19. Project development¶

Complete your final project, tracking your progress:¶

What tasks have been completed and what tasks remain?¶

- Completed Task:

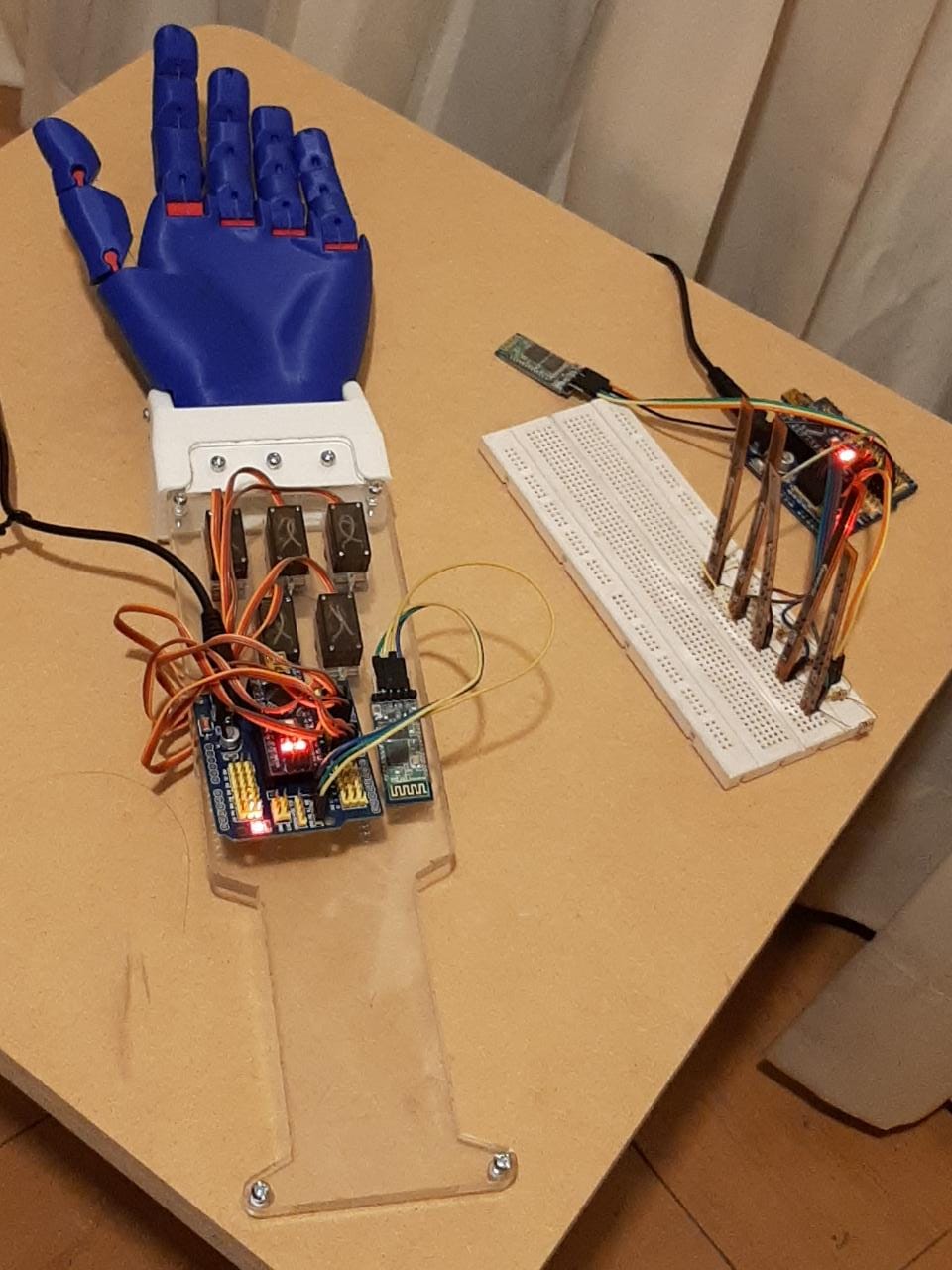

The design and manufacture of the plate, fingers, wrist in 3D printer and the arm in laser cut have already been completed, the servomotors have also been assembled and connected to the printed circuit of the microcontroller, of course the control program of the servomotors, with bluetooth network communication and the program on the other card with microcontroller for reading sensors and their respective sending.

