Molding and casting¶

This week there are two types of assignments, one group and one individual. In my case I’m alone in ESNE’s Fab Lab so I am doing both.

Assignment¶

Group assignment:

- Review the safety data sheets for each of your molding and casting materials, then make and compare test casts with each of thems

- Extra credit: Try other molding and casting processes

Individual assignment:

- Design a mold around the stock and tooling that you'll be using, mill it, and use it to cast parts

- Extra credit: Use more then two mold parts

Group assignment¶

Group assignment page¶

In the following link you can access the Leon Fab Lab page that contains all the group assignments: Fab Lab Leon group assignment page

Review the safety data sheets for each of your molding and casting materials¶

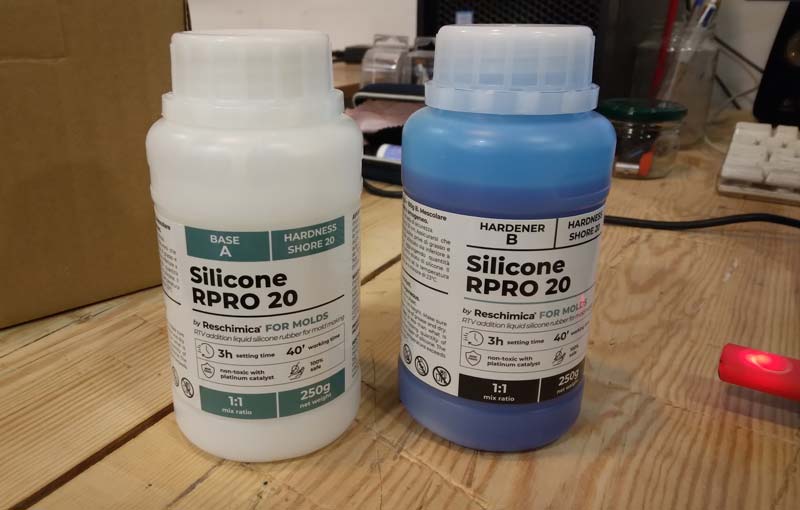

Last week my Leon Nuria instructor sent me the silicone along with a millable block of wax for this week’s homework

My silicone is RPRO 20 from Reschimica, it is a bi-component addition rubber (base + platinum catalyst) of orange color that thanks to its low viscosity and high elasticity allows copying faithfully even the smallest details. It has excellent resistance to tearing, great resistance to high temperatures and aging and an excellent non-stick effect. The main areas of application are:

- Mouldmaking and modeling (due to its remarkable reproduction precision, high dimensional stability and high mechanical strength)

- Artistic ceramics (due to the high dimensional stability, the remarkable fluidity, and the good mechanical resistance)

On the manufacturer’s website you can download the material’s technical sheet, so I downloaded it to attach it to my documentation.

