fernando meneses

18 project development

what tasks have been completed, and what tasks remain?_

So far, I have advances in management interface and database, progress can be seen in the activity “14 interface and application programming” also started to design my PCB (but still does not work).

interface_

Here is a video of the interface.

Here a video of the database.

PCB_

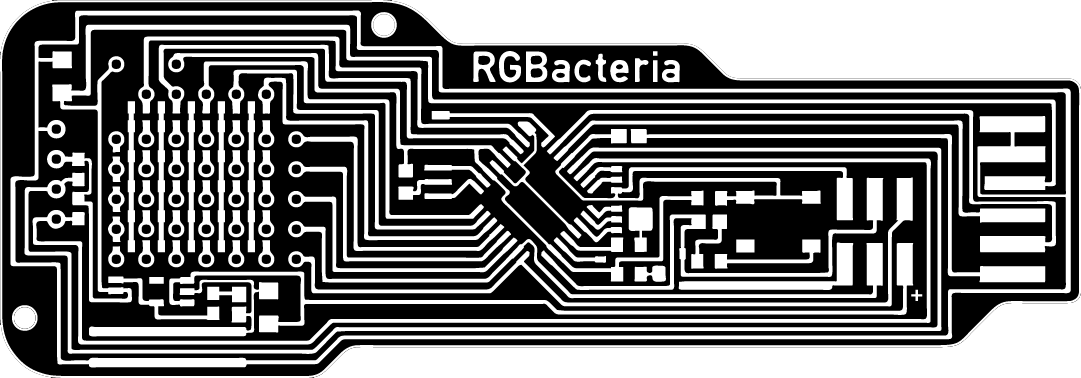

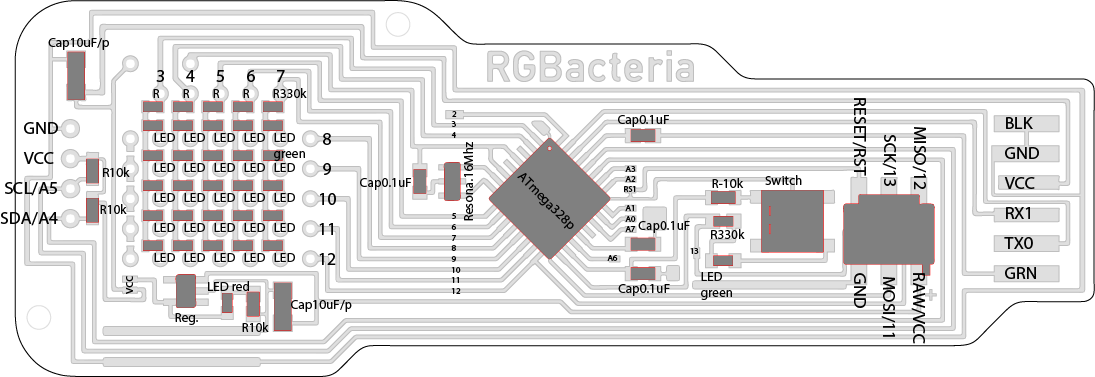

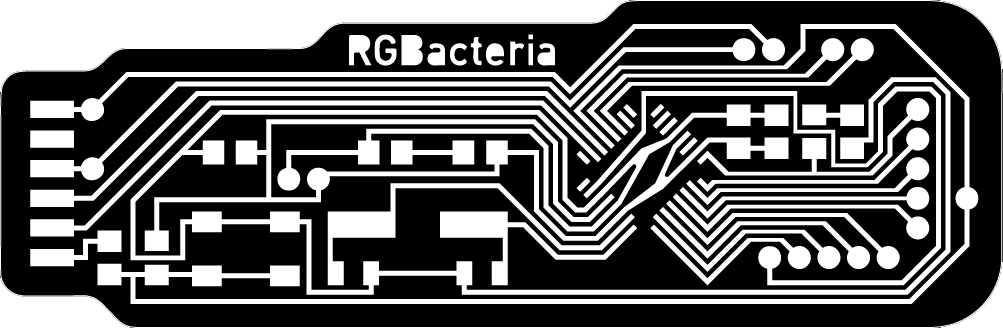

I decided to design a PCB with color sensor array as input and output LEDs, called RGBacteria-PCB, here image the first version of the PCB.

