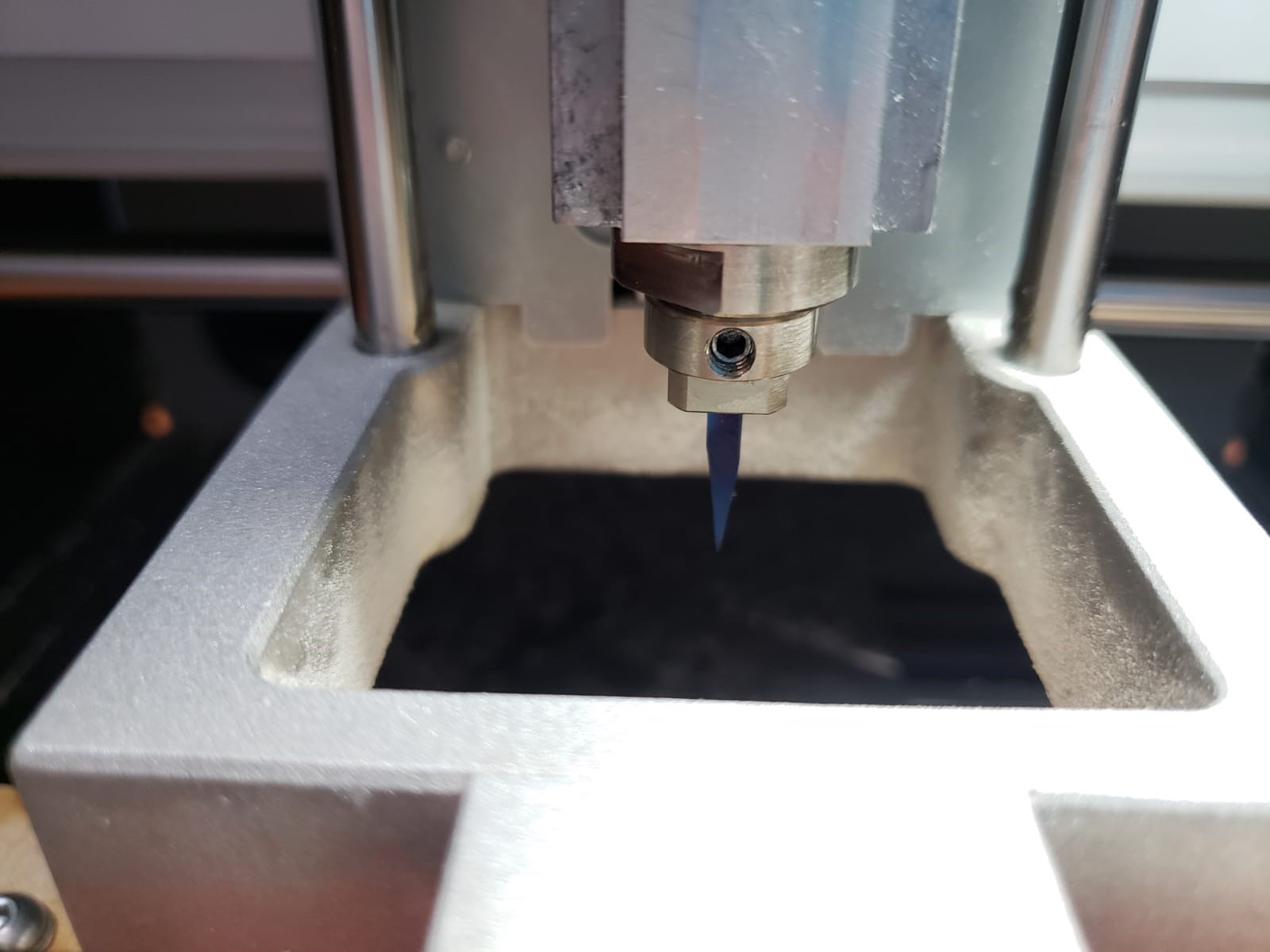

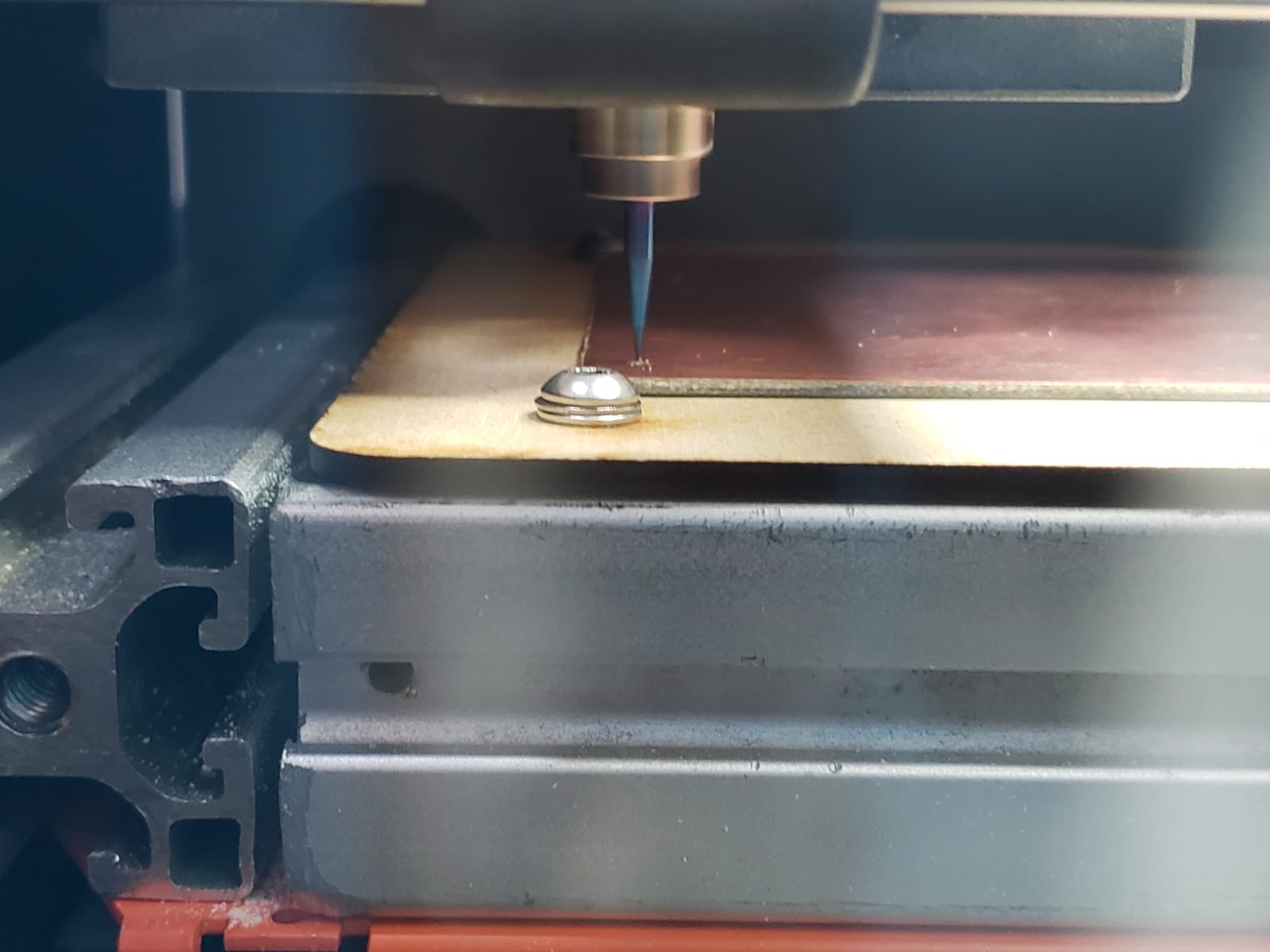

We put the cutting tool that is not flattened at the tip.