Individual assignment¶

Design a mold¶

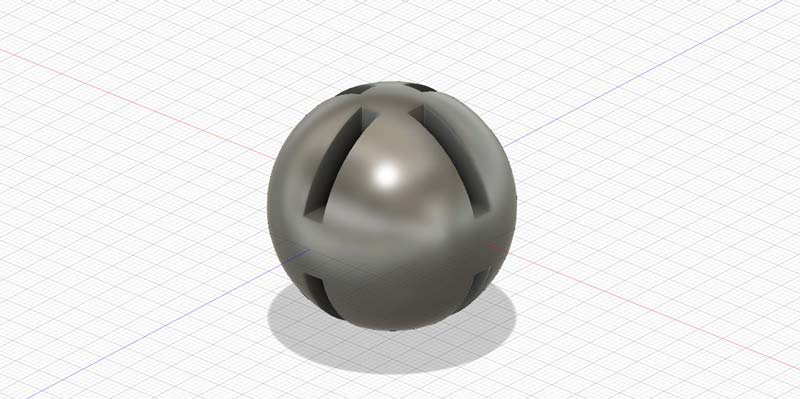

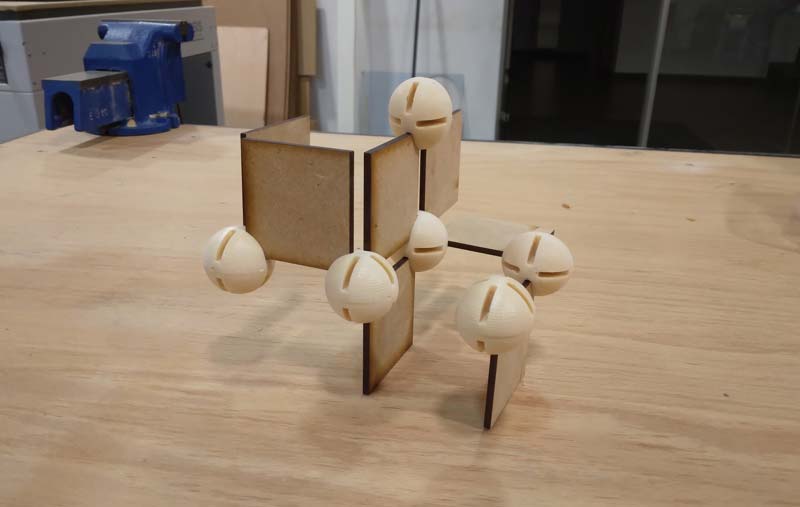

Since I was going to make a mold I wanted to design something that would make sense to replicate several times, the design that I wanted to get out of my mold was a sphere with 8 holes, this sphere would be part of a “construction toy” with it you could join DM pieces together and build something bigger.

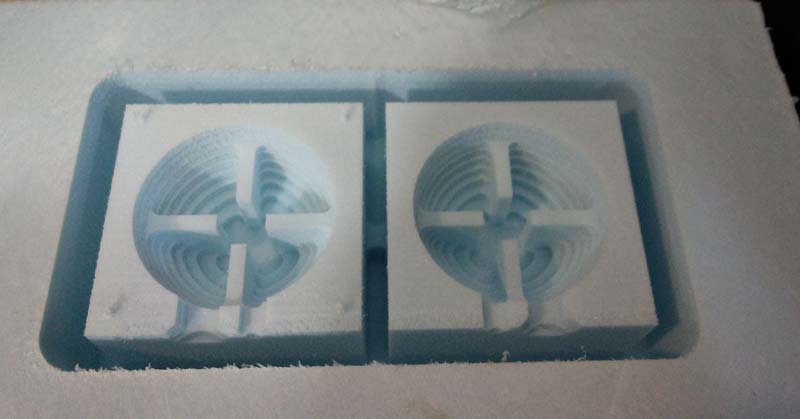

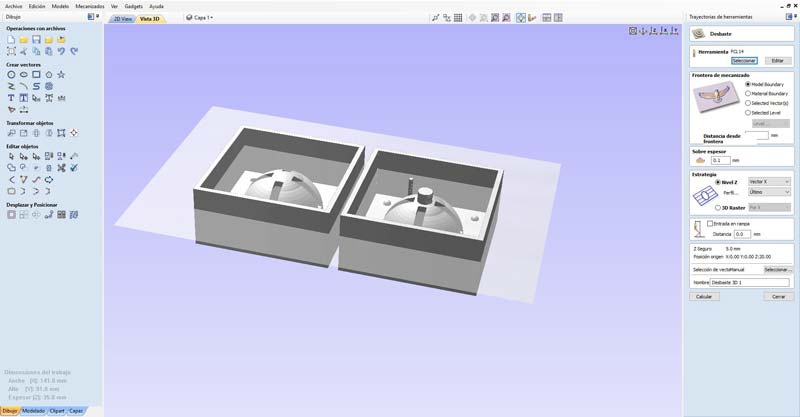

As I only had a block of wax to mill when I had the design of my mold, I first milled it in foam, first I did the roughing and then the finishing.