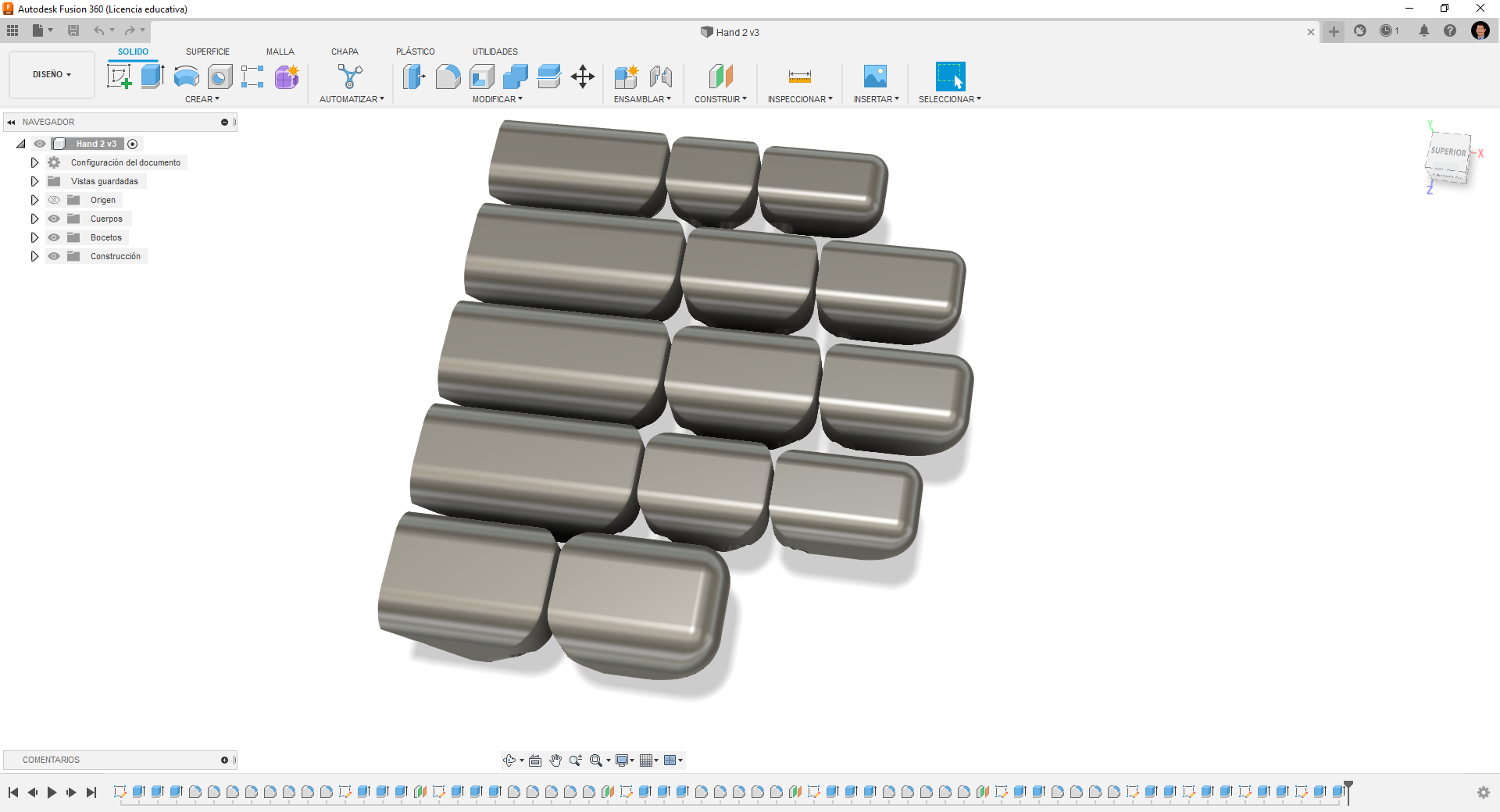

Fingers design.