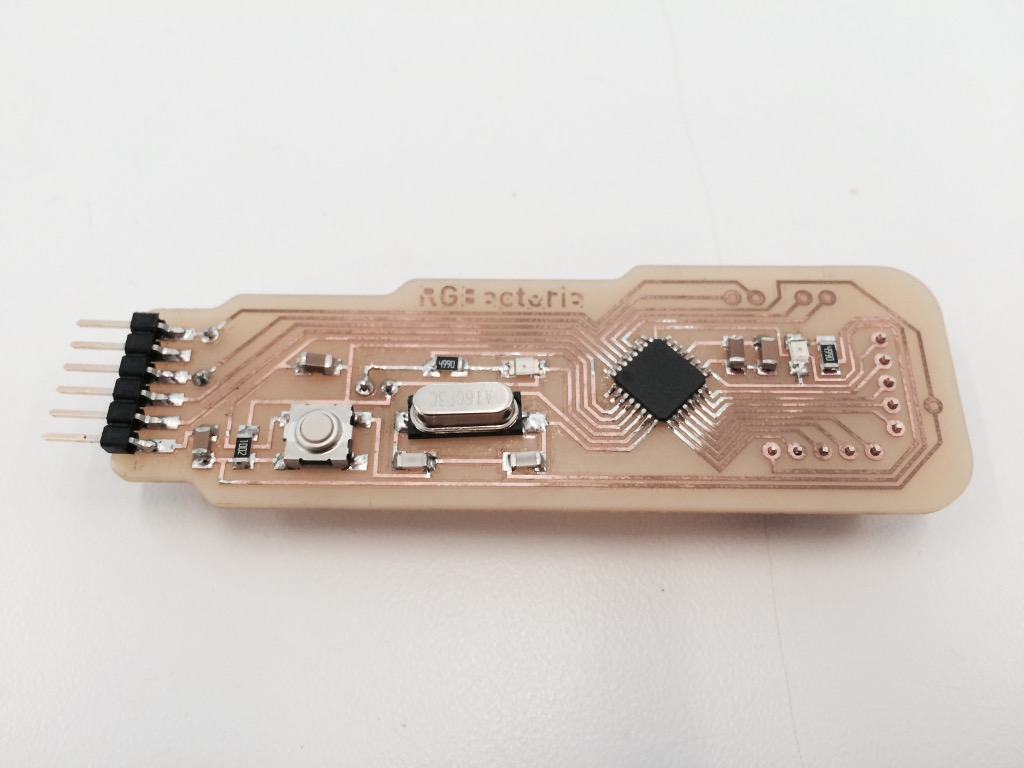

the components.

