3. Computer controlled cutting¶

Hero Shots¶

Assignment Requirements¶

Group assignment:

Characterize your lasercutter’s focus, power, speed, rate, kerf, joint clearance and types

Individual assignment:

Cut something on the vinylcutter Design, lasercut, and document a parametric construction kit, accounting for the lasercutter kerf, which can be assembled in multiple ways, and for extra credit include elements that aren’t flat

Group Assignment¶

Requirements:

Characterize your lasercutter’s focus, power, speed, rate, kerf, joint clearance and types

Link to group assignment page

The group assignment page can be found on the Energylab 2023 website here

it is also embedded directly in the webpage below.

Individual assignment¶

Workflow Laser Cutting¶

Step 1: Modelisation¶

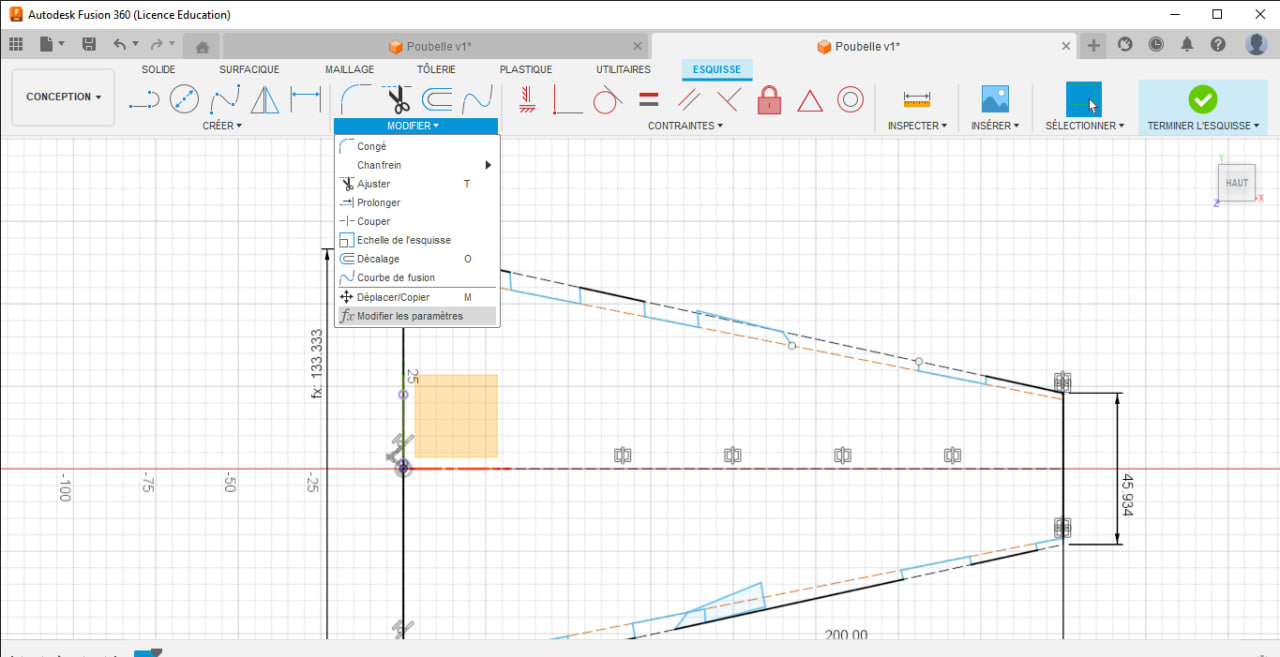

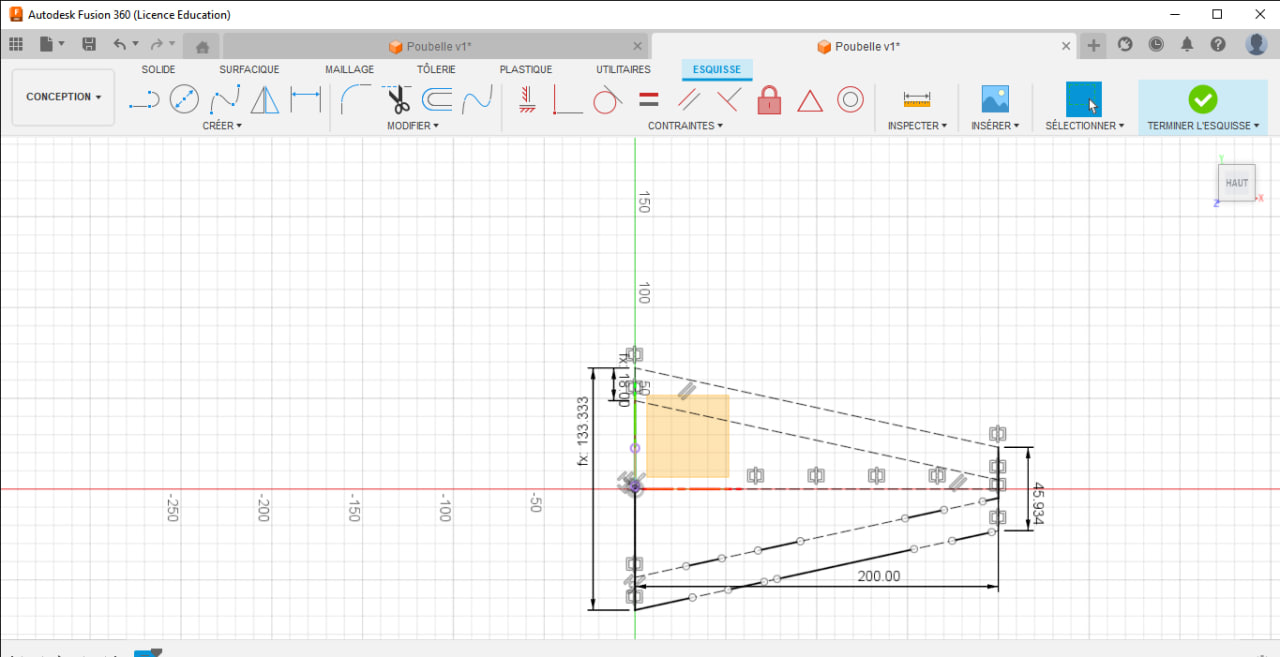

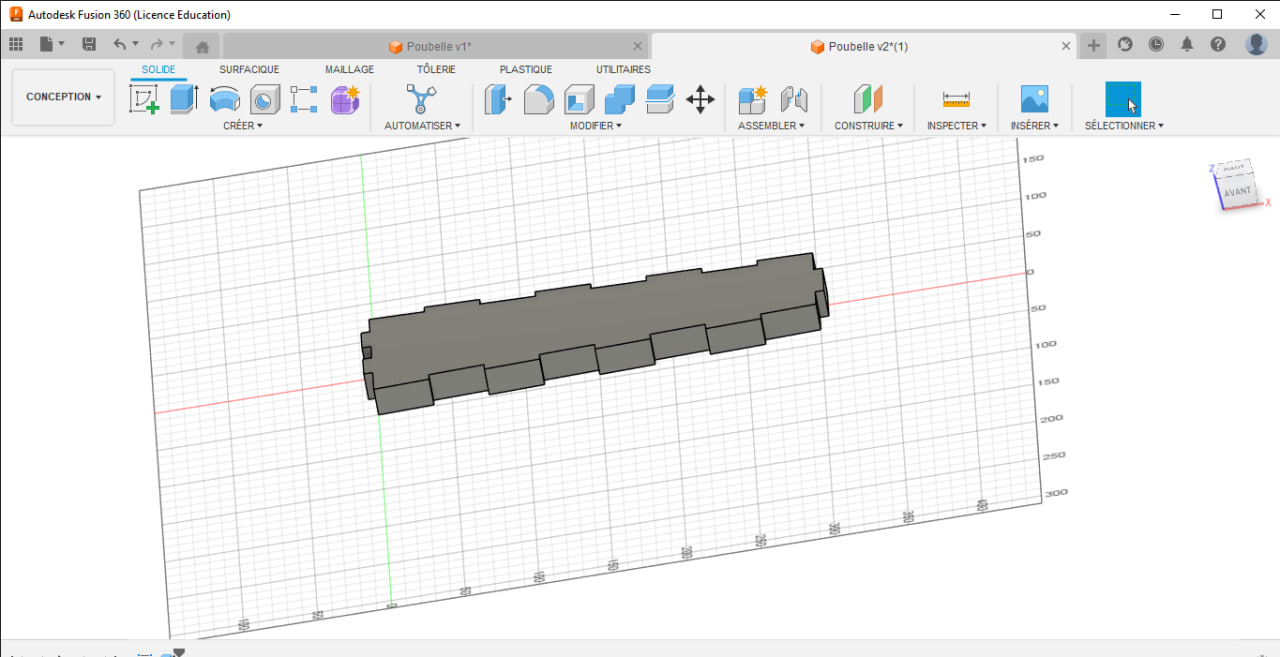

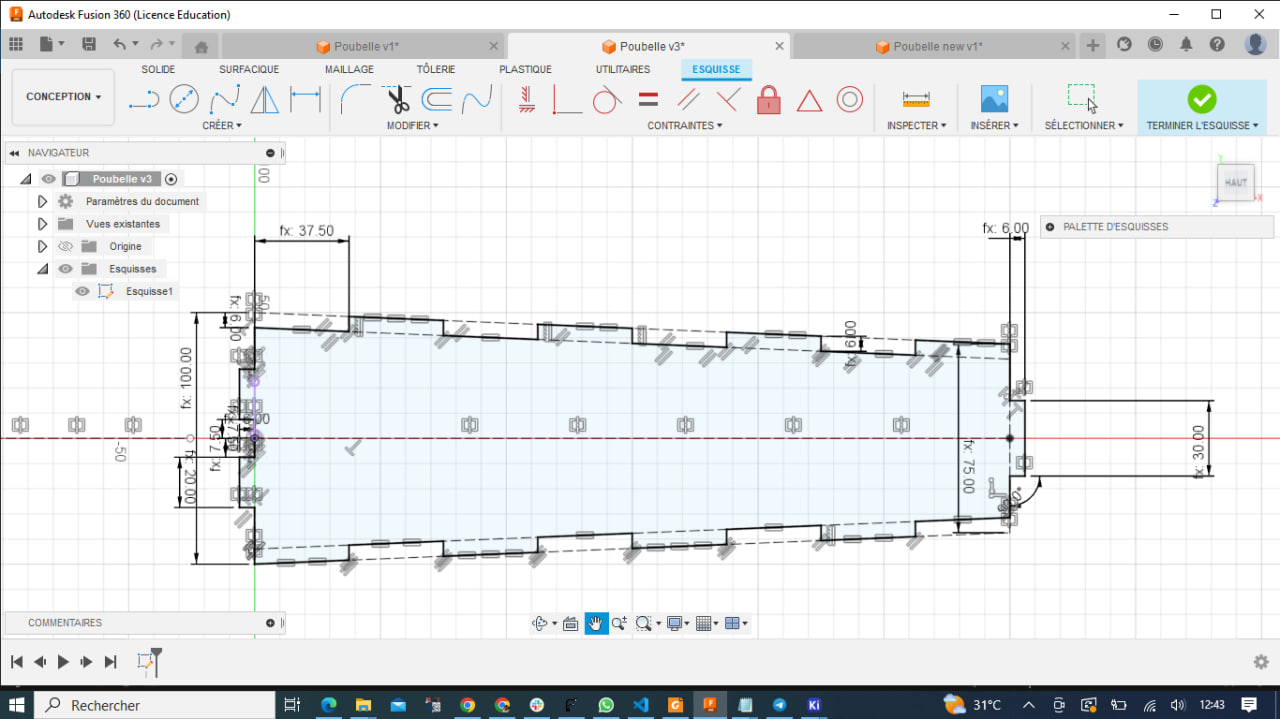

For the modeling, I decided to model part of the garbage can to be used in my final project. The model was created using fusion 360 software.

