3D Scanning and printig¶

This week there are two types of assignments, one group and one individual. In my case I’m alone in ESNE’s Fab Lab so I am doing both.

Assignments¶

Group assignment:

- Test the design rules for your 3D printers.

Individual assignment:

- Design and 3D print an object that could not be made subtractively.

- 3D scan an object.

Group assignment¶

Group assignment page¶

In the following link you can access the Leon Fab Lab page that contains all the group assignments: Fab Lab Leon group assignment page

Print test¶

In each of the 3d printers of my fab lab I will imitate this test to compare the results of the different printers

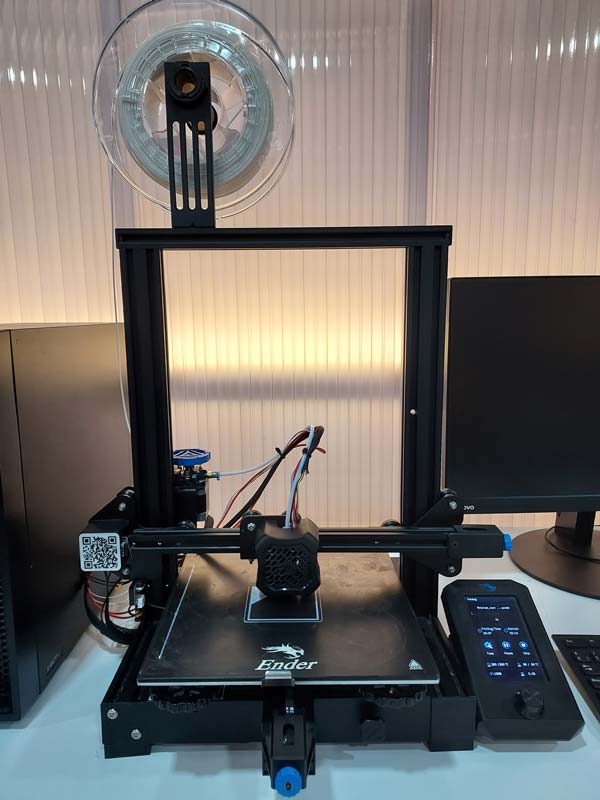

Ender 3 V2¶

- Type: Fused Depositon Modeling (FDM).

- Nozzle Diameter: 0.4 mm

- Layer Thickness: 0.05 mm -> 0.35 mm

- Filament Diameter: 1.75 mm

- Materials: PLA, ABS, PETG... (Do not print flexible materials)

- Slicer: Creality Slicer

- Build volume: 220 x 220 x 250 mm

The Ender is a faster machine than the Zortrax that is good value for money. It is true that it gives me more problems than the Zortrax but its price is much lower.

Zortrax M200¶

- Type: Fused Depositon Modeling (FDM).

- Nozzle Diameter: 0.4 mm

- Layer Thickness: 0.09 mm -> 0.39 mm

- Filament Diameter: 1.75 mm

- Materials: Z-PLA, Z-ABS, Z-FLEX ...

- Slicer: Z-Suite

- Build volume: 200 x 200 x 180 mm

The Zortrax is a slower machine that also works better with Zortrax’s own materials (more expensive than the standard ones) but it is also a machine that gives very few problems and printing errors.

Delta WASP 3MT¶

- Type: Fused Depositon Modeling (FDM).

- Pellet Nozzle diameter: 3 mm

- Filament Nozzle diameter: 1.75 mm

- Layer Pellet Thickness: 1.2 mm

- Layer Filament Thickness: 0.05 mm -> 0.35 mm

- Filament Diameter: 1.75 mm

- Materials: PLA, ABS...

