(good one)Parametric Construction Kit

Write something at the front

Written on 5.17th, I finally got the idea of laser cutting machine and how it works, how I get the files, etc... Now I am starting to do it.

File Sharing

- The Onshape link for curf detecting is here

- The Onshape link for my Parametric Construction Kit is here

Test the machine and get the curf

This is the laser cutting machine in the ChaiHuo Fab Lab:

And here is the information about it

And it provides some information about the materials cutt settings.

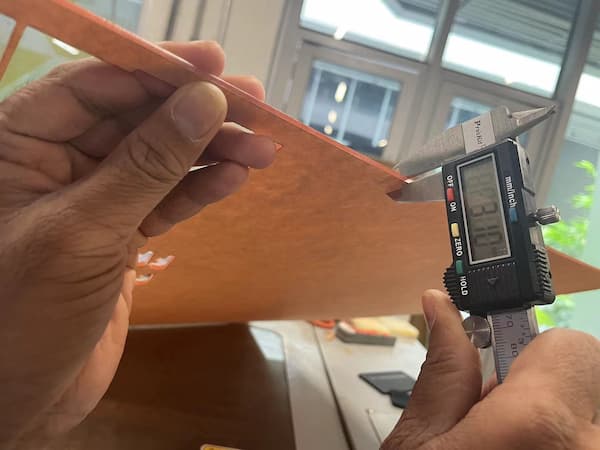

We are going to use the acrylic board to do the cutting, for the first we need to know the thickness of it:

It is about 3mm, so on the Onshape I need to design a test board for testing the curf of it. Then I can make sure this board will be complete fit:

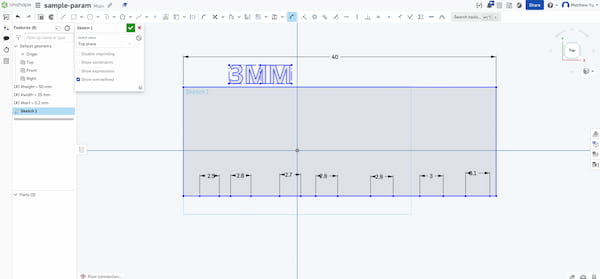

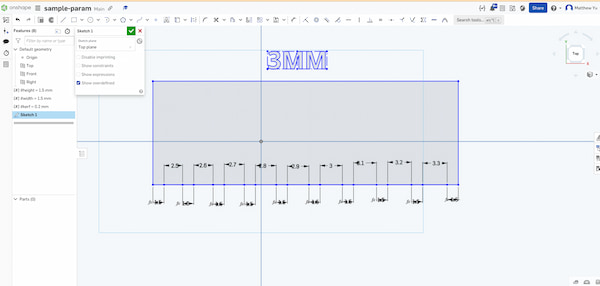

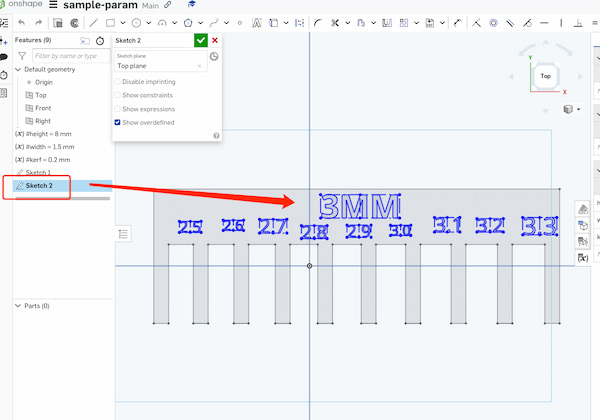

I design a board from 2.5mm to 3.1mm:

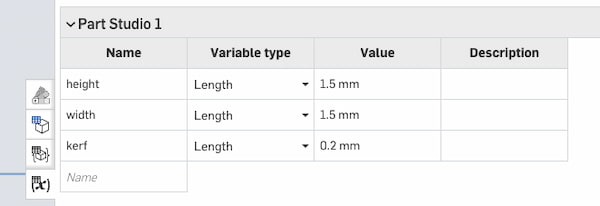

but it is a little no in the order, so I add some Variable Parameters:

for the width I think 1.5mm is fine.