Fusion 360

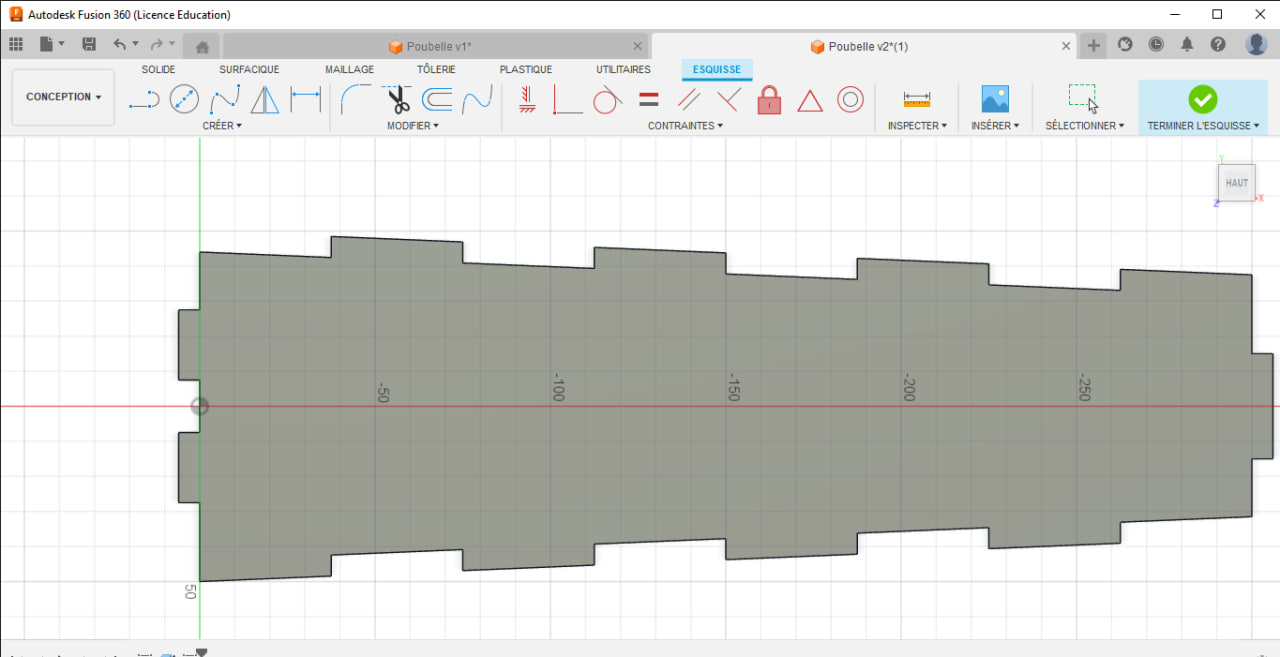

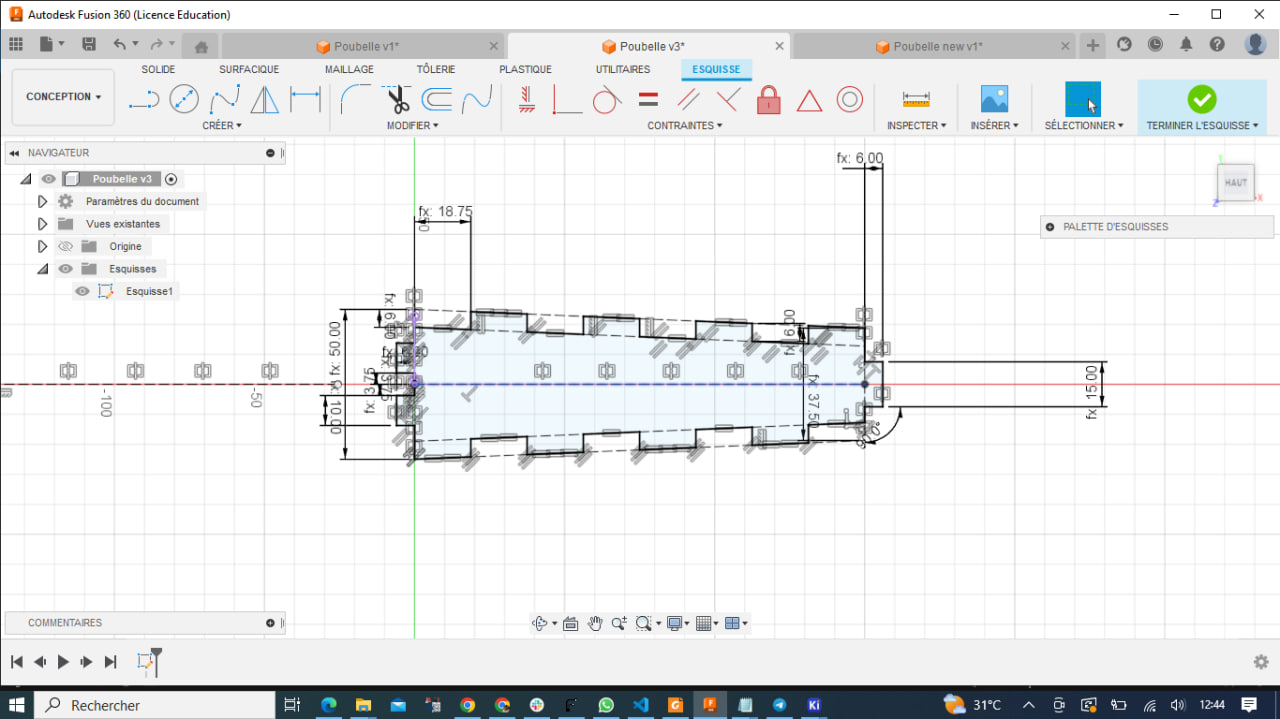

Here are a few images of the modeling

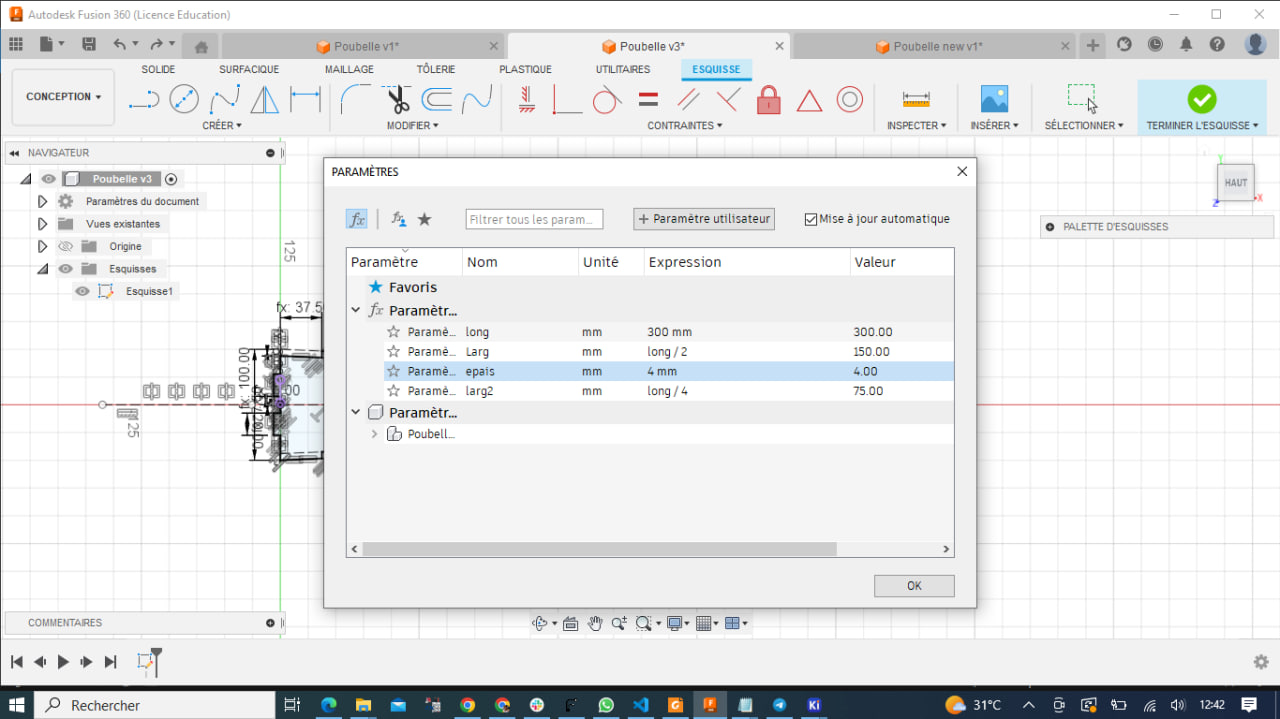

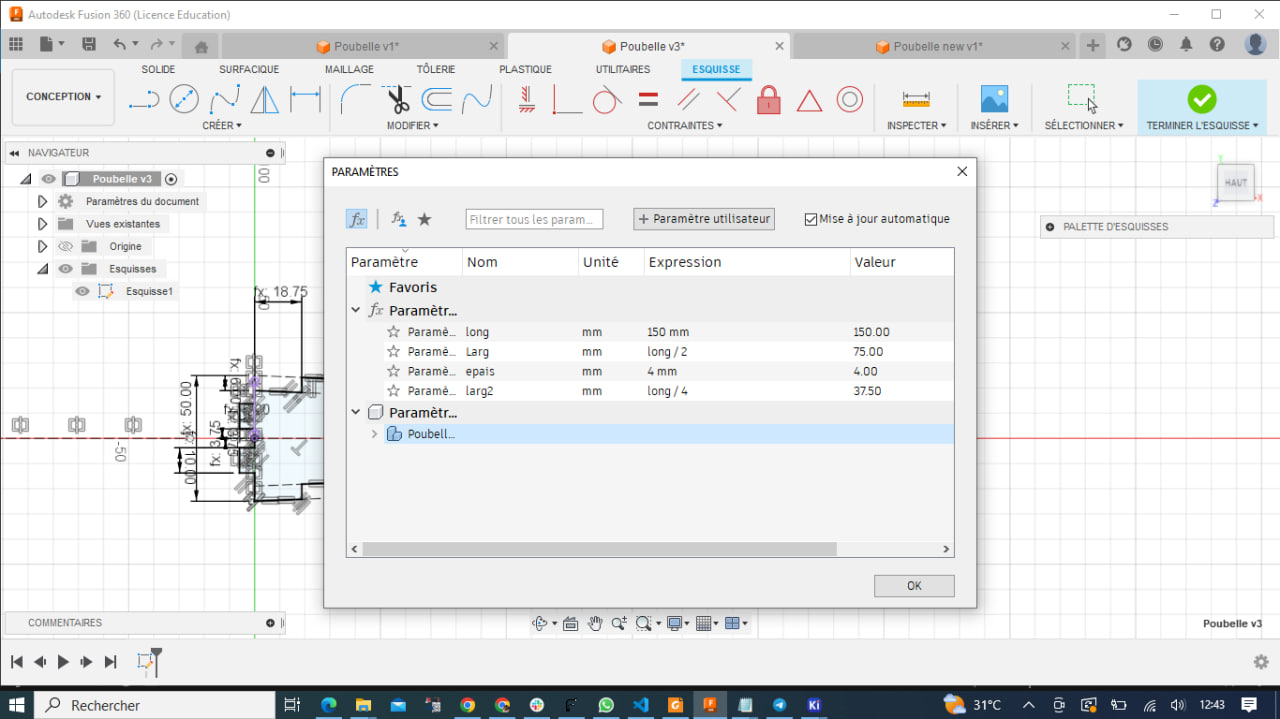

Parametrisation

As my modeling is parametric, I can modify my model by playing with a few parameters to adapt it to the material I want to cut. In