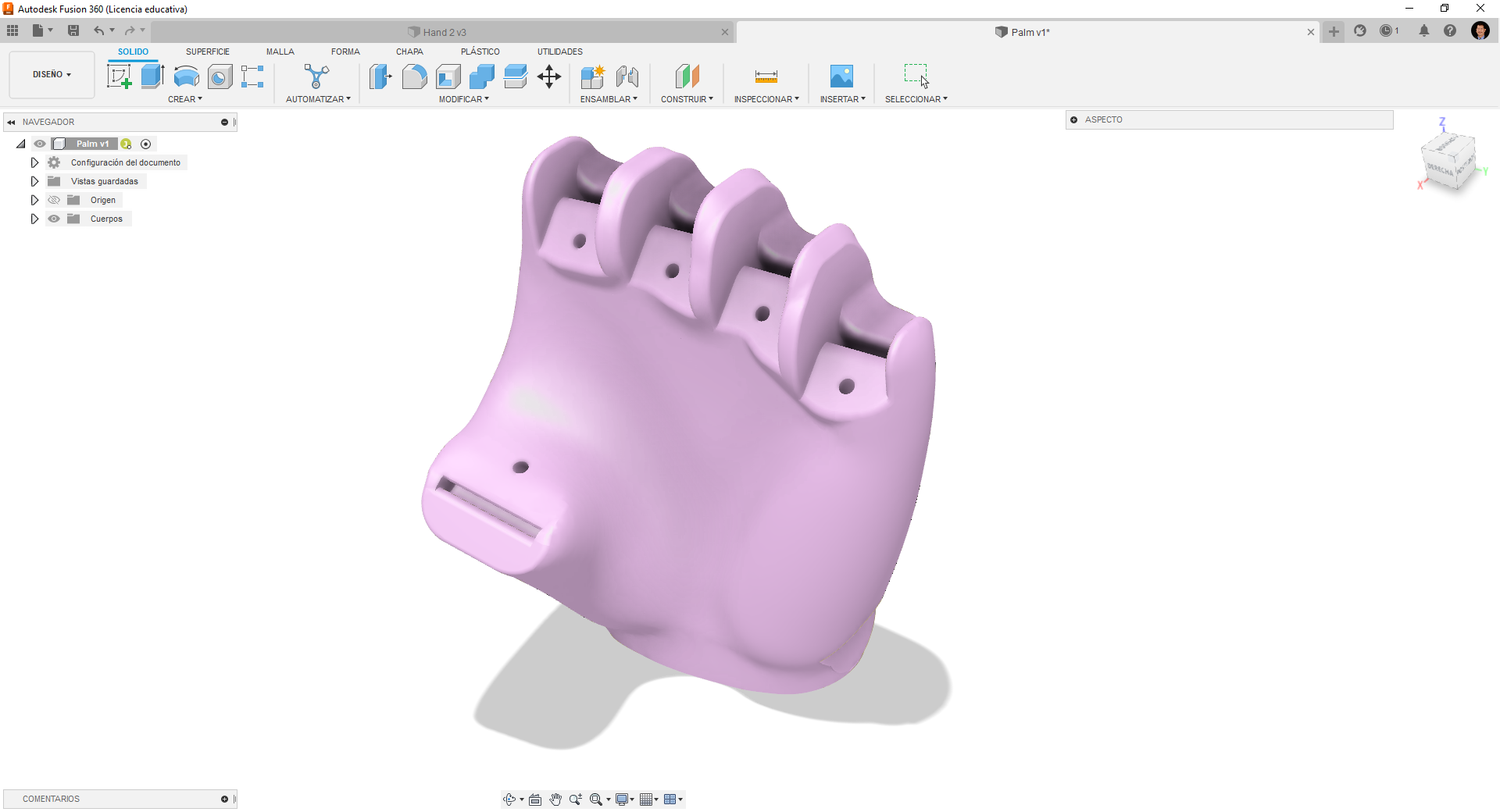

Palm design.