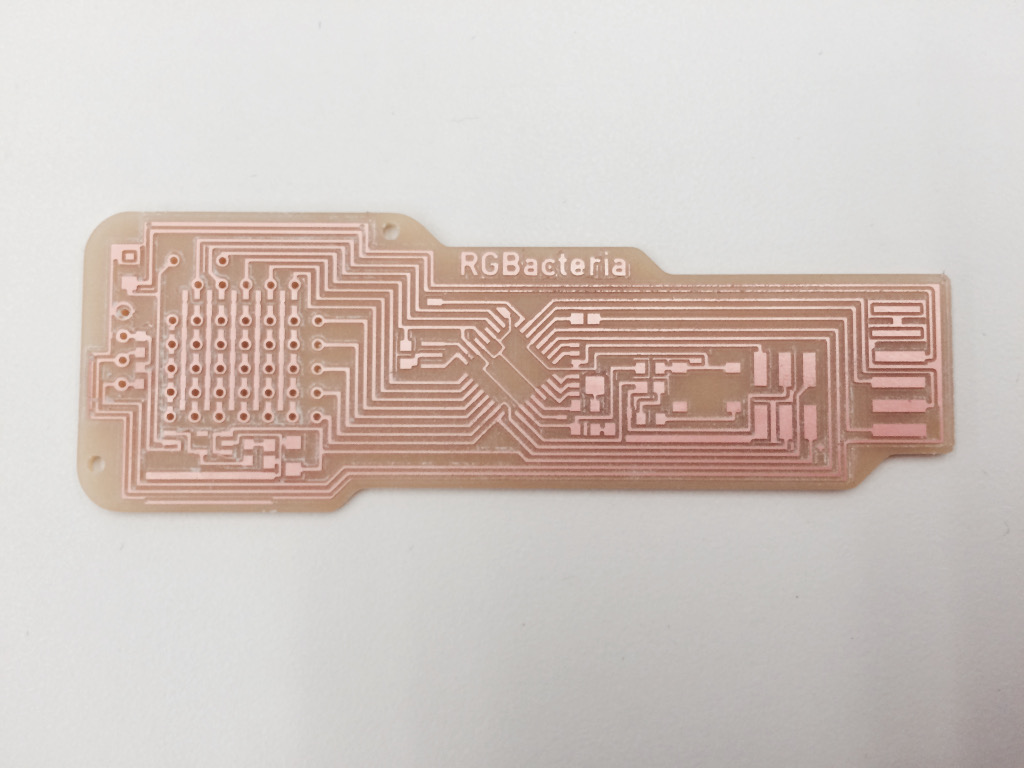

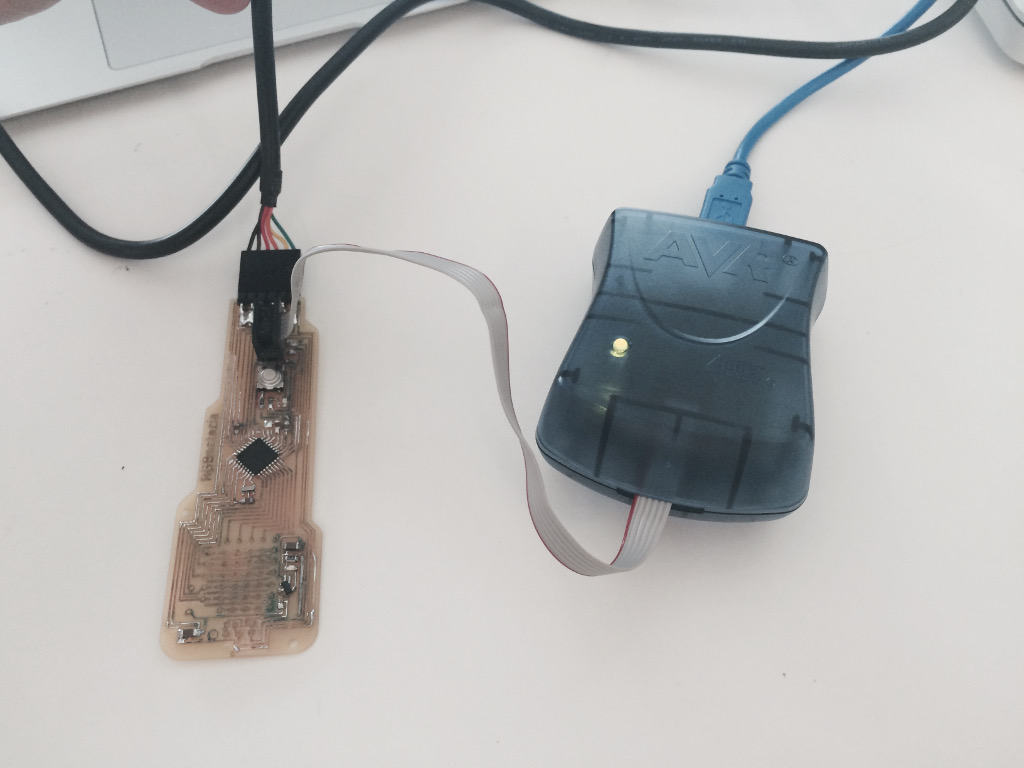

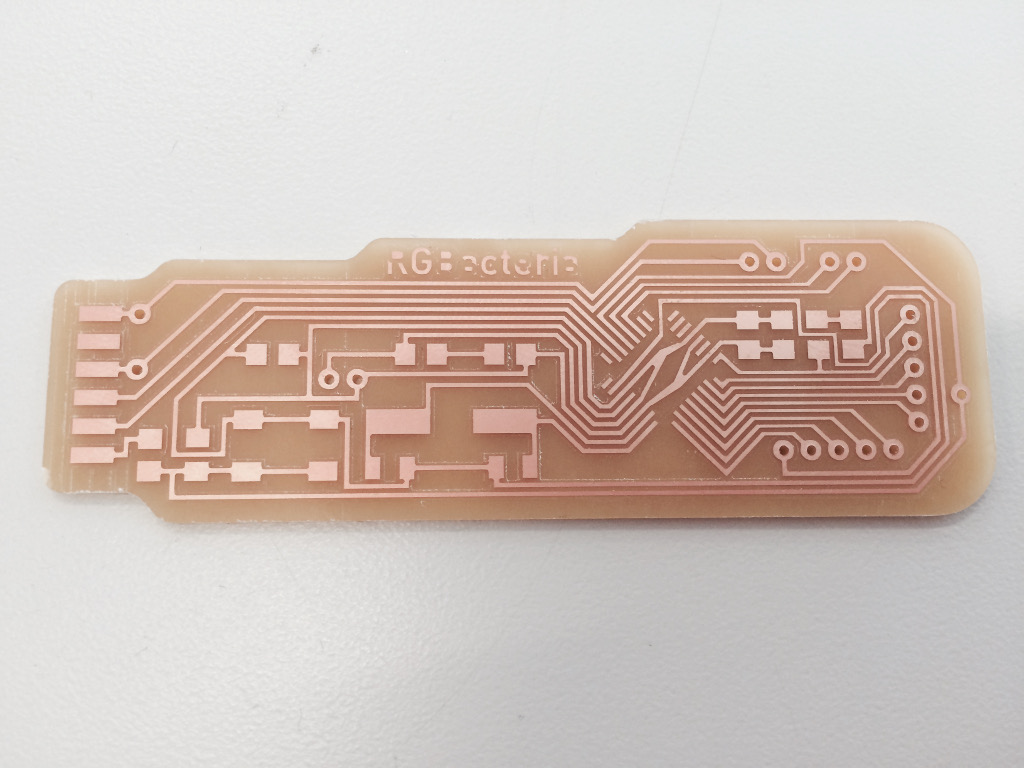

Here are some pictures of the production.

Here is a picture of the finished and burned PCB (no longer run).

The main problem is that when concentrated all on one PCB the risk of burning all the work run, I think something plate was burned at the beginning to achieve programmed and a fire to the LED, but after some tests, died and was later impossible to make it work. I think, in general, at least for the prototypes is not good centralize everything in a PCB.

what has worked? what hasn’t?_

As a second option to the PCB, now separated into several parts, leaving isolated the most difficult to weld, such as LED array areas, here are some images.

Here PNG new array of LEDs.

demonstrative video.

The color sensor is a bit more complicated, for now I will use the TCS34725-Adafruit, but the idea is to develop and future.

what questions need to be resolved?_

In recent weeks will work on the object. The initial requirements are, keep it simple, ergonomic and having an outlet for the array of LEDs to the color sensor, the FTDI cable and a button.

On the other hand, I’ll have to make another PCB with these changes.

what will happen when?_

The first objective is the color sensor function, then the matrix of LEDs and button, and if the time reaches could begin to think of a rotating system for Petri.

what have you learned?_

In these weeks working in the production of all physical elements, their assembly, connections and unions to concentrate.

I think the area where he had less experience is designing, manufacturing and PCB program, and is here where I spent more time and more time.

For the project, the world of microorganisms is wonderful, I think that after the final project I would need further study.g.

documentation during development_

(during these weeks)

PCB_

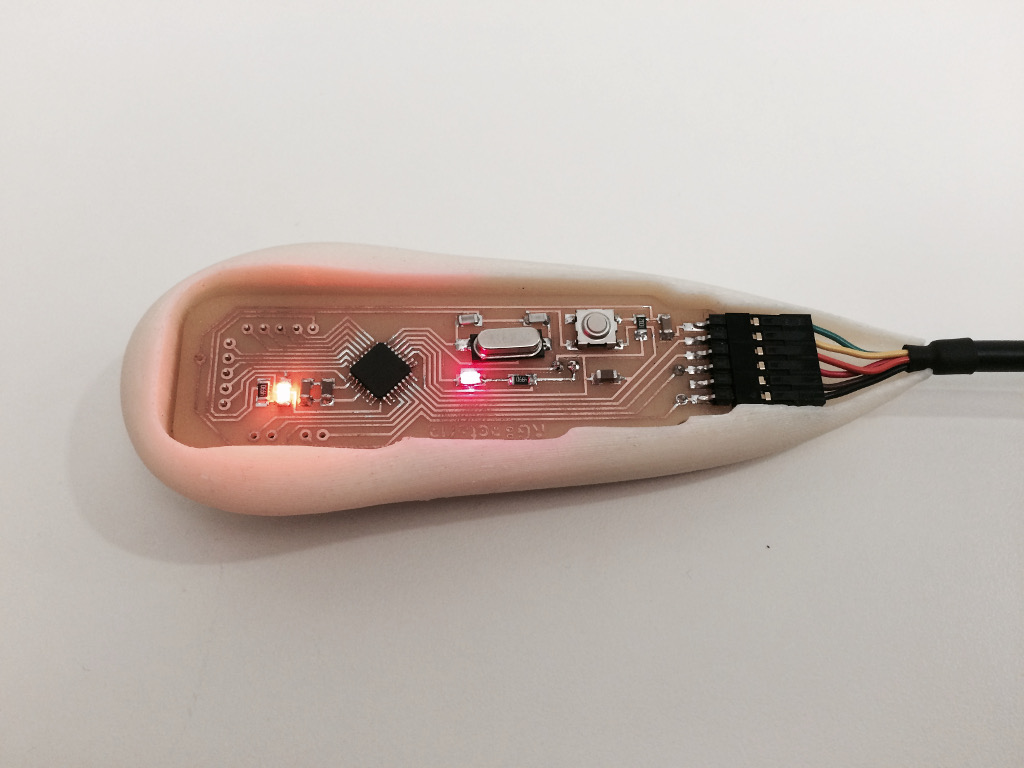

This is the final PCB. Is based on the FabKit and controls an output LED array and a color sensor as input, also has a button, here are some pictures.

programming

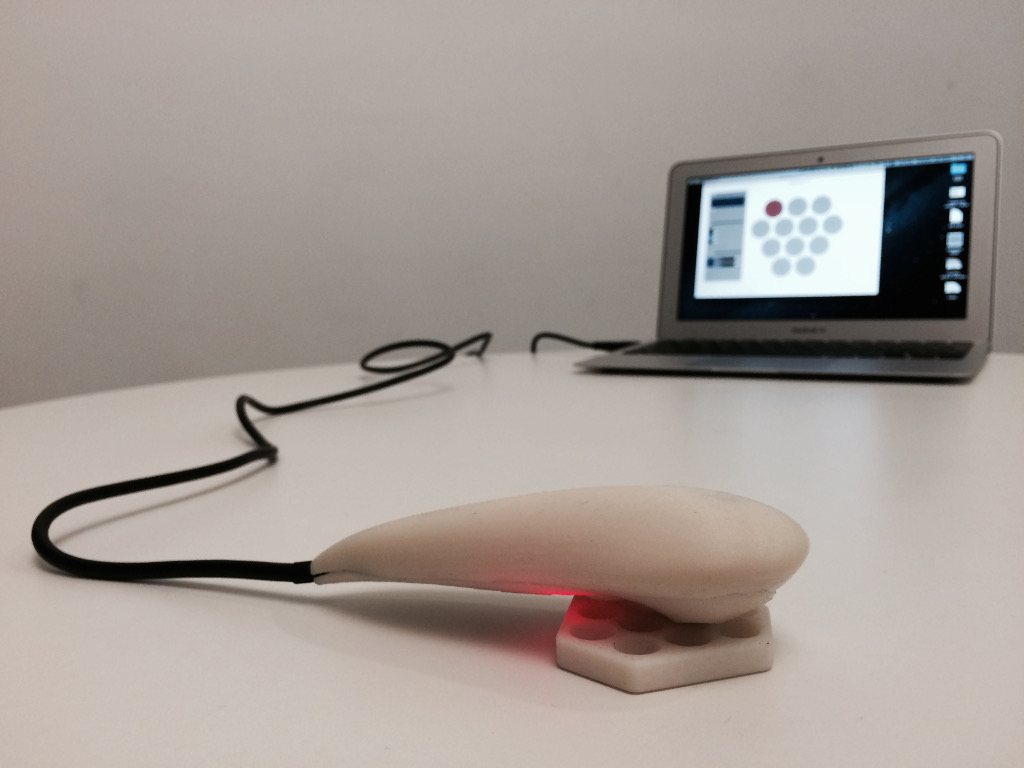

Chassis_

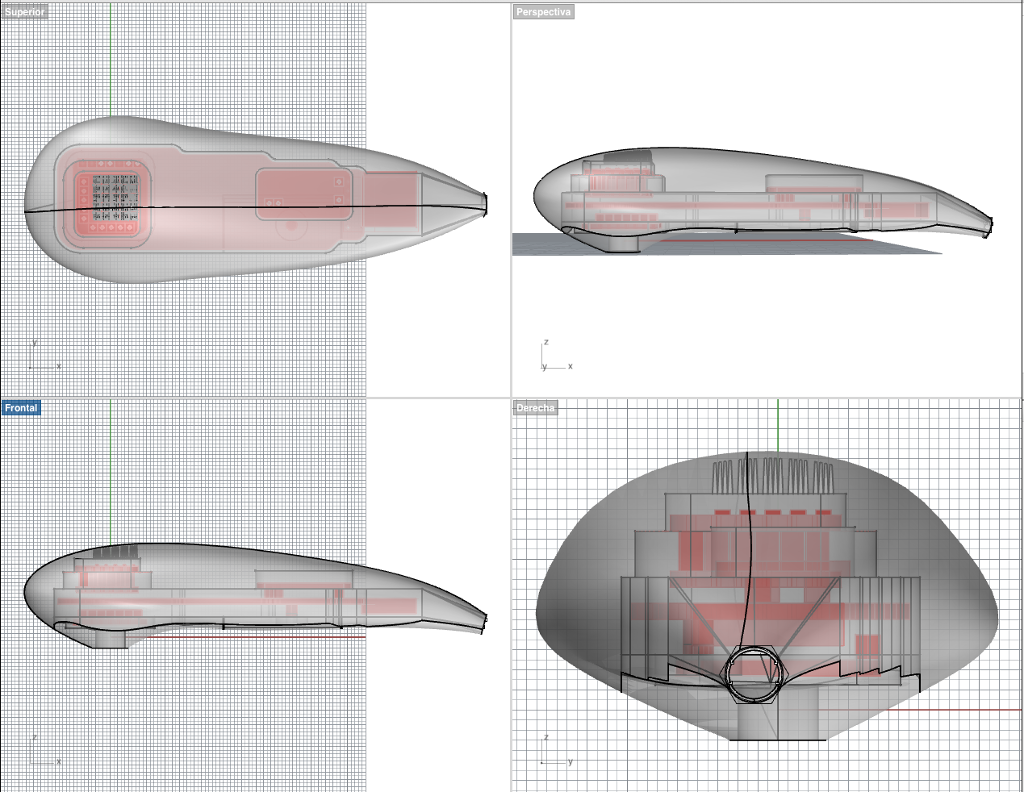

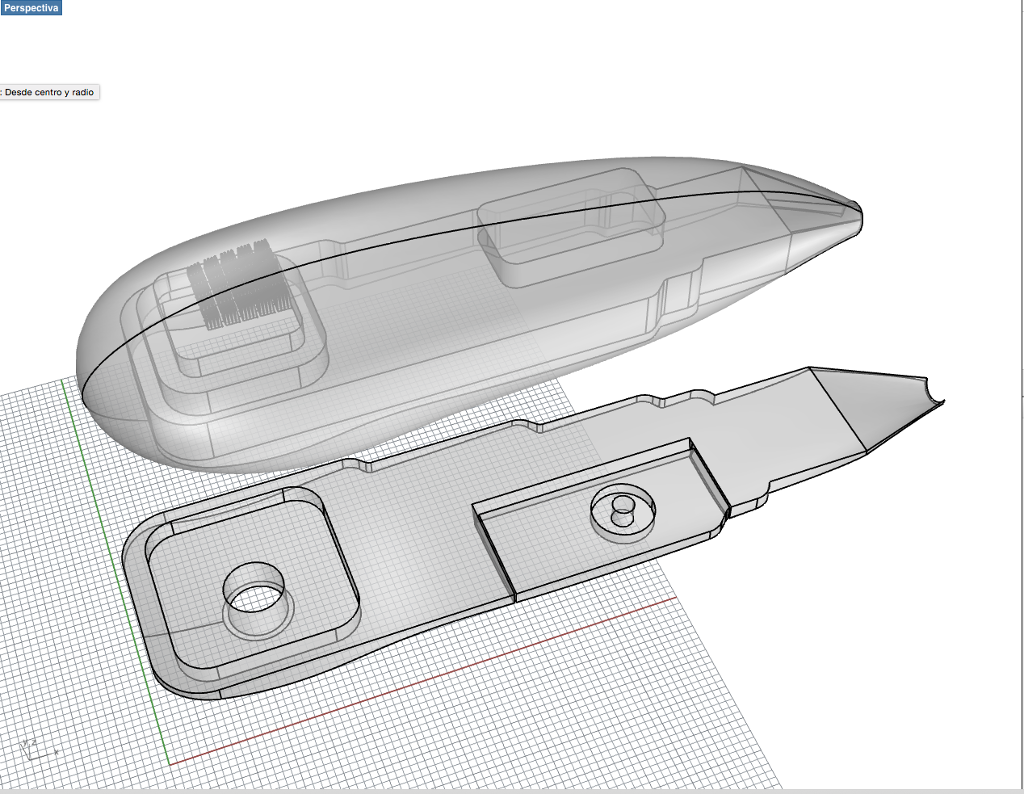

The chassis is composed of two parts, this to allow mounting of the PCB, has space for the array of LEDs, color, and output FDTI integrated sensor button mechanism. Here are some pictures.

Chassis views

two piece chassis

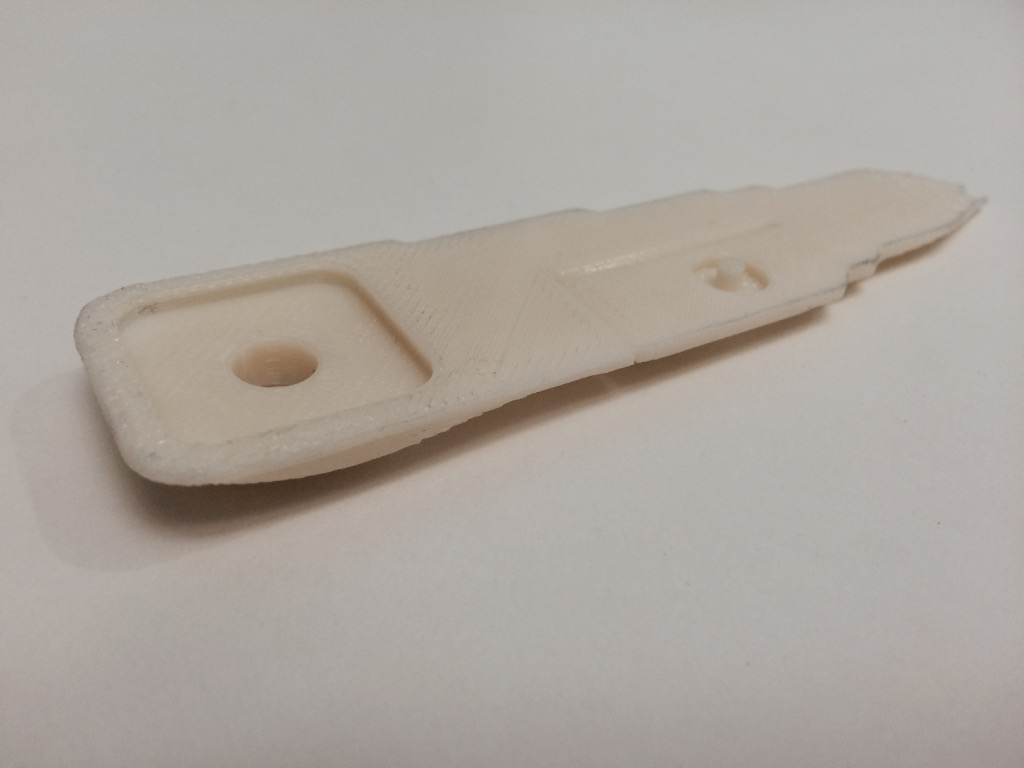

3D printing, Part One.

3D printing, part two.

3D printing and assembly testing.