Then I add the different cutting intervals as 1.5mm.

for the heigh I think 8mm is fine.

Then I add the different cutting intervals as 8mm.

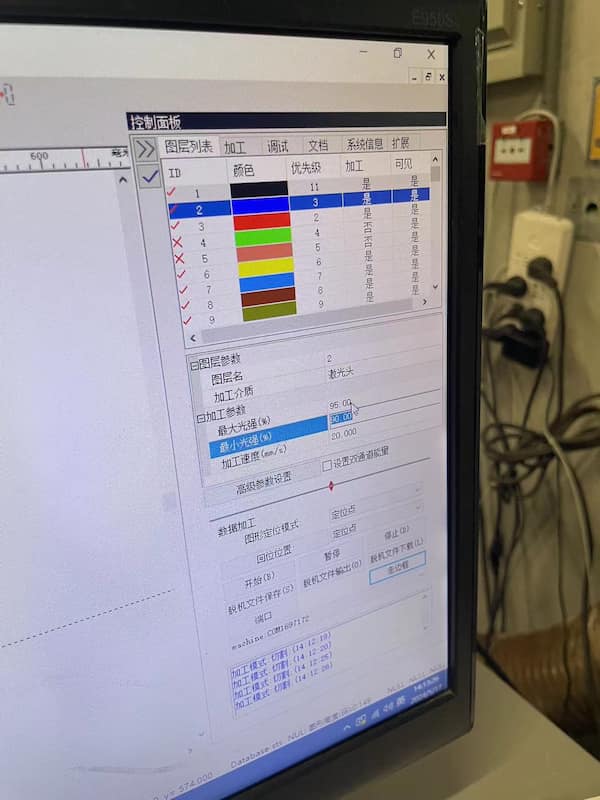

Since the software for machine seems not supporting editing different contents, I have to make two layers for it cutting.

Then I output two DXF files:

And send them to the machine

Then I should have torn the paper off the acrylic sheet so it wouldn't catch fire:

Setting the zero ppoint:

Finally, setting the power of laser as 90%, and the speed as 20mm/S, as recommended before.

The I can send the file from the software to the machine and begin the cutting:

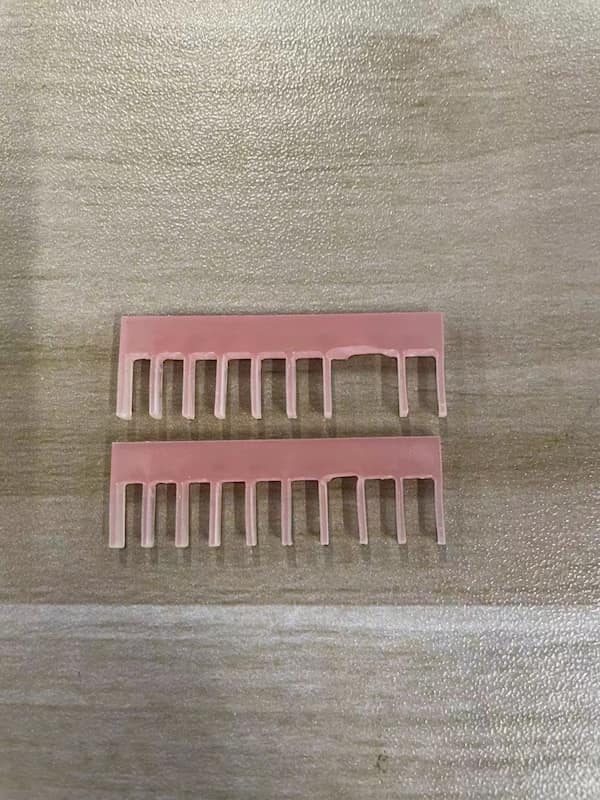

The first is brkoen and the second one is great:

But it also gave me a chance to see which one would fit right in:

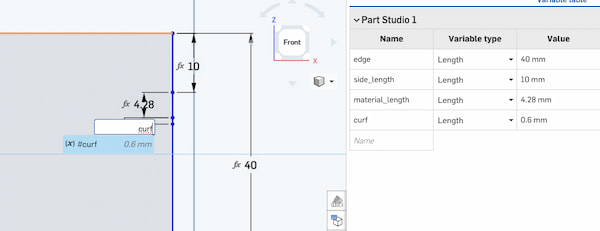

I forgot to cut the text first. But after checking with the files I design, the curf should be 0.6mm.