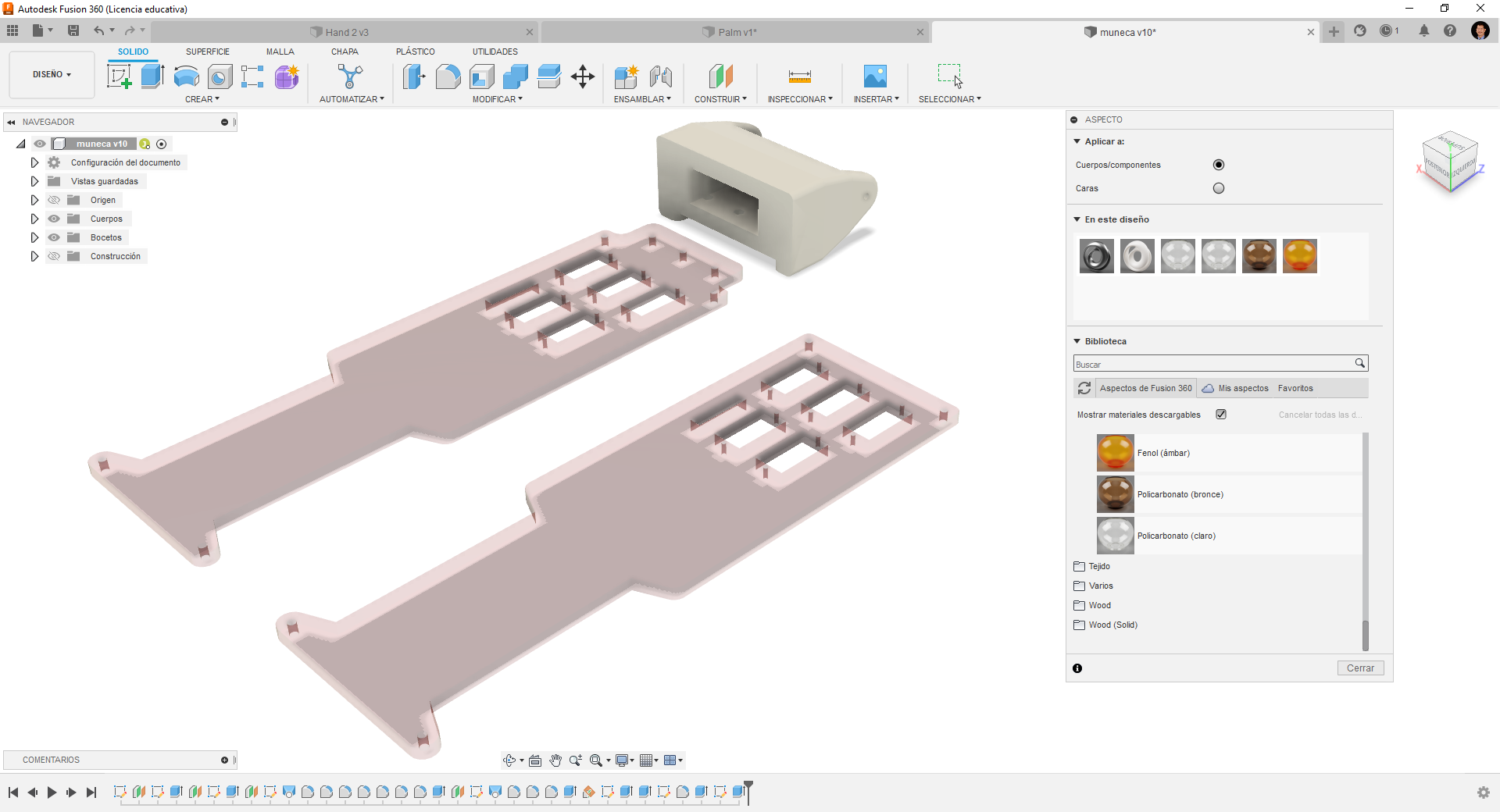

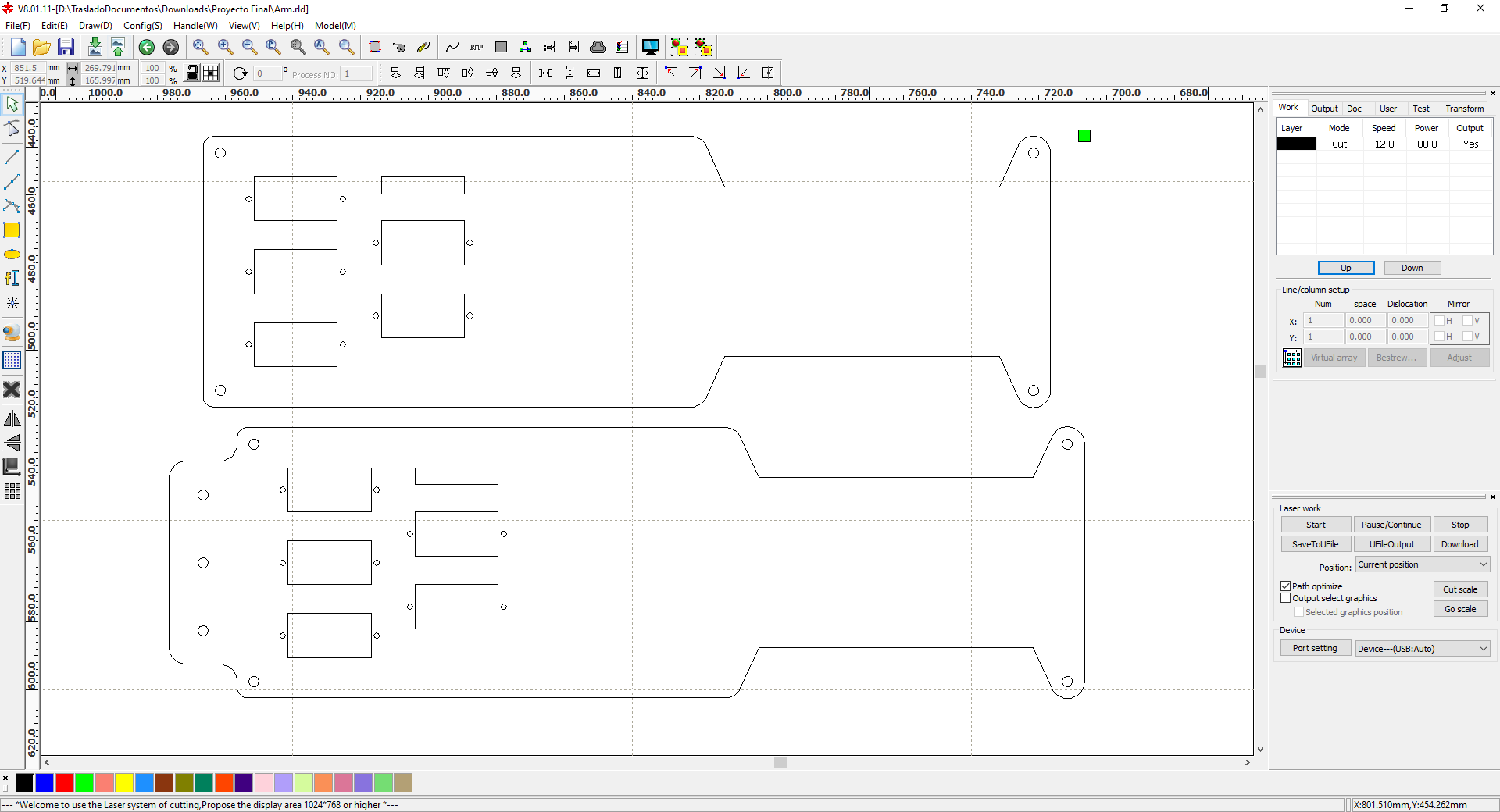

Wrist and arm design.

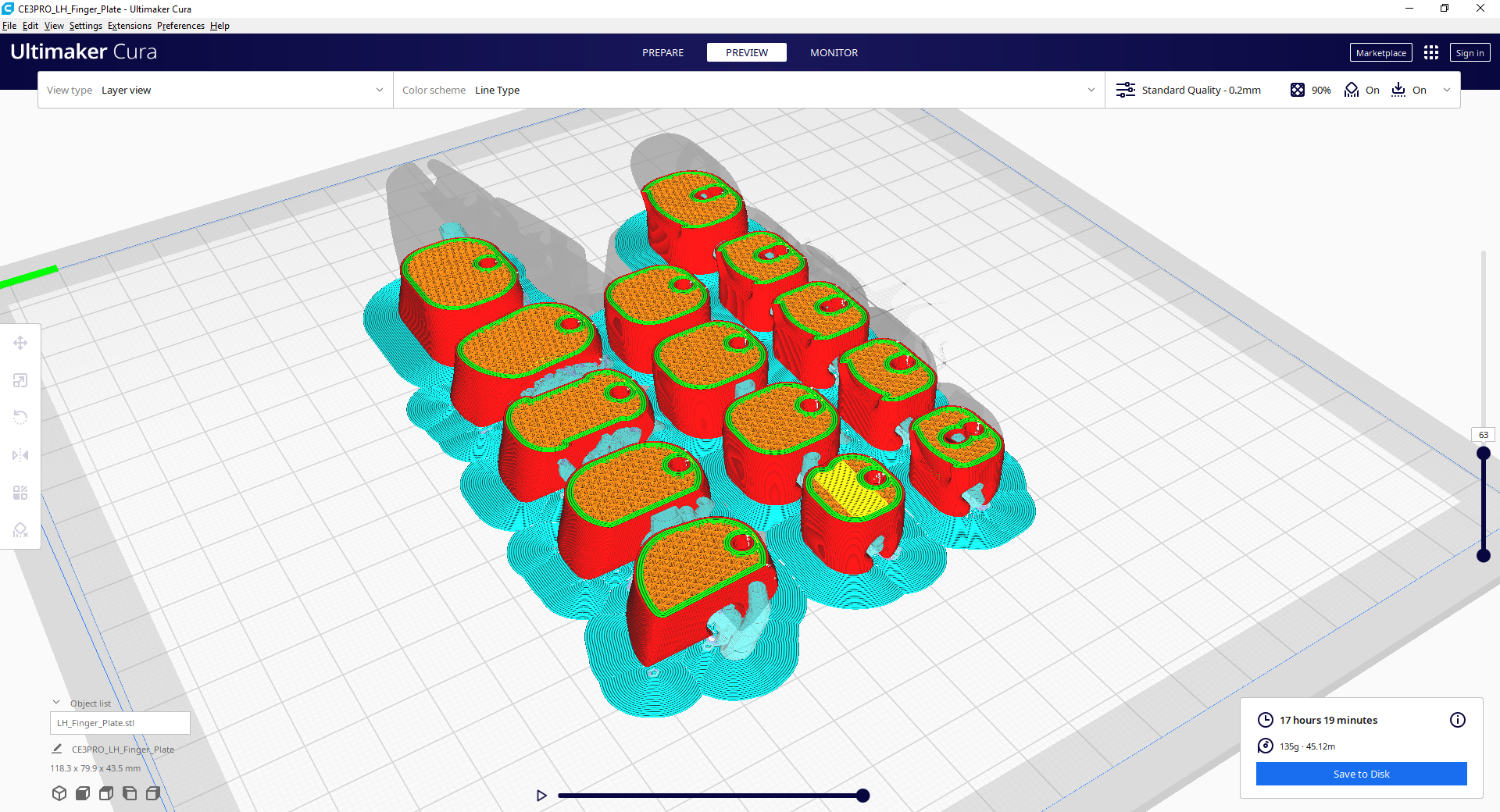

Slicing fingers.

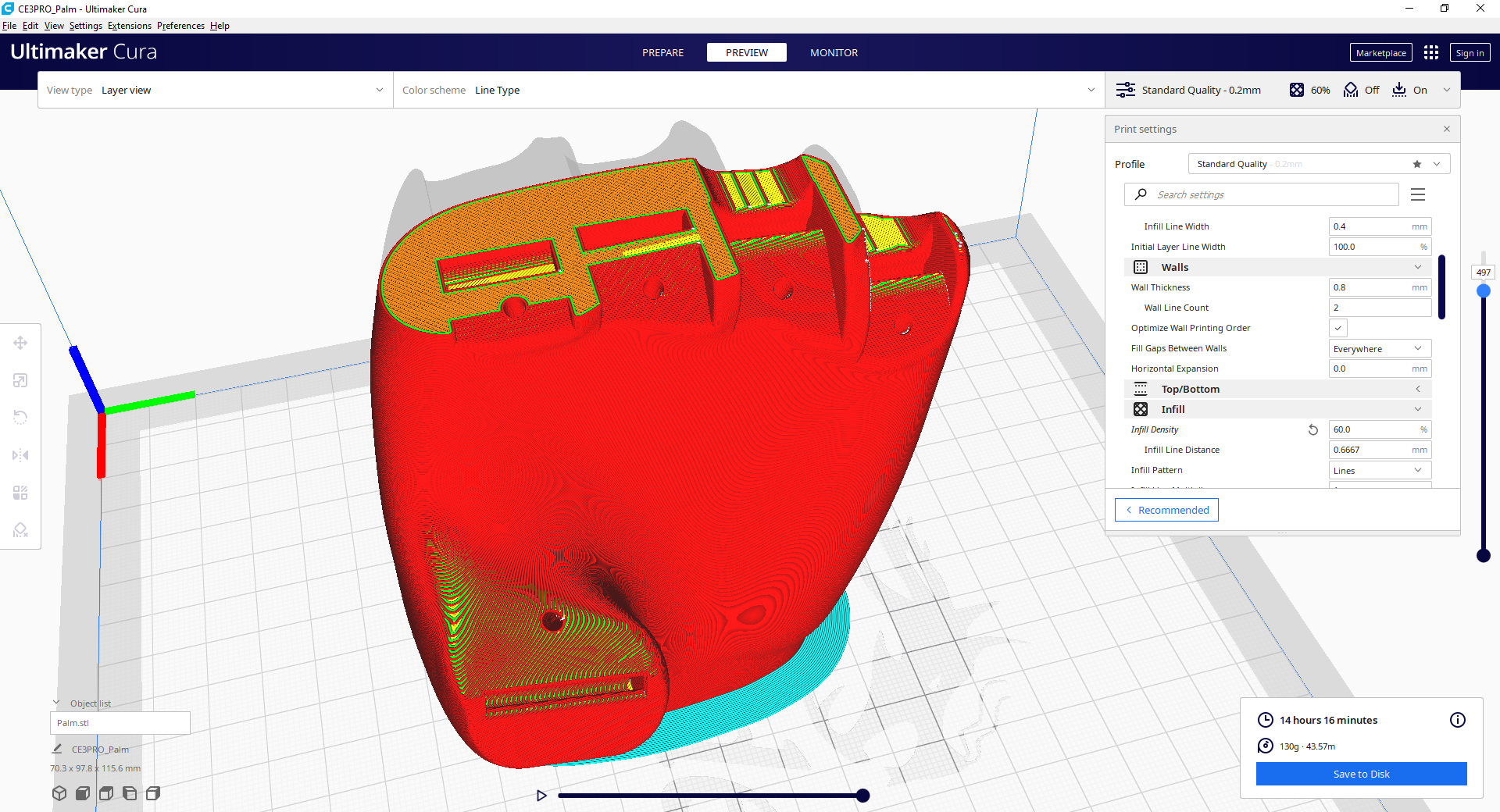

Slicing palm.

Setting up cutting operation for laser cutter.

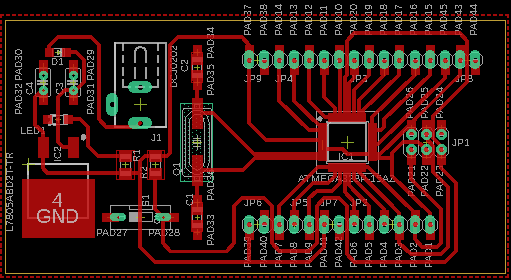

PCB microcontroller design.