- Slicer: Simplify 3D

- Build volume: 1000 x 10000 x 1000 mm

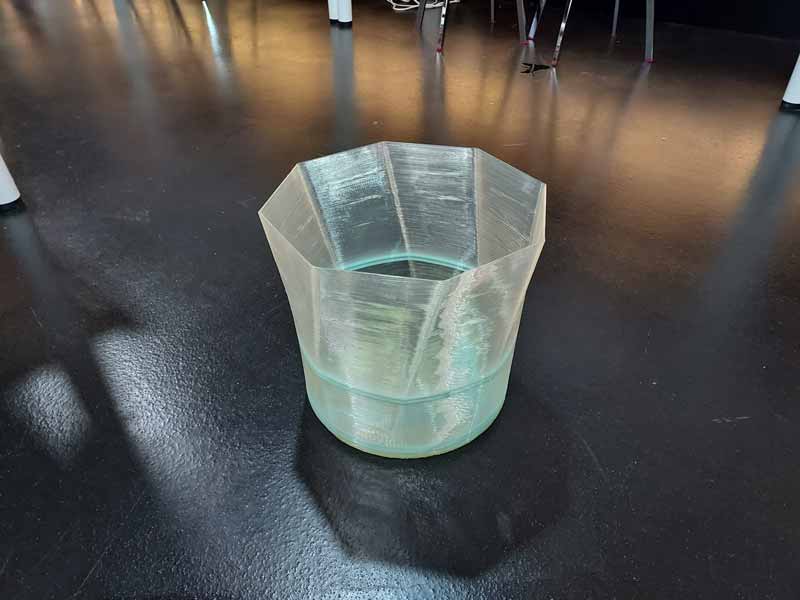

The WASP is good at making great spiralized designs so I printed a new trash can for my Fab Lab.

During the extrusion the WASP had to be loaded with more material, something curious about this printer is that it prints with pellets instead of filament.

The Delta WASP is a large format printer, the pellet module is ideal for printing spiralized parts as the supports are too strong. With the 1.75 mm extruder module parts can be printed with better quality and supports could also be used, the main problem is that being so large and open gives many warping problems.

Individual assignment¶

Design and 3D print an object that could not be made subtractively¶

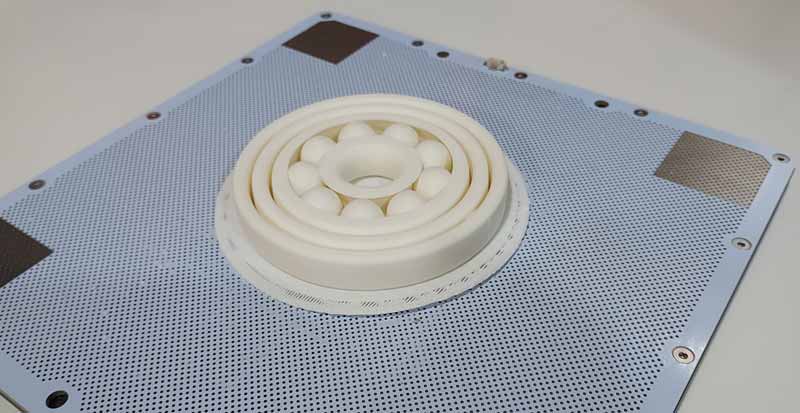

I started by printing an already designed piece that I would like to leave it in the showcase of my Fab Lab, I decided to print a bearing inside two rings, the bearing is functional and also each ring rotates inside the next. You can download the design here.

I printed the part on the Zortrax M200 in white ABS.