Design the 3D file for Parametric Construction Kit

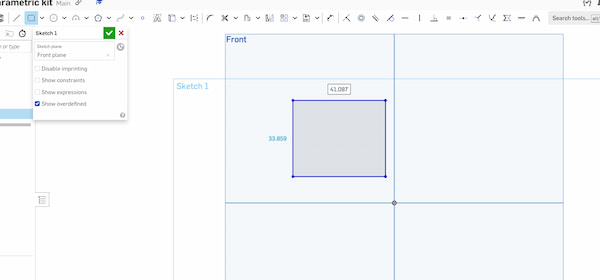

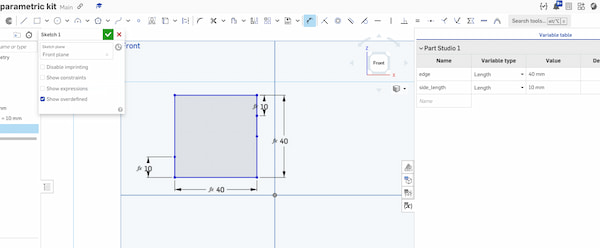

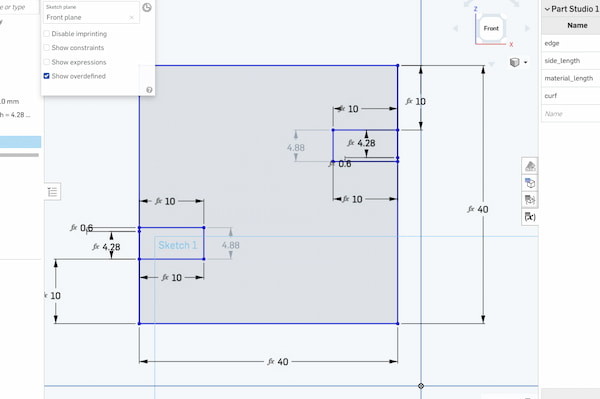

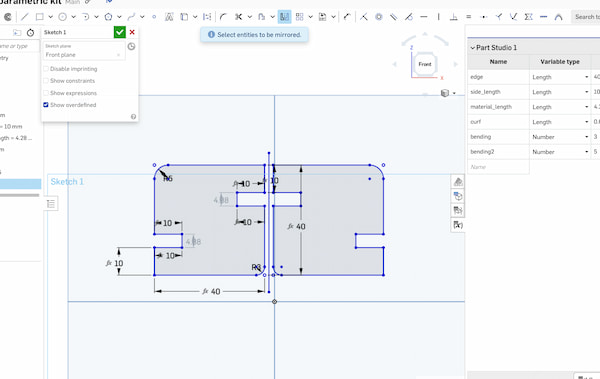

I am using Onshape to design my Parametric Kit, and first I draw a rectangle:

Put the "edge" parameter as the square as 40mm. And prepare the distance to be cut as 10mm:

Then I checked the material I am going to use:

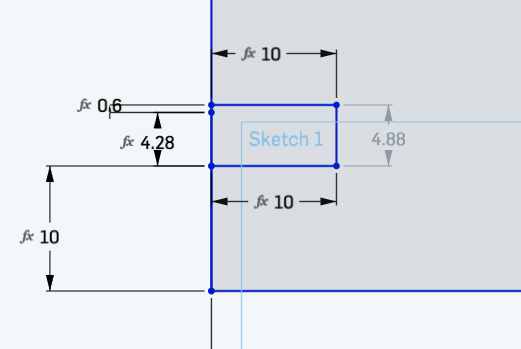

I set 4.28mm and add the curf:

