Final Project, Principle and Practice.

For my final project, I have thought of making a turntable for scanning operations; my motivation for this idea because here in the lab, we are using a rotating chair to scan objects, and sometimes, while I'm using the handheld scanner I struggle to rotate the part while scanning, because one hand is always busy.

To start working on my my final project, first I had to define my specification:

1. It is closed body.

2. It have a rotating plate.

3. It has the ability to control the speed pf rotation.

4. It has power switch ON/OFF.

5. It has a speed switch ON/OFF.

6. It have has an indication led to know if it is powered or not

7. It could handle weight up to 5 kg.

8. It powered through the grid.

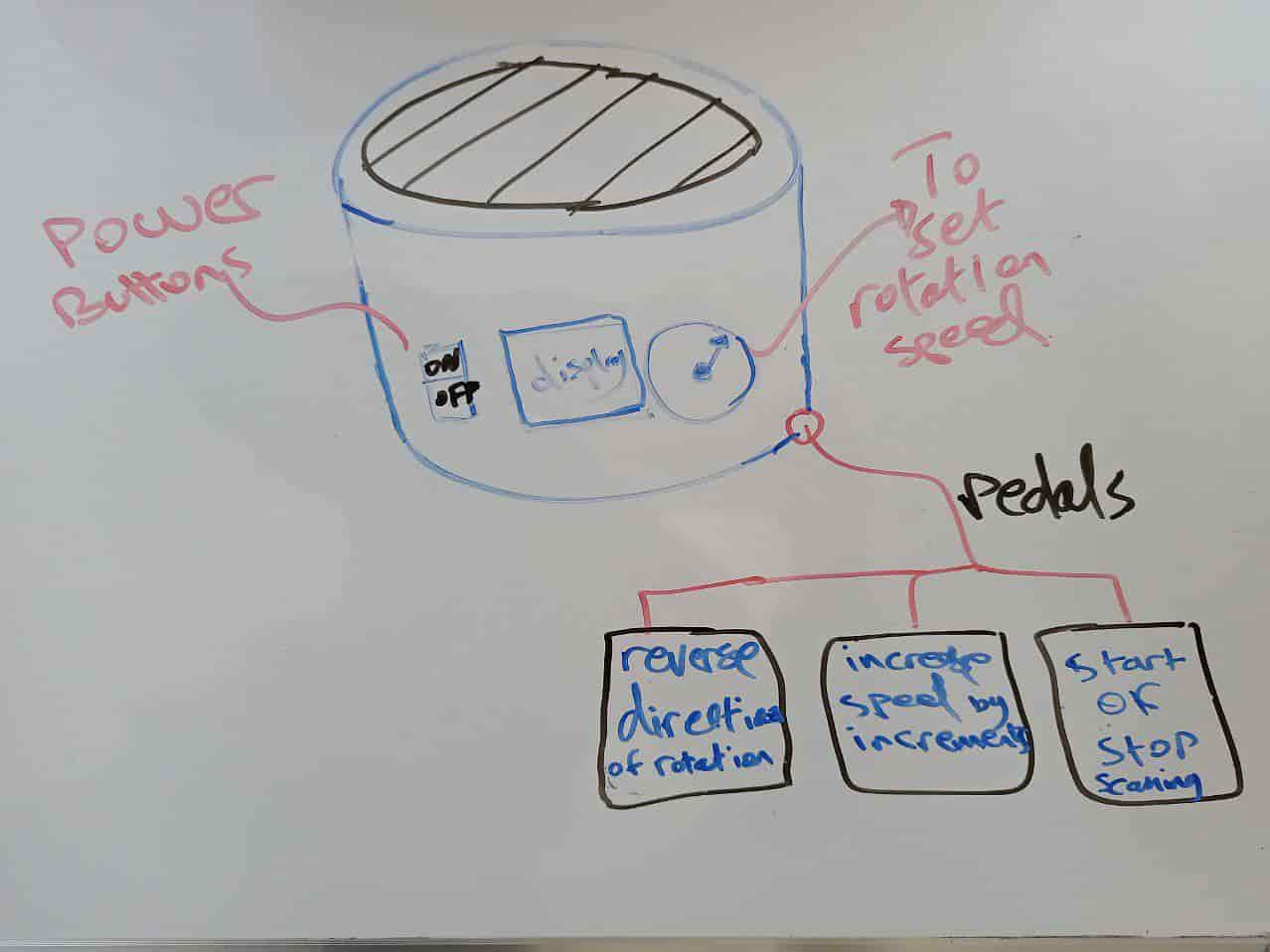

And this is a simple sketch that represents the idea:

It will be hard thing to do if I did not separate it into tasks, so there are 3 main things should be accomplished to have the scanning table done:

A- The structure(body).

B- Mechanical System.

C- Electronics.

Starting with the structure, I was thinking of what is the suitable material to make the body, and how to do it, but during the wildCard week, it came to my mind why not to make the body with composite fabric and resin. The fabric will provide structural reinforcement and the resin will act as a bonding agent to hold the fabric together.

The design of the structure contains the following sections:

1- The disk.

2- The chair (the place where have the bearing balls and the disk will set on)

3- Motor bracket.

4- Foots of the body.

5- Interface and Electronics housing.

The mechanical part contains the following sections:

1- Flange to connect the rod to the disk.

2- Bearing balls.

3- Flexible coupling between motor and rod.

The electrical part is contains the following:

1- Stepper motor.

2- The MCU.

3- Motor driver.

4- Potentiometer.

5- Slide switch.

6- Push button.

7- ON/OFF switch.

8- indication led.

9- PCB board with pin headers and some smd components such as voltage regulator, power jack, smd led.

The plan is first to make the CAD in parallel collecting the components and materials then start manufacturing parts, testing each part alone and then assembly and testing the integration.

I have listed the BOM(bill of material) in Application& Implication week.