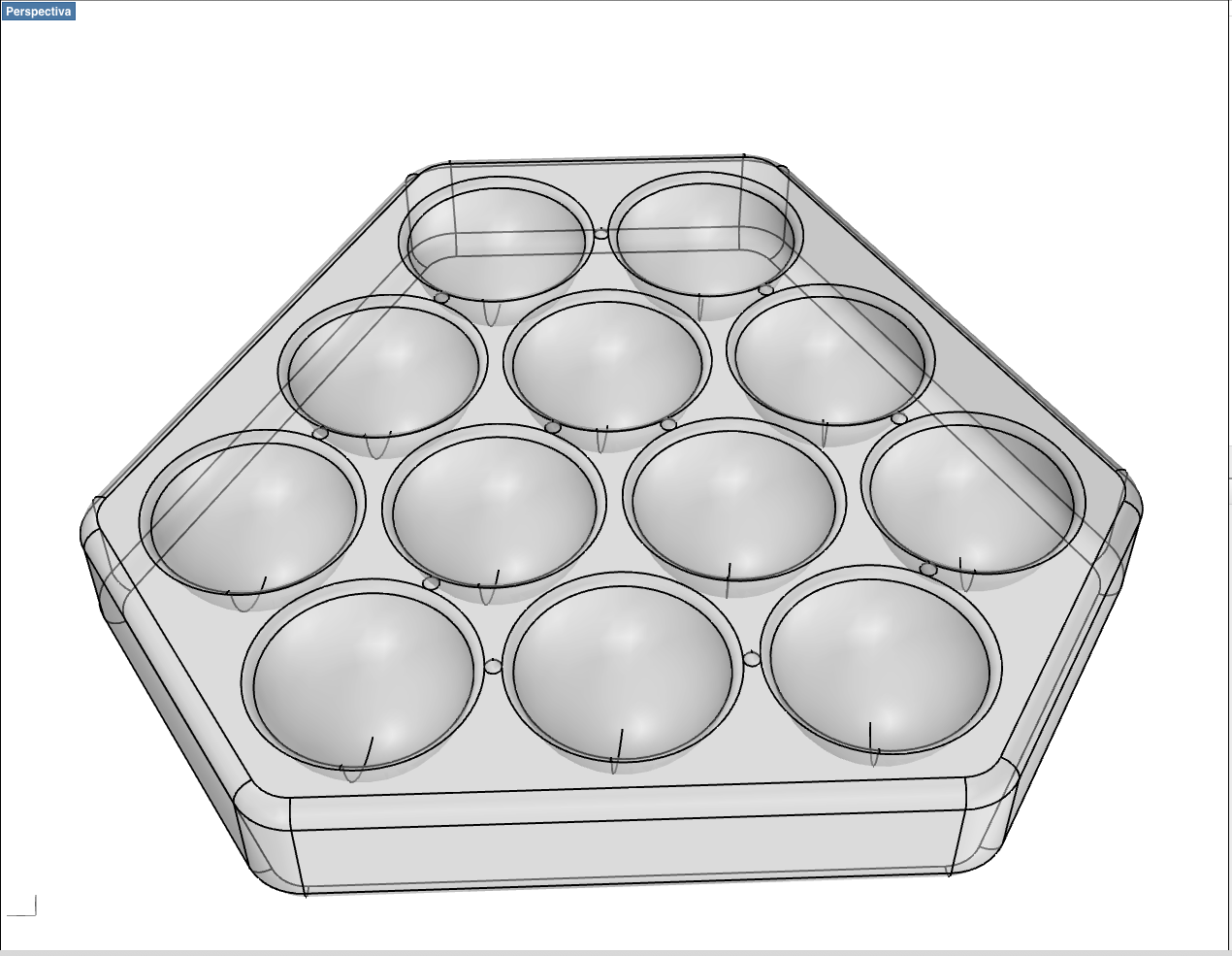

Petri_

Petri 3D

demand- vs supply-side time management_

Currently, I will only finish the manufacturing and developed documentation, ending with a prototype ready to start a formal investigation.

spiral development_

In this category, I propose that the spiral development is the future of research, with the following phases of the cycle.

cycle:

- The production of the latest version

- Manufacturing cost

- Recognition of bacteria

- Quality Assessment Recognition

- Proposal for improvement in cost and quality

- The development of improved

- Testing and demonstration of improvements

- Release of the new version

_conclusions

Open RGBacteria, will be an open and inexpensive for the recognition of bacteria device, drink based on user experience and look for the best relation between quality and cost.

It is important that is affordable and easy to replicate, and most importantly to allow recognition of bacteria.

It will consist of a chassis, PCB, Petri, interface and database.

_files

OpenRGBacteri / PCB

OpenRGBacteri / Chassis

OpenRGBacteri / Petri

OpenRGBacteri / interface

OpenRGBacteri / Database

_

Original source: http://academy.cba.mit.edu/classes/project_development/index.html

Contact: fernando.meneses@udem.edu / fernandomeneses@nodolab.com / f / in / g+ / b / v / mx / w