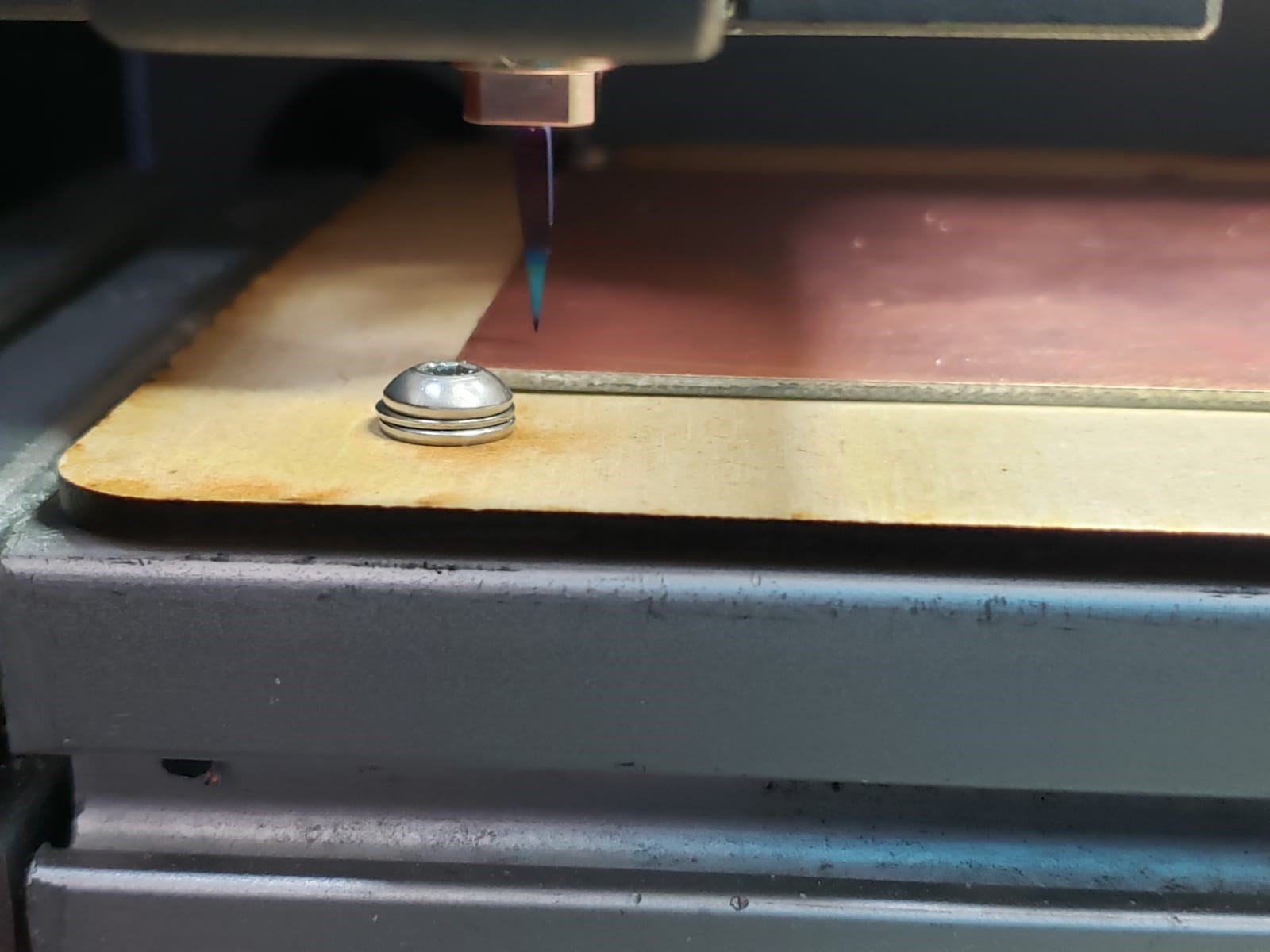

Then, we adjust the "sacrificial board" with the copper board already glued.

Then we adjust the tip on one of the corners of the copper board. We use the arrows to move on the x and y axis. And to move down we use the arrows on the z-axis.

Then, using a piece of paper to adjust the z-axis, we carefully go down using the cursor step x100 and x10.

We lower until the paper can't come out.

Select the first file in the Cut option and the engraving starts.