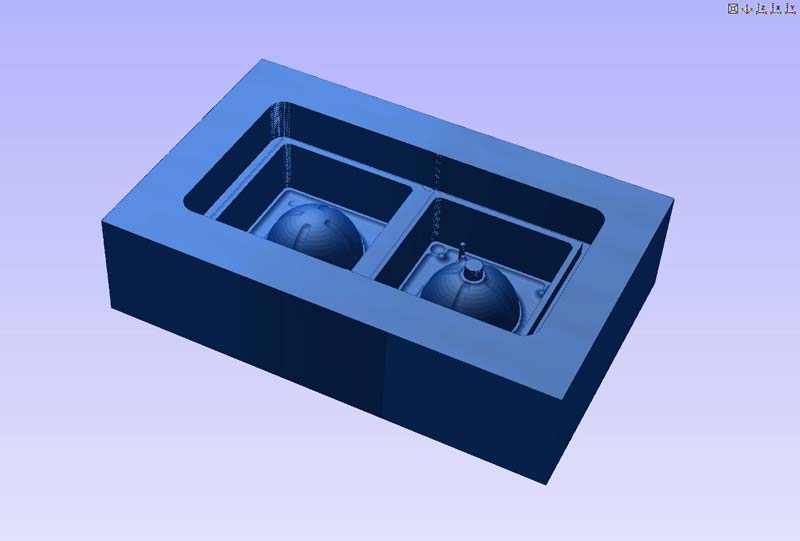

When talking to my instructors in León and passing them the photos, I realized the mistake I had made, I needed the opposite of what I was doing! At least I had milled it in foam and could correct the design and mill it in wax. I changed the design of the mold in Fusion 360 and did a foam test again, as the test worked well, I went on to mill it in wax.

In the following video you can see how I designed the mold in Fusion 360

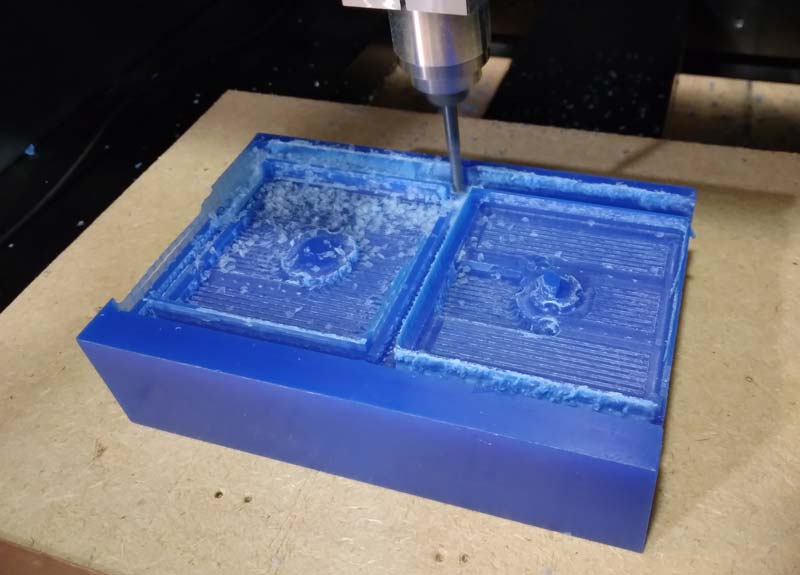

When I was already milling about 15 mm of my design the light of my Fab Lab went out :(I lost the zeros of the milling machine and the gcode generated in VCarve, in addition I had lost the first 10-15 mm of my wax pear to mill

To fix this I scaled my design so that it lost height, then milled out the first 15mm of my wax block to leave a flat face. When the face was flat my new (smaller) design would fit on the new wax block.