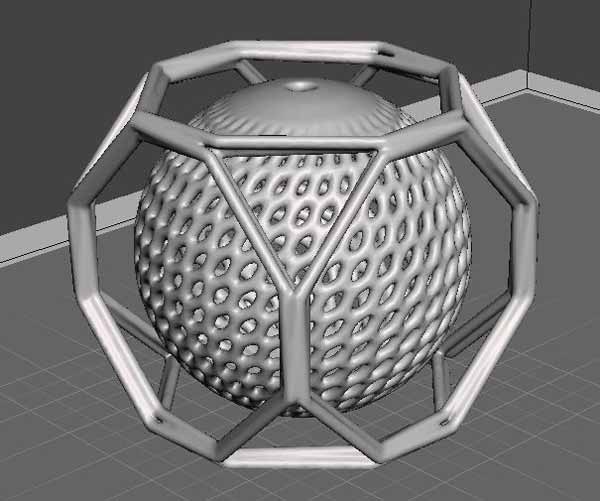

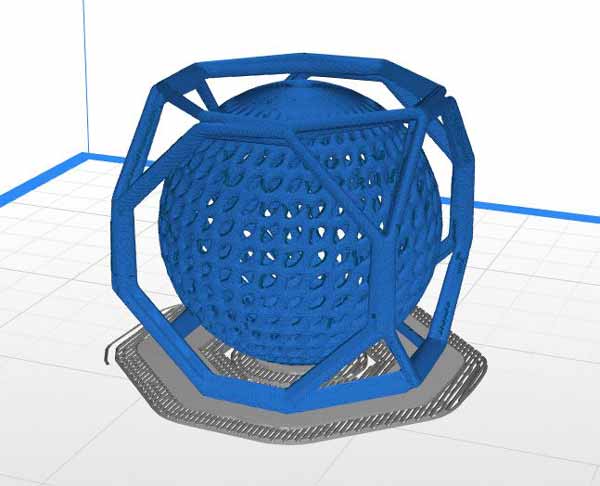

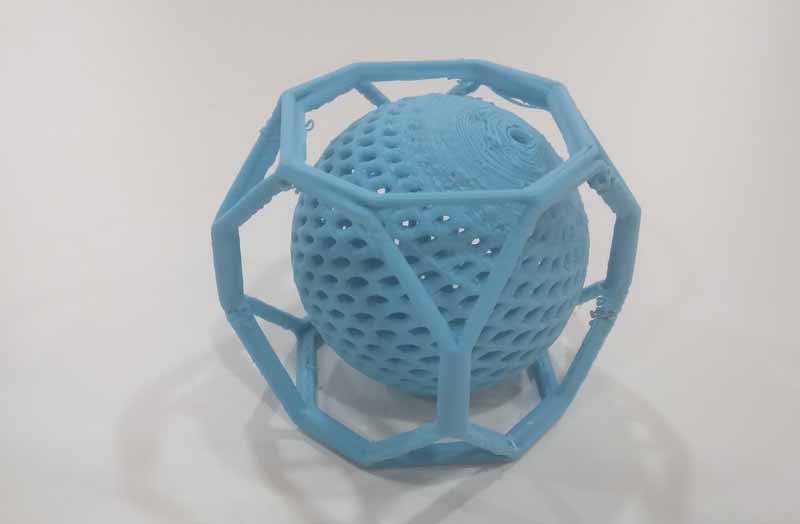

Then I modeled my own piece to be manufactured in an additive way, I chose a sphere inside a cube to which I would later apply a borni pattern in meshmixer, the modeling was simple, I did it in fusion 360, here you can see the design process.

Then print it on the Zortrax M200.

3D scan an object¶

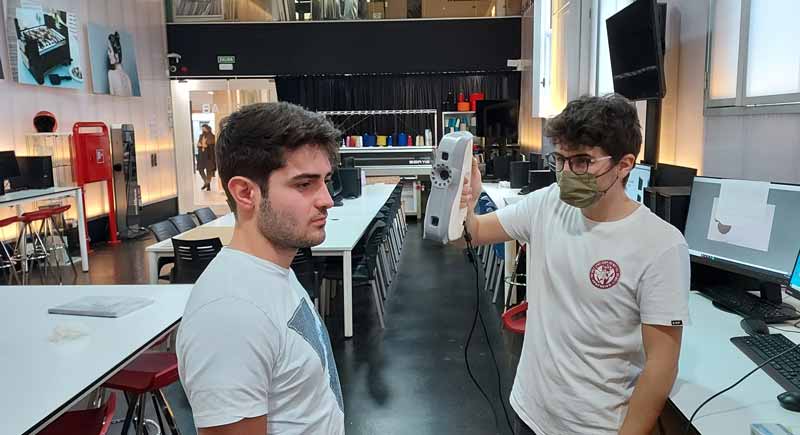

For this assignment we did a training session on the scanner for all those interested in the university with my friend Pablo Ramirez, he works at 3dz Madrid, Pablo gave us a scanner masterclass and then we scanned several objects.

