fernando meneses

8_make something big

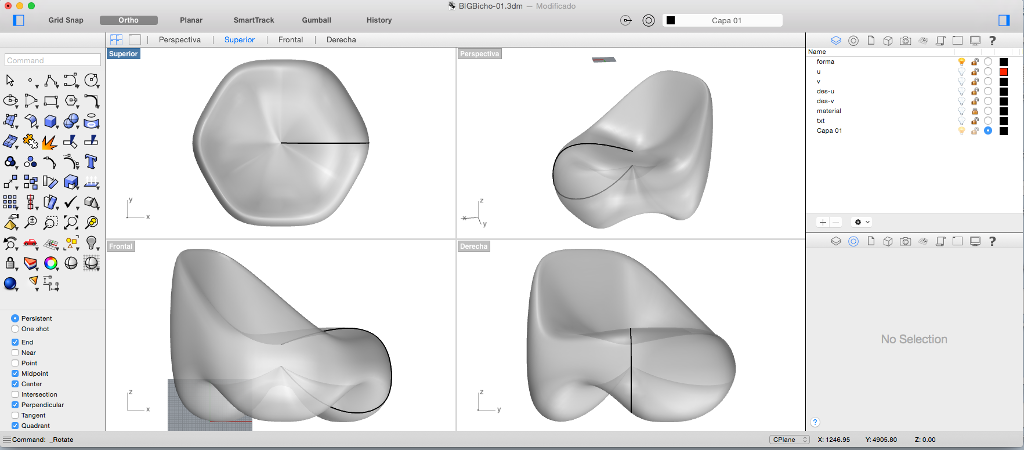

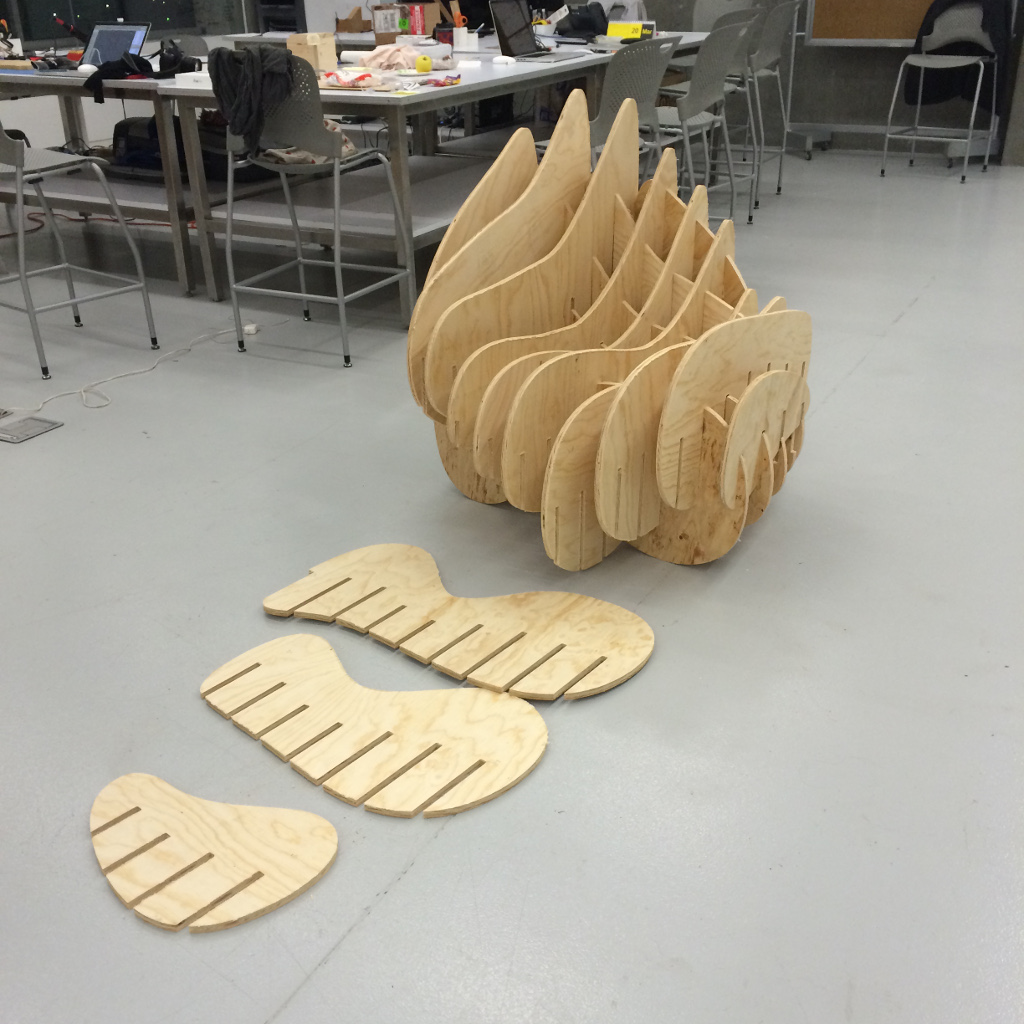

The objective of this activity is to design something big, in my case will design a chair, here are some points of view of geometry.