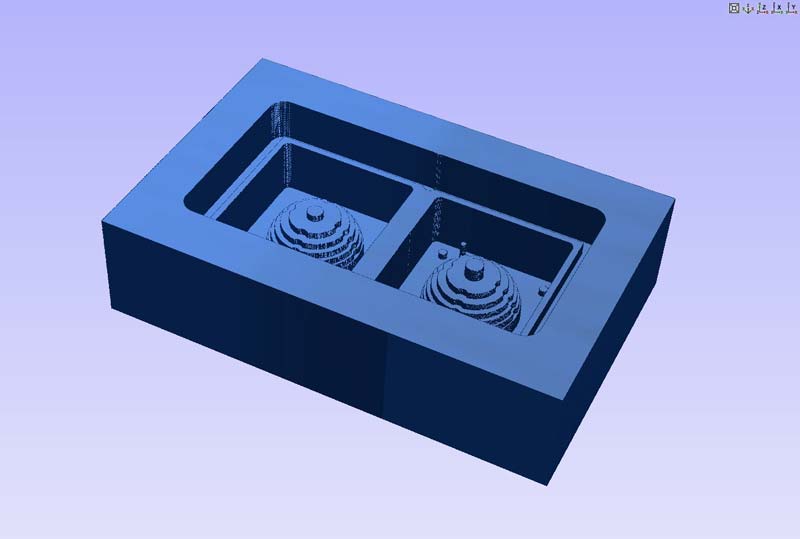

I put the new design back on the milling machine to do the roughing, this time the light did not go out and I got the first step to make my mold.

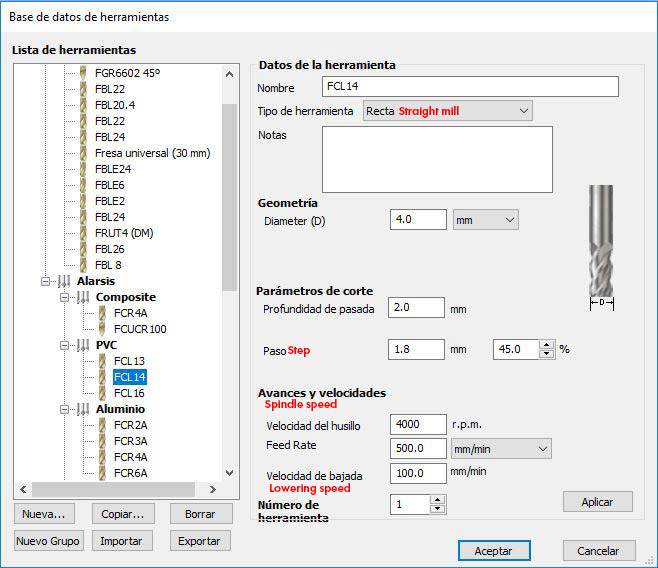

This time I tried to do the roughing with a special FBL cutter for cutting plastics, it is a single flute.