Set the depth of the cut and check whether the parameters are right or wrong

Update on both sides:

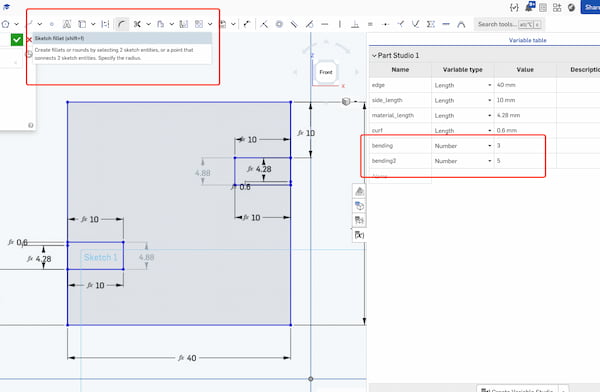

Then I want to build some bendings, with Sketch Fillet:

Put 3 and 5, as number:

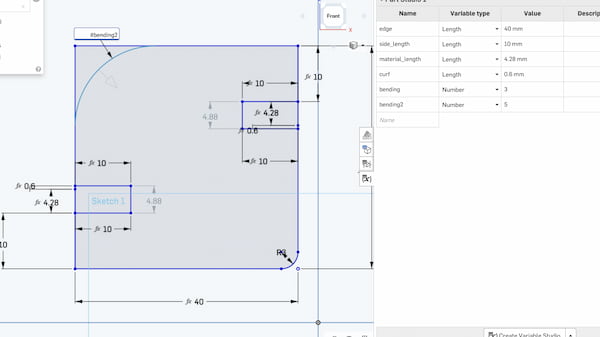

The single one will look like:

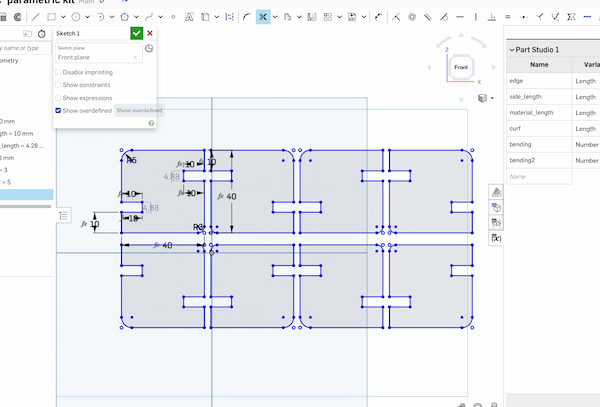

Then use "Mirror" function to duplicate:

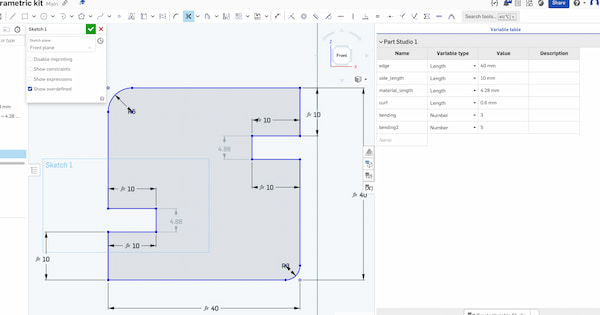

The final one:

But at the same time I should test the machine if it can cut through. So I add another one:

Later I have these two files:

Then I can move to the Laser Cutting Machine.

Cutting 3D file on the machine

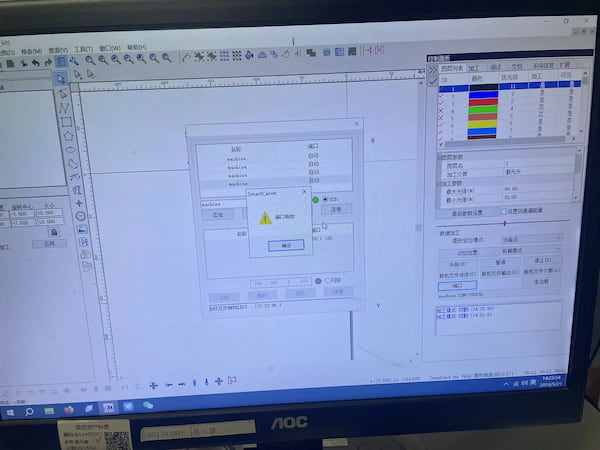

First I connect the software to the machine:

Then I upload the text file to the software and test the cut. I set the power 90 and the default speed as 20mm/s. This is the output:

Not cut through:

I then change to 10mm/s and it cut through.