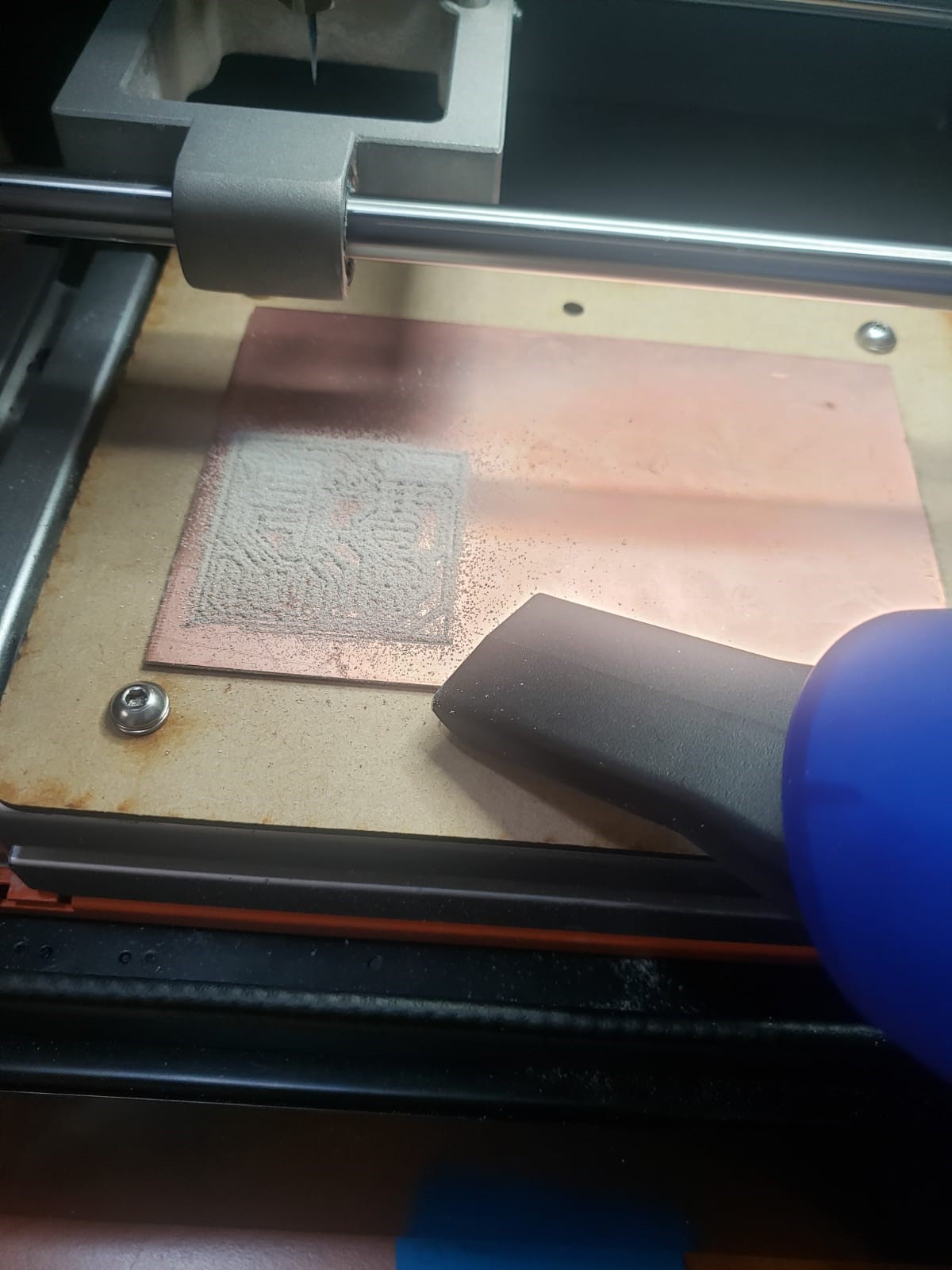

At the end, we remove the residues with a vacuum cleaner.

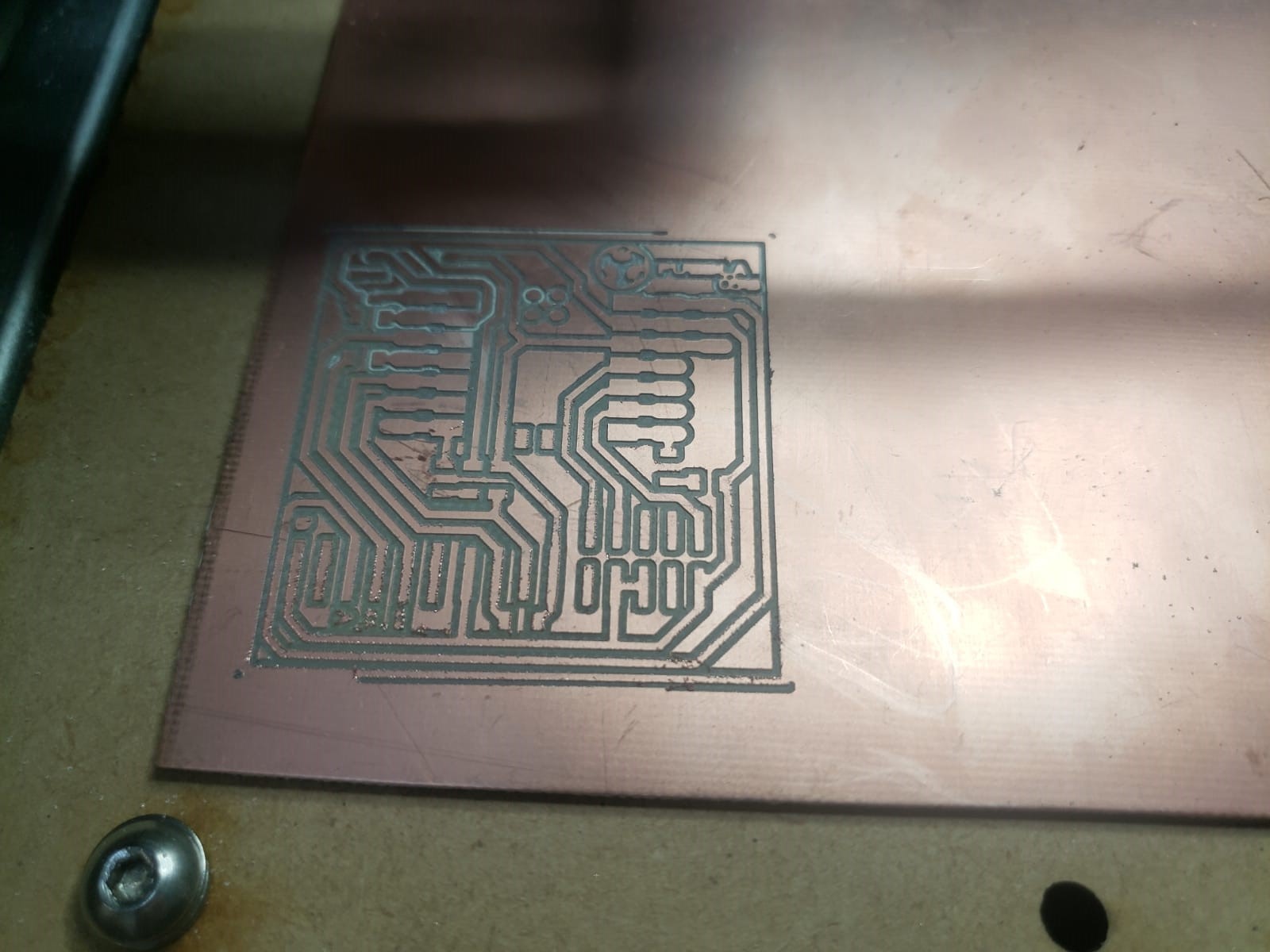

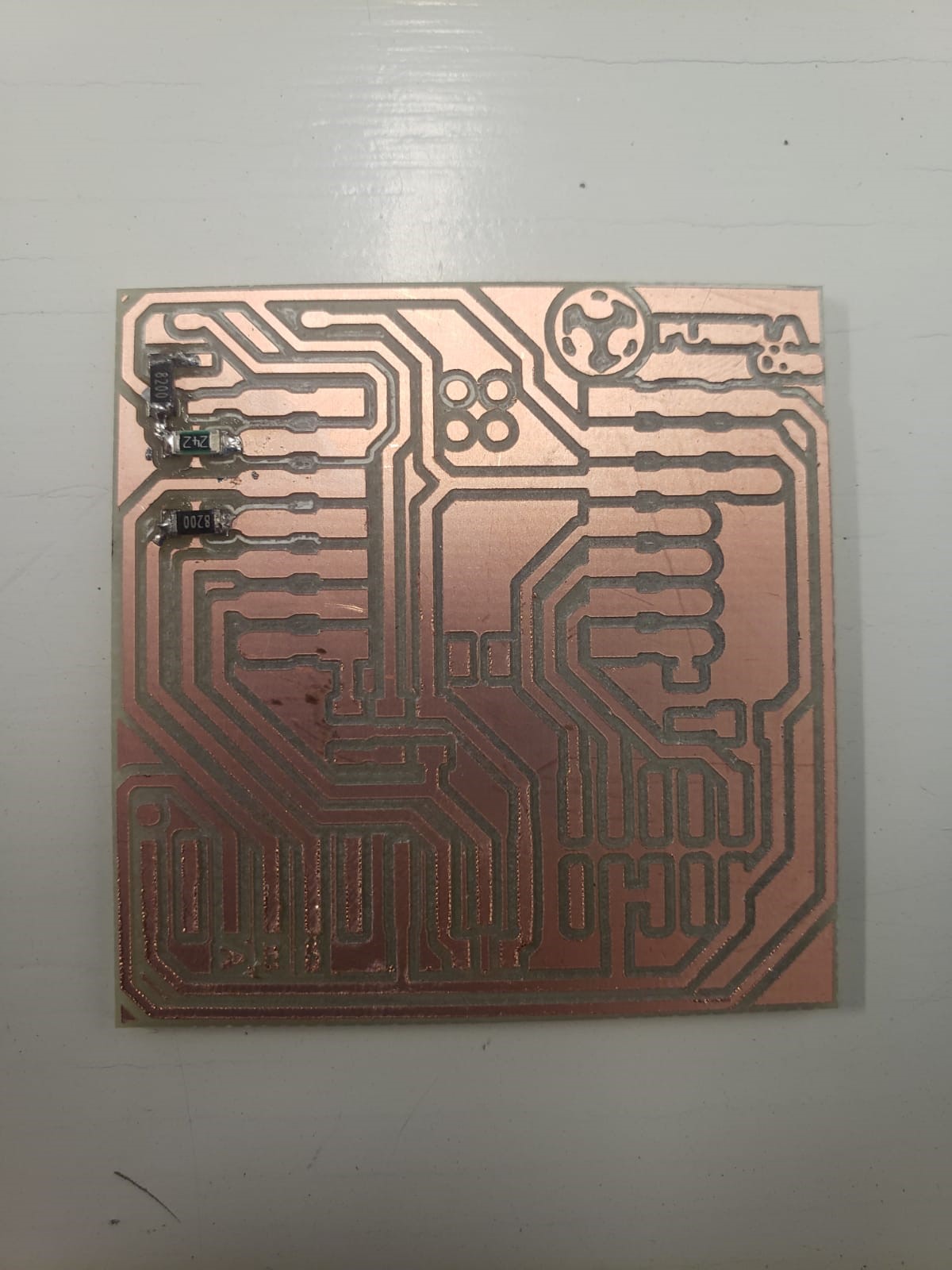

The result of the engraving is as follows:

Then, we change the drill bit. We adjust the origin again using the arrows. And we start the engraving of the second file.