my case, I’ll just modify the length to have 2 models of the same shape but different sizes.

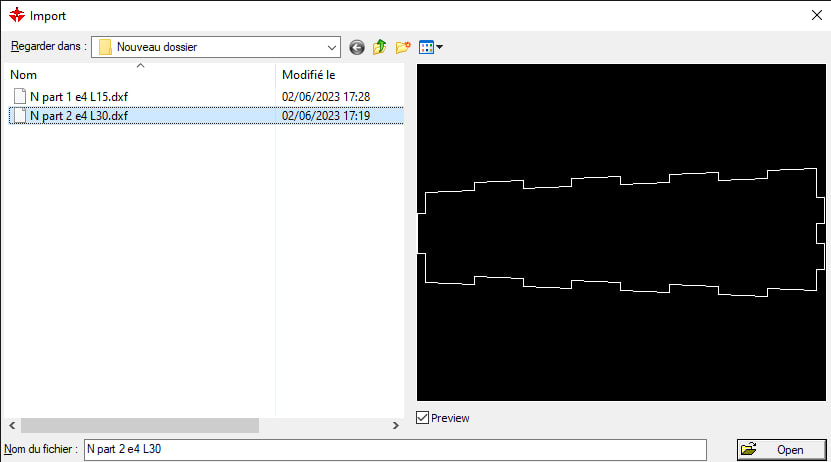

- My first model is 300 mm long and 4 mm thick

- My second model is 150 mm long and 4 mm thick

Step 2: Export dxf¶

To be able to use the software (RDWORK V8) that controls our laser cutter, I exported my 3D model in DXF format.

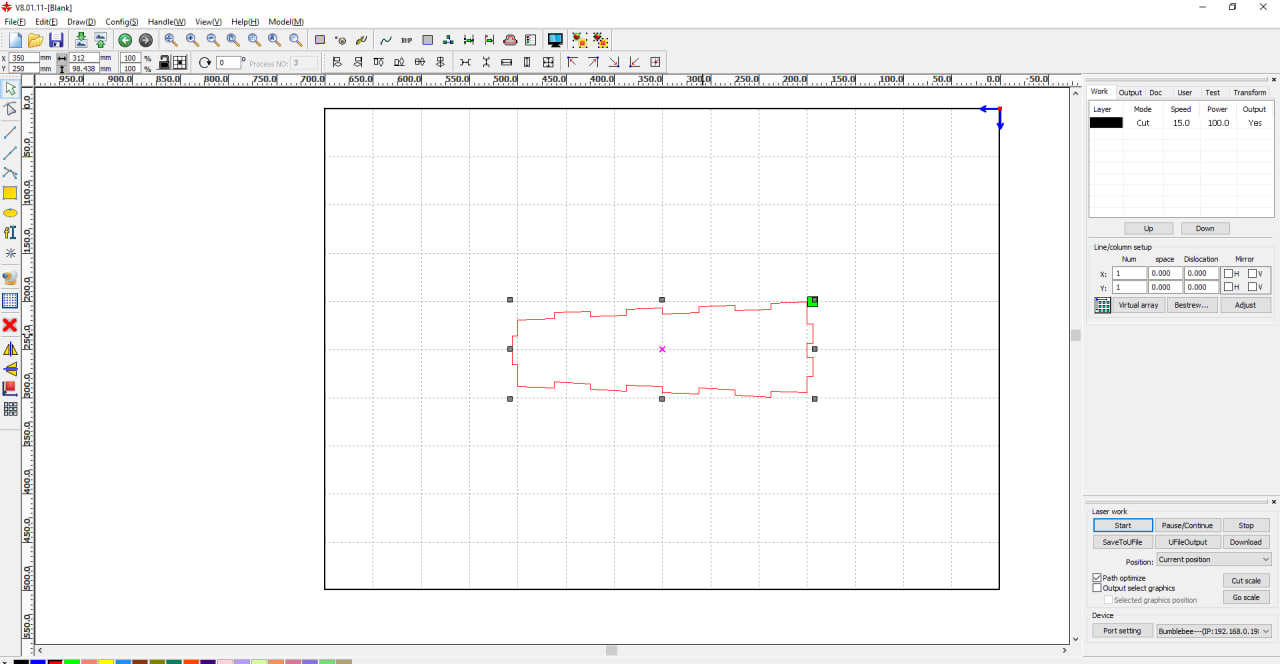

Step 3: Upload to software¶

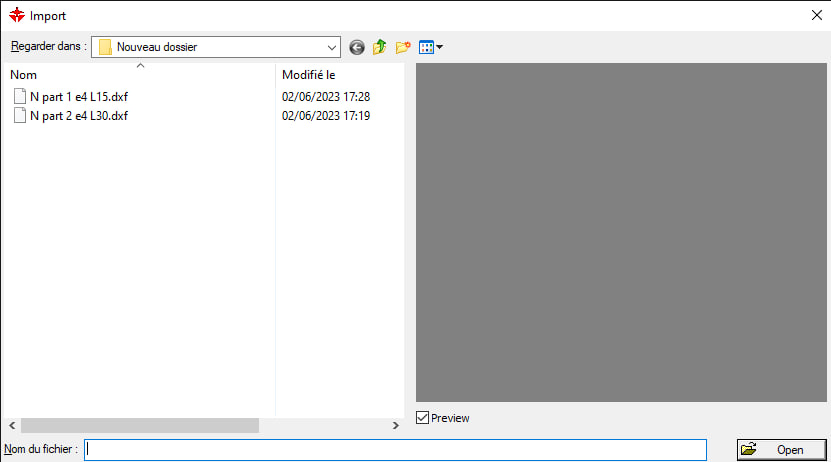

Now we need to import our file in “dxf” format into RDWORK V8 in order to parameterize it for cutting.

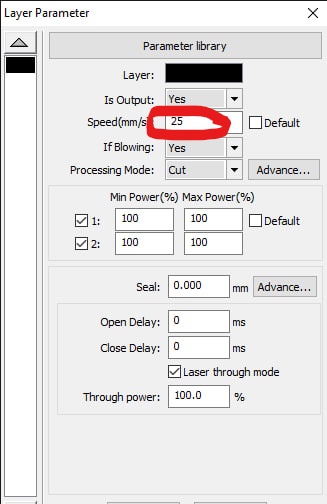

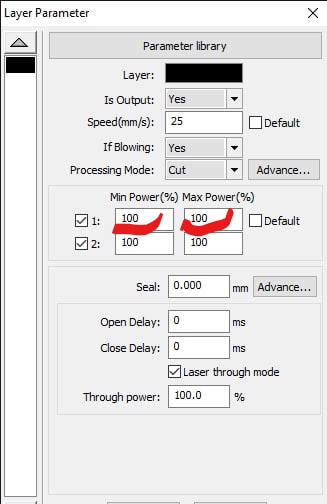

speed

For the settings, I’ve chosen a cutting speed of 25 mm/s.

Power

I’ve also set the power to 100%.

Step 4: Cut¶

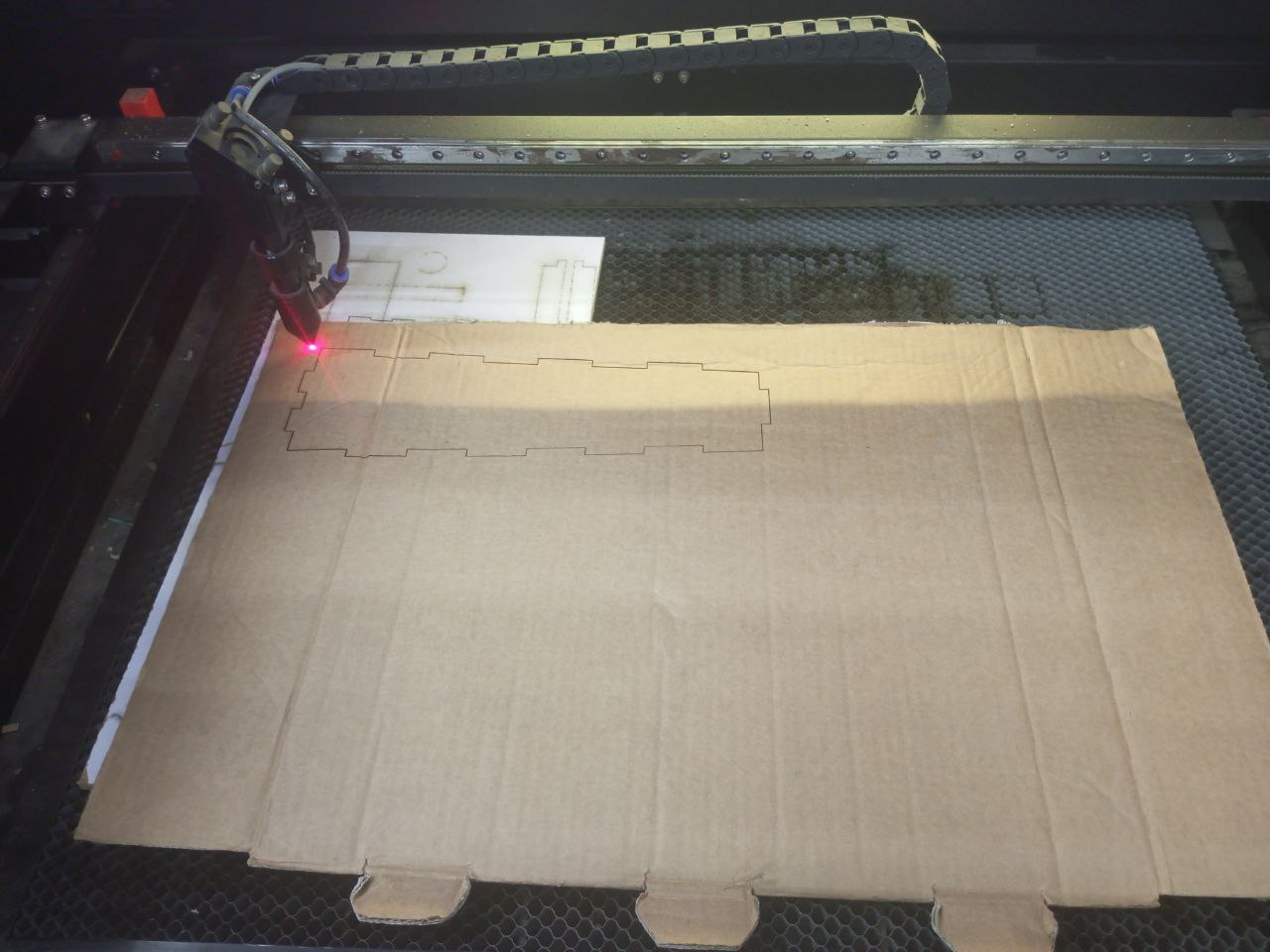

Having set up the software, let’s move on to our laser cutter.

Switch on

First, let’s switch on the machine

Place material

Let’s place the material to be cut in the machine. In my case, it’s cardboard.

Focus

Next, let’s calibrate the machine’s focus.

Start

At the end of all these steps, we can start the machine for cutting.

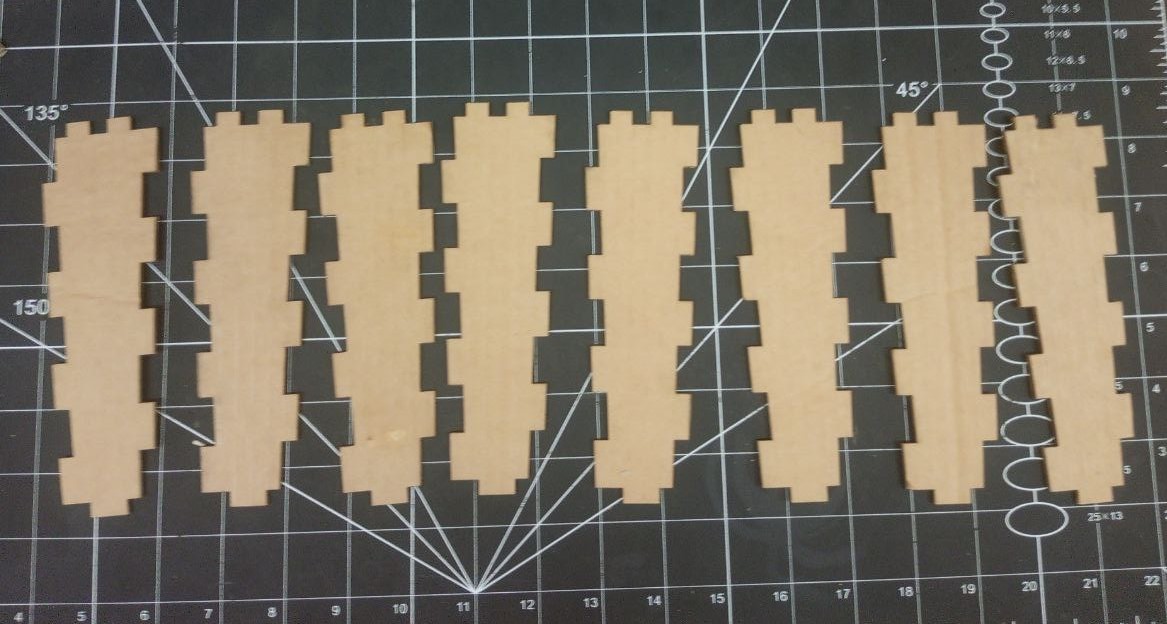

Results¶

Here are a few images of the product obtained after cutting.

Assembly

After complete assembly

Workflow: Vinyl Cutter¶

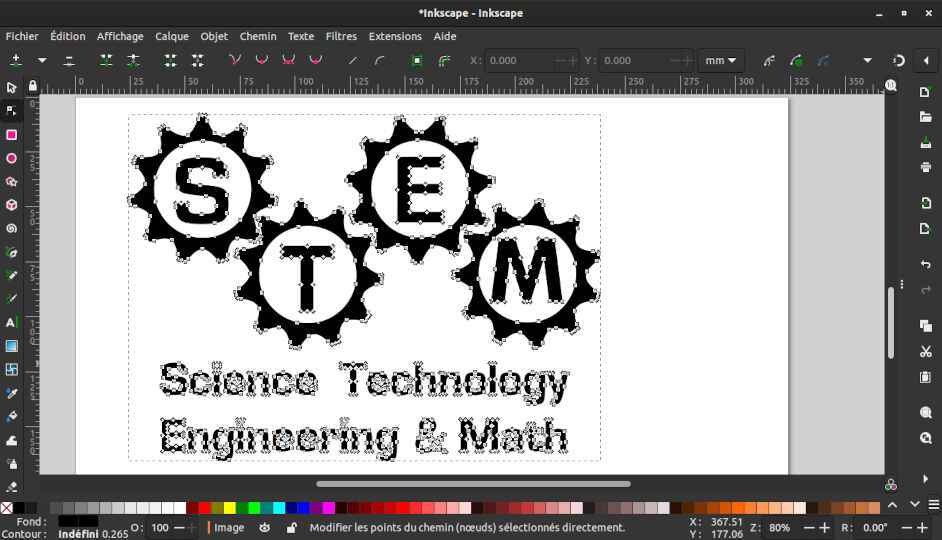

For the vynil cutter, we need to convert the file to svg. To do this, we’ll use the image I used in inkscape last week (Computer aided design).

Step 1: Creating the svg file¶

You can find the different steps I followed to convert the PNG image to “svg” format in this week’s Computer aided design.