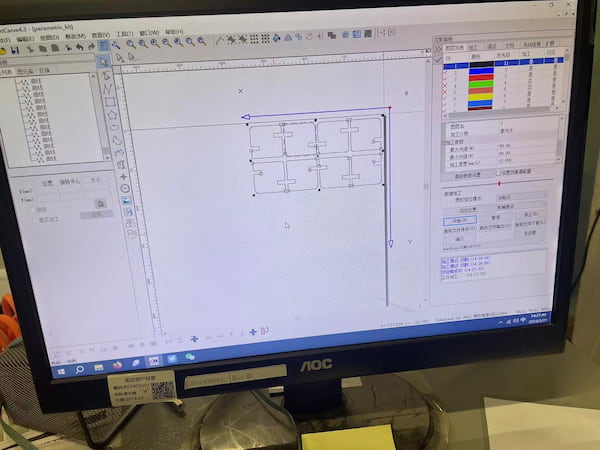

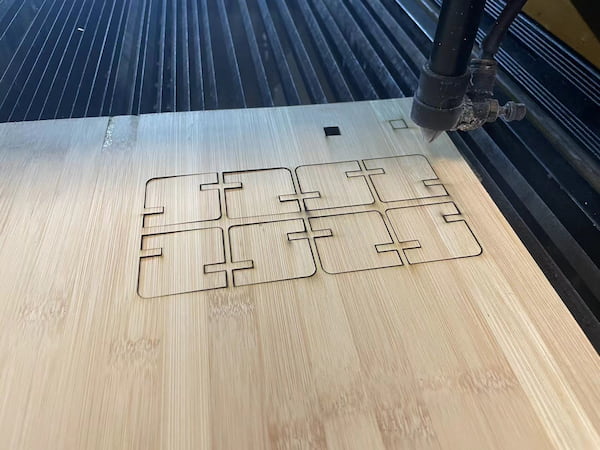

Now I upload my own file:

And begin the cutting:

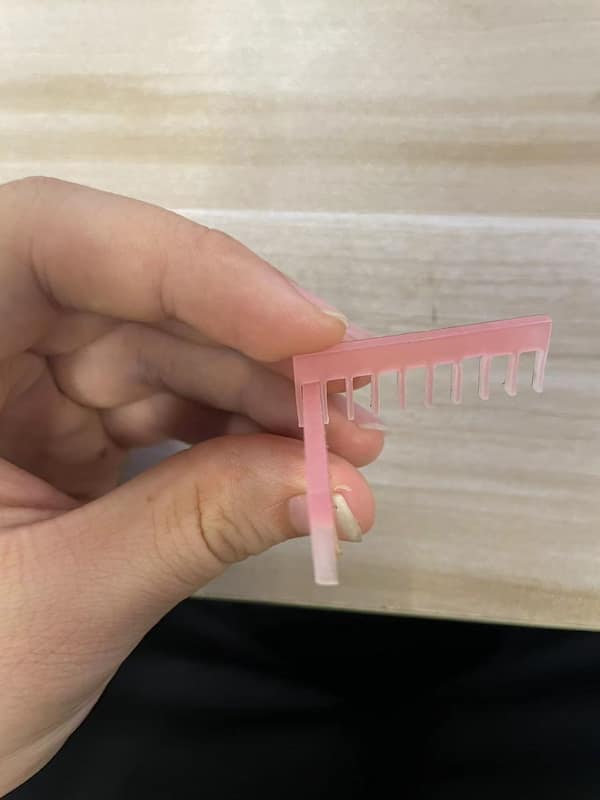

Finally done:

If the length of edge cut is longer would be perfect: