18. Wildcard week¶

This week we work with two machines. The first a styrofoam cutter and the second thermoformer for plastic.

Team work¶

We start with the manipulation of the machines. The configuration of the plastic thermoforming machine is as follows: 15 second warm up Blow the mold when it has acquired its shape so that the plastic does not stick to the styrofoam. Make several holes in the base so that the air from the blow can pass through.

The configuration of the styrofoam cutting machine is as follows: Empirically we must manipulate the heating of the Thread. We note that the Inkscape version is a variant to recognize the plugin Universal Gcode Platform. Version 9.2 was compatible with our machine.

The following work tests were carried out with textile mesh and hydraulic cement. For the fastening of the textile mesh, it was glued with liquid silicone to the plastic mold. Subsequently, the textile mesh was oiled so that it does not stick to the cement paste.

After this experimentation we concluded that it is not necessary to glue the mesh to the plastic mold. since the cement paste is easy to handle and allows it to be shaped according to the mold. We also concluded that it is not necessary to apply oil to the textile mesh. Once the cement paste is dry, the textile mesh is easily removed.

Individual work¶

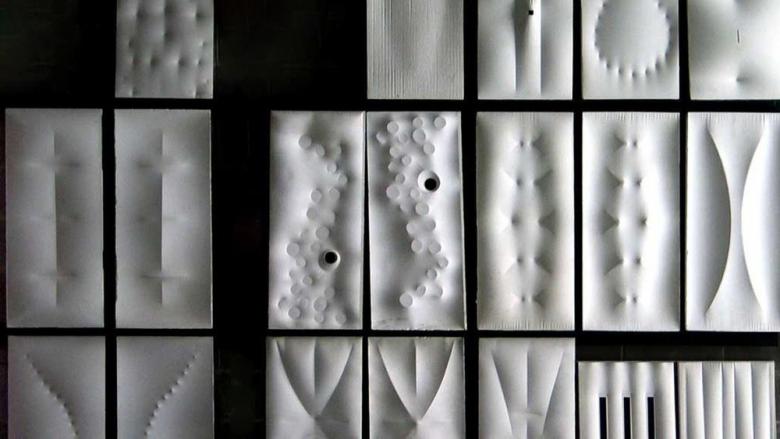

For this work I was inspired by the work of the architect Mark West. Work with the expression of concrete with textile-type finishes. The shapes of the concrete expressed the nature of a textile fiber. The following image shows the concrete experimental work of the architect Mark West.

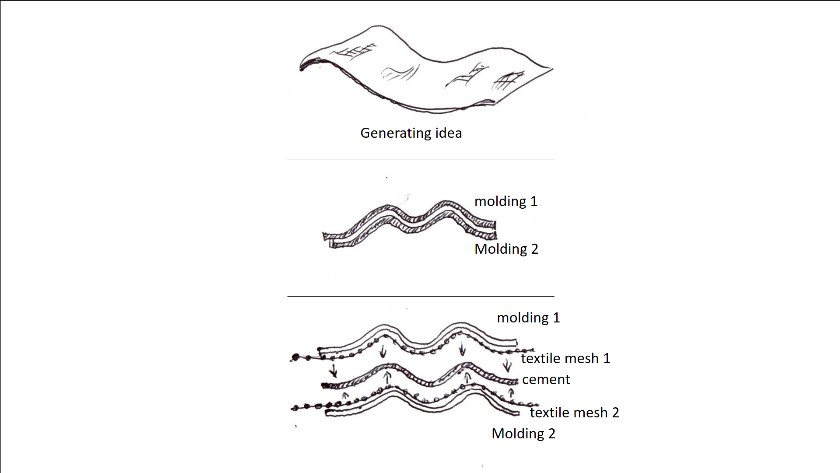

The idea is to generate a corrugated cement block in which the texture of a fabric can be appreciated. For this, a flexible and undulating formwork is required.

Mold Manufacturing¶

The first step was to generate the design and code with the Inkscape software.

Creation of curved lines with the purpose of cutting it in the styrofoam cutting machine.

Converted object lines to path

The Gcode file was generated through the plugin [Universal Gcode Platform](https://winder.github.io/ugs_website/).

The following image shows the described procedure:

The second step was to execute the code on the platform Universal Gcode Platform.

We insert and hold the Styrofoam block to be cut in the machine

We locate the origin point manually and press [Reset Zero]

We heat the cutting wire

We execute the Gcode

The following image shows the described procedure:

The third step was to use the high-density styrofoam cut blocks to make the plastic molds that would serve as formwork.

We place the styrofoam blocks on the machine platform

We check the vacuum pump and the air compressor

We turn on the heat and configure the heating time (15 seconds)

We run and get the plastic molds

The following image shows the described procedure:

Experimentation with the material (concrete and textile mesh)¶

The textile mesh was cut according to the size of the plastic mold. The cement was mixed with water until it is manipulable by hand. The mixture was poured into the mold and waited 24 hours. It was carefully disassembled and we obtained the piece of cement

Final result¶

The constructive expression of the piece shows plasticity through its digitally designed undulations. The shape of the piece expresses the styrofoam mold and the compression of the plastics. The texture of the surfaces shows the details of the fabric.