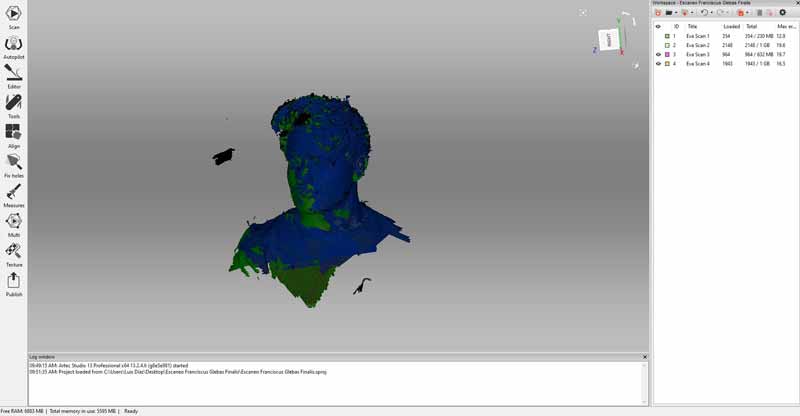

The ARTEC EVA is a scanner designed to scan objects of a medium size, approximately twenty cm to about two meters, it is necessary for a good scan that the object does not move during the scan, otherwise the scanner is lost and you have to go back to start or correct it in the software, but this takes a lot of time. One factor to keep in mind is that smooth glossy surfaces scan less well than matte surfaces, with white scanning the best and black scanning the worst. In order to scan a piece with a matt black finish, the trick of sprinkling talcum powder on it is used to improve the scan.

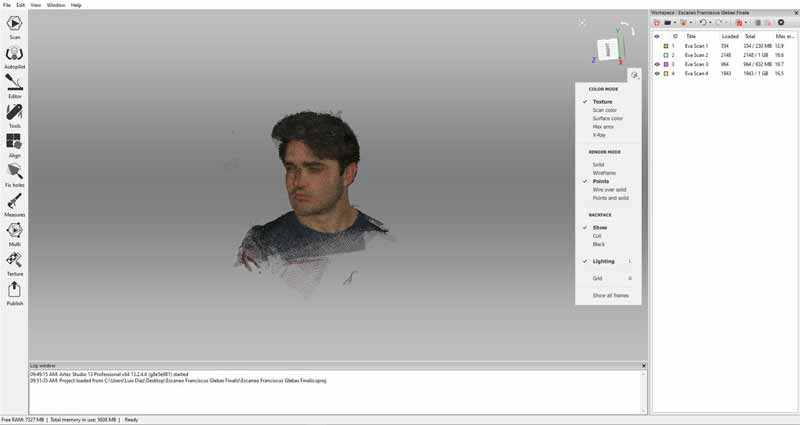

After the masterclass, I scanned my intern Francisco, it is important not to laugh in the middle of the scan, because you will have to start again.

The scan result was pretty good, plus the artec software corrects bugs and removes noise almost automatically.