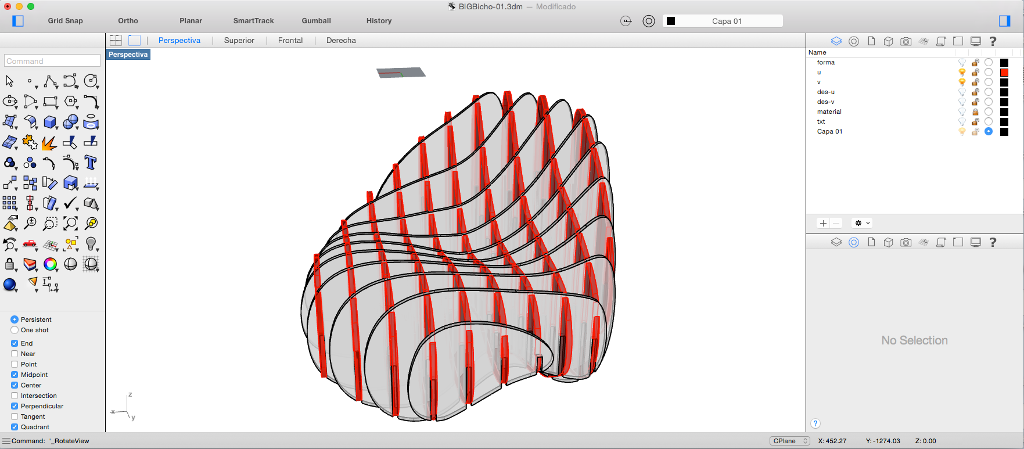

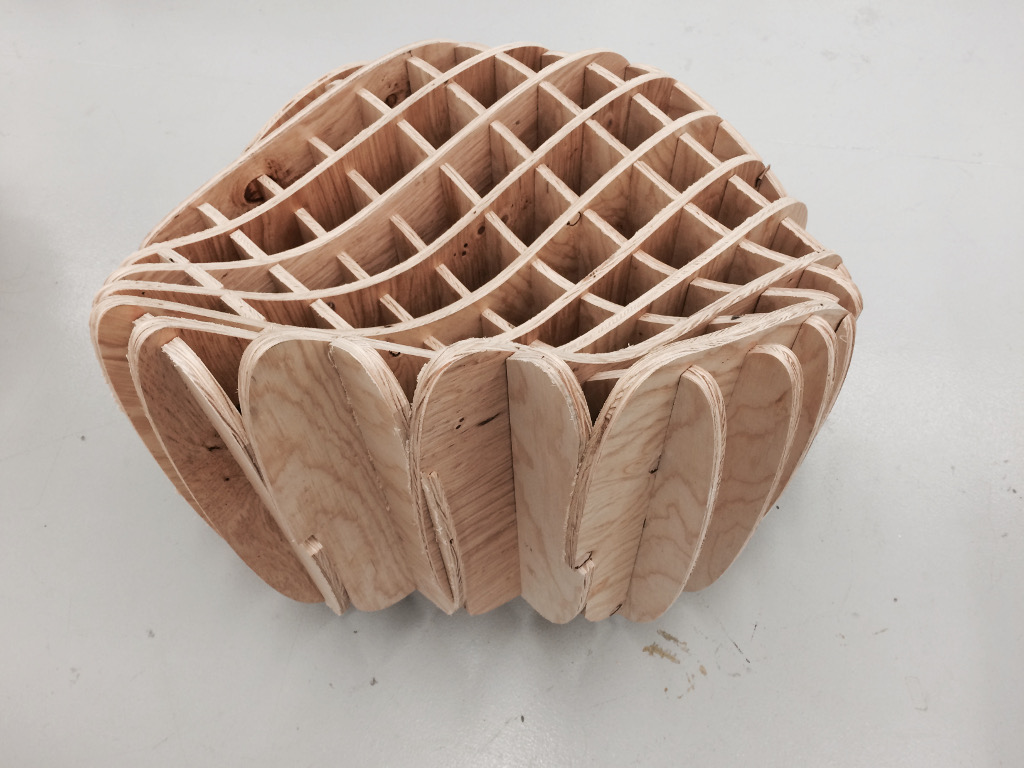

I applied to build a crosslinked at 45 degrees in the original geometry.