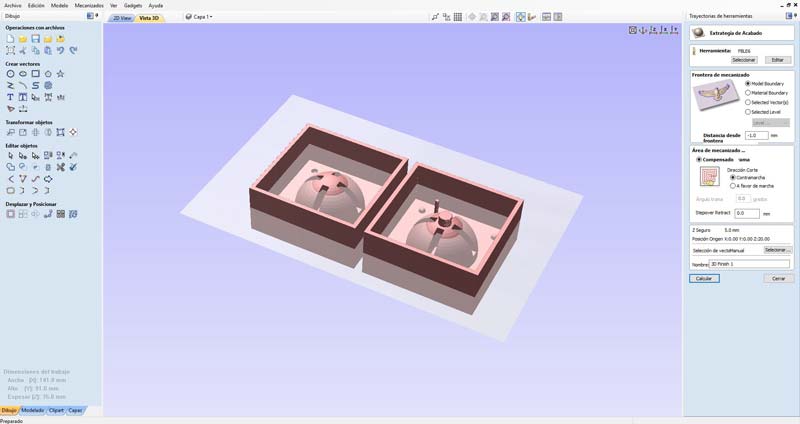

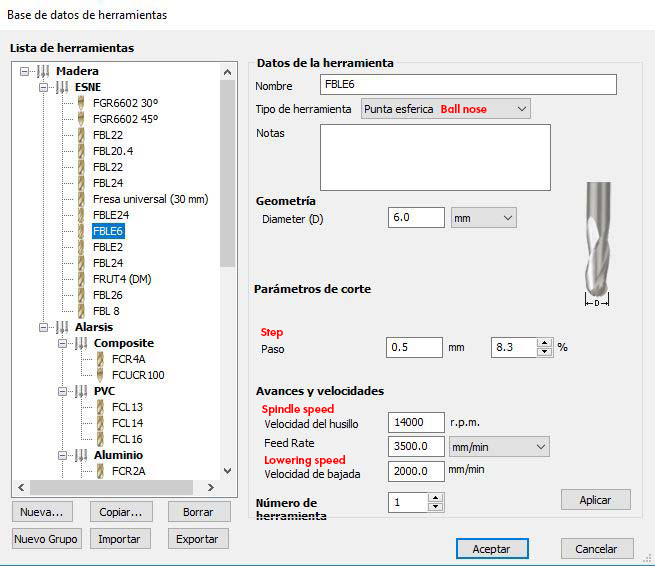

Then I finished with the round end mill.

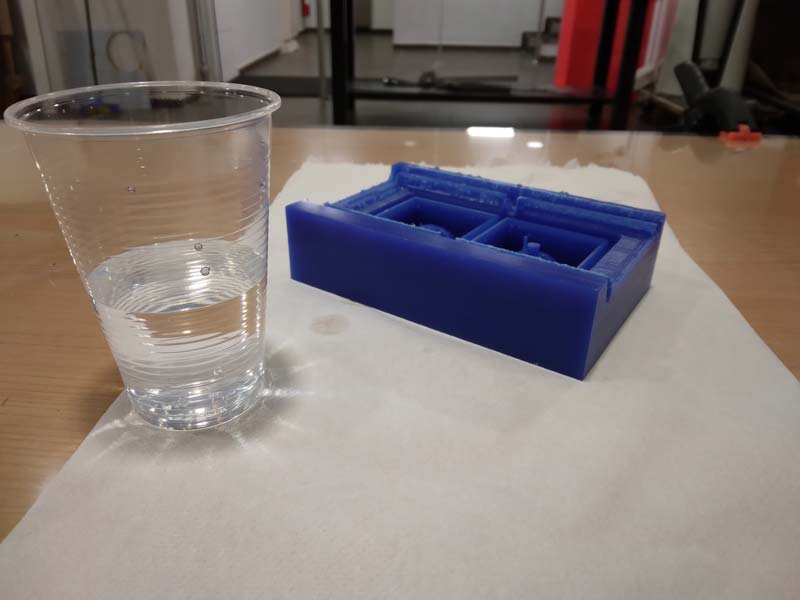

With my block of wax ready I measured the volume of silicone I would need to fill the mods, use water to fill it and then measure its volume.

Before putting the silicone, go over the female holes of my mold since they had been too small to make a little bigger.

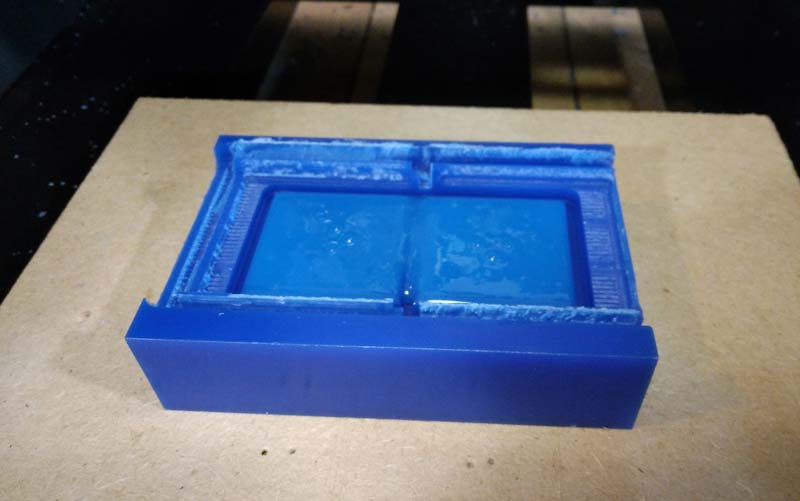

Then I prepared the silicone mixture and put it in the mold, I had to wait about 3 hours as indicated by the manufacturer, the measure sistem works very well, i dont waste any silicone almost.