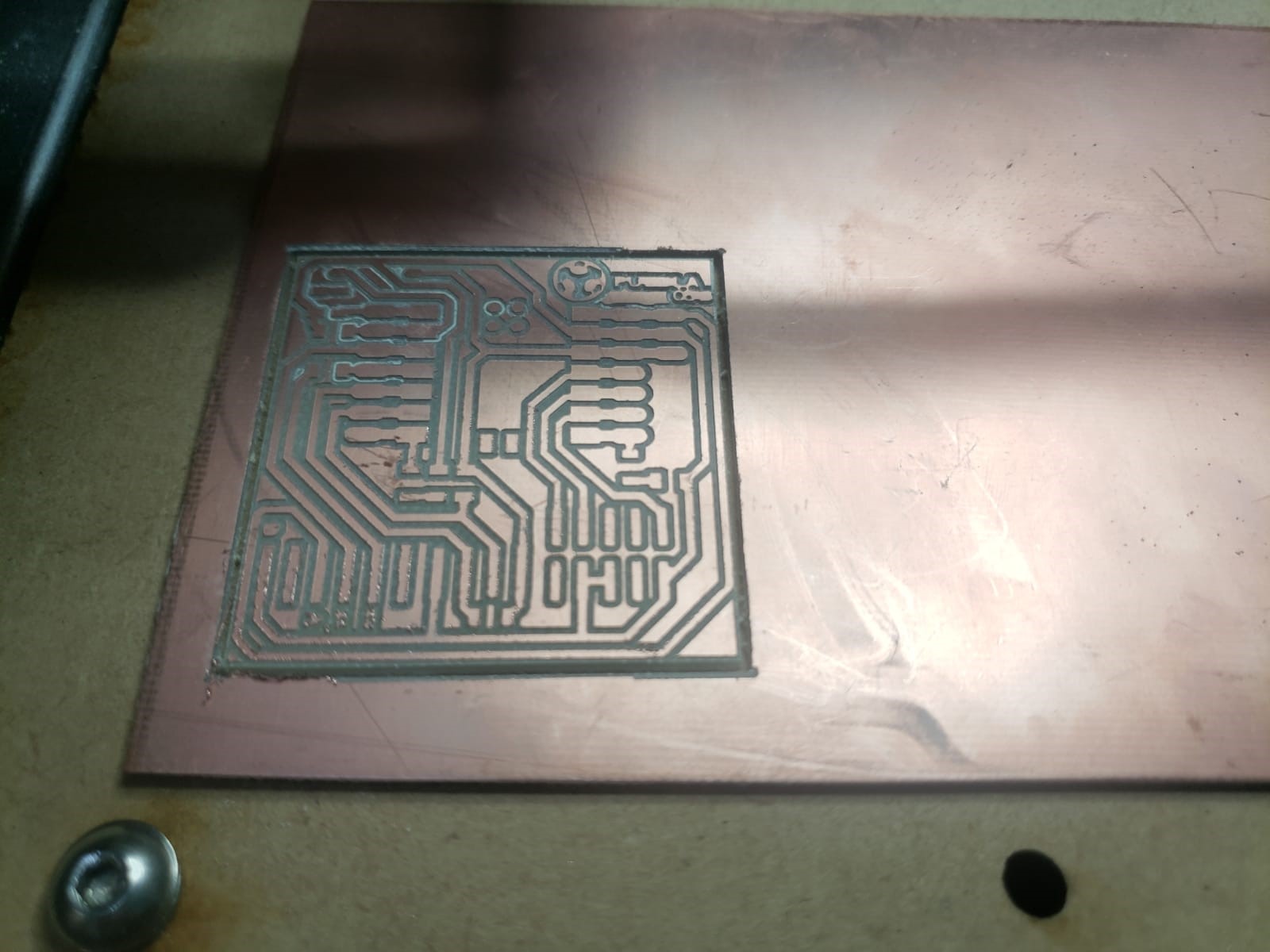

The final engraving on the board is as follows:

