fernando meneses

3_computer-controlled cutting

_design, make, and document a press-fit construction kit

1-idea

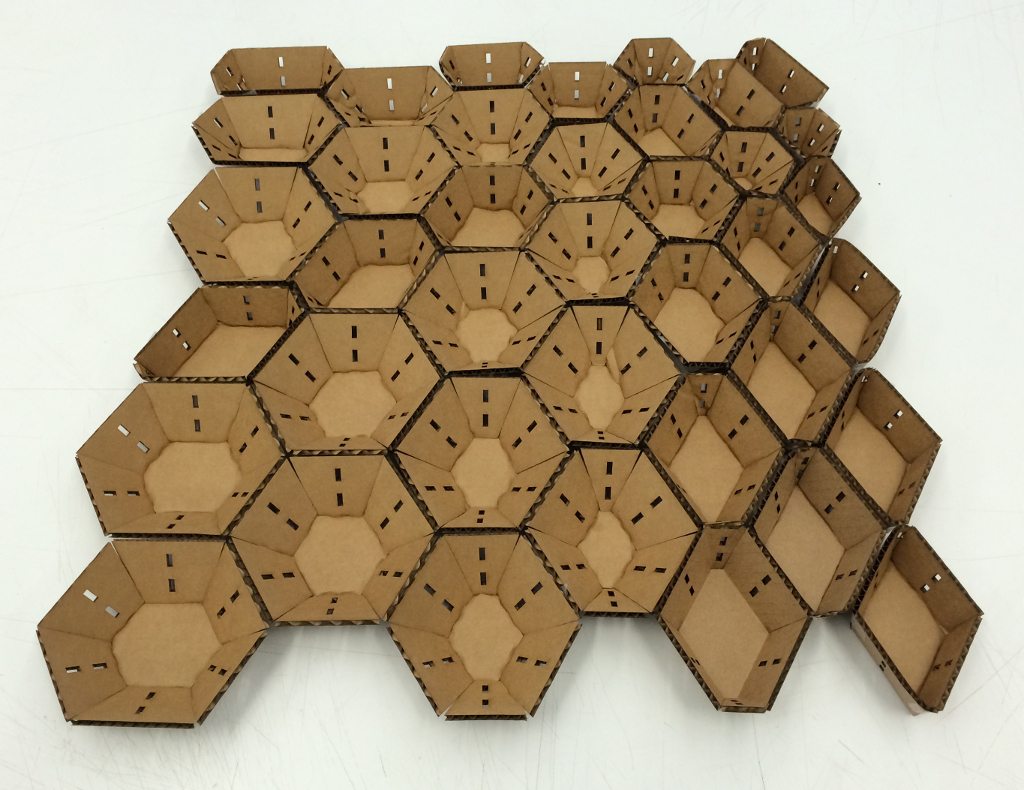

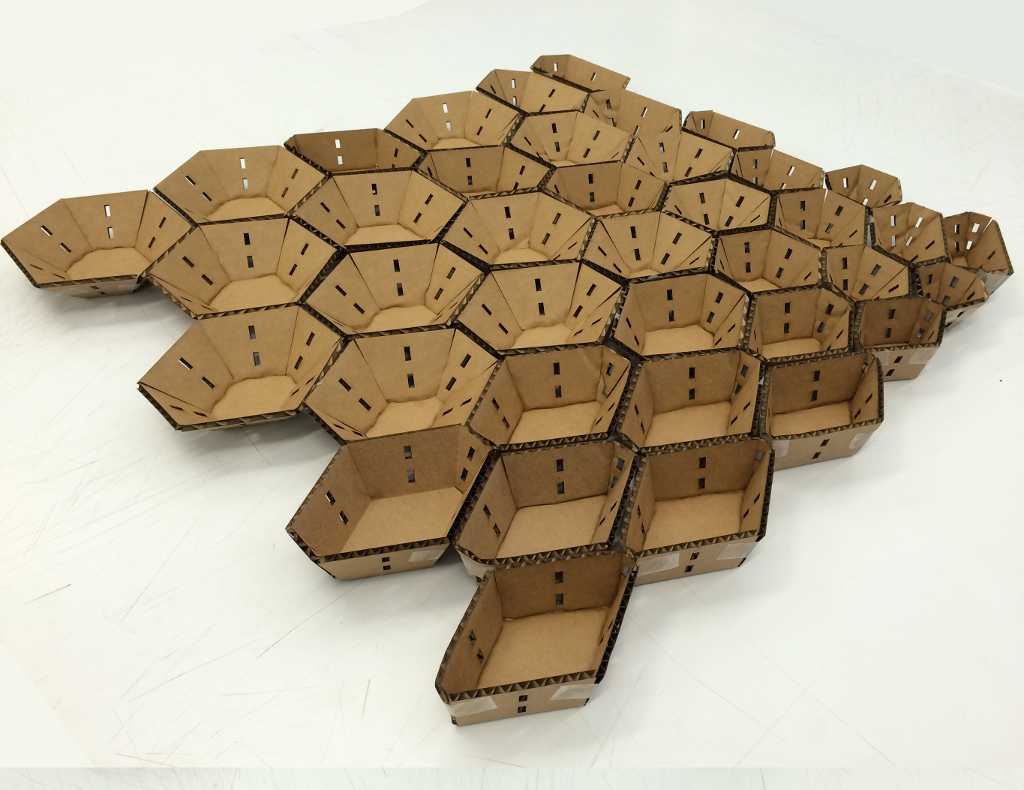

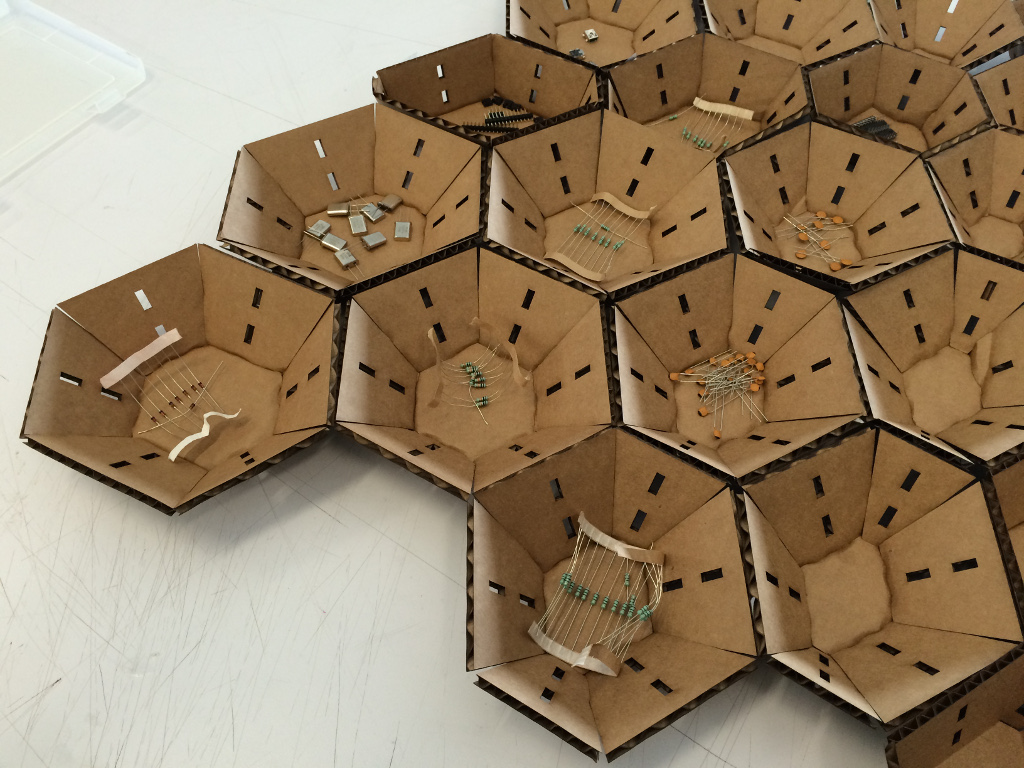

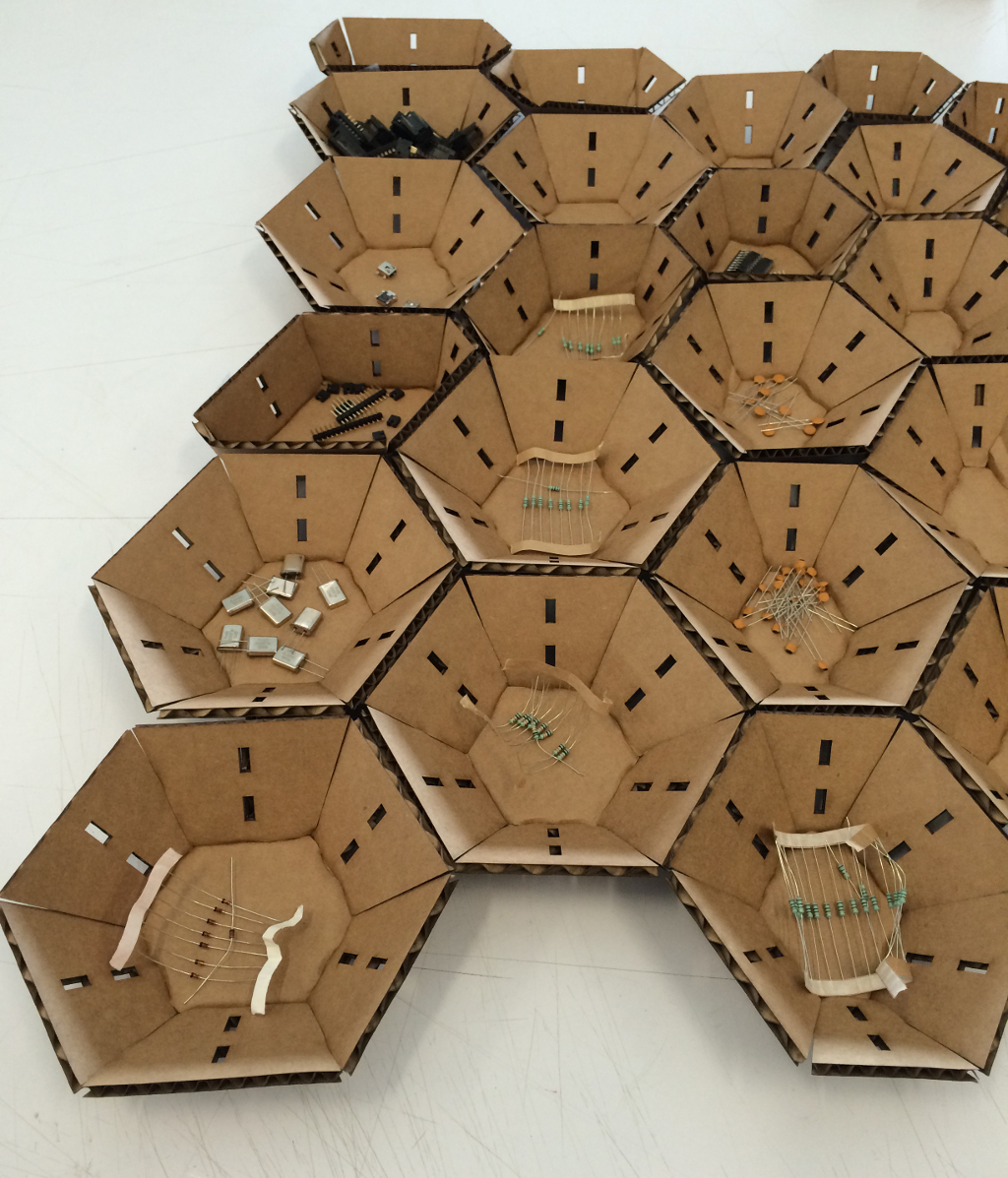

For this week, I will make an electronic components organizer, I think this may be useful in the coming weeks

2-form finding

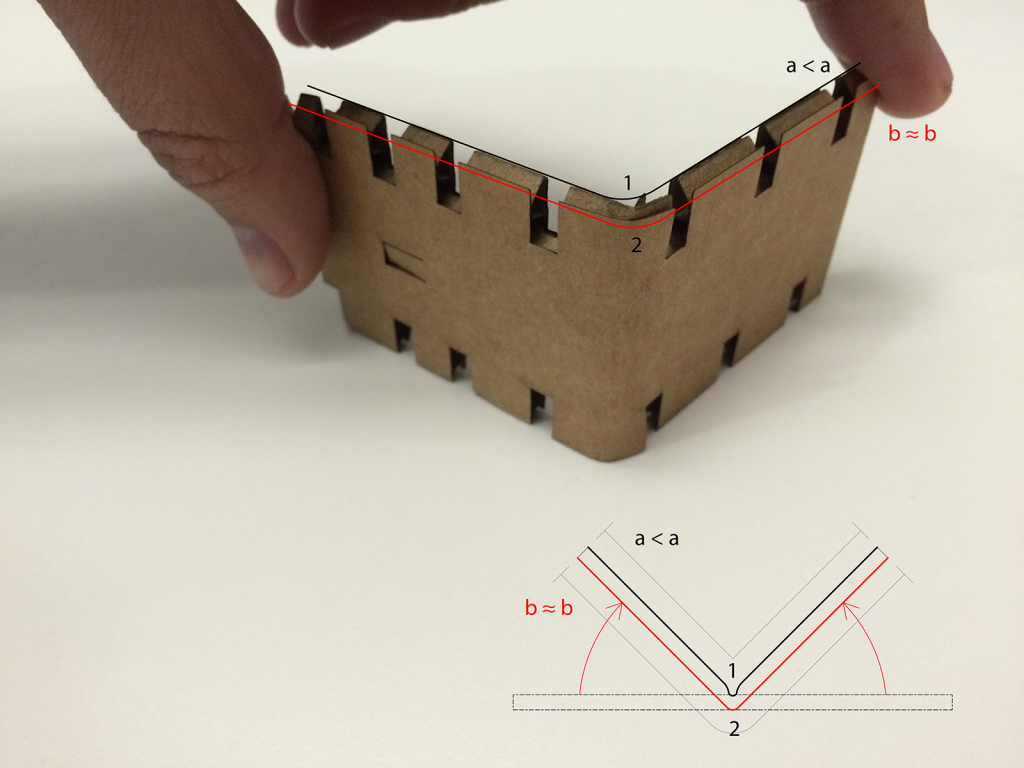

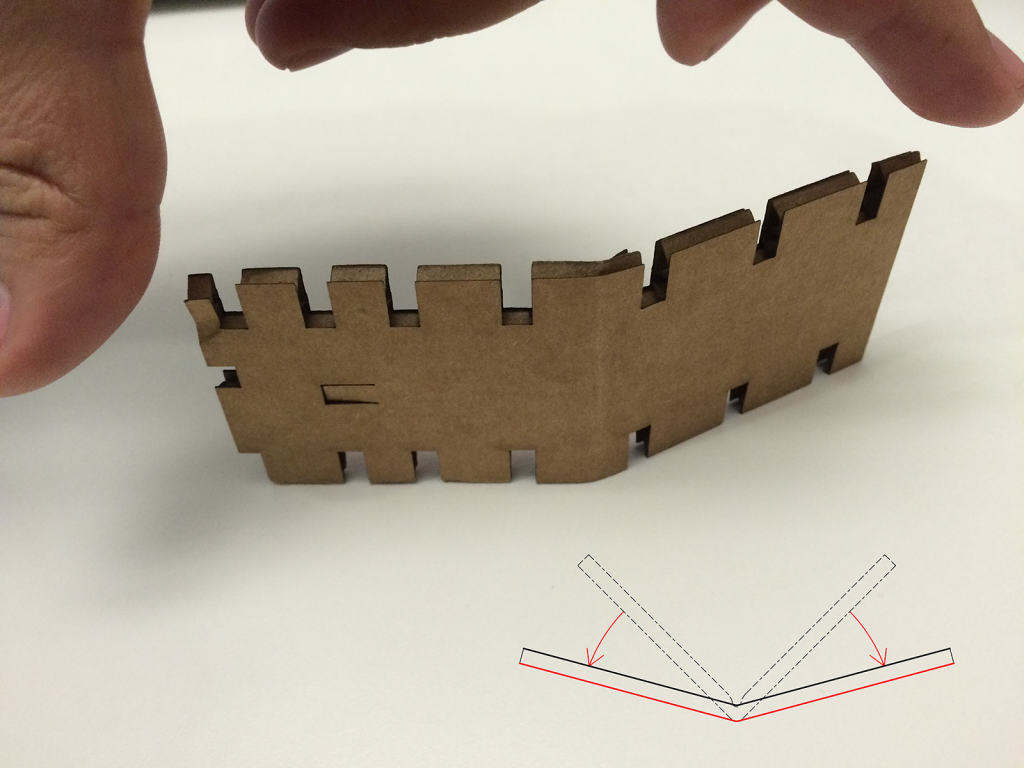

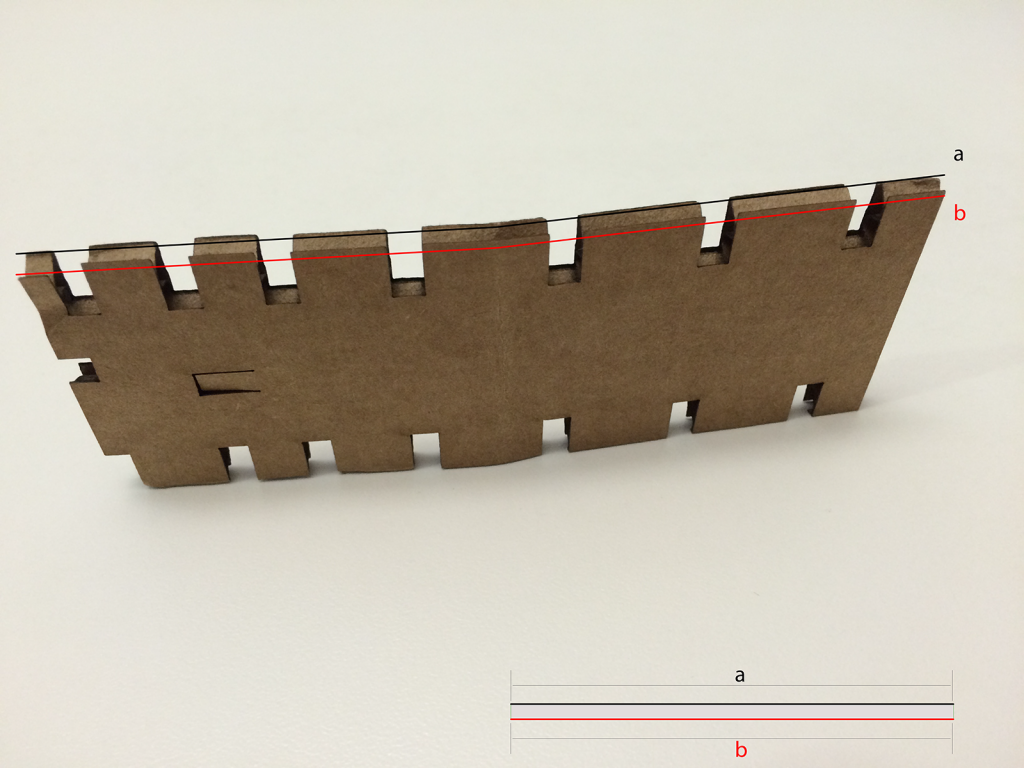

For this exercise I will use a 4mm corrugated cardboard, in the first tests we can see that it is a good material for cutting and folds. After some basic explorations with the material, the limits of its resistance to folding can be seen, to better explain in the next picture a component board can be seen, with the fold in the side “a” and side “b”.

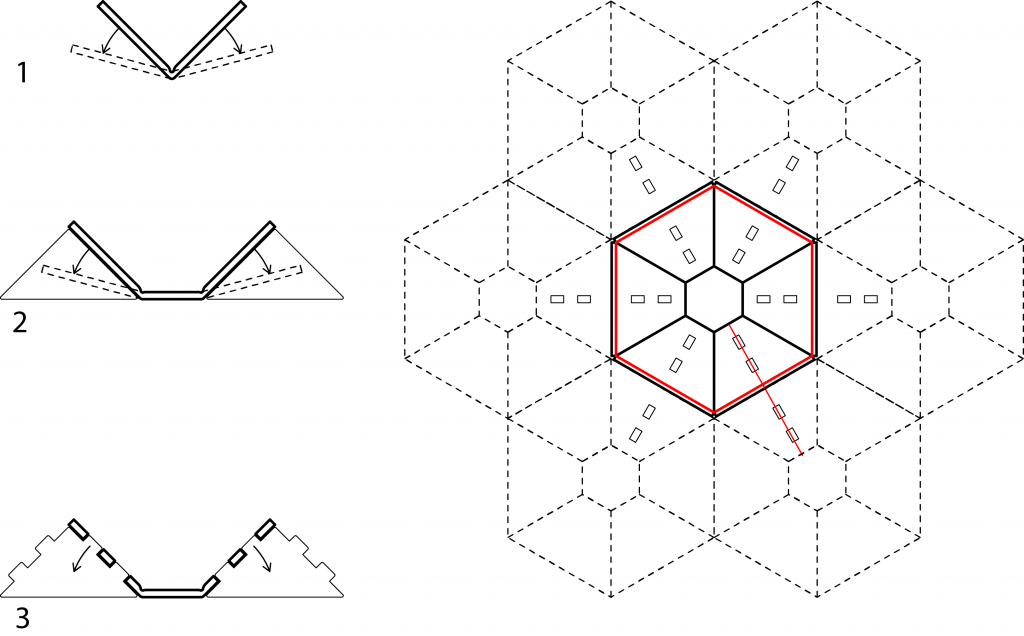

3-construction system

1- I will try to design a construction system, using the return deformation back to the original state of the material, the following diagrams show how the effort can be used to secure the connection with the other pieces a little more, in the end this effort squeezes the union and somehow prevents it from disconnecting.

2-This connection system connects to a network of folded pieces (hexagonal) in a second network of bases (triangular)

3- The stress in the material is not sufficient, therefore, a joint with teeth is proposed between the parts.

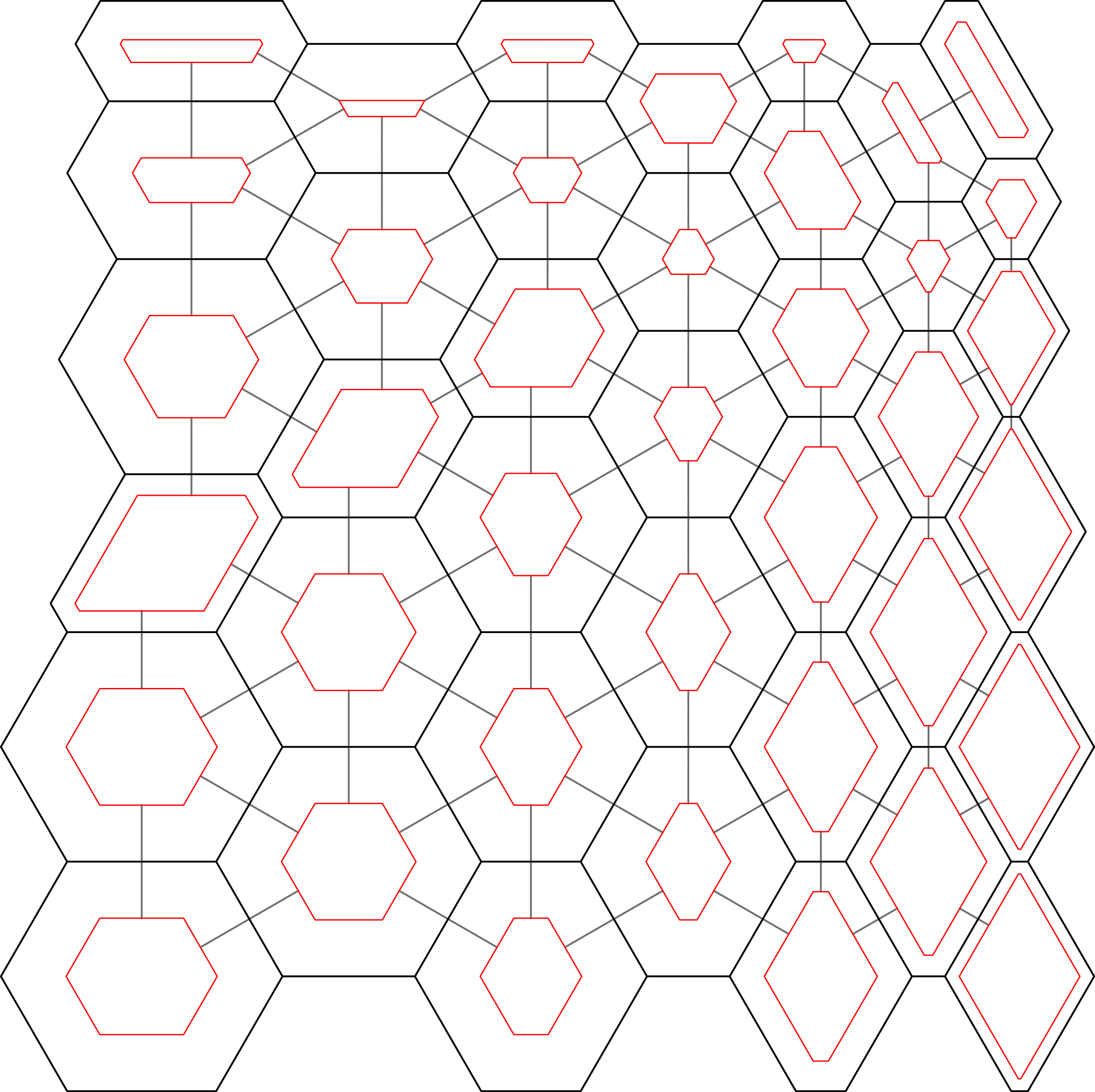

Finally, we can see an example of the connections (red line) in a hexagonal network (red piece) so the pieces come together.

4-geometry

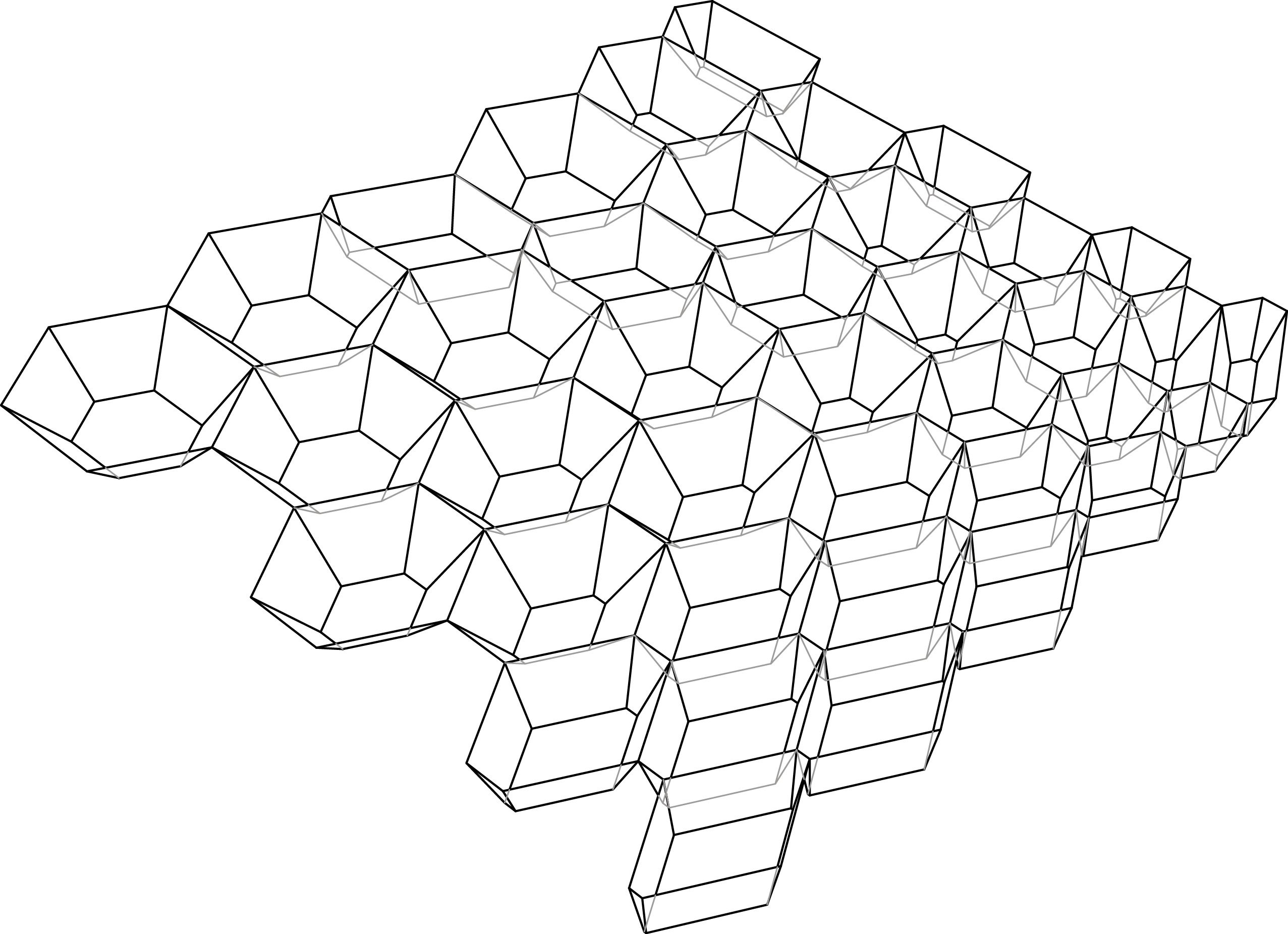

I would like to have an organizer box with a twist, for this reason, I will develop a parametric hexagonal network. For this I will use “grasshopper” and also a little “antimony”, here a generation geometry, with a diagonal modifier in a regular network, in descending order [10, 9, 8, 7, 6, 5, 4] . Here the result.

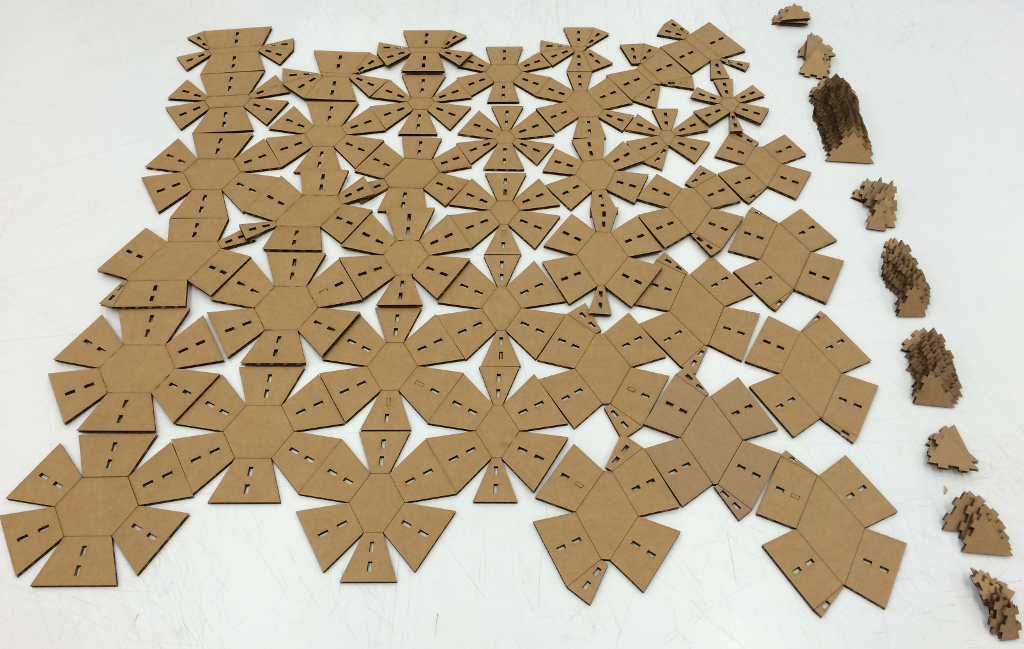

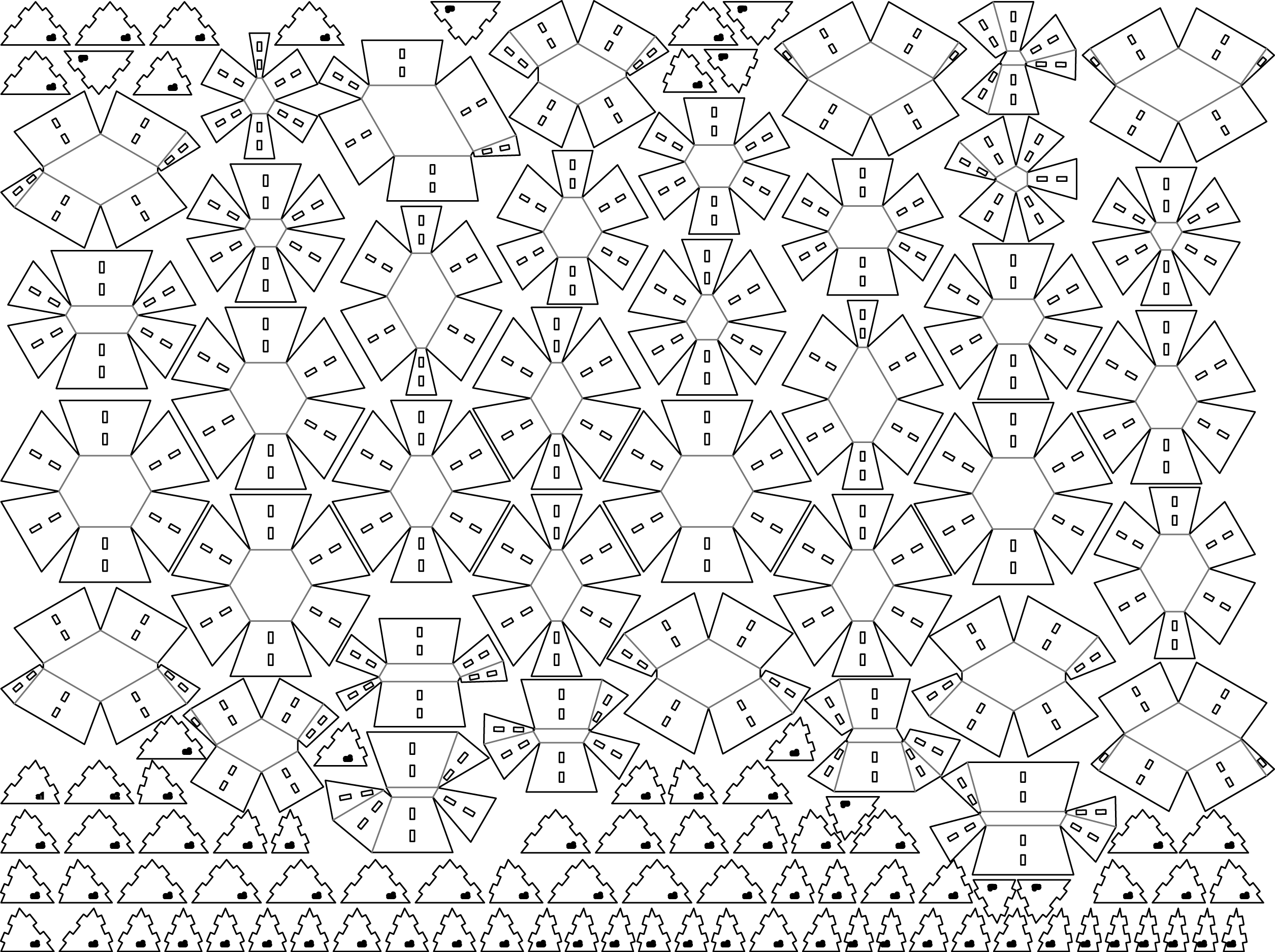

Here the development of the parts.

cutting process …

_conclusions

This activity is intended for using the potential of the deformability of the material to ensure the union, this system is very interesting and efficient because it is able to use the same material to create pressure, it is also quicker to assemble and from the point of view design, it is always good to see original solutions in the manufacturing system.

In this case, I used cardboard and I have to admit the resistance that can be achieved is surprising, cardboard is cheap and very easy to cut, in the exploration I am presenting, it can be seen how the resistance, but at the same time the cardboard, has a lot of flexibility. The joints can be allowed to be compressed between them. Certainly, the pressure fitting is a very interesting technique with great potential.

_files

diagram

nesting

red

3D

_

Original source: http://academy.cba.mit.edu/classes/computer_cutting/index.html

Contact: fernando.meneses@udem.edu / fernandomeneses@nodolab.com / f / in / g+ / b / v / mx / w