Step 2: Loading the Vynil into the machine¶

Step 3: Import file into software¶

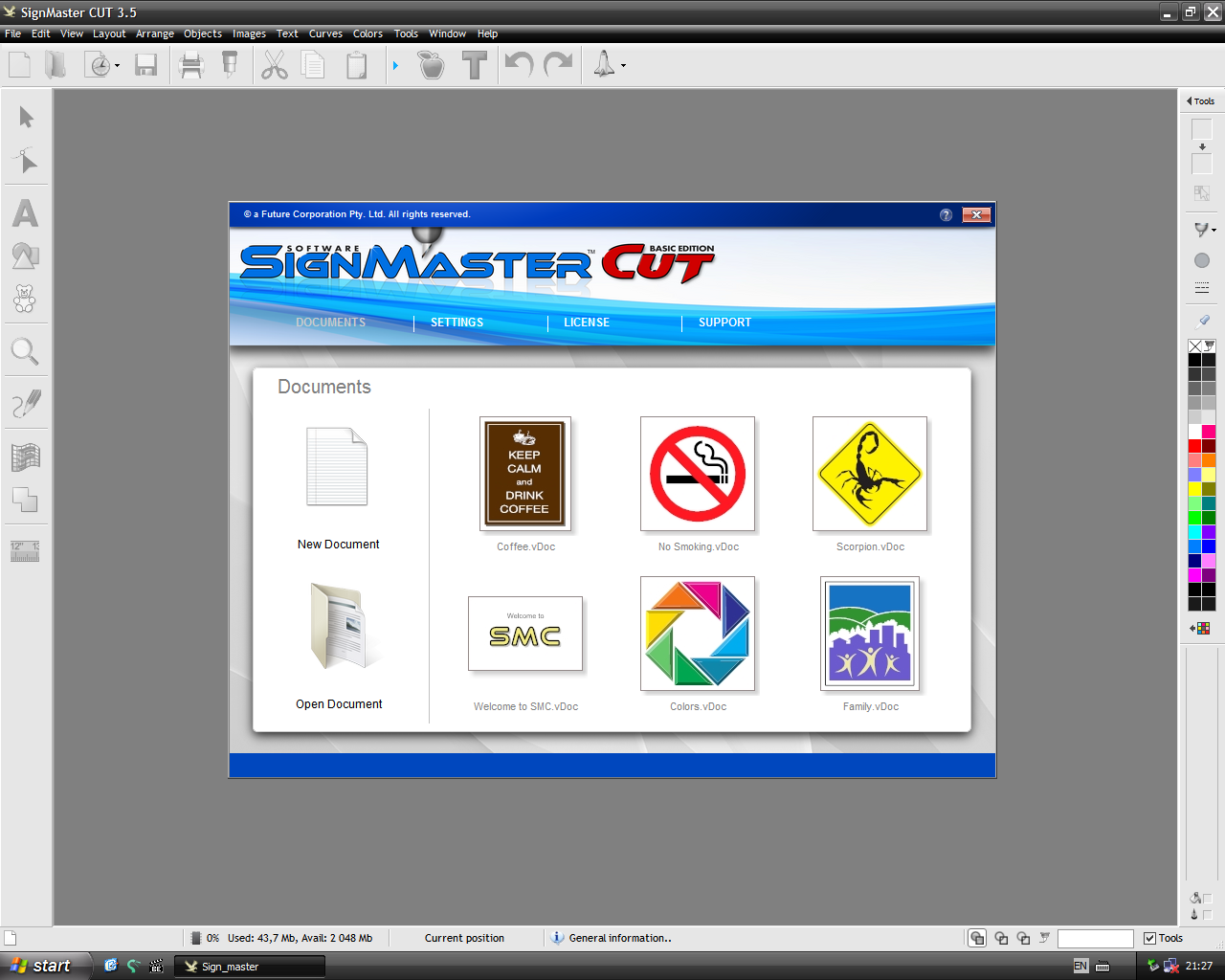

To control our vynil cutter, we use the software SignMaster CUT 3.5

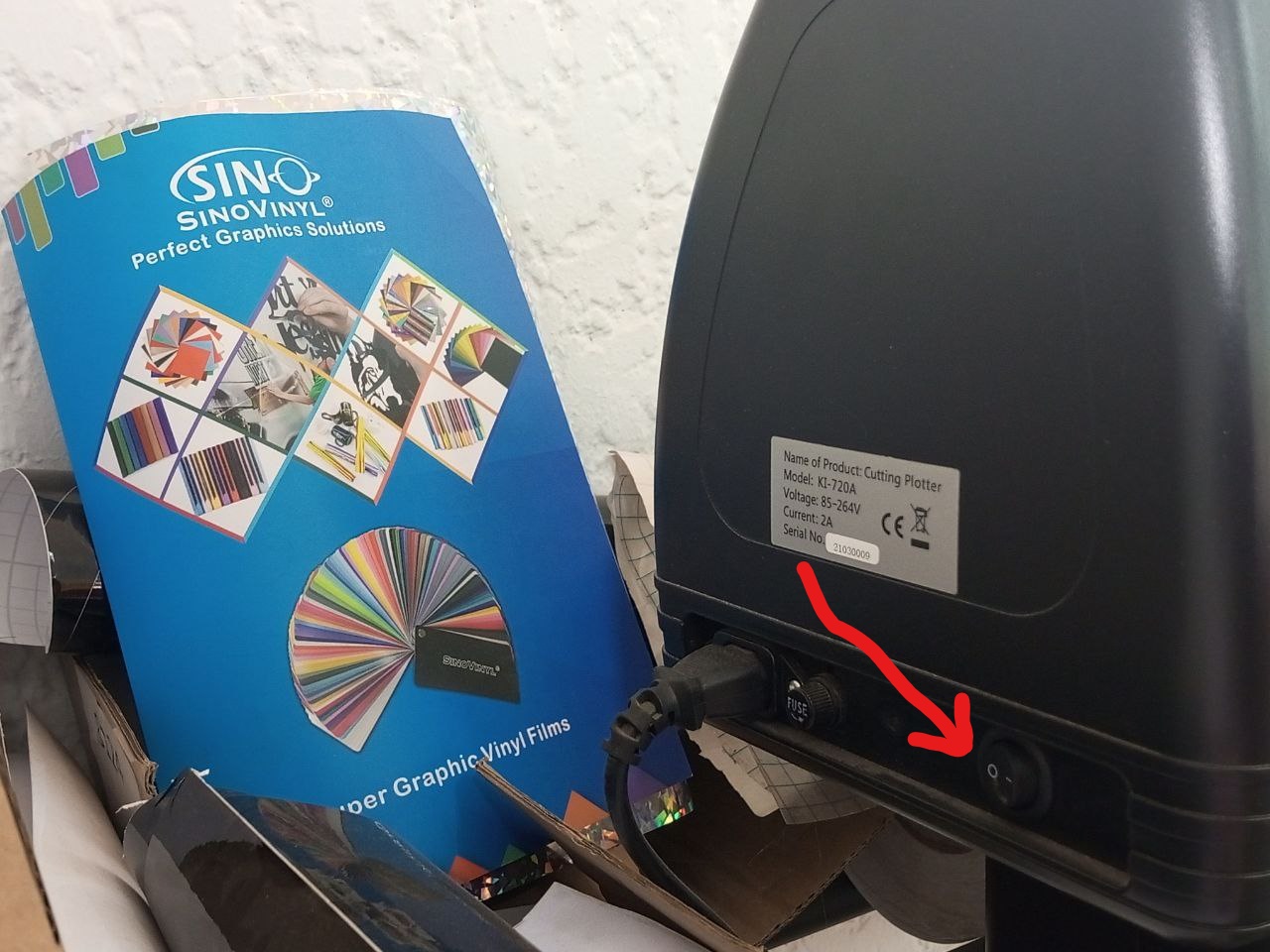

Step 4: Switch on vynyl cutter¶

Step 5: Start cutting¶

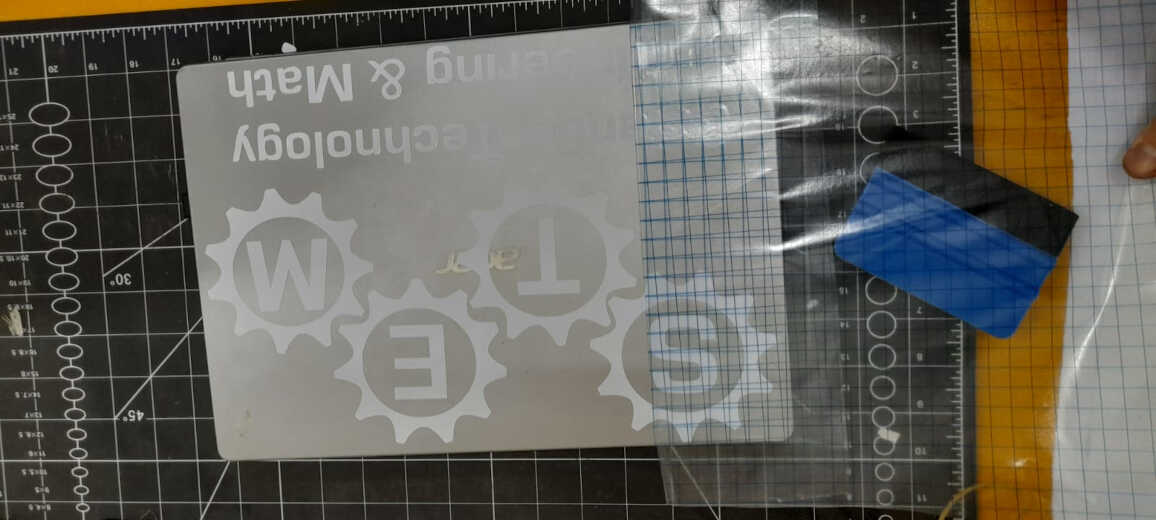

After all these steps, we’re ready to start cutting on the software

Step 6: Result¶

After all the cutting operations, I used the transfer ribbon to transfer my self-adhesive to my laptop, giving the final result below.

Files¶

What went wrong / what went well¶

During this module, I discovered and learned new things, namely how to use the laser cutter and the vynil cutter. I can say that everything went well. Nevertheless, there’s still a lot I need to learn about these machines. And I intend to do so over time.