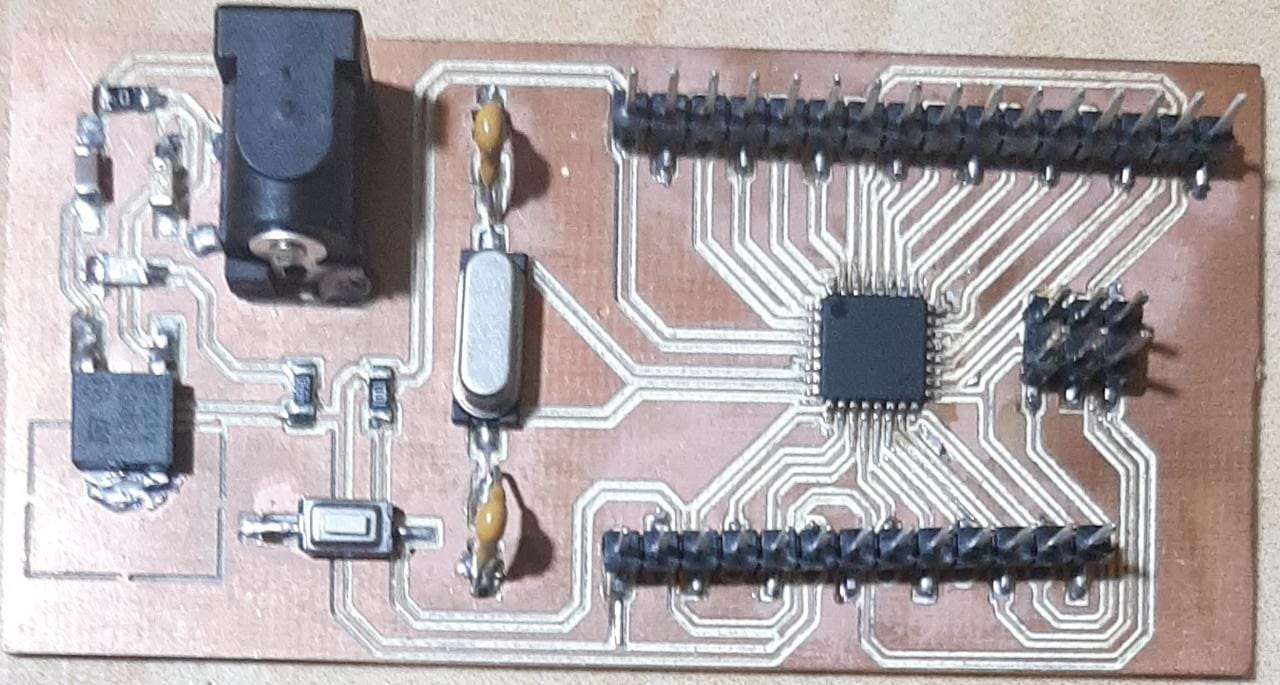

PCB manufacture and components.

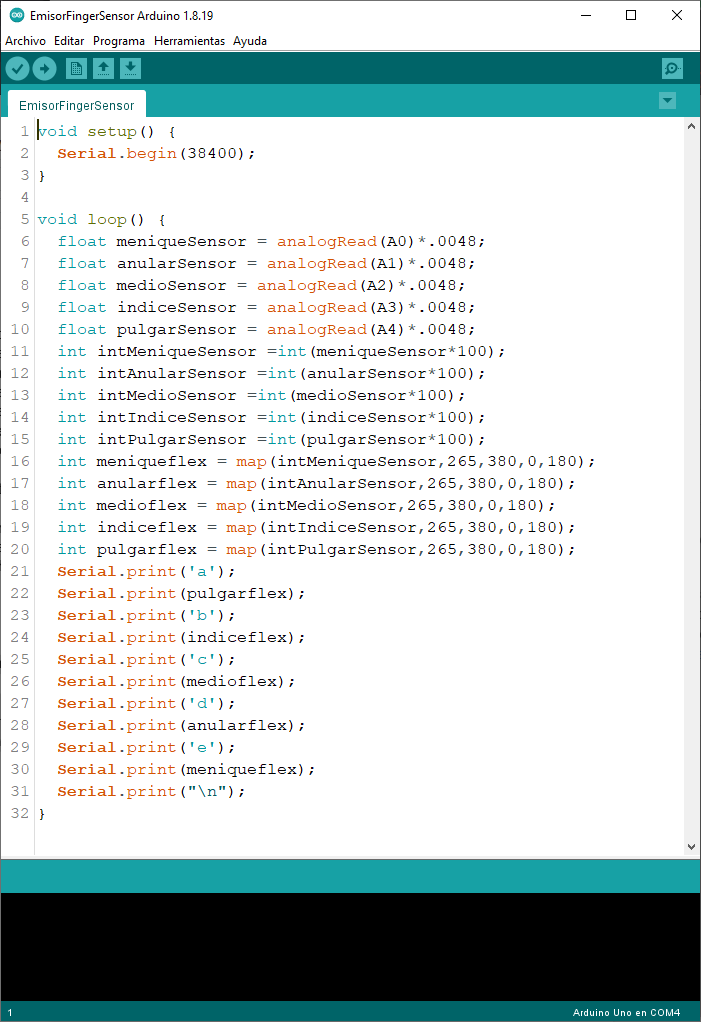

Programs for sending and acquiring data from flex sensors to control finger flexion.