Wait about 4 hours to unmold the silicone mold from the wax, the result was very good

I already had my silicone mold ready, now I had to find something to make my pieces with. In the store I found polyurethane resin , it had been there for at least two years and it was also open. I did a test mixing it in a plastic cup to see if it worked, surprisingly it did.

The supplier says the following about this resin:

FEROPUR PR-55 is a fast two-component polyurethane that hardens at room temperature to work by casting. The product is made up of a colorless resin (polyol) and a yellowish hardener (isocyanate), both unfilled.

FEROPUR PR-55 offers excellent fluidity, easy manual mixing and adjustable viscosity by simply adding more or less filler, to achieve the required level of reproduction fidelity. The qualities of the product are its rapid hardening and the easy machining of the hardened material.

The technical sheet of the resin was available on the web, so I downloaded it and attached it to my documentation.

The best thing about using this resin is that the working time is very fast (60 seconds) and the curing time too (8 minutes), so in a very short time you can make several pieces.

I started by holding the silicone mold with a rubber band, but this rubber squashed the mold too much and my sphere was not shaped like a sphere but rather an egg.

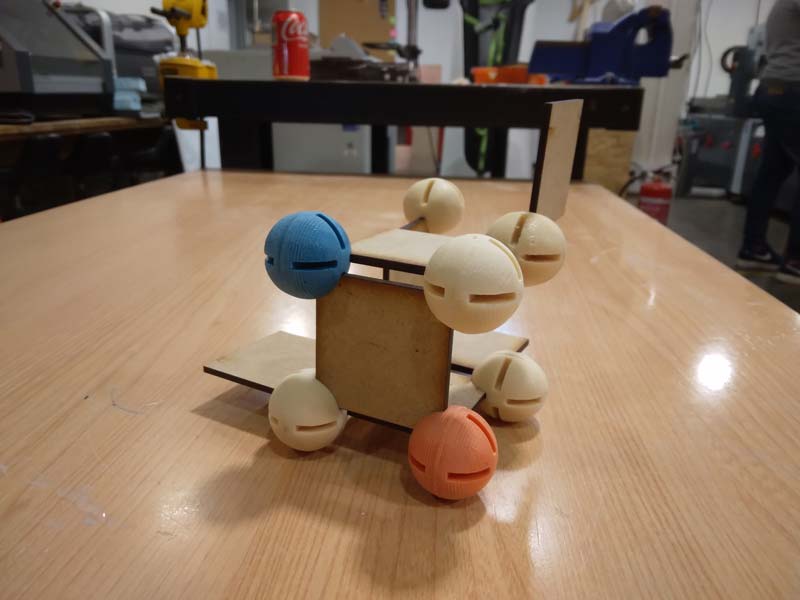

I tried to make the spheres without holding the mold with the rubber and the resin did not escape, so I made the rest of the pieces without rubber, in this way the sphere was perfect

After that, all that remained was to cut the hole through which the resin entered and sand the edges.

All ready to build a structure with the sphere connectors.

Blue pigment + flexible polyurethane resin¶

After the first piece I tried another flexible polyurethane resin mixed with blue pigment for resins

The resin is the Feroca Easyflex 60, I will leave the technical sheet uploaded in my documentation

This resin with the blue pigment was denser than the one I used before, also the reaction made quite a few bubbles that remained inside the mold, I think I used too much blue pigment in the mix…

Red pigment + polyurethane resin¶

Then I did a test with the red pigment and the non-flexible polyurethane resin, this time I used less pigment and the result was very good.

Download archives¶

Reschimica datasheet (Silicone) .pdf

Feroca datasheet (Polyurethane resin) .pdf

Sphere mold .stl

See you next week!