Soldering the components on the PCB

Components

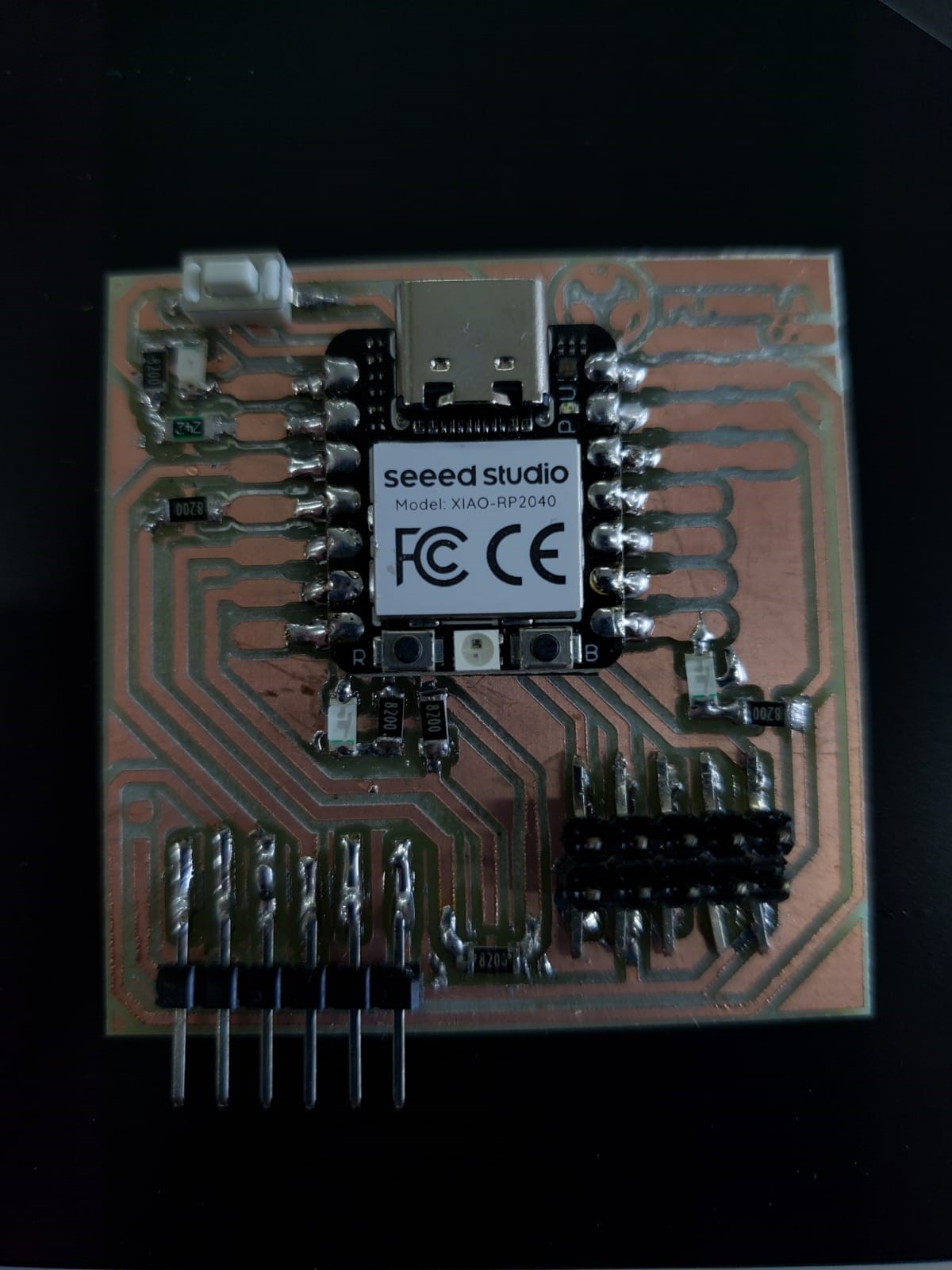

Microcontroller

Xiao-Rp2040

Micro leds

Three leds

R820E-1206 SMD Surface Resistor

Six resistors

Resistor SMD RR0816P-242-B-T5

One resistor

Buttons

One button

Pins

Sixteen pins

SMD Resistor “R820E-1206”

Resistance Value: 0.82 ohms

Package Size: 1206, which measures approximately 3.2 mm x 1.6 mm

Maximum Power: Generally between 0.25 watts to 0.5 watts

SMD Resistor “RR0816P-242-B-T5”

Resistance Value: 2.4 kiloohm

Package Size: 0816, approximately 2 mm x 1.6 mm

Tolerance: ±0.1%, indicating high accuracy

The soldering process was complicated for me. I had never done it before. So I decided to practice before soldering the main board.

After some practice I started soldering. I started with resistors and leds, which are the smallest components.

The result of my first time welding is as follows:

Check that the board works

To check that the PCB is well done, I used the following code. Basically what it does is to turn on two LEDs in a loop, and the third LED turns on when I press the button.