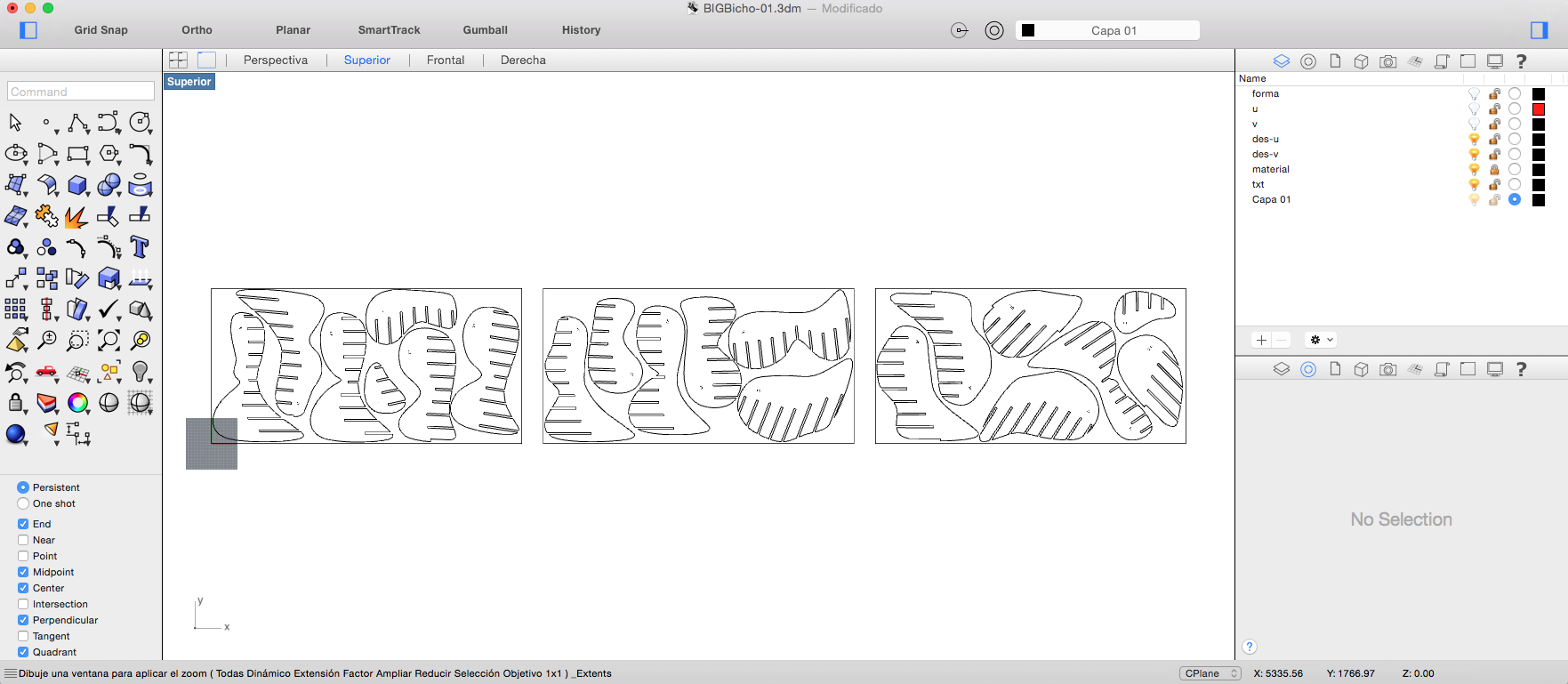

here the files for cutting:

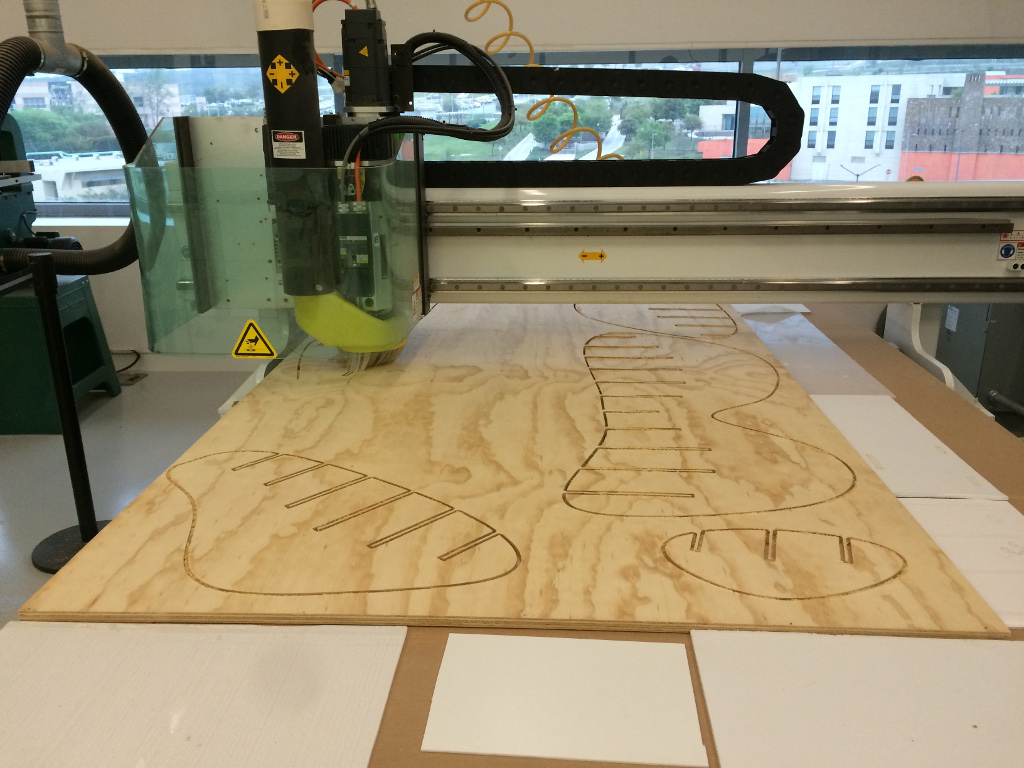

For cutting 2.5 has used a CNC axes.

Here are some pictures of the process.

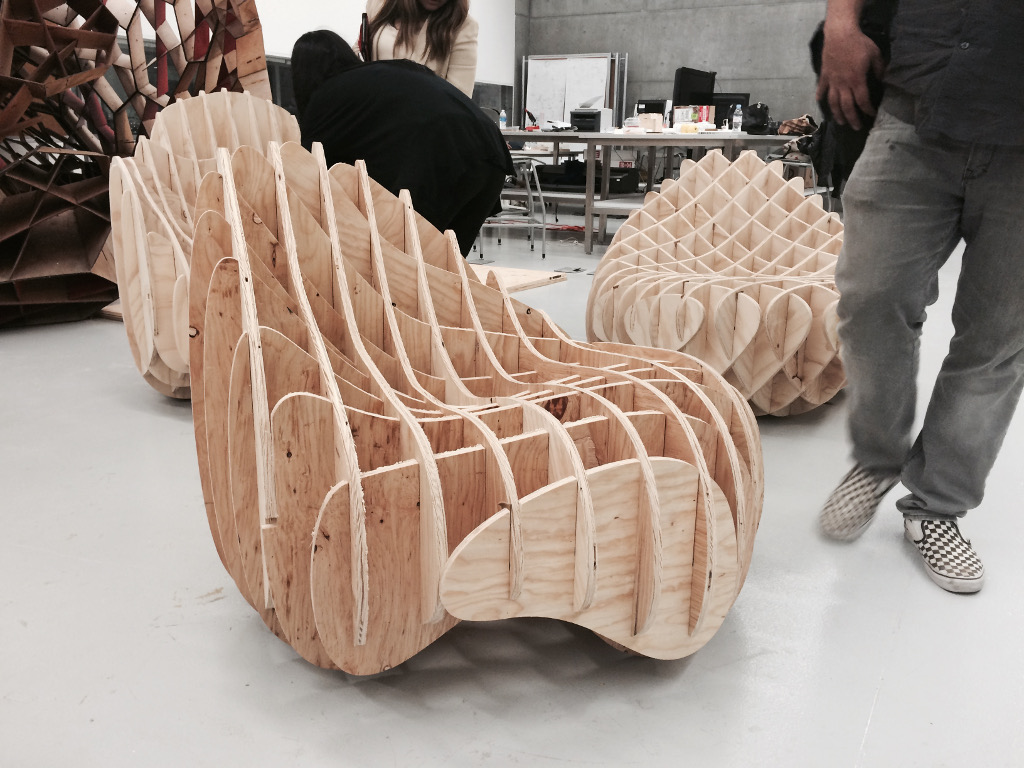

Here the final result

_conclusion

In this activity I tried to develop a large object, that this object is big is important, first, because it forces us to confront the resistance of the material, so the first step was the selection of material, in this case wood plywood 18 mm as construction system that crosslinking at 45 °.

Important things to remember:

Not all wooden slats are rectified, so they are not really some 18 mm, it is important to measure the sheets at various points to know its true thickness and error ranges.

It is important to think that the thickness of the cutting tool, and that sometimes the tool is not very strong, so we also have errors in the tool wear. And obviously, it is also important to consider the thickness of the cutting mouth.

When the boards are generated, it is important to remember that the corners are not as they were drawn, geometry actually would be the result of the trajectory of the drill, in general, the corners are round. I like a lot to make big things and I think that wood is an ideal place for this equipment.

_files

geometry.3dm

3D.3dm

nesting.3dm

_

Original source: http://academy.cba.mit.edu/classes/computer_machining/index.html

Contact: fernando.meneses@udem.edu / fernandomeneses@nodolab.com / f / in / g+ / b / v / mx / w