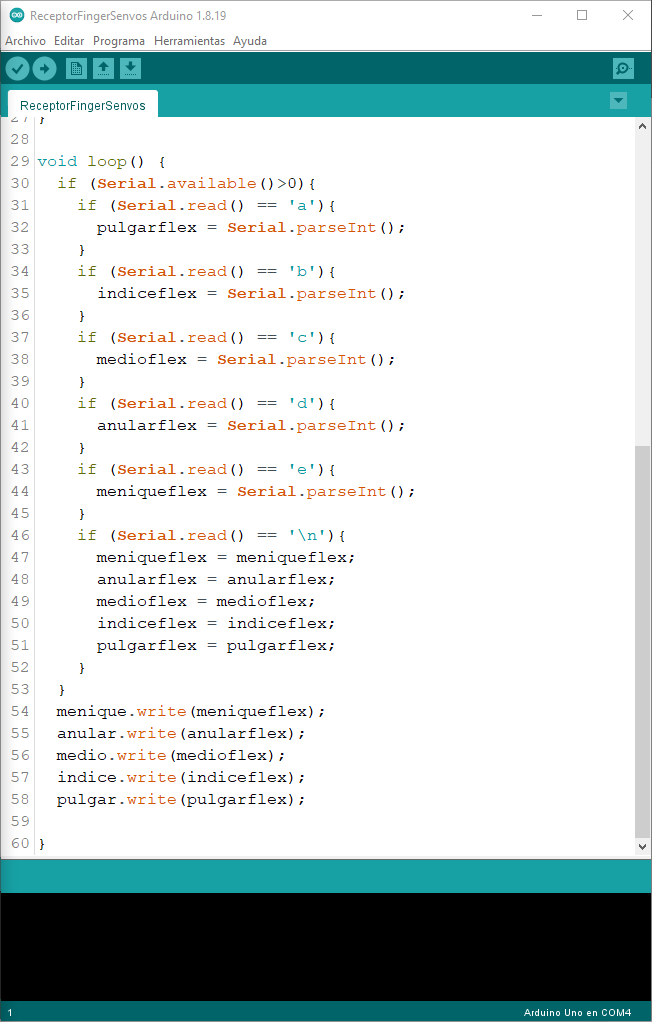

Programs for reception and control of finger servomotors.

Test of programs and assembly of the whole hand.

- Missing:

It remains to design the glove or mechanisms that will be used in the human hand, for now I am thinking of making it out of acrylic with laser cutting and finally completing the final presentation and the final video.

What is working? it’s not¶

According to my tests, everything done is working, however I noticed that when I flex 4 fingers or more, the mechanical hand replicates the movement for a few seconds and then the position is lost. I plan to solve this with the design of a card that only feeds to the servomotors, since for now I am removing the power from the same card of the microcontroller.

What questions need to be resolved?¶

What do I need to better feed the servomotors? What shape should the control mechanism be, maybe I should just wear a glove?

What will happen when?¶

I hope to find the inspiration to design the control mechanism, maybe I will need to study some mechanical design later.

What have you learned?¶

I really learned quite a bit. I learned different manufacturing processes and techniques, especially PCB manufacturing, since before I did it with the iron technique. Each week was a valuable opportunity to explore and strengthen the use of new tools and machines. I’m glad I joined this course, it expanded my knowledge in digital fabrication.

Project management:¶

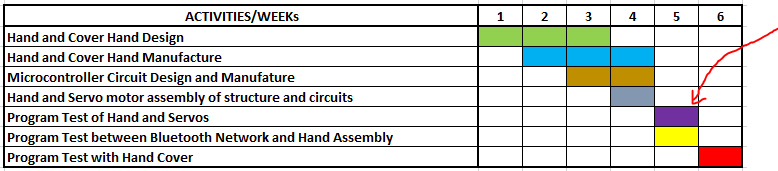

According to my timeline, I am 2 weeks late, the design of the palm and the fingers took me much longer than I expected, it was 4 weeks to get my design satisfactory. I tried to catch up but I could only recover 2 weeks, that’s why I’m a little behind.

The arrow indicates where I am now.