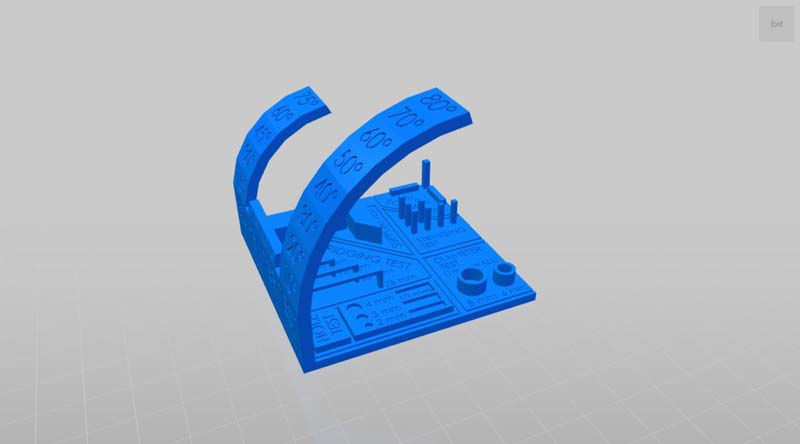

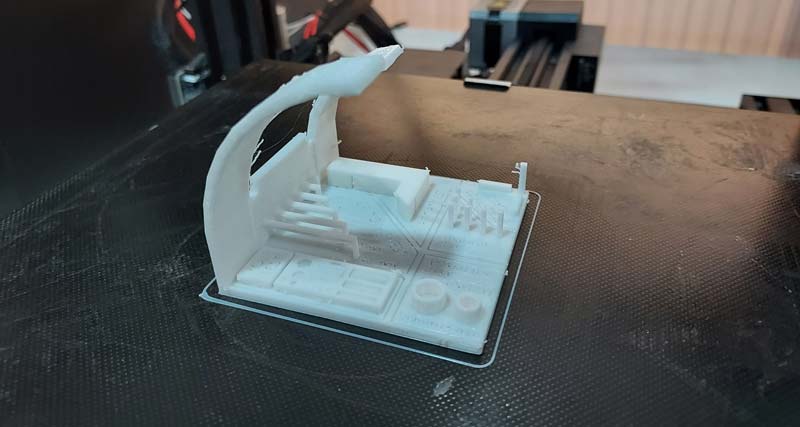

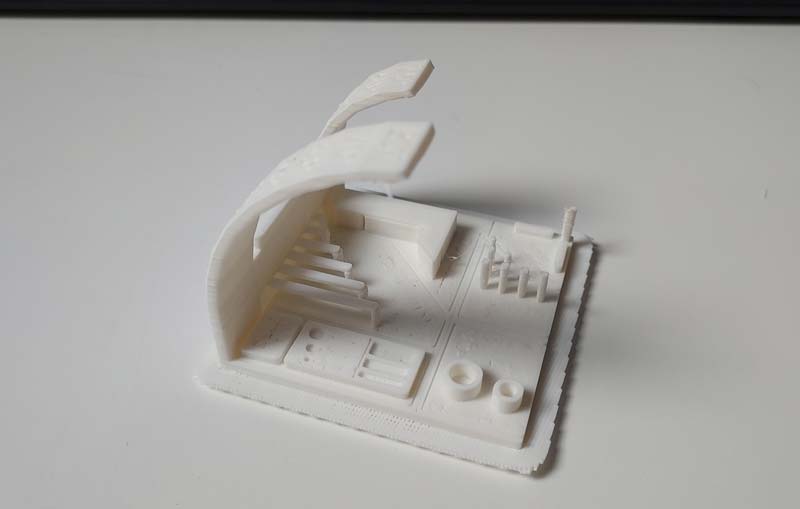

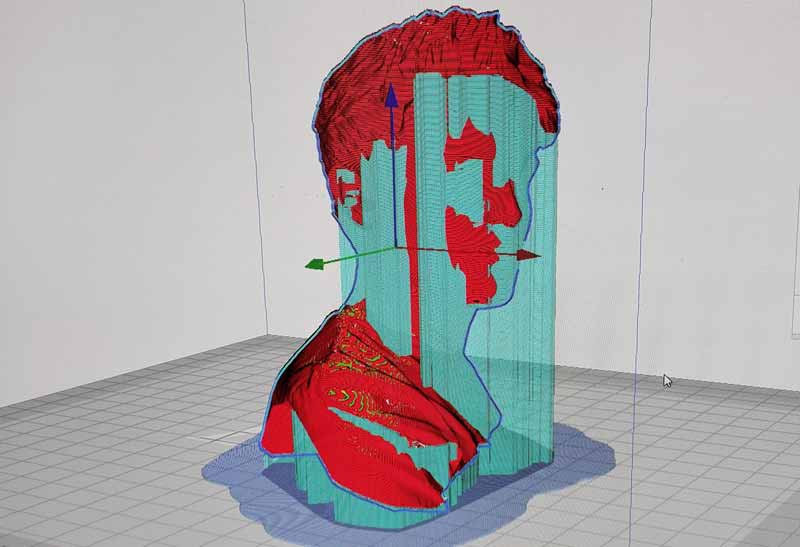

Then we prepare the G-Code to print it on an Ender.

The result was pretty good.

Download archives¶

Scan .ply

Scan .stl

Sphere in cube .f3d

Sphere in cube .stl

Sphere in cube with voronoi pattern .stl

See you next week!